What Kind Of Liquid Is In Solar Panels?

Solar panels, also known as photovoltaic (PV) panels, are devices that convert sunlight into electricity. They are made up of PV cells which absorb photons from sunlight and generate an electric current. The PV cells contain a semi-conductor material, usually silicon, that undergoes a chemical process to release electrons when exposed to sunlight. The freed electrons flow through the PV cell to produce direct current electricity.

In order to work properly, solar panels need to maintain a cool operating temperature. As the PV cells absorb sunlight and generate electricity, they also produce heat which can build up and reduce the panel’s efficiency. To combat this, most solar panels contain a liquid coolant that transfers excess heat away from the PV cells and prevents overheating.

The goal of this article is to examine the different types of liquid coolants used in solar panels and understand their unique properties and benefits.

PV Cell Basics

PV cells are made of semiconductor materials such as silicon which is commonly used. The PV cell is constructed of two layers of silicon placed together to form a photovoltaic cell. When sunlight hits the PV cell, electrons are knocked loose from the atoms of the semiconductor material which generates an electric current. The PV cells also contain top and rear metal contact layers which function as conductors to capture the electrons. The cells are enclosed between a sheet of glass on the sun-facing side, and a polymer encapsulation on the rear side to protect the semiconductor and conductors. (1)

The photovoltaic effect causes PV cells to convert sunlight directly into electricity. When photons from sunlight strike the cell, they transfer their energy to the electrons in the semiconductor material which causes the electrons to break free of the atomic structure. The freed electrons are captured by the conductors to generate an electric current. So in essence, the PV cells absorb photons from sunlight and convert that light energy into electricity. (2)

Heat Transfer Need

PV cells heat up when exposed to sunlight due to the solar irradiance. The photons in sunlight excite electrons in the PV cell’s semiconductor material, generating electricity. However, not all of the solar energy is converted into electrical energy. The portion that is not converted generates waste heat in the PV cell, causing the temperature to rise. Typically around 15% of the solar energy is converted into electricity while the rest increases the temperature of the PV module.

This excess heat negatively impacts the electrical output and conversion efficiency of the PV cells. As the temperature increases, the band gap of the semiconductor material shrinks. This makes it easier for electrons to transition between the valence and conduction bands, increasing carriers but reducing voltage. The net effect is that the electrical power output decreases with higher temperatures.

Studies have shown that for crystalline silicon PV modules, the module efficiency decreases by around 0.4-0.5% for every 1°C increase in temperature above 25°C. Therefore, this waste heat must be dissipated to prevent PV cell overheating and reduced performance.

Liquid Coolants

Liquid coolants are used to regulate the temperature of PV cells and prevent overheating. The most common liquid coolants are water, glycol solutions, and thermal oils.

Water is an effective coolant due to its high specific heat capacity and thermal conductivity. Water cooling can improve solar panel efficiency by 10-15% (Moharram, 2013). However, water can cause corrosion and freeze damage in cold climates. It also requires a closed loop system to prevent evaporation.

Glycol solutions like propylene glycol are commonly mixed with water for solar panel cooling. Glycol lowers the freezing point to prevent damage in winter. It also mitigates corrosion and biological growth issues. Mixtures of 20-30% glycol provide adequate freeze resistance for most climates (Dwivedi, 2020).

Thermal oils like synthetic hydrocarbon oils have advantages for passive cooling systems. Their viscosity allows slower flow rates without pump circulation. Thermal oils also remain liquid at very low temperatures. However, they are more expensive than water or glycol solutions (Dwivedi, 2020).

Overall, glycol solutions offer a good balance of performance, cost, and freeze protection for liquid cooling PV panels in many climates. Proper corrosion inhibitors should be added as well.

Glycol Advantages

Glycol, specifically ethylene glycol, has many advantages as a coolant in solar panels compared to just using water. Glycol is added to water to prevent freezing, boiling, and corrosion in the solar panel system (https://www.chardonlabs.com/resources/why-glycol/).

Unlike water, glycol does not freeze at the same temperature and allows the fluid to stay liquid at much lower temperatures. This prevents freezing and cracking of pipes and components in the solar panel system during cold weather (https://www.scfuels.com/the-sc-fuels-guide-to-coolants/). Ethylene glycol also has a much higher boiling point than water, allowing the fluid to absorb heat at higher temperatures without turning into steam.

Glycol is also non-corrosive and helps prevent corrosion of pipes and components that pure water could cause through oxidation. By reducing corrosion, glycol improves longevity and reliability of the solar panel system.

In addition, glycol has good heat transfer properties, making it an efficient coolant. The specific heat capacity of ethylene glycol solutions allows effective transfer of heat away from the solar cells (https://www.motortrend.com/how-to/glycol-or-water-coolant/). This helps regulate operating temperatures for optimal solar panel performance.

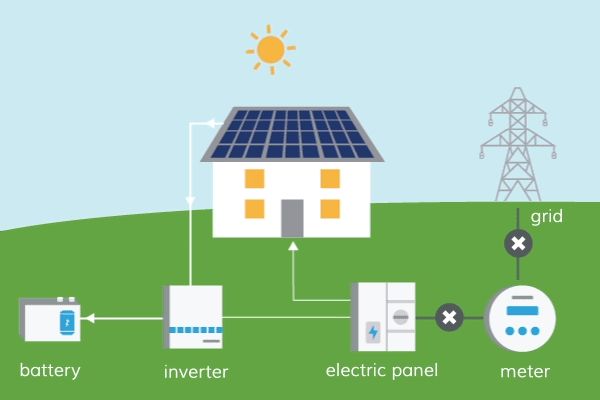

Installing Liquid Coolant

The liquid coolant used in most solar panels is a water and glycol mixture that flows through microchannels or small tubes behind the PV cells. It is important when installing the coolant to properly fill these tubes and channels without any air bubbles, as bubbles can cause hot spots and reduce efficiency. Most solar panel coolants contain corrosion inhibitors to prevent damage to internal components over time.

To install, solar glycol fluid is pumped through fill ports or inlet tubes, gradually filling all the microchannels and tubing pathways. The installers must ensure the fluid is flowing smoothly and steadily, tapping or tilting the panels if needed to dislodge trapped bubbles. Once filled, the ports are sealed and the glycol solution remains sealed inside the closed loops throughout the lifetime of the solar panel. Proper filling ensures every PV cell has liquid circulating behind it, maintaining even temperature distribution.[1]

[1] https://www.reddit.com/r/nvidia/comments/p9j5e4/3090fe_propylene_glycol_loop_fill/

Maintenance

Proper maintenance is critical for keeping a solar panel liquid cooling system operating efficiently. Over time, the glycol mixture can become diluted or contaminated, reducing its effectiveness. Regular checks and preventive maintenance will extend the life of the system.

One important maintenance task is checking for leaks in the piping system. Small leaks can gradually lead to a loss of coolant over time. Visually inspecting connection points and hoses can identify leaks early before they become problematic. Any leaks should be repaired immediately to prevent coolant loss.

Another key maintenance job is periodically testing the glycol concentration in the fluid. The glycol and water mixture has an optimal balance for freeze protection and heat transfer. This balance can shift over time through accidental dilution or water evaporation. Using a refractometer or titration kit allows testing the percentage of glycol. If the concentration is off, fluid can be added or drained as needed to restore the proper balance.

The glycol fluid should also be topped off to maintain full levels in the cooling system. Over time, small amounts of fluid can be lost due to minor leaks or evaporation. Keeping the system full ensures the maximum amount of coolant is available to remove heat from the PV panels. Glycol fluid should only be added after testing its concentration to avoid diluting the mixture.

Improving Efficiency

Liquid cooling can significantly improve the efficiency of solar panels, especially in hot climates. According to research by Khosravi and Ahmadi (2023), water cooling can increase electrical efficiency by up to 12% compared to air-cooled panels. By removing excess heat, the solar cells operate at lower temperatures where they are more efficient at converting sunlight into electricity.

Optimizing the flow rate of the liquid coolant is important for maximizing efficiency gains. As discussed by Dwivedi et al. (2020), computational fluid dynamics analysis can determine the optimal coolant flow rate to balance removing heat while minimizing pumping power. Too high of a flow rate wastes energy. Research found the best performance came from a moderate flow rate that kept the solar cell temperature 25°C below ambient air temperature. This optimized design resulted in 11% greater energy output compared to air cooling.

Properly installing liquid cooling with optimized flow allows solar panels to operate more efficiently, especially during hot conditions where solar cell efficiency would otherwise drop substantially. Liquid cooling systems can be designed to provide the ideal balance between heat removal and energy consumption.

New Research

There is active research into improving the specific heat capacity and thermal conductivity of fluids used for cooling solar PV panels. Scientists are exploring advanced fluids like nanofluids and ionic liquids to optimize heat transfer and keep panel temperatures low (The Future of Solar PV Cooling: Immersion Cooling Fluids).

For example, researchers have developed nanofluids containing copper oxide nanoparticles which have shown a significant enhancement in thermal conductivity (A new technique for cooling solar panels). The improved heat transfer allows the nanofluid to remove heat from the solar cell more efficiently. Ionic liquids are also being studied as they have negligible vapor pressure and can remain liquid at high temperatures.

Such advanced coolants can maintain lower solar cell temperatures without excessive pumping requirements. They offer great promise for improving solar PV efficiency and performance in hot environments.

Conclusion

In summary, glycol is the most commonly used liquid coolant in solar panels today. Its properties like low freezing point, high boiling point, and low viscosity make it ideal for removing heat from PV cells. Proper installation of the liquid cooling system, with considerations like external plumbing and leak prevention, is critical. Ongoing maintenance, like checking glycol concentration and replacing worn pump parts, ensures optimal performance.

Liquid cooling has been clearly shown to lower solar panel temperatures, increase electrical efficiency, and prolong equipment lifetime compared to air cooling alone. With improved designs and advanced cooling liquids on the horizon, the performance and adoption of Concentrated PV and other solar technologies will continue to grow. Liquid coolants provide an effective solution for removing wasted heat and enabling solar panels to operate at their highest potential.