How Is A Solar Made?

Solar technology refers to technology that harnesses energy from the sun to generate electricity or heat. The most common solar technologies today are solar photovoltaics (PV), which convert sunlight directly into electricity, and solar thermal systems, which use the sun’s heat to provide hot water and space heating.

The history of solar technology dates back to 1839 when French physicist Edmond Becquerel first discovered the photovoltaic effect. In 1954, scientists at Bell Labs in the United States created the first practical solar cell made of silicon, with an efficiency of around 6%. Through continued research and development, the efficiency of solar cells has steadily increased over the decades.

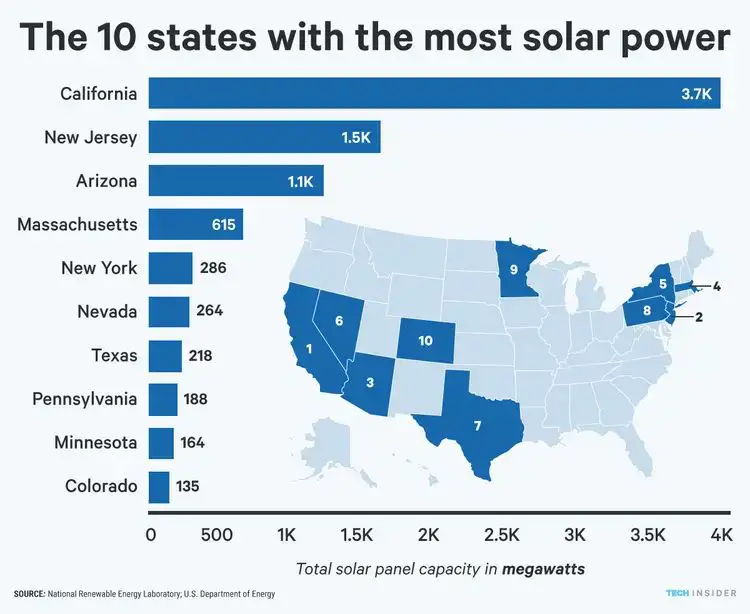

Today, solar energy is one of the fastest growing renewable energy sources worldwide. According to the Solar Energy Industries Association (SEIA), the amount of solar capacity installed in the United States has grown at an average annual rate of 24% over the past decade 1. This growth is driven by decreasing costs as well as supportive policies and incentives for solar adoption. The SEIA projects that by 2030, solar energy could account for up to 20% of U.S. electricity generation.

Solar Cell Components

The key component of a solar cell is the semiconductor material, typically silicon. Silicon atoms are doped with other elements to create an excess or deficiency of electrons The 5 Key Components of a Solar Panel System. The P-N junction is formed by combining positively doped (p-type) and negatively doped (n-type) silicon. When sunlight hits the solar cell, photons strike the electrons in the P-N junction and excite them to a higher energy state, causing them to become free and flow as electricity Basics of Solar Cell, Solar Photovoltaic Modules. The front side of the solar cell has an anti-reflective coating and metal contact grid to collect the electrons. On the backside, a full area metal contact collects and conducts the electrons out of the cell as electric current.

Monocrystalline Solar Cells

Monocrystalline solar cells are made from a single crystalline ingot of silicon that is cut into wafers [1]. The single crystal structure allows electrons to move through the silicon more freely compared to other types of solar cells, giving monocrystalline solar cells the highest efficiency ratings. Typical monocrystalline solar cells have efficiencies between 15-20% [2], making them the most efficient commercially available solar technology.

The single crystal silicon structure has a uniform look with a single color tone. Monocrystalline solar panels typically appear as large black cells with no visible grain boundaries. The high silicon purity and orderly atomic structure lead to better conductivity and higher efficiency potential.

Because of the complex manufacturing process, monocrystalline solar panels tend to be more expensive than polycrystalline. However, the higher efficiency ratings mean you need fewer monocrystalline solar panels to achieve the same electrical output as polycrystalline, so the higher upfront costs are offset by requiring a smaller overall system.

Polycrystalline Solar Cells

Polycrystalline solar cells are made from molten silicon that is poured into a square mold and allowed to cool and solidify into ingots. The ingots are then sliced into wafers to make solar cells.1 Polycrystalline cells have a recognizable bluish color and shiny, metallic appearance.

Polycrystalline solar panels tend to be lower in cost compared to monocrystalline panels, but they are also less efficient. Polycrystalline solar panels have an efficiency rating of 13-16%, while monocrystalline panels are usually 15-23% efficient.2 The lower efficiency of polycrystalline cells is due to the random arrangement of silicon crystals, which creates more defects and limits electron flow.

However, the lower price point makes polycrystalline panels a good choice for some homeowners and businesses looking to adopt solar power. Polycrystalline panels are a proven technology capable of lasting 25-30 years.

Thin Film Solar Cells

Thin film solar cells are made by depositing one or more thin layers of photovoltaic material onto a substrate like glass, plastic or metal (Thin-Film Solar Panels (2024 Guide)). They use a fraction of the semiconductor material compared to conventional solar cells, making them lighter and more flexible. The photoactive layer is typically a few micrometers thick, versus hundreds of micrometers for crystalline silicon cells.

Some of the advantages of thin film solar cells are (Thin-Film Solar Panels):

- Low semiconductor material usage

- Lightweight and flexible

- Better performance in low light and high temperatures

- Easy integration into buildings

However, thin film solar cells tend to have lower efficiency rates compared to crystalline silicon panels. The most efficient thin film cells achieve 20-22% efficiency in lab tests, while monocrystalline silicon panels can exceed 20% in commercial modules (Thin-film solar cell). Ongoing research aims to improve the efficiency and stability of thin film solar technology.

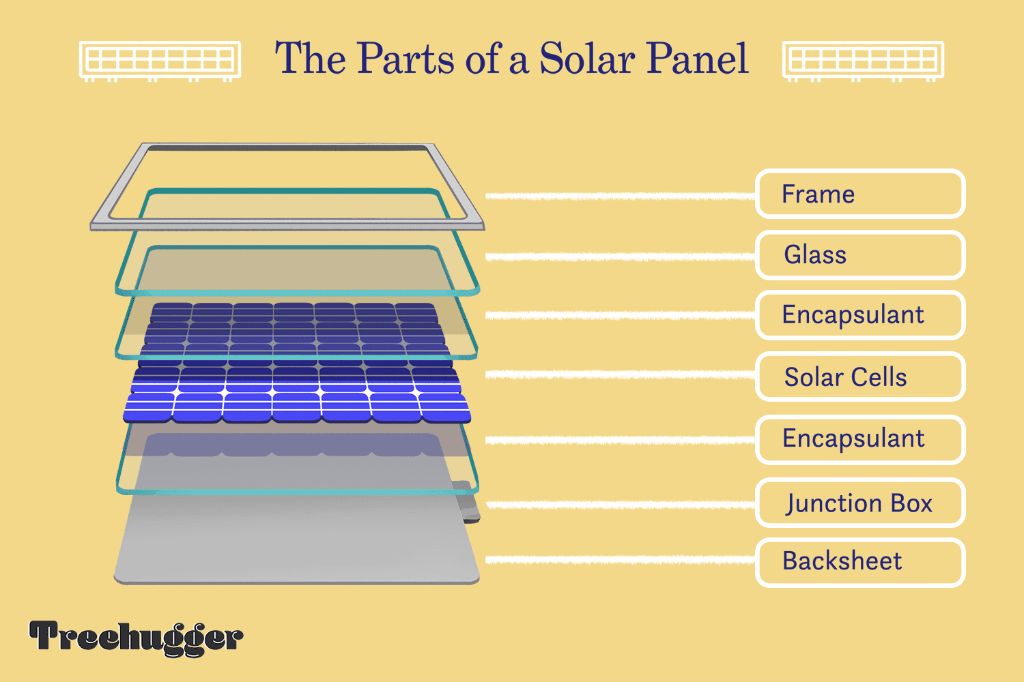

Solar Module Construction

Solar modules, also known as solar panels, are constructed by assembling together individual solar cells. The cells are encapsulated between a front glass cover and a polymer backsheet to provide electrical insulation and weather resistance. Common materials for solar module construction include:

Encapsulation: Silicon-based solar cells are sensitive to moisture and oxygen. To protect the cells, they are laminated between layers of ethylene vinyl acetate (EVA) or other encapsulant polymers using heat and pressure. The EVA fills in gaps between cells and provides electrical insulation.

Front Glass: A sheet of tempered glass covers the front of the solar module to allow light to pass through while protecting the solar cells from impact and weather. The glass is usually low iron for maximum transparency.

Backsheet: The back of the module is covered with a polymer backsheet, typically made of polyvinyl fluoride (PVF) or polyethylene terephthalate (PET). The backsheet is white or foil-laminated to reflect light back to the solar cells.

Frame: An aluminum frame surrounds the edges of the solar module to add mechanical strength. The frame has mounting holes for securing the modules to racks or rooftops.

Photovoltaic Effect

The photovoltaic effect is the process by which solar cells convert sunlight into electricity (https://energyeducation.ca/encyclopedia/Photovoltaic_effect). When sunlight hits the solar cell, photons from the light are absorbed by the semiconducting material, usually silicon. This excites the electrons in the material, causing them to break free from their atomic bonds. The energized free electrons can then flow through the material to produce an electric current.

Specifically, when a photon hits the solar cell, its energy frees an electron from an atom in the semiconductor. The removal of the electron leaves behind a “hole” with a positive charge. The freed electron then moves to another location in the material, while the hole stays put. This separation of charges creates a voltage difference within the cell. When the two surfaces of the solar cell are connected in a circuit, electrons can then flow from the negative side to the positive side as an electric current (https://www.sciencedirect.com/topics/engineering/photovoltaic-effect). This is the photovoltaic effect, which allows sunlight to be directly converted into electricity.

Connecting Solar Panels

Solar panels are connected together in “strings” to produce the desired voltage and power output. Strings are series connections of solar panels, and multiple strings can be connected in parallel.

The solar panels in a string are wired together in series, usually using 10-12 AWG wiring, to add up their individual voltages. Connecting panels in series increases the voltage while the current remains the same. Most residential systems use strings of 4-12 solar panels in series to achieve a system voltage around 300-600 volts.

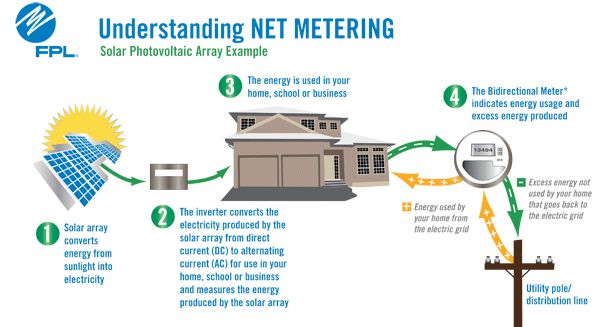

The string wiring runs through combiner boxes, which consolidate the outputs of multiple strings. The combiner boxes contain overcurrent protection devices and may also house monitoring equipment. The outputs of the combiner boxes feed into a central inverter, which converts the DC electricity from the solar panels into AC electricity that can power the home (source).

Inverters also maximize power production through MPPT technology. Some large solar arrays have multiple inverters to optimize efficiency. The inverter outputs connect to the home’s electrical panel to supply power. Understanding string configuration, combiner boxes, and inverters is key to properly connecting solar panels.

Installing Solar Panels

Installing solar panels typically involves roof mounting or ground mounting. For residential systems, roof mounting is the most common method. This involves attaching racking equipment to the roof using lag bolts, and then attaching the solar panels to the racks. Proper spacing between the panels is important to avoid shading. Typically, roof mounting is simpler and less expensive than ground mounting.

For larger commercial or utility-scale systems, ground mounting may be preferred. This involves installing posts into the ground, attaching racks, and then mounting the solar panels. Ground mounted systems can utilize tracking equipment to follow the sun throughout the day and maximize energy production. However, the land requirement, materials, and labor make it a more expensive option.

A key part of the installation process is securing the proper permits. Most local jurisdictions require permits for solar installations to ensure they meet electrical and structural codes. The permitting process can include submitting a site plan, electrical diagrams, and other documentation. Once the installation is complete, an inspection is required before final approval.

Future of Solar Technology

The future of solar technology looks bright as new innovations aim to improve efficiency and lower costs. One emerging technology is the perovskite solar cell. Perovskites have the potential for high efficiency solar energy conversion and can be produced at low cost. According to researchers, the material’s Shockley-Queisser efficiency limit is 33.7% (Source: Challenges & Trends for Emerging Solar Cell Technologies). While perovskites have instability problems currently, researchers are working to improve durability through encapsulation and interface engineering.

Another area of innovation is solar shingles and building-integrated photovoltaics (BIPV). Companies like Tesla are developing solar shingles that look just like regular roof shingles but also generate solar energy. Integrating solar technology directly into roofing and building materials has great potential for widespread adoption. According to one source, solar shingles could reduce installation costs by up to 15% over traditional solar panel systems. (Source: The 5 Most Exciting New Solar Panel Technologies in 2022).

Tandem solar cells that stack materials with different light absorbing properties are also an active area of research. By using multiple absorbing layers, tandem cells can achieve higher efficiencies by capturing a broader spectrum of sunlight. Researchers are working on developing low-cost tandem cells by combining silicon with perovskites or other high efficiency materials.

With continued research and investment into solar technology, we can expect efficiencies to gradually increase, costs to decrease, and new form factors like solar shingles to gain adoption. Exciting innovations like perovskites give hope that the future of solar power will be brighter than ever.