Why Are Solar Cells So Expensive?

Introduction

Solar cells, also known as photovoltaic cells, are devices that convert sunlight into electricity. They have become an increasingly popular source of renewable energy over the past few decades. The biggest benefit of solar cells is that they harness power from the sun, which is a free and practically limitless resource. Once installed, they provide electricity without generating any air or water pollution. Solar energy is also extremely versatile and modular, with solar panels able to be installed on rooftops, integrated into building materials, and set up as freestanding arrays. Despite their many advantages, widespread adoption of solar power has been hampered by the high costs associated with solar cells.

Manufacturing Costs

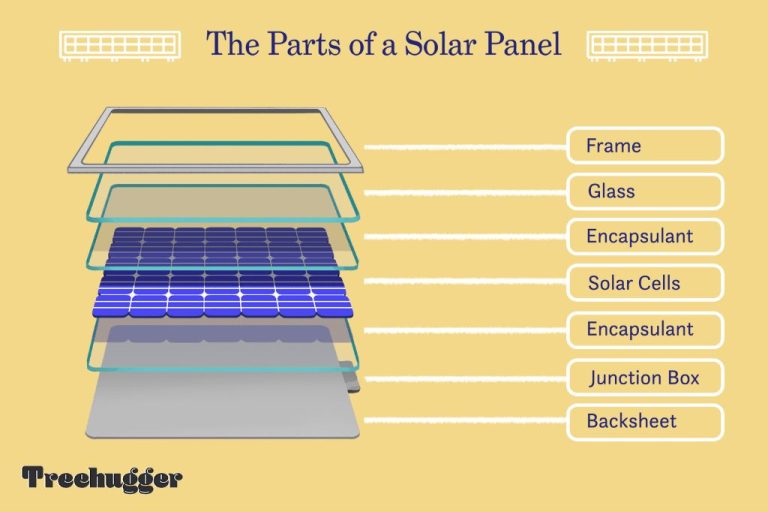

One major reason solar cells are expensive is the high cost of materials and manufacturing processes involved in producing solar photovoltaic (PV) panels. Solar cells today are primarily made from either crystalline silicon or thin film materials such as cadmium telluride (CdTe) or copper indium gallium selenide (CIGS). Silicon in particular must undergo an energy-intensive, complex refining and crystallization process to achieve the purity required for solar cells. Materials like tellurium and indium are also relatively rare and must be mined and processed. Depositing or growing thin uniform semiconductor films requires sophisticated equipment and controlled environments inside fabrication facilities (fabs). The initial capital costs of setting up such fabs is therefore very high. While manufacturing costs have declined over the years with economies of scale and technology improvements, they still account for a substantial portion of the finished module cost.

Installation Costs

Installing solar panels on rooftops or ground mounts requires significant labor costs. Trained solar installers are needed to properly mount, wire, and connect the panels and inverters. Depending on the size of the solar array, the installation process can take multiple days or even weeks to fully complete.

There are also permitting costs associated with solar installations. Local jurisdictions require permits for both roof and ground mount solar arrays, which often cost several hundred dollars. Electrical permits are also needed to connect the solar system to the electrical panel and grid.

Finally, electrical upgrades may be required to support the solar system, like upgrading the existing electrical panel or installing a new meter. Running conduit, wires, and connections from the roof or solar site to the electrical panel and grid tie inverter can add thousands to the installation costs.

Efficiency Limitations

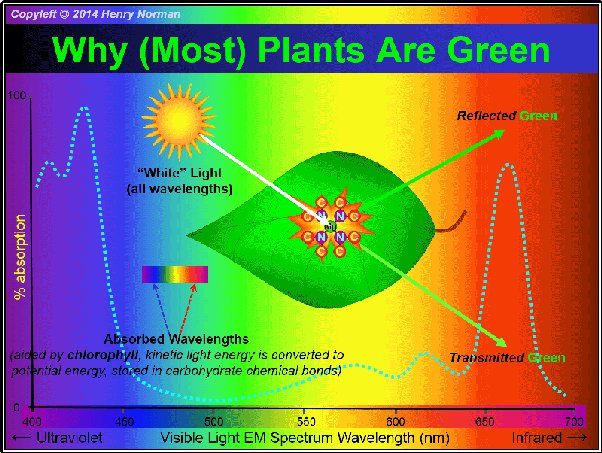

Solar cells have physical limits on how much of the sun’s energy they can absorb and convert into electricity. The theoretical maximum efficiency is around 33% for traditional silicon solar cells. However, the best lab prototypes can only achieve 25-27% efficiency under ideal conditions. The record lab efficiency for silicon solar cells is 26.7%, set in 2020. Most commercial products on the market are between 15-22% efficient.

The discrepancy between lab and commercial efficiencies is due to difficulties in scaling up new technologies and processes. Lab environments allow for precise control and optimization that is hard to achieve in large-scale manufacturing. The priority for manufacturers is reducing costs, even if it means slightly lower efficiency. Ultimately, there is a tradeoff between performance and affordability that the solar industry is still navigating.

Economies of Scale

Solar panel manufacturing has yet to achieve the same economies of scale as more established energy sources like coal, natural gas, and nuclear power. Fossil fuels have been used at an industrial scale for over a century, allowing generations of refinement and cost optimizations in extraction techniques, transportation networks, and power plant designs. In comparison, solar panels were first invented in the 1950s but have only become widely adopted for electricity generation in the last couple of decades. As a result, solar panel production is small – only around 600 gigawatts worldwide, compared to over 2,000 gigawatts of coal and 1,500 gigawatts of gas electricity generation capacity. With lower production volumes, manufacturers cannot take advantage of economies of scale to the same degree as conventional energy sources. The costs per unit stay higher when producing at lower volumes.

Storage Requirements

One significant factor that drives up the cost of solar power is the need for batteries to store the energy generated. Solar panels only produce electricity when the sun is shining. To provide power at night or on cloudy days, energy storage is required. Most residential solar installations are tied to the grid, which acts as a battery backup. But for off-grid systems or solar+storage installations, batteries are needed to store excess daytime solar energy for use at other times.

Battery technology remains expensive compared to traditional fossil fuel power plants, which can dispatch power whenever it is needed. Lithium-ion batteries used in home solar systems can cost anywhere from $5,000 to $20,000, depending on the size of the system. These batteries also degrade over time and need replacement every 5-10 years. The high upfront cost and maintenance requirements of batteries is a significant portion of the overall expense of solar power installations.

Advances in battery storage capacity and costs will be an important factor in making solar power more affordable and competitive with conventional energy sources. But for now, the need for energy storage adds substantially to the price tag.

Soft Costs

One significant factor that contributes to the high cost of solar is soft costs, which include things like permitting, regulations, policies, customer acquisition, inspection, and interconnection. As solar projects are usually installed on individual residential or commercial properties, there is a lot of red tape involved in getting permits and inspections at the local level.

Each jurisdiction may have different rules, fees, and processes for permitting solar installations. Navigating this complex regulatory environment adds time and expense to each project. Things like permitting, interconnection, inspection, and other non-hardware costs can account for over 50% of the total cost of an installed solar system. There is a lack of standardization across jurisdictions, which creates additional soft costs compared to more uniform traditional energy sources.

Policies and regulations also vary widely, with some municipalities and utilities creating additional roadblocks for solar adoption through restrictive rules, limitations, and charges. Overcoming these bureaucratic and regulatory hurdles adds to the cost and complexity of going solar for homeowners and businesses. Simplifying and standardizing solar policies could significantly reduce soft costs.

Transportation Costs

Transporting solar panels long distances or overseas can significantly add to their overall cost. Many of the raw materials and components needed for solar panel manufacturing are sourced globally and must be shipped to the factories.

Once the solar panels are manufactured, they again need to be shipped long distances to installation locations. Large utility-scale solar arrays require transporting thousands of panels over many miles. Even for small residential installations, the panels still need delivery from warehouses to homes.

The shipping and logistics involved at every stage – from raw materials to finished product to end installation – require extensive coordination and management. Fuel, labor, packaging and loading all contribute to the transportation expenses. Without localized manufacturing and supply chains, solar power relies heavily on a global distribution network.

In addition, solar panels are bulky, fragile items that require specialized packing and handling to prevent damage. This further adds to the shipping costs compared to transporting more durable finished goods.

Lack of Standardization

One factor driving up costs is the lack of standardization in the solar industry. Unlike traditional utilities which benefit from economies of scale, the solar market is still fragmented. There are many small installers working independently, with little coordination or standardization between them.

This increases soft costs, as each installer must evaluate products, create custom designs, and follow separate permitting/inspection processes. There is also duplication of efforts. By contrast, an integrated utility can streamline operations across its entire service area.

The lack of standardization also limits interoperability. Components from different manufacturers may not work together seamlessly. Additional customization and integration costs are often required.

As the solar industry matures, increased standardization and consolidation could drive down costs. But for now, the decentralized nature of the market contributes to high expenses.

Conclusion

Solar energy holds great promise as a clean, renewable energy source that can help mitigate climate change and reduce dependence on fossil fuels. However, the current high costs of solar cells present obstacles to wider adoption. With continued technological improvements, economies of scale, and streamlining of soft costs like permitting and installation, solar power costs can decrease further in the years ahead. If these cost declines are achieved, solar energy could become more affordable and make a bigger contribution to the world’s electricity mix. More policies and incentives to promote solar adoption can also accelerate cost reductions. The future is bright for solar power to play a major role in the global clean energy transition.