What Is Solar Electric Cell?

A solar cell, also known as a photovoltaic cell, is a device that converts sunlight directly into electricity. Solar cells have been in use since the late 19th century, though the technology has continuously improved over time to become more efficient and affordable. Each individual solar cell is made of semiconductor materials, most commonly silicon. When sunlight hits the semiconductor, electrons are knocked loose from their atoms, allowing the electrons to flow through the material to produce electricity. This process of converting light (photons) to electricity (voltage) is called the photovoltaic effect. Solar cells have no moving parts and require minimal maintenance. In solar panels, individual solar cells are linked together in networks to produce higher voltages, and arrays of these photovoltaic panels are used in various applications ranging from powering small devices to supplying electricity for whole buildings.

How Solar Cells Work

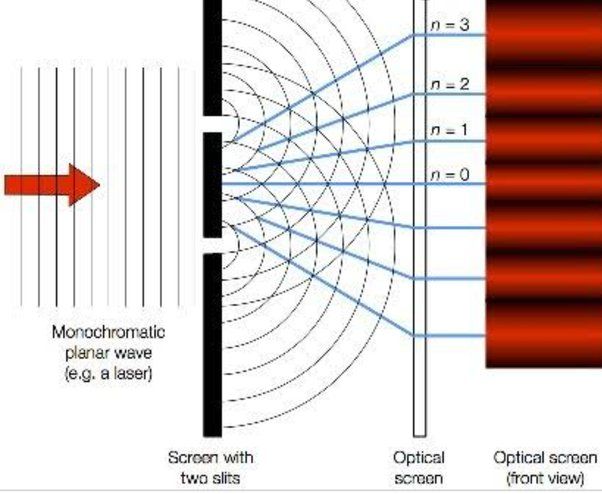

Solar cells work through the photovoltaic effect, which describes the process of generating electricity from sunlight. When sunlight hits the solar cell, the photons are absorbed by the semiconductor material in the cell. This energizes the electrons in the atoms of the semiconductor, causing them to break free and flow as electric current.

Solar cells are made of semiconductor materials such as silicon that have a unique atomic structure. Semiconductors have electrical conductivity between that of a metal and an insulator. They can be engineered to have excess negative charge (n-type) or excess positive charge (p-type).

Solar cells contain a p-n junction between two layers of semiconductor material. At the junction, the excess electrons in the n-type layer diffuse across to fill holes in the p-type layer. This creates an electric field that causes charge carriers to flow in one direction across the junction when sunlight hits the solar cell, generating electricity.

The photovoltaic effect and the p-n junction allow solar cells to absorb sunlight and generate an electrical current that powers devices and systems. Understanding these key operating principles is essential to improving solar cell efficiency and performance.

Solar Cell Materials

The most common materials used in solar cells are silicon, thin-film, and organic photovoltaics (OPV).

Silicon solar cells use either monocrystalline silicon or polycrystalline silicon. Monocrystalline silicon is created using the Czochralski process, producing a highly pure crystalline structure that leads to high efficiency rates up to 25%. However, monocrystalline silicon is more expensive than other materials. Polycrystalline silicon is made from less pure silicon and has a more complex crystalline structure, with slightly lower efficiency rates around 20%. But it is less expensive than monocrystalline. Overall, silicon panels have proven reliability and lifespan.

Thin-film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate, like glass, plastic or metal. Thin-film materials include cadmium telluride (CdTe), copper indium gallium diselenide (CIGS), and amorphous silicon (a-Si). Thin-film solar cells are lightweight and flexible, making them useful for some applications like building-integrated photovoltaics. However, they tend to have lower efficiency rates of around 15-20% and can degrade faster than silicon panels.

Organic PV uses organic electronics made of polymers or small molecules to produce solar cells that can be flexible, transparent and colored. While organic PV is an emerging and promising technology, it currently has very low efficiency rates of around 10-15%. Lifetime and stability of organic solar cells remains a key challenge.

Overall, silicon continues to dominate the solar cell market currently due to its excellent balance of efficiency, stability and cost-effectiveness. But ongoing research aims to improve other technologies to expand applications and reduce manufacturing costs further.

Solar Cell Efficiency

Solar cell efficiency refers to the percentage of sunlight that hits the cell and gets converted into electricity. There are two main measures of efficiency:

Record Lab Efficiencies

Research labs are constantly working to push the boundaries of solar cell efficiency. The highest confirmed lab efficiency is 47.1% for multi-junction concentrated solar cells developed by the National Renewable Energy Laboratory (NREL) in the United States. However, lab conditions are pristine and unattainable in the real world.

Commercial Cell Efficiencies

The average commercial solar panel operates at 15-20% efficiency. The most efficient mass-produced solar panels from manufacturers like SunPower can reach up to 22.8% efficiency. However, higher efficiency comes at a greater cost per watt.

Factors Affecting Efficiency

Several factors influence the efficiency of a solar cell in real-world conditions. These include the performance of the semiconductor material, light absorption properties, reflective coatings, temperature, and the level of sunlight exposure based on geographic location and climate.

Applications of Solar Cells

Solar cells have many useful applications that take advantage of their ability to convert sunlight directly into electricity. Some of the most common applications of solar cells are:

Off-grid Power

Solar cells can provide electricity in remote locations that lack connections to utility grids. Individual solar cells are connected into larger solar panels that can be installed on rooftops, vehicles, and portable devices to provide power off-grid. Solar-powered outdoor lighting, road signs, water pumps, electric fences, and communications equipment often rely on off-grid solar power.

Grid-tied Power

Grid-tied solar power systems feed excess electricity back into the utility grid. Homes and businesses with grid-tied solar panels can reduce their reliance on the electric grid while contributing clean energy back into the overall supply. Utility companies can also use large solar farms to supplement conventional power plants.

Solar Calculators/Toys

Small solar cells provide electricity for a variety of consumer devices. Portable calculators, watches, radios, toys, and battery chargers often rely on a single solar cell to recharge their batteries and operate electronics.

Space Applications

Solar cells provide power aboard spacecraft and satellites, where solar energy is more abundant and consistent than on Earth. They are an important renewable energy source for space missions, remote weather stations, and communications technology.

Solar Cell Manufacturing

The manufacturing process for solar cells involves several key steps to produce high-quality semiconductors. The process begins with purification and crystal growth to form large ingots or boules of ultra-pure silicon, germanium or other semiconductor materials. The crystal growth techniques include popular methods such as the Czochralski process and float zone process.

Once grown, the crystalline ingots are sawn or cut into thin wafers using wire saws or other specialized cutting tools. The wafers are then polished and cleaned in preparation for solar cell fabrication.

In cell fabrication, the purified semiconductor wafers undergo processes to introduce controlled amounts of impurities (doping) in order to form the p-n junction, apply anti-reflection coatings, and add electrical contacts. Common methods include diffusion furnaces, ion implantation, sputtering, and screen printing of metal pastes onto the wafers. The doped wafers are also annealed at high temperatures.

The front and back contacts are interconnected, and the finished solar cells are tested and sorted based on performance parameters like efficiency and maximum power. They are then assembled into panels and modules ready for installation.

Automation and quality control at each stage in the solar cell manufacturing process are critical to produce high-efficiency, reliable products for the solar photovoltaics industry.

Installation and Maintenance of Solar Cells

Installing and maintaining solar cells properly is key to ensuring they operate efficiently and safely. Here are some key considerations for solar cell installation and maintenance:

Mounting Solar Cells

Solar cells need to be mounted securely, most often on rooftops or ground mounts. The mounts must be able to withstand weather conditions like wind and storms over 20-30 years or more. Rooftop mounts are secured into roof rafters and must maintain the integrity of the roof. Proper seals prevent leaks. Ground mounts are anchored deeply into the ground.

Wiring Solar Cells

The solar cells are wired together into arrays, then connected to electrical components like inverters, disconnect switches, and the main electrical panel. Proper weatherproof wiring and connections are essential for safety and performance. Only experienced solar installers should handle the electrical work.

Cleaning Solar Cells

Solar cells should be cleaned at least 2-4 times per year, more often in areas with more dust, pollen or pollution. Gently wash the cells with water and a soft brush or sponge. Do not use abrasive cleaners or brushes. Check for debris like leaves on mounts. Clean at times when cells aren’t in direct sunlight.

Troubleshooting Issues

If solar cells underperform or malfunction, ensure all connections are secure. Check for damaged cells, mounts, or wires. Inspect electrical components for issues. Use a solar production meter to identify problems. Contact a solar installer for repairs. Proper maintenance prevents most issues.

Cost of Solar Cells

The cost of solar cells, also known as photovoltaic (PV) cells, has declined substantially in the past decade. However, the total cost to manufacture, install and maintain a solar energy system remains higher than conventional energy sources like coal and natural gas.

The main costs associated with solar PV systems include:

Manufacturing Costs

The cost of the silicon solar cells, wiring, inverters and racking equipment. Manufacturing costs have fallen over 90% since 2009 as production has scaled up, manufacturing techniques have improved, and silicon prices have declined.

Balance of System Costs

Additional components like labor, permitting, land acquisition, grid connection and structural mounts. Balance of system costs now make up over half the total installed cost of solar PV systems as manufacturing costs have decreased.

Levelized Cost vs. Conventional Energy

Levelized cost of energy (LCOE) estimates the overall competitiveness of different generating technologies. Utility-scale solar PV LCOE ranges from $37-55 per MWh, compared to $28-68 for natural gas and $65-159 for coal. Rooftop residential solar LCOE remains high at around $187 per MWh.

As total solar PV installed costs continue to decline, the LCOE is projected to fall further, making solar more competitive with conventional energy generation.

Environmental Impact of Solar Cells

The environmental impact of solar cells, also known as photovoltaic cells, has both benefits and potential concerns. On the positive side, solar cells provide clean, renewable energy that does not emit greenhouse gases when generating electricity. This can greatly reduce carbon emissions from fossil fuel-burning power plants. Some estimates suggest that over their lifespan, solar panels offset 20 times the emissions from their manufacturing and installation.

However, producing solar cells does require energy and raw materials that may have environmental impacts. Poly- or monocrystalline silicon is the most common solar cell material, requiring quarrying and energy-intensive refining processes. Other semiconductor materials like cadmium telluride and copper indium gallium selenide have toxicity concerns if improperly disposed. Manufacturing solar cells generates some harmful air emissions and liquid waste. Recycling solar panels at the end of their usable lifespan (typically around 20-30 years) is important to avoid waste and recover valuable raw materials.

Overall, most experts agree the benefits of solar power greatly outweigh the potential impacts. Continued efforts to increase solar cell efficiency, develop non-toxic alternative materials, minimize manufacturing waste, and improve recycling can further reduce the environmental footprint of this important renewable energy technology.

Future of Solar Cell Technology

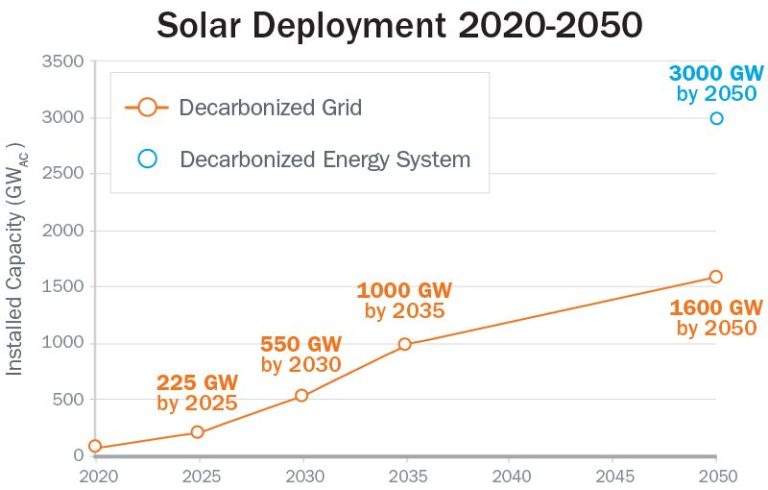

The future looks bright for advances in solar cell technology that will improve efficiency and lower costs. Researchers are exploring new materials, manufacturing techniques, and solar cell designs that could dramatically increase performance.

One area of focus is developing new semiconductor materials that are more efficient at converting sunlight into electricity. Emerging thin-film materials like perovskites and organic polymers have shown potential to reach higher efficiencies than traditional silicon solar cells. Quantum dot solar cells are also being researched. However, more work is needed to improve stability and manufacturability of these new materials.

Concentrator solar cells, which use lenses or mirrors to focus sunlight onto small high-efficiency solar cells, are gaining interest. This approach can use less semiconductor material while increasing energy yield. Concentrator cells have achieved over 40% efficiency in lab testing, though practical challenges remain in applying this technology commercially.

Advances in building-integrated photovoltaics (BIPV) are accelerating as well. Solar shingles, windows, siding and other products allow solar cells to be seamlessly incorporated into buildings. BIPV provides an aesthetic and space-saving way to deploy solar technology. As manufacturing and installation costs come down, BIPV will become an increasingly attractive solar power solution.

With continued research and investment, solar cells could reach dramatically higher levels of efficiency and flexibility in the future. We can expect great strides in materials science, product integration and manufacturing that will make solar power a pillar of the global renewable energy economy.