Can You Use An Alternator For A Water Turbine?

An alternator is a device commonly used in automobiles that generates electricity from the rotational motion of the crankshaft. It provides power for the electrical components of the vehicle when the engine is running. A water turbine is a rotary machine that converts the kinetic energy of flowing water into mechanical energy that can then be used to generate electricity. Water turbines are a common method of producing renewable hydropower from flowing water sources like rivers and streams.

The purpose of an alternator in a car is to keep the battery charged and power the vehicle’s electrical system while the engine is operating. The purpose of a water turbine is to harness the natural flow of water to produce electricity that can be supplied to homes, businesses or fed back into the grid. Both technologies ultimately aim to convert mechanical rotation into electrical energy.

How Alternators and Water Turbines Work

Both alternators and water turbines are used to generate electricity, but they do so in slightly different ways.

An alternator is designed to convert the mechanical energy from an engine into electrical energy. It consists of a rotor attached to the engine’s crankshaft which rotates within a stator. The rotor generates a magnetic field while the stator contains coils of wire. As the rotor spins, it induces an alternating current in the stator coils. This generates an AC voltage that is rectified into DC for battery charging and onboard electrical systems.

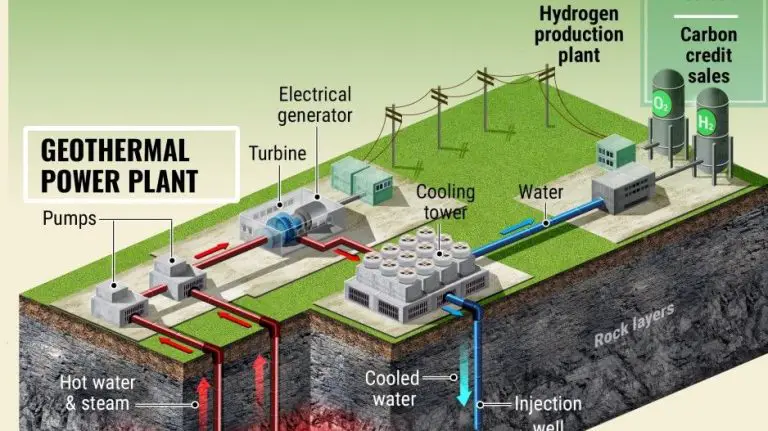

A water turbine converts the kinetic energy of moving water into rotational mechanical energy. The most common types used for hydropower are Pelton, Turgo, and crossflow turbines. In a Pelton wheel, one or more water jets hit paddle-like buckets along the wheel’s rim, causing it to spin. Turgo turbines use shaped nozzles and buckets optimized for low heads. Crossflow turbines have cylindrical runners that allow water to flow through them in two directions. The turbine shaft is connected to a generator which converts the rotational mechanical energy into electrical energy.

So in summary, an alternator starts with mechanical rotation and generates electricity, while a water turbine starts with water flow and ends with electricity after converting the kinetic energy into rotational mechanical energy.

Comparing Alternator and Water Turbine Designs

While automotive alternators and water turbines operate on similar principles to generate electricity, there are some key differences in their design and construction that make each optimized for their respective energy sources.

Automotive alternators use a rotor winding energized by the vehicle’s battery to generate a rotating magnetic field. This induces current in a stationary stator winding as the rotor spins, producing electricity. They are designed to be compact, lightweight, and operate at high speeds from engine rotation.

In contrast, hydro turbines like Pelton wheels have buckets or curved blades attached to a rotor. The kinetic energy of moving water hits the blades, causing the rotor to spin. This rotation drives magnets past coils in a generator to induce current. Hydro turbines are engineered for the lower speeds of flowing water and to efficiently capture energy from the water’s momentum.

While alternators generate electricity from mechanical rotation, turbines convert the natural kinetic energy of water into rotation and electricity. Alternators are optimized for intermittent high-RPM operation, while hydro turbines work continuously at lower speeds matched to the water flow rate. Understanding these differences helps explain why each device is suited for its particular energy source.

Using Alternators for Small Scale Hydropower

Using an automotive alternator for small scale hydropower generation is an inexpensive DIY option that has become increasingly popular. With the right modifications, an alternator can work effectively as a generator when spun by a water wheel or turbine. This provides a way to generate electricity from small streams and flows for off-grid applications.

Many hobbyists and homesteaders have demonstrated small-scale hydropower systems using old alternators. Since alternators are easy to find at junkyards for low cost, this presents an accessible alternative to buying new equipment. With some mechanical adaptation and electronic modifications, the alternator can be optimized to produce usable electric power from a small water source. Power output usually ranges from 100 watts to a couple kilowatts.

Small residential-scale hydropower from streams, irrigation flows, or other water sources generally requires a flow rate of just a few gallons per minute. So an automotive alternator, designed for high RPMs, can work well with a small turbine or water wheel. The main challenge is adjusting the alternator’s internal regulators so it can output proper voltages at the lower rotational speeds the water source can provide. But overall, an alternator can be a practical and inexpensive generator for micro-hydropower systems.

Challenges of Using an Automotive Alternator

Using a standard automotive alternator for small scale hydropower comes with some significant challenges that need to be addressed:

Lower Efficiency

Automotive alternators are designed to charge a car battery, not generate electricity efficiently. They will likely have a lower efficiency, perhaps 60-70%, compared to a purpose-built generator with 80%+ efficiency. This means more water flow is needed to produce the same electrical output.

Vibration

Alternators rotate at high speeds around 2,000-10,000 rpm. This can cause heavy vibration issues. The alternator needs to be securely mounted and balanced to handle these vibrations without shaking itself apart.

Sealing

Since automotive alternators are air cooled, they are not designed to be waterproof. The housing will need to be sealed to prevent water getting inside and shorting out or corroding the windings and electronics. Rubber seals and potting compounds can help.

Modifications and Considerations

To adapt an alternator to work effectively as a water turbine, several modifications would need to be made:

Waterproofing – Automotive alternators are not designed to be immersed in water continuously. The housing and internal components would need to be sealed and protected to prevent water damage and short circuits.

Efficiency – Alternators are designed to generate electricity at high rpm ranges when running an engine. To work at lower water flow speeds, the internal coil windings and magnet strength may need to be adjusted.

Rotation – Most alternators rotate clockwise to generate power, while water turbines often spin counterclockwise. The internal components and coil wiring would potentially need reversing.

Bearings – Upgrading to sealed stainless steel bearings could handle the continuous water exposure better than standard automotive bearings.

Input – Adapting the alternator’s pulley shaft to connect to a propeller or other turbine design that can extract energy from flowing water.

Voltage Regulation – Adding a charge controller or regulator to manage optimum voltage output if used for charging batteries or connecting to other electrical systems.

Performance Testing – Prototype testing would be needed to assess power generation across various water speeds and flow volumes to optimize the modified design.

Is It Worth the Effort?

Using an alternator for a homemade water turbine can certainly be an interesting DIY project. However, before investing significant time and money into modifying and installing an automotive alternator, it’s important to weigh the costs versus the potential benefits.

In most cases, purpose-built hydro turbines designed specifically for small scale hydropower systems will be more efficient and cost-effective. Professional micro-hydro turbines convert a higher percentage of the available hydro energy into usable electricity compared to improvised designs using alternators.

The process of adapting an alternator to work properly with a homemade turbine takes a fair amount of custom engineering. Even with modifications, efficiency and electricity output is likely to be low. And the system requires ongoing maintenance and monitoring.

Alternatively, there are affordable “plug and play” micro-hydro systems available that have been optimized by experts. These complete packages avoid the need for complex DIY fabrication and modifications.

While repurposing an old alternator can be a rewarding challenge, the costs in terms of equipment, custom parts, and labor hours may exceed the value of the electricity generated. Carefully assessing the local hydro resources and electricity needs can determine if a professional micro-hydro system is a better turnkey solution.

For the right motivated tinkerer with abundant hydro power, creatively adapting an alternator to homebrew a water turbine can certainly be done. But for most residential applications, purpose-built systems are more practical, efficient, and cost-effective.

Example Implementations

Several hobbyists and energy enthusiasts have experimented with using alternators as small scale hydro turbines. Here are some case studies and performance results:

Backyard 5kW System

An enthusiast in the Pacific Northwest created a 5kW system by repurposing two automotive alternators to generate power from a stream behind his house. He modified the alternators by replacing the internal components and housings with new stainless steel parts designed for underwater operation. The alternators are belt-driven by a small impulse turbine made from PVC pipe and low rpm car alternator pulleys. At optimal stream flow, each alternator can generate around 2.5kW. Over a year, this DIY hydro system produces an average of 3-4kW.

Cabin Creek Micro-Hydro

A small 200W system was built using a single car alternator, a 5-inch pipe, and local creek in rural Virginia. The pipe increases the water velocity enough to spin the alternator at sufficient rpm. The system powers several LED lights and charges a battery bank that runs a fridge and other low-wattage appliances in a cabin. While the output is modest, the simplicity and low cost make it worthwhile for basic electricity needs.

12V Camp Power

Backpackers and overlanders have created small “mobile” hydro systems using old alternators to recharge batteries while camped near flowing water. Typically a small water wheel or Pelton wheel spins the alternator input shaft. A 12V charge controller regulates the power to charge a spare car battery. This compact DIY solution provides enough power to run LED lights, smartphones, and other devices without any noise or emissions.

Recommendations

Based on the pros and cons discussed, using an automotive alternator for small scale hydropower may make sense in certain situations but not in others. Here are some recommendations on when an alternator conversion may or may not be suitable:

An alternator conversion can work well for:

- Small, low-head water sources like streams or irrigation ditches where a commercial turbine is not feasible

- Using readily available, free, or low-cost car alternators that would otherwise go to waste

- Micro-hydropower projects with a capacity up to about 1-2 kW

- Off-grid electric systems that need just a small amount of supplemental power

- DIY tinkerers wanting a low-cost hydro project for experimentation

An alternator conversion may not be ideal for:

- Higher head installations like pressure pipes where commercial turbines can reach better efficiency

- Sites with debris or sediment that can damage the alternator

- Permanent installations where reliability and minimal maintenance are critical

- Large scale hydropower systems producing significant amounts of electricity

- Sites that require permitting where unconventional designs may not be approved

Overall, alternator turbines can be a creative, low-cost solution for small backyard hydro projects, but likely not an optimal choice for larger scale commercial hydropower installations.

Conclusion

Overall, using an automotive alternator as a small-scale hydroelectric generator is technically feasible but requires some modifications and careful planning. The alternator’s internal design is not optimized for use as a turbine, so efficiency will be lower compared to commercial hydropower systems. However, for small DIY or hobbyist renewable energy projects, recycling an old alternator can provide a low-cost way to generate some electricity from a stream or waterfall.

Important factors to consider are matching the alternator size and rotation speed to the water source, making mechanical modifications for waterproofing and coupling, and understanding that the electricity output may be modest and intermittent. With the right site conditions and some tinkering, an alternator turbine can produce usable energy for charging batteries or low-power applications. But for larger or more reliable hydropower, purpose-built turbine systems are recommended.

Overall, repurposing an automotive alternator as a hydroelectric generator can be an interesting and educational renewable energy project. While it has limitations, with some creativity and patience it’s possible for a DIY enthusiast to produce modest homemade hydropower on a small scale.