Which Machine Is Used For Converting Mechanical Energy Into Electrical Energy?

Electrical energy plays a vital role in powering many aspects of modern life. From large-scale industrial applications to small home appliances, electricity provides the energy that makes our technological world function. But where does this electrical energy come from? The answer lies with generators – machines that convert mechanical energy into electrical energy through electromagnetic induction.

This article provides an overview of the different types of generators used to produce electricity. We’ll explore common generator designs like AC and DC generators, as well as renewable energy generators like wind turbines and hydroelectric systems. By the end, you’ll have a better understanding of how generators tap into mechanical power sources and convert them into the electricity that powers our daily lives.

Generator Overview

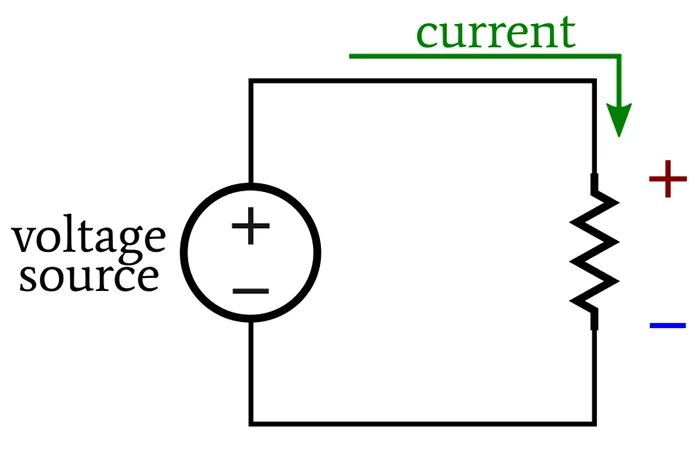

A generator is a machine that converts mechanical energy into electrical energy. It uses the principle of electromagnetic induction discovered by Michael Faraday in the 1830s. Faraday found that moving a magnet near a coil of wire causes an electric current to flow in the wire. Generators operate based on this phenomenon.

In generators, mechanical energy is used to rotate a coil of wire between magnets. As the coil rotates through the magnetic field, the magnetic flux changes around the coil, inducing an electromotive force (EMF) or voltage in the coil. This voltage causes electrons to move through the wire, producing an electric current. So in essence, a generator uses rotational motion to move a conductor through a magnetic field continuously, generating a steady electric current.

The most common type of generator uses an internal combustion engine or turbine to spin the coil. The mechanical rotation gets converted into usable electrical energy. The faster the coil rotates, the bigger the voltage generated. Generators are a key component of power generation systems, enabling the widespread distribution and use of electricity.

Types of Generators

There are several main types of generators used to convert mechanical energy into electrical energy:

AC Generators

AC (alternating current) generators are commonly used in power stations to generate electricity for power grids. They convert mechanical energy from turbines into alternating current electricity. The voltage and frequency of the electricity produced aligns with grid requirements.

DC Generators

DC (direct current) generators produce electricity in the form of direct current. They are useful for charging batteries and powering DC equipment. Common DC generator types include dynamos found on bicycles and magnetos used in combustion engines.

Diesel Generators

Diesel generators burn diesel fuel to run an internal combustion engine that spins an alternator to produce electricity. They are a popular backup power source for buildings and equipment. Diesel generators can produce AC or DC current.

Wind Turbines

Wind turbines convert the kinetic energy of wind into electricity. Modern horizontal-axis wind turbines use rotational energy from turbine blades to spin an internal shaft connected to a generator.

Hydroelectric Generators

Hydroelectric generators use the energy from flowing or falling water to produce electricity. They convert the mechanical energy from the moving water by spinning a turbine connected to an electrical generator.

AC Generators

AC generators, also known as alternators, produce alternating current or AC power. They work based on the principles of electromagnetic induction discovered by Michael Faraday. AC generators consist of two main components – a stationary structure called the stator and a rotating part called the rotor.

The rotor contains electromagnets or permanent magnets which produce a magnetic field. As the rotor spins, the magnetic field passes through wire coils in the stator, inducing an alternating voltage or EMF (electromotive force) across the coils. The alternating voltage causes the electric current to continuously reverse direction in the form of a sine wave. This is known as alternating current or AC.

The AC output voltage and frequency depends on two factors – the speed at which the rotor spins and the number of wire coils in the stator. Faster rotor speeds and more turns of wire in the coils produce higher voltage and frequency. The most common frequency of AC current is 50-60 Hz, suitable for commercial power transmission and electric motors.

In summary, AC generators convert mechanical rotational energy into alternating electric current. The spinning magnetic field induces changing voltage in the stator coils, generating useful AC power. AC generators form the backbone of electrical grids and are essential for supplying electricity to homes, offices and factories.

DC Generators

DC generators, also known as direct current generators, produce a direct electric current rather than an alternating current. They operate by using mechanical energy from a rotating shaft to turn electromagnets or permanent magnets within a wire coil. This induces a voltage across the coil according to Faraday’s law of electromagnetic induction. The voltage causes electrons to flow through the wire, producing a direct electric current.

The key components of a DC generator include:

- Rotating shaft – Provides mechanical energy to turn the armature

- Armature – Houses the electromagnets or permanent magnets that rotate within the generator

- Stator – Stationary component that surrounds the armature. Contains wire coils that output the electrical current.

- Commutator – Device that converts alternating current into direct current by reversing the polarity as the armature rotates.

- Brushes – Stationary conductors that transmit current from the rotating commutator.

As the shaft turns the armature, the permanent magnets or electromagnets rotate past the wire coils in the stator. This changing magnetic field induces an alternating current in the coils. The commutator then converts this into a pulsing direct current by periodically switching the contacts that transfer current from the armature. The brushes pressing against the commutator output this pulsed DC current to an external circuit.

DC generators are useful for applications that require a steady direct current rather than a fluctuating AC current. This includes charging batteries, powering motors, and supplying current in electroplating. Their simple and robust construction makes them ideal for portable generators and automotive charging systems.

Diesel Generators

Diesel generators are powerful machines that convert the chemical energy in diesel fuel into mechanical energy. This mechanical energy is then used to rotate electromagnets within the generator, producing an electric current.

Here is a quick overview of how diesel generators work:

- Diesel fuel is injected into the combustion chamber of the diesel engine.

- The fuel ignites due to the high compression within the chamber, causing small explosions that release energy.

- These small explosions push pistons up and down inside the cylinders of the diesel engine.

- The moving pistons spin a crankshaft that is connected to the rotor of an alternator/generator.

- The spinning rotor consisting of wire coils rotates within the magnetic fields of the stator, inducing an electric current.

- This alternating current electricity that is generated can then be used to power equipment and appliances.

Diesel generators are extremely useful machines thanks to their high reliability, durability, and fuel efficiency. Some of their key applications include:

- Providing backup power to hospitals, data centers, industries etc. during grid power outages.

- Supplying primary power for off-grid locations like remote villages, cellular towers, mining sites, oil rigs etc.

- Powering heavy equipment and machinery at construction sites and other project locations.

- Onboard power for trucks, boats, trains, mobile homes, RVs and more.

Wind Turbines

Wind turbines harness the power of the wind to generate electricity. They consist of blades that rotate when wind blows over them, converting the kinetic energy of the wind into rotational energy. This rotational force spins a shaft connected to a generator which then converts the mechanical rotation into electrical energy.

The blades are connected to a rotor which spins when the blades rotate. The rotor is connected to the main shaft that drives the generator. The generator contains magnets that rotate around a coil of copper wire, producing an electric current. This electricity is then fed into power lines for distribution and use.

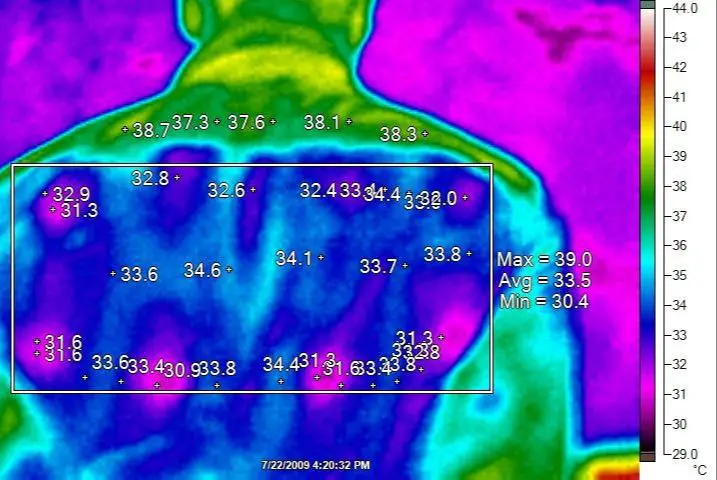

Wind speed is a critical factor in how much electricity a turbine can produce. Faster wind speeds exert more force on the blades, spinning them faster to generate more power output. Locations with consistent strong winds are ideal sites for wind farms containing clusters of wind turbines.

Wind turbines provide a renewable source of electricity that does not produce any greenhouse gas emissions. As wind energy technology continues to advance, wind turbines are becoming larger and more efficient at harnessing wind power.

Hydroelectric Generators

Hydroelectric generators convert the kinetic energy of falling or fast-flowing water into electricity. They rely on dams built across rivers to create large reservoirs. The water in the reservoir has potential energy due to its height above the turbines. This potential energy gets converted into kinetic energy as the water falls towards the turbines at high speed and pressure.

The turbines are connected to generators which consist of rotors containing magnets and coils of conducting wire. As the turbines spin from the moving water, the rotors also spin, moving the magnets past the coils. This motion of the magnets near the coils induces a current in the coils due to electromagnetic induction. This generates an electrical voltage and current which is the electric power output.

Hydroelectric generators provide a reliable and renewable source of electricity in many parts of the world. Countries like Norway and Brazil get the majority of their electricity from hydro power. Advantages include low operating costs once built, no carbon emissions, and ability to quickly adjust output to meet demand. Downsides are high initial construction costs and potential environmental impact on rivers and habitats.

Applications

Generators have many important applications in modern society. Here are some of the main uses of electrical generators:

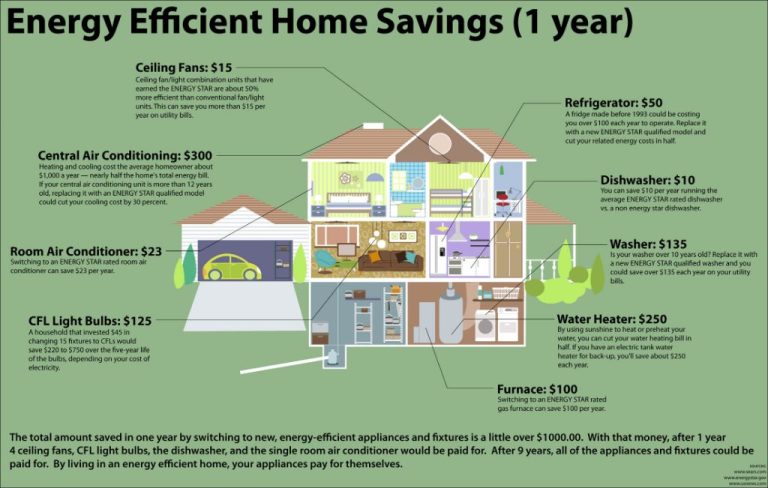

Power Plants: Most electricity is produced at power plants through generators. Different types of power plants use various energy sources like coal, natural gas, nuclear, hydro, wind, or solar to spin large turbine generators.

Backup Power: Generators provide backup electricity in many facilities like hospitals, data centers, and industries during grid outages. Diesel generators are commonly used for backup power.

Remote Locations: Generators are often the only source of electricity in remote areas without connection to the main grid. They allow things like lighting, appliances and equipment to be run.

Vehicles: In vehicles like cars and trucks, generators create electricity to charge the battery and power electrical components while the engine is running.

Marine Vessels: On ships and boats, generators supply onboard electricity for lighting, navigation, communications and other electrical equipment.

Portable Power: Portable generators allow temporary electrical power for outdoor sites, construction projects, events, camping and emergencies when grid electricity is unavailable.

Conclusion

Generators play a crucial role in supplying power for a variety of applications and industries. Their ability to convert mechanical energy into electrical energy makes them vital for power generation, emergency backup systems, remote power systems, and diverse industrial processes. While there are different types of generators and various technological implementations, they all rely on the fundamental principles of electro-magnetism and induction to generate electricity.

Generator technology has evolved significantly over the past century, leading to major advances in efficiency, power output, durability, and reliability. The widespread availability of electricity today owes greatly to the pioneering work and incremental improvements made in generator design and manufacturing over decades. Generators enable modern civilization to function and thrive by powering homes, businesses, hospitals, farms, and critical infrastructure.

Looking to the future, generators will continue to be a core technology supporting economic progress and higher standards of living globally. Further innovations and discoveries in materials science, controls, and integration with renewable energy sources like wind and solar will open up new possibilities for generators. However, the fundamental scientific principles underpinning their operation are well understood and unlikely to change. Generators will maintain their indispensable role in society for the foreseeable future.