What Is Biomass Carbon Removal And Storage?

What is biomass carbon removal?

Biomass carbon removal refers to processes that utilize plant biomass to extract carbon dioxide (CO2) from the atmosphere and store it away from the atmosphere for long periods of time. It is considered a form of carbon dioxide removal or negative emissions technology.

Biomass carbon removal works by growing plants that absorb CO2 from the air through photosynthesis as they grow. The plants are then harvested and processed in various ways to store the carbon they accumulated. For example, the biomass can be burned in power plants equipped with carbon capture and storage to sequester the CO2 underground. It can also be processed into biochar and buried, or used to create long-lived products like timber for construction.[1]

The key difference between biomass carbon removal and other methods like direct air capture is that it utilizes the natural carbon absorption capabilities of plants. While direct air capture uses chemical processes and significant energy inputs to extract CO2, biomass carbon removal leverages photosynthesis and biomass processing technologies.

Why remove carbon with biomass?

Biomass carbon removal provides important benefits for mitigating climate change. According to the World Resources Institute, removing carbon through sustainable biomass can help counteract emissions from hard-to-decarbonize sectors like aviation, shipping, and manufacturing (1). Biomass carbon removal also creates a carbon sink that actively takes carbon dioxide out of the atmosphere. A report from the Department of Energy found that large-scale deployment of biomass carbon removal and storage technologies could significantly reduce atmospheric CO2 levels (2). Overall, experts widely agree that some form of carbon removal, including biomass approaches, will be necessary to achieve net zero emissions and avoid the worst impacts of climate change.

(1) https://www.wri.org/insights/sustainable-biomass-carbon-removal

(2) https://www.osti.gov/servlets/purl/1763937

How does biomass carbon removal work?

Biomass carbon removal relies on the natural process of photosynthesis. During photosynthesis, plants use sunlight, water, and carbon dioxide to produce carbohydrates and oxygen. The carbon from the absorbed CO2 gets incorporated into the plant’s tissues as it grows.

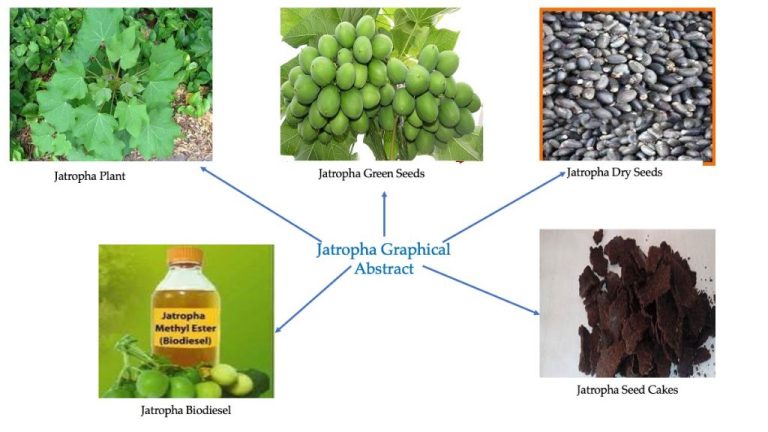

By harvesting and storing plant biomass, such as trees, grasses, or algae, the carbon absorbed during photosynthesis gets locked away and prevented from returning to the atmosphere. Common forms of biomass storage include growing forests, burying charcoal, or converting biomass into biofuels or bioproducts. This process removes CO2 from the atmosphere and can help offset emissions.

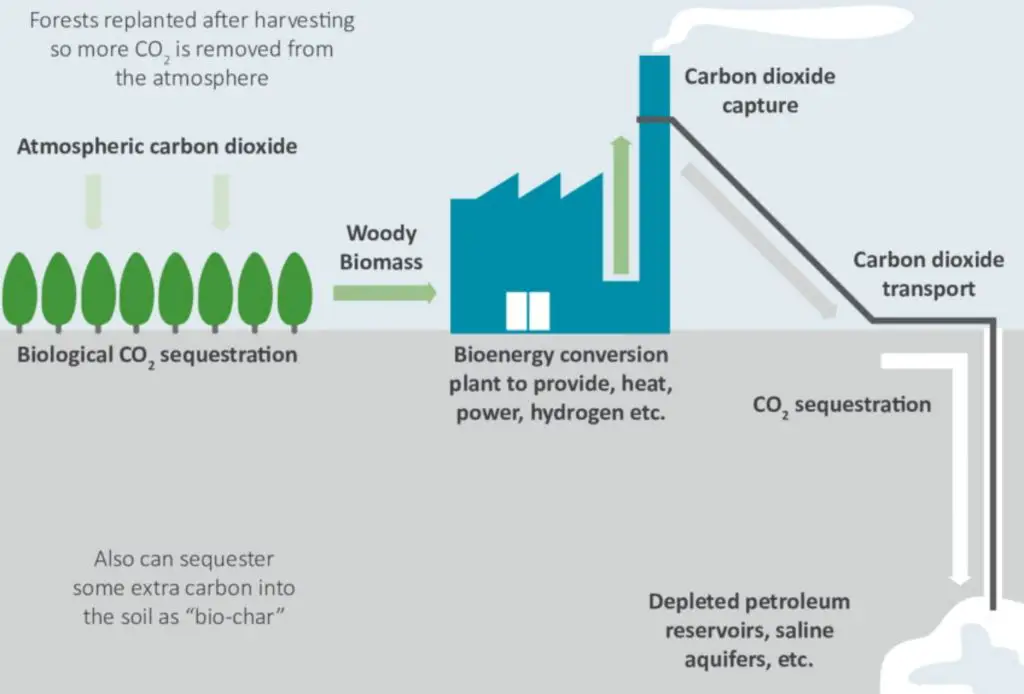

One key technology for enhancing biomass carbon removal is bioenergy with carbon capture and storage (BECCS). BECCS involves burning biomass for energy production, capturing the CO2 emissions, and storing them underground. By combining bioenergy with carbon capture and storage, BECCS results in negative emissions, actively drawing down atmospheric CO2. [1]

Overall, biomass carbon removal relies on natural photosynthesis combined with technologies to enhance the storage and prevent re-release of the absorbed carbon.

Key technologies and processes

Two key technologies for biomass carbon removal and storage are bioenergy with carbon capture and storage (BECCS) and using biomass for long-lived products.

BECCS involves burning biomass for energy production and capturing the resulting CO2 emissions before they are released into the atmosphere. The captured CO2 can then be stored underground through geological sequestration. According to the Biomass Carbon Removal and Storage (BiRCS) Roadmap report by the U.S. Department of Energy, BECCS has the potential to achieve gigatonne-scale carbon removal if deployed at large scales (Sandolow, 2021).

Using biomass feedstocks to create long-lived products like construction materials and furniture is another carbon removal approach. As plants grow, they remove CO2 from the atmosphere through photosynthesis. Using biomass for durable goods can sequester that carbon for extended time periods. Key technologies in this area include manufacturing biochar, wood products, and bio-based plastics and chemicals. According to Reuters, the IPCC estimates using biomass for long-lived products could deliver around 5 billion tonnes of CO2 removal per year by 2050 (Reuters, 2023).

Scale needed for climate impact

According to the DOE’s Biomass Carbon Removal and Storage (BiRCS) Roadmap, removing gigatonnes (Gt) of CO2 from the atmosphere annually using sustainable biomass will be required to meaningfully reduce atmospheric CO2 levels and limit global warming to 1.5°C. Most scenarios estimate that 5-15 GtCO2 of removal will be necessary by 2050.

Biomass carbon removal technologies like bioenergy with carbon capture and storage (BECCS) have the potential to scale up to gigatonne levels according to the National Academies report New analysis outlines national opportunities to remove carbon dioxide at gigaton scale. However there are limitations and challenges, including land use constraints, biomass availability, infrastructure needs, and transportation logistics that must be addressed to achieve full technical potential.

Case studies and examples

The Drax BECCS power station in the UK is a leading example of biomass carbon capture and storage (BECCS) technology. Drax converted several of its coal-fired generating units to burn wood pellets instead, capturing the CO2 emissions and preventing them from entering the atmosphere (Source 1). The captured CO2 is then compressed and pumped via pipeline to permanent geologic storage deep underground. As of 2022, Drax has captured over 1 million tonnes of CO2 using BECCS (Source 2).

Other companies exploring biomass carbon storage solutions include Mitsubishi Heavy Industries, Thyssenkrupp, and Net Power. These companies are developing technology to burn biomass or biofuels in power plants and industrial facilities, while capturing the resulting CO2 for permanent storage or utilization (Source 1). For example, Net Power has developed a natural gas power plant that burns methane while capturing all CO2 emissions for use in enhanced oil recovery.

Challenges and criticisms

While biomass carbon removal and storage has potential benefits, it also faces some key challenges and criticisms. Two major areas of concern are land use changes and debates around carbon accounting:

Land use changes for biomass production could potentially cause ecological harm or displace other agriculture if not managed properly. Large-scale biomass crops require significant amounts of land, which creates risks around deforestation, loss of biodiversity, and competition with food production (https://www.wri.org/insights/sustainable-biomass-carbon-removal). Careful planning and policies are needed to ensure biomass production does not negatively impact ecosystems, wildlife habitats, or food security.

There are also ongoing debates around how to properly account for the net carbon effects of biomass energy and BECCS systems. Some argue that burning biomass emits CO2 upfront before the regrowth can reabsorb it, while others say this carbon is balanced out over time as new biomass regrows. The timeframe for neutrality could range from years to decades depending on the feedstock and other factors (https://www.reuters.com/sustainability/climate-energy/burning-questions-surround-biomass-based-removals-2023-10-23/). More research is still needed to provide definitive carbon accounting guidelines.

Costs and economics

The cost per tonne of CO2 removed via biomass carbon capture and storage varies significantly depending on the specific technologies and processes used. However, estimates typically range from $100 to $200 per tonne of CO2 according to recent analyses.

For example, one 2021 study found that connecting biomass sources and CO2 storage sites across several hundred kilometers resulted in costs of $20-40 per tonne of CO2 removed (https://www.frontiersin.org/articles/10.3389/fenrg.2021.639943). Another 2022 study estimated the breakeven carbon price needed for profitable biomass carbon removal to be around $155 per tonne of CO2 (https://www.frontiersin.org/articles/10.3389/fclim.2022.993230).

At the current costs, biomass carbon capture and storage is not yet economically viable compared to the market price of carbon credits and offsets. However, costs are expected to fall as technologies scale up. Some startups like Graphyte claim they can already remove carbon for as low as $100 per tonne, which could make biomass CCS profitable at today’s carbon prices (https://time.com/collection/time-co2-futures/6333975/startup-graphyte-trap-carbon-emissions-affordably/).

Overall, experts estimate biomass CCS needs to achieve costs below $100 per tonne to become economically competitive for large-scale deployment. Reaching this target will likely require technological improvements, process optimization, supportive policies, and scale.

Regulations and policies

Government incentives and UN programs are playing an important role in advancing biomass carbon removal and storage. The U.S. Department of Energy has invested over $160 million in BiCRS research since 2017, helping scale up technologies and reduce costs (https://www.osti.gov/servlets/purl/1763937). The Inflation Reduction Act passed in 2022 also provides tax credits for carbon sequestration, which makes BiCRS projects more financially viable.

On the global level, the UN Convention on Climate Change has recognized BiCRS as an important carbon dioxide removal solution. The UN’s Clean Development Mechanism has approved methodologies for quantifying emission reductions from BiCRS projects in developing countries. Additionally, the UN’s REDD+ program provides incentives to developing countries to grow biomass for carbon storage through reforestation and afforestation.

Future outlook

Biomass carbon removal and storage has significant potential for growth and development in the coming years. According to the IEA, bioenergy with CCS could reach just under 50 Mt CO2/yr removed by 2030 based on current projects in development. Further cost reductions and efficiency improvements could enable much larger scale deployment by 2050.

Key areas for growth and development include:

- Improving biomass production and logistics to lower costs

- Developing more efficient conversion processes with reduced energy penalties

- Optimizing integrated BECCS facilities and clusters for maximum efficiency

- Advancing carbon capture, utilization and storage technologies

- Increasing policy support and investment in large-scale BECCS projects

With continued research, development and investment, biomass carbon removal and storage has the potential to scale up significantly in the coming decades and play a major role in climate change mitigation.