How Much Does It Cost To Build A Hydroelectric Dam 2023?

Hydroelectric dams are large infrastructure projects that utilize the natural flow of rivers to generate renewable electricity. Building and operating these massive structures requires substantial investment, although costs can vary widely depending on the scale, location, and technological complexity of each project.

Estimating dam construction costs is a complex endeavor, as many factors like site geology, transmission infrastructure, and environmental impact all weigh into the final price tag. However, hydroelectric power is cost competitive with other generation sources over the long run, providing low operating costs and emissions-free renewable energy.

Dam Construction Costs

The main costs of building a hydroelectric dam include materials, labor, site preparation and permitting. Materials such as concrete, steel, piping and electrical equipment make up a significant portion of the budget. Skilled labor is required for specialized tasks like dam construction, turbine installation and electrical work. Site preparation involves excavation, road building, and creation of infrastructure to support construction. Extensive permitting is required, involving multi-year environmental studies and regulatory approval. Overall, a major dam project will have high upfront capital costs, often running into the billions of dollars. Costs scale with the size and complexity of the dam structure and powerhouse.

Ongoing Operating Costs

The operating costs of a hydroelectric dam are significant and ongoing over the life of the project. Key operating cost factors include:

Maintenance

Regular maintenance is crucial to keep the dam, turbines, generators and other infrastructure in good working order. This includes inspections, repairs, replacements and upgrades over time. Major overhauls of turbines/generators can cost millions of dollars.

Staffing

Hydroelectric dams require round-the-clock staffing by trained technicians and engineers to monitor and operate the equipment. Staffing costs include salaries, benefits, training and overhead.

Insurance

Comprehensive insurance policies are necessary to cover any accidents, failures or natural disasters that could damage the dam infrastructure.

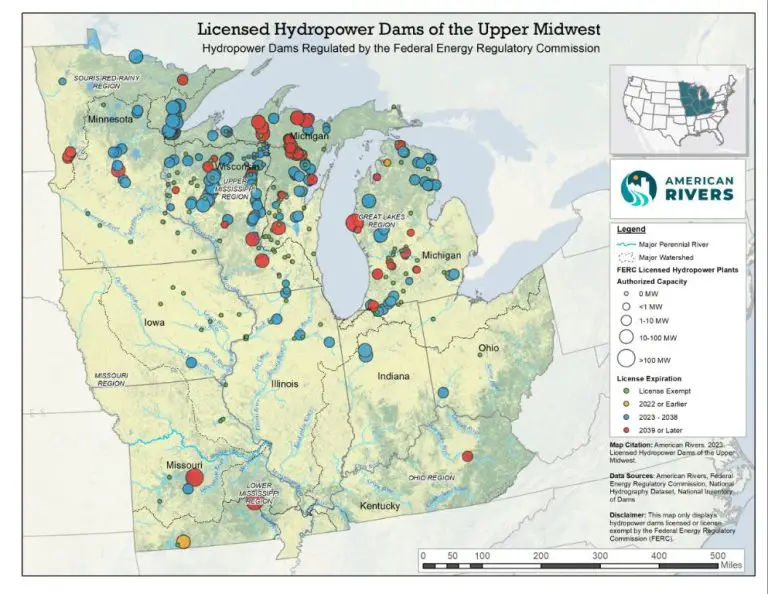

Licensing

There are licensing, permitting and regulatory costs related to dam operation and environmental impacts.

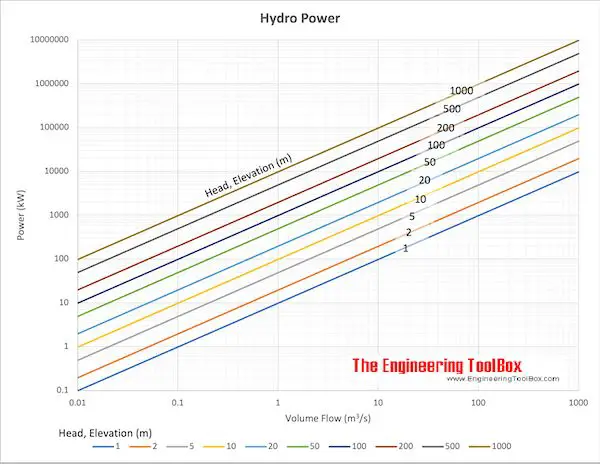

Typical kWh Generation Cost

Hydroelectric power is one of the most cost-effective sources of renewable energy. The cost per kilowatt-hour (kWh) of electricity generated from hydropower is generally lower than electricity generated from other renewable sources like solar or wind power.

The levelized cost of energy (LCOE) from hydropower plants is estimated to be around $0.085 per kWh. This is significantly cheaper than solar photovoltaics ($0.145/kWh) or onshore wind ($0.081/kWh). The low operational costs of hydropower plants make the kWh price very competitive compared to fossil fuel power plants as well.

Once a hydroelectric dam and power plant are constructed, the annual operating costs are relatively low compared to thermal power plants that require ongoing fuel purchases. Dam operators face maintenance and repair costs as well as licensing fees, but hydropower’s high efficiency and longevity results in low electricity generation costs over the long term.

Cost Factors

There are several key factors that influence the total cost to build a hydroelectric dam.

Size

The size of the dam is a major cost driver. Larger dams capable of generating more electricity require exponentially more materials, labor and land area. Massive projects like China’s Three Gorges Dam cost billions of dollars.

Location

Dams built in remote areas far from roads, rail and power infrastructure have much higher transportation costs. Ideally, sites should be easily accessible to transport construction equipment and materials.

Geology

The underlying rock structure impacts foundation excavation and construction. Weak or unstable geology requires additional stabilization which adds to project costs. Hard bedrock is preferable for anchoring the dam structure.

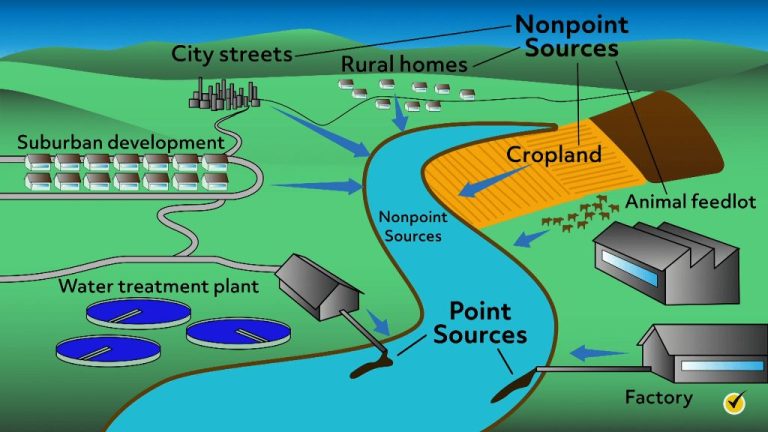

Environmental Impact

Extensive environmental impact studies and mitigation efforts like fish ladders or wildlife relocation can be very costly. Stringent regulations to protect ecosystems and minimize disruption add to the overall budget.

Recent Project Cost Examples

Some of the most expensive hydroelectric dam projects completed in recent years include:

Baihetan Dam in China, finished in 2021, cost $26 billion to build. This massive dam on the Jinsha River has 16 generators with a total capacity of 16,000 megawatts.

Belo Monte Dam in Brazil, finished in 2019, had a $16 billion price tag. It’s now the fourth-largest hydroelectric plant in the world at 11,233 megawatts.

Xiluodu Dam in China, completed in 2014, cost $6.7 billion to construct. With a height of 278 meters, it’s the third tallest dam in the world and has a capacity of 13,860 megawatts.

Jirau Dam in Brazil, finished in 2013, had a final budget of $7.3 billion. This run-of-river project has an installed capacity of 3,750 megawatts.

La Yesca Dam in Mexico, completed in 2012, came with a price tag of $2 billion. This 7MW gravity dam provides an important boost to Mexico’s hydroelectric capacity.

Cost Saving Innovations

New techniques and technologies are lowering the cost of hydroelectric dam construction. Here are some innovations that are reducing project costs:

Roller-compacted concrete (RCC) is a leaner mix of concrete that is placed without forms. This allows for faster installation, lower materials cost, and less skilled labor required compared to conventional concrete. RCC dams are becoming more widespread globally.

Pre-cast concrete embedding parts can be manufactured offsite and then installed onsite to speed up construction timelines. This improves quality control in a controlled factory setting.

Hydraulic modeling software provides detailed analysis of water flow, allowing for optimization of dam and turbine design. This prevents over-engineering and costly adjustments during construction.

Improved tunnel boring machines are drilling spillway tunnels faster and more economically through hard rock. Drone technology is used for rapid and accurate site surveying and monitoring.

Overall, innovation is driving down hydroelectric project costs, making this renewable energy source more financially attractive.

Financial Incentives

There are a number of financial incentives available from federal, state, and even local governments to offset the costs of building a new hydroelectric dam. These incentives help make hydro projects more economically feasible.

The main federal incentive is the Renewable Electricity Production Tax Credit (PTC). This provides a tax credit per kilowatt-hour of electricity generated by qualified renewable energy sources like hydropower. The PTC has helped spur growth in the hydro industry over the past couple decades.

Many states also offer production incentives or rebates for renewable energy generation. These vary by state but can be a significant offset to project costs. States like California, Massachusetts, and New York have particularly generous incentives for hydroelectric.

Additionally, hydro projects can benefit from the sale of Renewable Energy Certificates (RECs). A REC represents the environmental benefits of renewable energy generation. RECs can be sold separately from the power itself and provide an extra revenue stream.

Local municipalities may also offer incentives like tax breaks or exemptions to encourage local renewable energy development. teamed with state and federal support, these incentives can improve the economics of a new hydroelectric dam.

Future Cost Projections

The cost of building hydropower dams is expected to decrease in the coming decades due to several key factors.

Technological improvements will continue to drive down costs. Advanced materials, more efficient turbine designs, and improved construction techniques will all contribute to lower capital costs for new dam projects.

Increased competition in the hydropower sector as more companies enter the market, especially in developing countries, will also put downward pressure on bid prices.

As the best sites for large dams become scarcer over time, there will be a shift towards building more small and low-head dams which have a lower average cost per MW of capacity.

Efforts by governments to streamline permitting and environmental approval processes could shorten project timelines and reduce financing costs.

Forecasts suggest capital costs per kW of capacity could decrease 10-20% in real terms by 2030 as these dynamics unfold. This trend has the potential to make hydropower more economically attractive.

Conclusion

Hydroelectric power remains one of the largest and most cost-effective renewable energy sources globally. While the upfront capital costs of dam and powerhouse construction are high, operating costs are relatively low and facilities can generate electricity for many decades. Recent projects have cost anywhere from $2-$8 billion depending on size and location, with costs continuing to rise due to inflation, supply chain issues, and environmental regulations.

Looking ahead, new dam construction will likely slow in developed nations but expand across Africa, Asia, and South America. Innovations in modular and low-head facilities can reduce project costs moving forward. Overall hydroelectricity offers a proven way to provide clean, renewable power at scale when natural resources allow.

In summary, building a hydroelectric dam requires extensive upfront investment but can pay off substantially over decades of operation. Careful planning and cost control is essential for keeping these megaprojects financially viable and environmentally responsible.