What Is The Best Material For Absorbing Kinetic Energy?

Kinetic energy is the energy possessed by a body due to its motion. When the body collides with another object, the kinetic energy is transferred to the other object or converted into other forms of energy like heat, sound, deformation, etc. Absorbing kinetic energy means reducing the severity of collision by dissipating the kinetic energy in a controlled manner.

Kinetic energy absorption is critical in several applications:

- Automotive – Absorbing crash energy in car collisions to minimize injury to occupants.

- Sports equipment – Dissipating impact energy in helmets, pads, shoes to prevent concussions and injuries in contact sports.

- Shipping – Protecting cargo from shocks and impacts during transportation and handling.

- Construction – Mitigating effects of earthquakes by absorbing seismic energy in building materials and isolation systems.

Effective kinetic energy absorption is vital for safer vehicles, athletic gear, shipped products, and earthquake-resistant structures.

Foam Padding

Foam padding works to absorb kinetic energy through compression. When a force hits foam padding, the foam compresses and deforms to cushion the impact. As it compresses, the foam absorbs and dissipates the kinetic energy so that less force is transmitted through to whatever the foam is protecting. Some of the energy gets converted to heat as the polymer strands in the foam rub against each other while compressing. The open cell structure of foams enables this compression and energy absorption.

Foam padding has several advantages as an energy absorbing material. It is lightweight, inexpensive, and easy to manufacture in a variety of densities and compressibilities. Foam can be cut into shapes to fit different needs. It provides good shock and vibration dampening across a wide range of impact speeds and forces. Foam pads are flexible and comfortable for wearable protective gear.

However, foam padding does have some limitations. It loses effectiveness after repeated impacts as the cell structure breaks down. Temperature can also affect the performance. Foam may bottom out and fully compact under high energy impacts, allowing force to transmit directly through. Durability over years of use can be a concern as foam pads degrade and compress permanently. Foam can be flammable unless treated with fire retardant chemicals. Overall, foam padding provides a simple and affordable way to absorb impacts and cushion kinetic energy for many applications.

Honeycomb Structures

Honeycomb structures are composed of hexagonal cells that are stacked together to form a lattice-like structure. The unique geometry of the hexagonal cells allows the structure to be both lightweight and highly energy absorbent.

The hexagonal cells collapse in a progressive and controlled manner when force is applied. As each cell buckles and compresses, it absorbs some of the kinetic energy. This sequential cell collapse spreads the load over the entire structure, preventing it from failing catastrophically.

The length of the hexagonal cells can also be varied to further optimize energy absorption. Shorter cells are stiffer and collapse less, while longer cells are more compliant and crumple more easily to absorb additional energy.

Honeycomb structures are widely used for energy absorption in helmet liners, car bumpers, packaging materials, and even racing car chassis. The hexagonal geometry provides excellent strength-to-weight ratio and energy management compared to solid foams and other materials.

Metal Foams

Metal foams are a class of materials with very low densities and novel mechanical, thermal, electrical and acoustic properties. They have an open-celled structure and are made from various metals including aluminum, nickel, copper, and steel. Metal foams have excellent energy absorption capabilities thanks to their cellular structure.

The cell walls of metal foams deform plastically when a load is applied, dissipating kinetic energy. The pores collapse progressively, absorbing and dissipating the energy. Metal foams can absorb 15-40 times more energy compared to solid metal of the same weight. Their energy absorption capabilities are maintained over a wide range of impact velocities and temperatures.

Metal foams are widely used for impact and blast energy absorption in the automotive and aviation industries. In cars, aluminum foam is used inside pillars and bumpers to absorb crash energy and protect passengers in collisions. Steel and aluminum foams are used as filler inside crumple zones. In airplanes, metal foams are used inside wings, fuselages and landing gear.

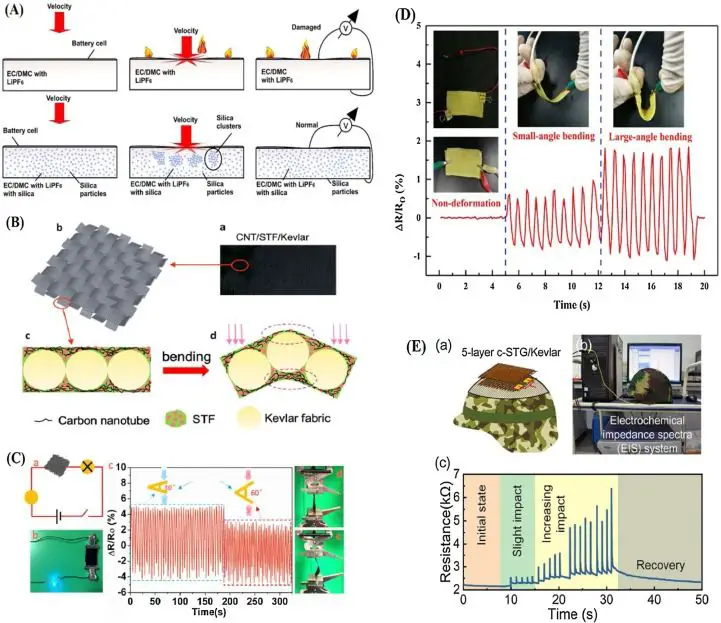

Shear Thickening Fluids

Shear thickening fluids, also known as dilatants, increase viscosity under impact or agitation. These non-Newtonian fluids contain hard particles suspended in liquid. Under normal conditions the particles flow easily, but when impact occurs they jam together forming a solid.

This temporary hardening makes shear thickening fluids ideal for absorbing sudden impacts while remaining flexible. Kevlar soaked in the fluid forms a less rigid armor that provides protection without compromising mobility. Many sports gear companies now use the fluid in helmets, protective pads, and other equipment. The fluid layer solidifies on impact, dissipating energy to reduce concussions and injuries.

Auxetic Materials

Auxetic materials are a special class of materials that have a negative Poisson’s ratio. This means that when they are stretched, they become thicker perpendicular to the applied force. Most conventional materials get thinner when stretched. The auxetic behavior gives these materials some unique properties that make them well-suited for absorbing kinetic energy from impacts or blasts.

The auxetic structure allows the material to flex, compress, and crumple when impacted, dissipating the energy. This prevents the impact force from being transmitted directly through the material. Auxetic materials can withstand multiple impacts without permanent damage or fracturing. They are very good at absorbing shocks and vibrations.

Some potential applications for auxetic materials in impact and blast protection include padding for helmets and body armor, shock-absorbing panels for vehicles and buildings, packaging protection for fragile items, and blast curtains. The energy absorption capabilities coupled with flexibility make them effective at shielding people and objects from impacts. Their fracture resistance allows them to maintain integrity after repeated impacts.

Research is ongoing into different materials and geometries that can produce auxetic properties. Some examples include foams, polymers, composites, and metallic structures. By tuning the microstructure, very high energy absorption can be achieved. Auxetics show promise for creating lightweight and reusable impact and blast protection solutions.

Layered Composites

Layered composites are materials made up of alternating layers of different materials, such as fibers and polymers. The layered structure allows the material to absorb kinetic energy through various mechanisms when under impact.

Some of the key advantages of layered composites for energy absorption include:

- The alternating layers can delaminate and deform individually to dissipate energy over a longer duration.

- The fiber layers provide strength and stiffness while the polymer layers provide ductility and toughness.

- The interface between the layers provides an additional source of friction and energy dissipation.

- The composition and thickness of the layers can be optimized for desired energy absorption properties.

In the aerospace industry, layered composites made of carbon or glass fibers in an epoxy matrix are commonly used. For example, these materials are used in aircraft and helicopter components like wings, rotor blades, and fuselages to handle crash impacts.

The automotive industry also uses layered composites of glass and carbon fibers reinforced with polymers to make energy absorbing crumble zones in vehicles. The layers delaminate in a controlled way to absorb crash energy and protect passengers.

Cellular Solids

Cellular solids such as foams, honeycombs, and lattices are very effective at absorbing kinetic energy. Their high porosity allows them to compress and crumple, dissipating energy over a longer distance and time period. The open-celled structure provides a larger surface area for deformation, maximizing energy absorption capabilities.

Foams like polyurethane or polystyrene foam have been extensively used for packaging and impact protection. The plastic or polymer matrix is filled with pockets of air, which compress on impact. Engineers can fine-tune the density, cell structure, and material composition to optimize energy absorption for different applications.

Honeycomb structures made from metals or composites provide excellent strength-to-weight ratios. The hexagonal cells can buckle and deform gradually as force is applied. Aerospace and automotive industries often use honeycombs for energy absorbing panels and liners.

Lattice structures with repeating three-dimensional truss patterns are an emerging area of interest. The open architecture and tuneable mechanical properties allow efficient energy absorption and customized crush response. Lattices can be fabricated from polymers, metals, or ceramics using 3D printing or other advanced manufacturing techniques.

Comparison

When selecting the best material for absorbing kinetic energy, there are a few key factors to consider:

Cost – Metal foams like aluminum foam tend to be more expensive than materials like foam padding or honeycomb structures. However, the manufacturing process for auxetic materials and shear thickening fluids can also be quite costly.

Effectiveness – Shear thickening fluids, metal foams, and auxetic materials are generally the most effective at absorbing impacts and dissipating kinetic energy. Foam padding and honeycomb absorb some energy, but are not as efficient per unit volume.

Applications – Foam padding is commonly used in helmets and protective gear. Honeycomb structures see use in packaging and automotive panels. Metal foams have applications in automotive and aerospace. Shear thickening fluids are still an emerging technology with potential uses in body armor and protective equipment.

In summary, while metal foams and shear thickening fluids may have the best technical performance for energy absorption, the cost and manufacturing considerations may make materials like foam or honeycomb more practical for many commercial applications.

Conclusion

In summary, there are several good options when it comes to choosing materials to absorb kinetic energy. Foam padding, honeycomb structures, metal foams, shear thickening fluids, auxetic materials, layered composites, and cellular solids all have unique properties that allow them to dissipate energy.

For consumer products like helmets and protective sports gear, foam padding is often the ideal choice as it is lightweight, inexpensive, and easy to shape. Honeycombs and metal foams are extremely lightweight and work well in automotive applications. Shear thickening fluids have interesting properties for body armor. Auxetic materials and layered composites provides flexibility and can conform to body shapes. Cellular solids like aluminum foam are great for automotive crashes.

There is no one-size-fits-all best material. The ideal choice depends on the specific application and requirements such as weight, cost, ability to conform to shapes, and more. With continued materials research and engineering, even better energy absorbing substances may be developed in the future.