What Is Solar Cell Diagram?

Solar cells, also known as photovoltaic cells, are devices that convert sunlight into electricity. They are made of semiconductor materials, such as silicon, which absorb photons from sunlight and release electrons. The flow of these electrons generates an electric current that can be captured and used as electricity.

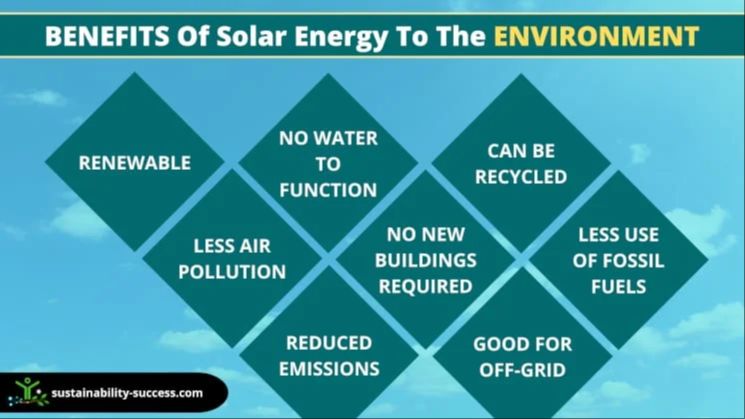

Solar cells have become an important renewable energy technology and have a wide range of applications. They are used on everything from small consumer devices like calculators and watches, to large-scale solar power plants that provide electricity to the utility grid. The key advantages of solar cells are that they generate electricity with no moving parts, require little maintenance, and produce no greenhouse gas emissions during operation. As the cost of solar power continues to fall, these clean energy devices are poised to play an increasingly significant role in our energy future.

Even though the first practical solar cell was built in 1954, the technology has advanced rapidly in recent decades. Today solar represents the fastest growing energy source worldwide. With concerns about climate change and energy security, solar cells offer a promising carbon-free technology to help meet the world’s electricity demands.

History of Solar Cell Development

The history of solar cells dates back to the 19th century when the photovoltaic effect was first observed. In 1839, French physicist Antoine-César Becquerel discovered that illuminating certain materials like silver chloride or gold in an electrolyte solution could generate electricity. However, it took over a century for the first modern solar cell to be invented.

In 1954, scientists at Bell Laboratories in the United States created the first silicon solar cell capable of converting enough sunlight into electricity to run everyday electrical equipment. The New York Times heralded this breakthrough as the beginning of a new era, which would make electricity from sunlight a practical reality. Within the next decade, solar cells were providing power aboard the Vanguard I satellite and other early spacecraft.

Throughout the 1960s and 1970s, space programs helped advance solar cell technology by funding further research to improve their efficiency. The oil crisis of the 1970s also led many countries to explore solar power generation more seriously. Steady improvements in manufacturing and materials science over the decades have increased solar cell efficiency from just 6% in the 1950s to over 20% today.

Some key innovations in solar cells over the years include the development of crystalline silicon cells, thin-film solar cells, multi-junction cells, and most recently perovskite solar cells. With increased commercialization and larger-scale manufacturing, costs have also declined dramatically, making solar power generation with photovoltaics cost-competitive with fossil fuels in many parts of the world.

Parts of a Solar Cell

Solar cells are made up of several basic components that enable them to convert sunlight into electricity. Here are the main parts that make up the structure of a basic solar cell:

Semiconductor Material

Solar cells are made from semiconductor materials such as silicon. Semiconductors have a unique ability to absorb photons from sunlight and release electrons. When light hits the solar cell, photons are absorbed by the semiconductor atoms, causing electrons to break free from their atomic bonds. This process generates electron flow, which is harnessed as electric current.

p-n Junction

At the heart of a solar cell is the p-n junction. The p-n junction is formed by adding impurities to the semiconductor material to create a positive-charged (p-type) layer and a negative-charged (n-type) layer. When these two layers meet, electrons begin to flow from the n-type side to the p-type side, creating an electric field across the junction.

Electrical Contacts

On the top and bottom of the solar cell are metal contacts. These allow the electric current generated by the solar cell to be captured and utilized. The top contact is a grid-like structure that allows sunlight to strike the surface of the solar cell. The bottom contact is a continuous sheet that completes the electrical circuit.

Anti-Reflective Coating

A solar cell usually has an anti-reflective coating on the top layer. This coating reduces reflections from the cell surface and allows more light to penetrate into the semiconductor material beneath, increasing efficiency.

How Solar Cells Generate Electricity

Solar cells generate electricity through the photovoltaic effect. When sunlight hits the solar cell, the photons are absorbed by the semiconductor material in the cell, most commonly silicon. This photon absorption causes electrons in the material to loosen and become able to move freely. The solar cell contains an electric field that acts to force these free electrons in one direction, creating an electric current from the movement of electrons. This electric current generated can then be captured and utilized as electricity.

The photovoltaic effect and resulting electron flow work as follows:

- Sunlight hits the solar cell surface and photons are absorbed.

- The energy from the photons causes electrons to break free of their atoms in the semiconductor material, creating mobile electron-hole pairs.

- The solar cell’s electric field causes the electrons to move in one direction, resulting in an electric current.

- Metal conductive plates capture the electrons and transfer them as usable electricity.

This conversion of sunlight to electricity via the photovoltaic effect is what defines solar cells and makes them a renewable source of electrical power generation. Understanding the movement of electrons is key to harnessing the photovoltaic effect efficiently.

Solar Cell Efficiency

The efficiency of a solar cell refers to how much light energy it can convert into electrical energy. There are several key factors that determine the efficiency:

Solar Cell Material

The material used in the solar cell, such as monocrystalline silicon, polycrystalline silicon, amorphous silicon, cadmium telluride, or gallium arsenide, affects how efficiently it can absorb photons and convert them into electricity. Materials like monocrystalline silicon tend to have higher efficiencies around 15-20%.

Reflection Losses

Some light energy is reflected off the solar cell’s surface rather than being absorbed. Adding an anti-reflective coating can improve light absorption and efficiency.

Recombination Losses

Electrons may recombine with holes in the solar cell before they can be extracted as current, turning the absorbed energy into heat instead of electricity. Reducing defects in the crystal structure can minimize recombination losses.

Resistance Losses

Resistance in the semiconductor material and metallic contacts causes some power loss. Larger solar cells tend to have lower resistive losses.

Thermodynamic Limit

Solar cells cannot convert more than a certain portion of the solar spectrum due to thermodynamic limits dictated by the Second Law of Thermodynamics. This theoretical maximum efficiency is around 33% for conventional single-junction silicon cells under 1 sun illumination.

Recent Advances

Tremendous research is underway to push solar cell efficiencies ever higher through advanced materials, device structures, manufacturing techniques, and light management. Some notable milestones include passing 20% efficiency for polycrystalline silicon cells, achieving 47% for concentrating multi-junction cells, and exceeding 20% for flexible thin-film cells.

Types of Solar Cells

There are several different types and classifications of solar cells. Some of the main types include:

Silicon Solar Cells

The most common type of solar cell is made from crystalline silicon. This includes monocrystalline silicon (c-Si) and polycrystalline silicon (multi-Si) cells. Silicon cells have module efficiencies between 15-22% and benefit from well-established manufacturing techniques.

Thin Film Solar Cells

Thin film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate, such as glass, plastic or metal. Types of thin film cells include cadmium telluride (CdTe), copper indium gallium selenide (CIGS) and amorphous silicon (a-Si). Thin film cells tend to have lower efficiencies than silicon but can be easier and cheaper to manufacture.

Organic Solar Cells

Organic solar cells, or organic photovoltaics (OPV), use organic electronics consisting of carbon-based polymers and molecules to absorb and convert sunlight. They can be made using inexpensive materials and processes but typically have low efficiencies around 5-10%.

Quantum Dot Solar Cells

Quantum dot solar cells contain tiny semiconductor particles known as quantum dots that can absorb energy from the sun and convert it into electricity. Quantum dots allow for precise tuning of optical and electrical properties. Efficiencies of 13% have been achieved in lab settings.

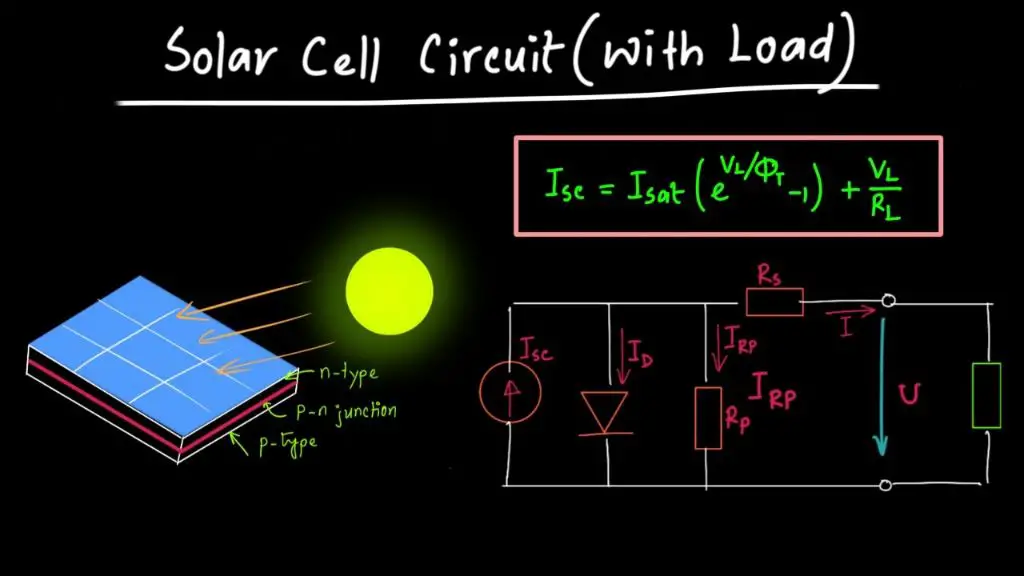

Solar Cell Circuit Diagrams

Solar cells are usually represented in circuit diagrams as a current source with a diode connected in parallel. This is known as the single diode model of a solar cell.

A simple solar cell circuit diagram shows a solar cell represented as a current source, with a diode connected parallel across the source, and wires connecting it to a load:

In this simple circuit diagram, a current source represents the electric current generated by the solar cell. The diode allows current to flow in one direction to the load. But when the load tries to send current backwards through the cell, the diode blocks it.

More complex solar cell circuit diagrams may include additional components:

- Multiple solar cells connected in series or parallel

- Blocking diodes to prevent reverse currents

- Bypass diodes to allow current to flow around shaded or damaged cells

- Fuses or breakers for protection

- Batteries for energy storage

When multiple solar cells are wired together in panels, the circuit diagrams help represent all the interconnections and components. Engineers use solar cell circuit diagrams to design, test and troubleshoot photovoltaic systems.

Manufacturing Solar Cells

The manufacturing of solar cells involves complex processes and advanced materials. The most common solar cell material is crystalline silicon, though thin-film materials like cadmium telluride are also used. Here are some key aspects of solar cell manufacturing:

Materials

The raw silicon material for solar cells must be extremely pure, over 99.999% pure silicon. Impurities can negatively impact the solar cell’s efficiency at converting sunlight into electricity. The manufacturing process therefore involves carefully cleaning and refining raw silicon.

For thin-film solar cells, semiconductor materials like cadmium telluride, copper indium gallium selenide, or amorphous silicon are deposited in very thin layers on a substrate like glass or plastic. This allows thin-film solar cells to be lightweight and flexible.

Processes

Manufacturing crystalline silicon solar cells involves several steps. First the refined silicon is melted and formed into ingots or blocks. The ingots are then cut into very thin wafers. Impurities are carefully added to enhance the silicon, a process called doping. The wafers then have electrical contacts added to the surfaces.

Thin-film solar cells are made by depositing thin layers of the semiconductor materials onto substrates using processes like vapor deposition or electroplating. Lasers are then used to scribe connection patterns before electrical contacts are added.

Challenges

Some key challenges in solar cell manufacturing include improving efficiency, reducing material waste, automating processes, and lowering costs through scale and technology improvements. Keeping manufacturing clean rooms and equipment dust-free is also critical.

Applications of Solar Cells

Solar cells have many practical applications and are used in a wide variety of technologies. Some of the most common uses of solar cells are:

Small consumer electronics – Small solar cells are integrated in calculators, watches, toys, and portable chargers to power these devices. The small surface area required makes them convenient for powering consumer gadgets.

Solar home systems – These provide electricity to households by installing rooftop solar panels connected to a battery storage system. They are popular for off-grid rural households without access to an electricity grid.

Solar vehicles – Cars and boats can be powered using solar cells. The solar panels may directly charge the propulsion batteries or generator. Solar race cars rely entirely on solar power.

Solar road studs – Solar cells can power LED road studs and signals for lane markings. This eliminates the need to connect each stud to the power grid.

Satellites and spacecraft – Solar cells are the primary source of power for satellites and spacecraft. Arrays of ultra-efficient multi-junction solar cells power communication, GPS, weather monitoring satellites.

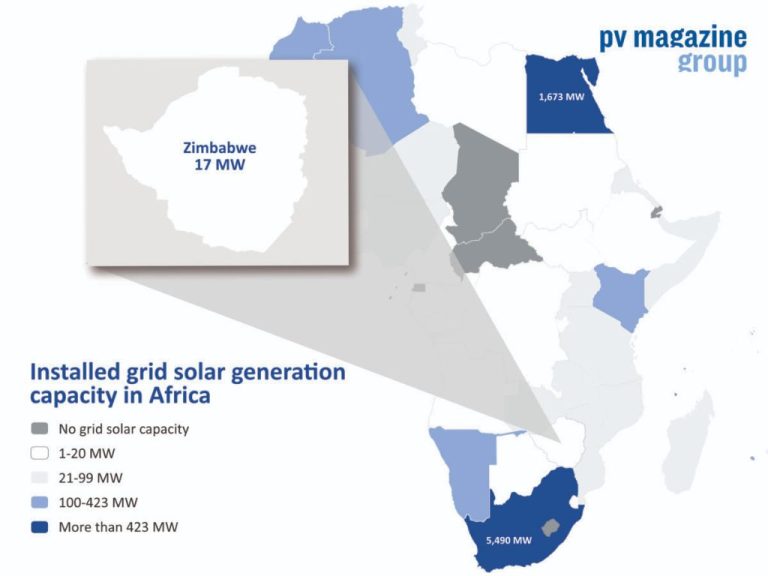

Solar farms – At utility scale, thousands of solar panels in solar farms feed into the electricity grid. Large solar farms can produce hundreds of megawatts of solar power.

Solar tiles – Solar shingles and tiles integrated with PV cells allow rooftops to generate solar electricity. This saves on installation costs compared to mounted panels.

The falling costs and versatility of solar cells have enabled mass adoption. With increased efficiency improvements, solar cells could become a leading renewable energy source worldwide.

Future of Solar Cell Technology

The future looks bright for solar cell technology as researchers continue to innovate and improve solar cells in significant ways. Some key emerging innovations and breakthroughs that will shape the future of solar cells include:

Perovskite solar cells – These new types of solar cells use perovskite structured compounds that have remarkable light absorption abilities. Perovskite solar cells have seen rapid efficiency improvements from 3.8% in 2009 to over 25% today. They are also inexpensive to manufacture. However, challenges remain in making perovskite solar cells stable and durable for long-term use.

Tandem/Multi-junction solar cells – By combining multiple solar cell materials and structures, tandem solar cells can capture more of the solar spectrum and achieve ultra-high efficiencies over traditional single-junction cells. The latest lab-scale multi-junction solar cells have reached efficiencies of over 47%. Ongoing research is focused on improving manufacturability and costs.

Thin-film solar cells – Thin-film solar cells reduce material usage by depositing photovoltaic materials in thin layers only a few micrometers thick. This makes them lightweight and flexible. Efforts to improve thin-film cell efficiency and manufacturability continue.

Organic solar cells – These experimental solar cells use organic electronics and polymers to absorb light. They can be made semi-transparent and are very lightweight and flexible. However, their efficiencies are still quite low compared to other types of solar cells.

Solar cell nanotechnology – By manipulating solar cell materials at the nanoscale, researchers can precisely control the optical and electrical properties of solar cells. Nanotechnology innovations are leading to major leaps in solar cell efficiency.

With continued research and development, solar cells are poised to become cheaper, more efficient, and versatile enough to power humanity’s transition to clean renewable energy.