What Is Carbon Capture And Storage To Generate Electricity?

What is carbon capture and storage?

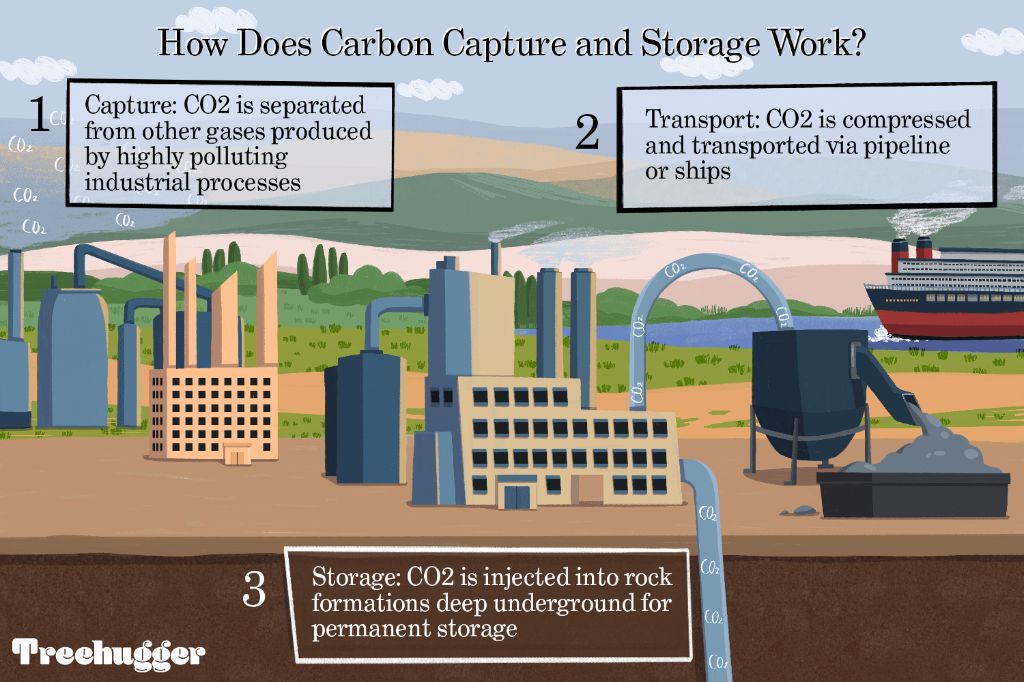

Carbon capture and storage (CCS) is a technology that captures carbon dioxide (CO2) emissions from sources like power plants and industrial facilities. The CO2 is then compressed and transported via pipeline to a suitable storage site where it is injected and stored deep underground.

The goal of CCS is to prevent large quantities of CO2 from being released into the atmosphere. This helps reduce greenhouse gas emissions and mitigate climate change. By capturing CO2 at the source and storing it away from the atmosphere, CCS technology offers a way to continue using fossil fuels while reducing emissions.

Why is CCS needed?

CCS is needed to help reduce global carbon dioxide (CO2) emissions and mitigate climate change. While transitioning to renewable energy sources is crucial, fossil fuels are still expected to provide a substantial portion of the world’s energy in the coming decades. CCS can reduce emissions from fossil fuel use by capturing CO2 before it is released into the atmosphere.

According to the Intergovernmental Panel on Climate Change (IPCC), CCS could contribute 13-14% of the cumulative emissions reductions needed by 2050 to limit global warming to 1.5°C above pre-industrial levels [1]. This makes CCS a critical technology for reducing emissions from fossil fuel use in power generation and industrial processes like cement and steel production where alternatives are limited. By enabling continued use of fossil fuels while minimizing emissions, CCS can help balance cost-effective energy production with climate protection.

CCS is especially important for reducing emissions from existing infrastructure and facilities with long remaining lifespans. Retrofitting CCS technology is often more feasible than replacing entire plants. CCS also preserves assets and jobs associated with fossil fuel industries during the clean energy transition.

In summary, CCS is an important emissions reduction option that allows fossil fuels to be part of the global effort against climate change. CCS provides a pathway for reducing CO2 emissions from major stationary sources where alternatives are limited, buying time to scale up renewable energy.

How does CCS work?

CCS is a three-step process that involves:

1. Capturing the carbon dioxide produced from burning fossil fuels like coal, natural gas or biomass for electricity generation or from industrial activities like cement and steel production. The CO2 can be captured either before or after combustion.

2. Transporting the captured CO2 via pipeline, ship, rail or truck to a suitable storage location. Compressing it to a dense liquid allows large volumes to be transported through relatively thin pipelines.

3. Injecting and securely storing the CO2 deep underground in geological rock formations like depleted oil and gas reservoirs, unmineable coal seams or deep saline aquifers. At depth and in the right site, the CO2 spreads through tiny pores in the rock and becomes trapped.

The goal is to prevent the CO2 from entering the atmosphere and contributing to climate change. When implemented correctly, CCS could capture up to 90% of CO2 emissions from power plants and industrial facilities.

Sources:

[What is carbon capture and storage? | CCS explained](https://www.nationalgrid.com/stories/energy-explained/what-is-ccs-how-does-it-work)

[Carbon Capture and Storage 101](https://www.rff.org/publications/explainers/carbon-capture-and-storage-101/)

CCS capture methods

There are three main methods for capturing CO2 from industrial sources like power plants or industrial facilities:

Post-combustion capture

This method separates CO2 from the flue gases produced after fossil fuel combustion. The flue gas is passed through an absorbent liquid that collects the CO2. The CO2 is then separated from the absorbent and compressed into a transportable state. This is the most mature CO2 capture technology today and can be retrofitted to existing power plants, but is relatively expensive. [1]

Pre-combustion capture

In this method, the fuel is converted to a mixture of CO2 and hydrogen before combustion. The CO2 is separated, leaving the hydrogen to be burned cleanly. While more efficient, this requires an industrial facility to be designed specifically for pre-combustion capture. [2]

Oxy-fuel combustion

This method uses pure oxygen rather than air for combustion, resulting in a flue gas that has high concentrations of CO2, making it easier to capture. However, the oxygen separation process consumes significant energy. Oxy-fuel systems could be retrofitted to existing plants. [3]

CCS transportation

Carbon dioxide transportation typically happens through pipelines, ships, rails, or trucks. Pipelines are the most common method for transporting large volumes of CO2 over long distances. According to the IEA, pipelines are the most cost-effective transport solution for large volumes of CO2 over distances greater than 100 km. The pipelines need to be corrosion resistant due to the properties of CO2 (IEA).

Ships can also transport CO2, often as a compressed liquid. This allows CO2 to be transported from coastal industrial facilities to offshore storage sites. According to the Global CCS Institute, ships may be used for smaller volumes of CO2 or where pipeline transport is not feasible (Global CCS Institute).

While less common, CO2 can also be transported via rail cars and trucks. This method tends to be more expensive than pipelines or ships and is only suitable for small volumes of CO2 over shorter distances. Trucks can carry CO2 in its compressed gaseous or liquid states (BetterEnergy).

Underground Storage

The most common method for permanent carbon storage is injecting CO2 underground into geological formations. Suitable formations include depleted oil and gas reservoirs, deep saline aquifers, and unmineable coal seams [1].

When injected deep underground, the CO2 becomes trapped within the microscopic pores of the rock formations. The CO2 fills the pores and becomes immobilized, preventing it from escaping back to the surface [2]. The overlying layer acts as a cap rock, sealing the CO2 within the formation.

Depleted oil and gas reservoirs are ideal as they have proven ability to store fluids for millions of years. Deep saline aquifers provide huge potential storage capacity. Unmineable coal seams can adsorb CO2 onto the surface of coal particles.

Monitoring and verification methods are used to track the migration of the CO2 and ensure permanent containment. This involves technologies like seismic imaging and groundwater sampling.

Using CO2 for enhanced oil recovery

Injecting CO2 into existing oil fields, known as enhanced oil recovery (EOR), is one technique that can utilize captured CO2. The CO2 is injected into the oil reservoir, which reduces oil viscosity and enables more oil to flow to production wells (NETL, 2023). This process increases the amount of crude oil that can be extracted from a field. According to the US Department of Energy, CO2 EOR has the potential to recover an additional 60 billion barrels of oil in the US (NETL, 2023).

While CO2 EOR can provide an economic use for captured CO2, it also enables more fossil fuel extraction. There is debate around whether CO2 EOR truly reduces emissions or if it just delays release of that CO2 when the oil is ultimately consumed (Vox, 2019). However, supporters argue CO2 EOR can be an interim solution to jumpstart carbon capture technology deployment while renewable energy scales up (IEA, 2019).

Costs of CCS

CCS technology comes with high capital costs, which can increase the costs of electricity generation. According to the International Energy Agency, adding carbon capture equipment to a power plant increases costs by less than 10% (source). However, the International Institute for Sustainable Development estimates the capital costs of CCS range from $800 to $1,000 per kW, compared to $1,000 to $1,800 per kW for a coal plant without CCS (source). The significant upfront investment for capture equipment contributes to higher electricity prices.

Post-combustion capture applied to coal or natural gas power plants is estimated to increase the cost of electricity generation by about 50-80%, from $50-70 per MWh without CCS to $80-120 per MWh with CCS (source). These costs put upward pressure on consumer electricity rates. However, costs are expected to decline as the technology develops and deployment increases.

CCS Deployment

CCS has seen increasing deployment worldwide in recent years, though it still accounts for a small fraction of global CO2 emissions reduction. According to the Global CCS Institute, there are currently 54 large-scale CCS facilities in various stages of development globally, capturing around 40 million tonnes of CO2 annually https://www.globalccsinstitute.com/. The International Energy Agency reports around 40 commercial capture facilities in operation globally, with over 45 million tonnes of annual CO2 capture capacity https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage.

While CCS deployment is growing, it faces challenges around high costs and lack of financial incentives in many regions. Significant investment and policy support will be needed for CCS to reach its emissions reduction potential. The IEA estimates that CCS could deliver 14% of required emissions reductions by 2050 in a net zero pathway, but this would require rapid scale-up, with capture capacity needing to increase 100-fold by 2050.

The future outlook for CCS remains uncertain but promising. More projects are in development and government policy is increasingly supportive in regions like Europe, the UK, Canada and Australia. If costs can be lowered and financial incentives improved, CCS may grow to play a major role in decarbonizing hard-to-abate sectors like industry and power generation.

Alternatives to CCS

While CCS is one way to reduce carbon dioxide emissions from fossil fuel use, there are other alternatives that can help lower emissions as well. Some key options include:

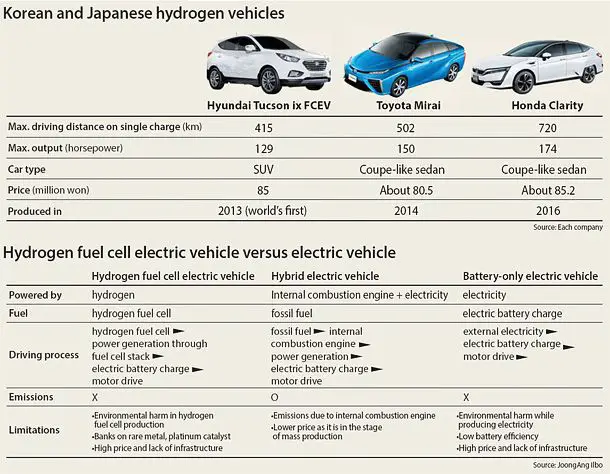

Transitioning to low-carbon or carbon-free energy sources such as renewable energy, nuclear power, and hydrogen produced from clean electricity rather than natural gas. Expanding the use of these energy sources can displace fossil fuels and avoid carbon emissions in the first place.

Improving energy efficiency across sectors like buildings, transportation, and industry can also significantly lower fossil fuel use and emissions. Upgrading equipment, appliances, vehicles, and processes to be more efficient reduces overall energy demand.

Using alternative methods to directly pull carbon dioxide out of the atmosphere, known as direct air capture. While more costly, this does not require capturing emissions at the source and provides a way to offset hard-to-decarbonize sectors.

Leveraging natural carbon sinks like forests and soil to sequester and store more carbon through restoration and improved land management practices. However, the storage capacity of natural sinks is limited.

While CCS has a role to play in reducing emissions from existing fossil fuel use, accelerating the transition away from fossil fuels through clean energy and efficiency alternatives is critical for reaching net-zero emissions goals.