Can Heat Produce More Heat?

Introducing the Concept of Heat Engines

A heat engine is a device that converts heat energy into mechanical work. Some common examples of heat engines include car engines, aircraft engines, and steam engines. At their core, heat engines rely on thermodynamic processes to produce useful work.

In a heat engine, heat is applied to a gas, fluid or other working substance within the engine. This heat causes the molecules in the working substance to move faster and take up more space (expand). The expansion of the working substance pushes on components of the engine to perform mechanical work. For example, in a car engine, the exploding gasoline vapors push the pistons to turn the crankshaft. In a steam engine, the expanding steam pushes the pistons to turn a wheel. So in essence, heat engines harness thermal energy and convert it into kinetic energy in the form of motion and mechanical work.

Heat engines follow a cyclic process where the working substance is heated, expanded, cooled, and compressed over and over. This allows the engine to produce continuous mechanical work as long as heat is applied. The efficiency of a heat engine depends on how much of the heat input is converted into useful work versus lost to the environment as waste heat. Engineers are constantly looking for ways to design more efficient heat engines to reduce waste energy.

The Laws of Thermodynamics

The laws of thermodynamics are foundational scientific principles that describe the relationship between heat, work, and energy. They are crucial for understanding how heat engines function.

The first law of thermodynamics is the law of conservation of energy. It states that energy cannot be created or destroyed in an isolated system. The energy before a process occurs must equal the energy after the process occurs. This means that heat engines cannot produce net energy out of nothing—the energy they output must come from the input heat energy.

The second law of thermodynamics states that entropy, a measure of disorder, always increases in a closed system. It describes the tendency of concentrated energy to disperse over time. For heat engines, it means that some heat input will always be irrevocably lost or wasted, limiting their efficiency. No real heat engine can convert 100% of heat into work.

Together, these thermodynamic laws set fundamental limits on the efficiency and work output possible for any heat engine. While energy is conserved, entropy increase will always constrain how much of the heat input can be converted into useful work. Understanding these principles is key to evaluating both the potential and limits of heat engines.

How Heat Engines Work

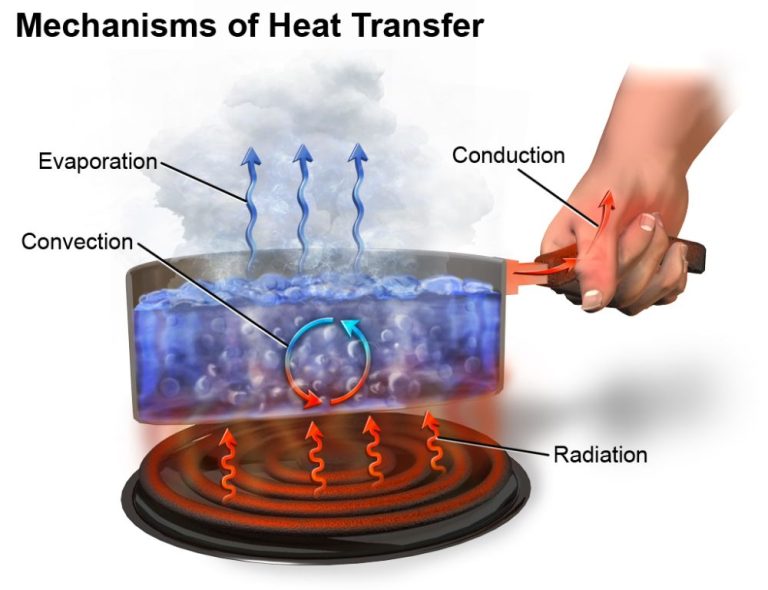

At the core of every heat engine is a process that converts heat into mechanical motion. There are two key requirements for making this possible:

First, there needs to be a high temperature heat source. This could be something like gasoline igniting in a car engine, coal being burned in a steam engine, or the nuclear reactions in a nuclear reactor. The high temperature source provides thermal energy to the engine.

Second, there needs to be a temperature difference or gradient. The high temperature source will heat up and expand a working material like water, air, or steam. As this heated material expands and gains pressure, it flows toward an area of lower temperature. The large change in temperature is what allows the heated working material to expand and generate pressure that can push on components of the engine.

Finally, as the hot, high pressure working material expands and moves towards lower temperature, the engine is designed so this expansion and pressure does mechanical work. For example, in a car engine, the expanding/exploding gasoline pushes up the car’s pistons to provide power to the drive shaft and wheels. Or in a steam engine, the expanding steam pushes the pistons to turn a wheel. So the temperature difference allows the heated working material to expand and generate pressure that is converted into motion.

Efficiency of Heat Engines

The efficiency of a heat engine is determined by the temperature difference between the hot and cold reservoirs. The greater the temperature difference, the more efficient the engine. This is because heat engines work by extracting energy from the temperature gradient between a hot and cold reservoir.

For example, a coal power plant uses steam at over 500°C generated from burning coal to turn a turbine. The steam then condenses into water at around 30°C and gets pumped back to the boiler. The large temperature difference allows for high efficiency energy extraction.

The maximum theoretical efficiency of a heat engine operating between two heat reservoirs is given by the Carnot efficiency. However, real heat engines have lower efficiencies than the Carnot efficiency due to irreversibilities like friction and heat loss to the environment.

For example, a car engine may have a peak thermodynamic efficiency of 30-35% compared to an ideal Carnot efficiency of 60-70% between the peak combustion temperatures and the engine coolant temperature. This discrepancy is due to the complexities of real engines versus the idealized Carnot cycle.

Examples of Heat Engine Applications

Some of the most common real-world examples of heat engines include:

Steam Engines

Steam engines were some of the earliest heat engines developed, starting in the 18th century. They burn fuel to boil water, which creates steam that expands to drive pistons or turbines. Steam engines powered early forms of transportation like trains and steamboats, as well as machinery in factories during the Industrial Revolution.

Internal Combustion Engines

Internal combustion engines are used in most motor vehicles today. They burn fuel within a combustion chamber and use the expanding gases to drive pistons. Examples include gasoline engines in cars and diesel engines in trucks.

Rocket Engines

Rocket engines generate thrust by expanding and accelerating hot exhaust gases. They burn fuel with an oxidizer, and the extremely hot, high-pressure gas is passed through a nozzle to propel the rocket forward.

Power Plants

Many power plants also rely on heat engines. Coal, natural gas, or nuclear power plants boil water to produce steam that spins turbine generators to generate electricity. Hydroelectric plants also use water’s movement to drive turbines.

Heat Engines in Everyday Life

Heat engines are an integral part of modern life. Some common examples of heat engines we use everyday include:

Cars, trucks and planes: Most transportation relies on internal combustion engines, which convert heat into mechanical motion. Gasoline or diesel is burned inside the engine, producing expanding hot gases that push pistons to generate power. This allows the vehicle to propel itself forward.

Electricity generation: Many power plants use heat to produce electricity. Coal, natural gas, or nuclear reactions heat water to generate steam that spins a turbine connected to a generator, converting the mechanical rotation into electrical energy.

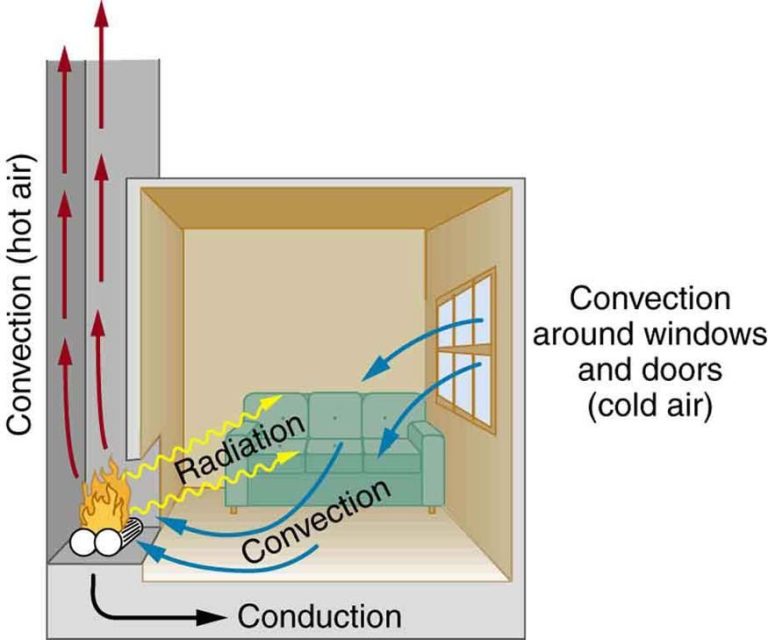

Heating and cooling systems: Furnaces, air conditioners, heat pumps and refrigerators are powered by heat engines. Furnaces and heaters use the combustion of fuel to heat homes and buildings. Air conditioners and refrigerators use a cycle of compression and expansion of gases to absorb and release heat for cooling.

Improving Heat Engine Efficiency

There are several ways to improve the efficiency of heat engines. Some key methods include:

Waste Heat Recovery – A significant amount of energy is lost in heat engines in the form of waste heat. Capturing and reusing this waste heat can greatly improve overall efficiency. Methods for waste heat recovery include recuperators, regenerators, combined heat and power systems, and waste heat boilers.

New Materials – Using materials that can withstand higher temperatures allows for higher efficiency cycles. Ceramics, nickel superalloys, and other advanced materials enable higher peak cycle temperatures. This reduces waste heat and improves thermal efficiency.

Regenerative Systems – Regenerative systems capture and store energy from the system’s hot exhaust and reuse that energy to preheat the next cycle’s cold intake. This recycling of heat significantly improves efficiency. Examples include regenerative braking in hybrid vehicles.

Optimization of heat engine systems, adoption of new technologies, and effective waste heat management can achieve substantial efficiency improvements. This maximizes usable energy output while minimizing wasted energy.

Limitations of Heat Engines

While heat engines are useful for generating mechanical work and electricity, they have some inherent limitations:

Maximum possible efficiency: According to the laws of thermodynamics, the maximum theoretical efficiency of any heat engine is determined by the temperature difference between the hot and cold reservoirs. Even the most optimized heat engines can only convert a portion of the heat input into useful work.

Requires temperature difference: In order for a heat engine to work, it requires a temperature difference between the heat source and the heat sink. The greater the temperature difference, the more efficiently a heat engine can operate. If there is no temperature difference, a heat engine cannot produce work.

Generates waste heat: All real-world heat engines generate waste heat that must be exhausted to the environment. This heat is not converted into useful work. The ratio of useful work generated to waste heat produced is a key measure of the engine’s efficiency.

Alternatives to Heat Engines

While heat engines have been a mainstay of energy production for over a century, recent advances in technology have enabled new methods of generating power without relying on heat differentials. Some key alternatives to traditional heat engines include:

Fuel Cells

Fuel cells produce electricity through an electrochemical reaction rather than a combustion process. Hydrogen fuel cells combine hydrogen and oxygen atoms across an electrolyte membrane. The reaction generates electricity, water, and heat. Fuel cells can achieve higher efficiencies than heat engines and have no moving parts that require maintenance.

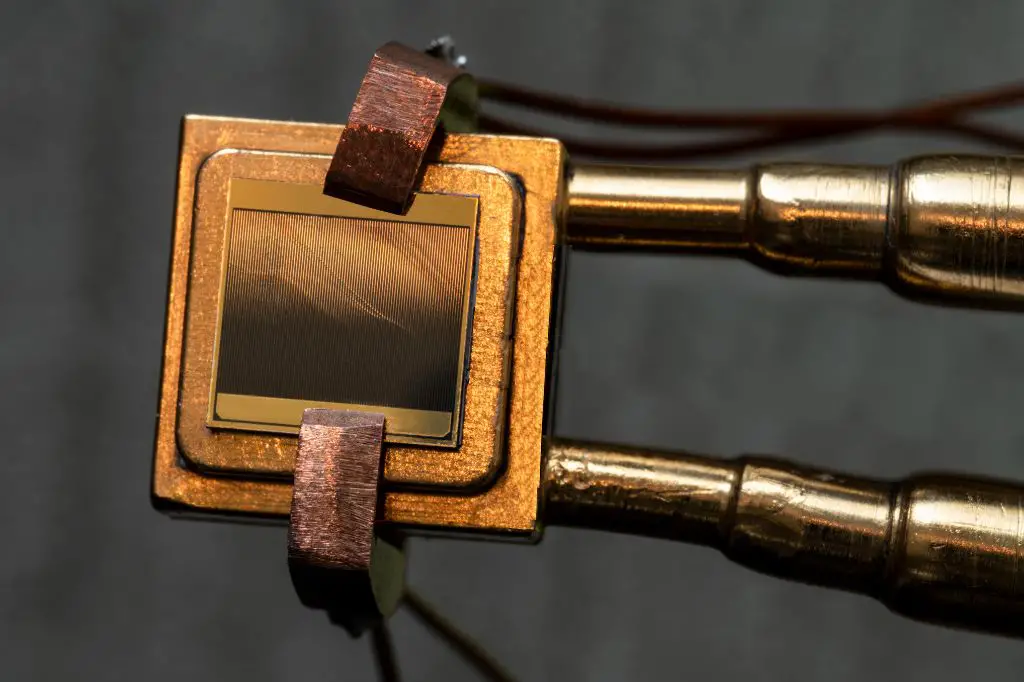

Photovoltaics

Solar photovoltaic (PV) cells convert sunlight directly into electricity using semiconducting materials. Arrays of PV cells can be installed on rooftops or as solar farms to provide renewable, emissions-free electricity. The modular nature of PV lends itself to distributed power generation close to where energy is consumed.

Wind/Hydro Power

Wind turbines and hydroelectric generators produce electricity by harnessing the kinetic energy of moving air or water, respectively. Wind power and hydropower provide carbon-free energy from renewable resources. Advances in turbine technology have made wind and hydro more cost competitive with traditional power plants.

Geothermal

Geothermal energy taps into naturally occurring heat within the earth’s crust to produce steam or heated fluid that can drive turbines and generate electricity. Geothermal provides constant base-load power and has a small footprint compared to other renewables. However, viable geothermal resources are geographically limited based on geological conditions.

Conclusion

In summary, heat engines are devices that convert heat into mechanical work. They operate on the principles laid out in the laws of thermodynamics, which describe the relationships between heat, work, and energy. Heat engines require a hot reservoir and a cold reservoir to operate, utilizing the temperature differential to generate power.

Some common applications of heat engines include internal combustion engines in cars and power plants that generate electricity. However, all heat engines are limited in their theoretical efficiency due to thermodynamic principles. The maximum possible efficiency depends on the temperatures of the hot and cold reservoirs.

Ongoing research aims to find ways to increase heat engine efficiency through new designs and materials. Areas of focus include waste heat recovery, renewable heat sources, and integration with other technologies like electric vehicles. However, heat engines will likely continue to play an important role in power generation and transportation despite their limitations.