What Is The Key Ingredient In Solar Panels?

A solar panel, also known as a photovoltaic panel, is a device that converts sunlight into electricity. They are commonly used in solar power systems to generate power for residential, commercial and industrial buildings. The key component inside solar panels that allows them to convert sunlight into electricity is the solar cell.

Solar cells are made of semiconductor materials, such as silicon, which can absorb photons from sunlight and convert them into electricity through the photovoltaic effect. When sunlight hits the solar cell, the energy from the photons knocks electrons loose in the semiconductor material, allowing them to flow freely and produce an electric current. This electricity can then be used to power electrical loads or fed back into the grid. The most common material used for solar cells today is silicon, which acts as the key ingredient enabling the photovoltaic effect in solar panels.

History of Solar Panels

Solar panels have evolved significantly since their invention in the late 19th century. The first functional solar cells were created in 1883 by American inventor Charles Fritts, who used selenium semiconductor wafers to convert sunlight into electricity (https://www.solarreviews.com/blog/the-history-of-solar-energy-timeline). However, these early solar cells were very inefficient with less than 1% conversion efficiency. The development of the modern silicon solar cell began in the 1950s. In 1954, researchers at Bell Labs discovered that silicon could be doped with other elements to create an electric field, enabling far more efficient conversion of sunlight to electricity. This paved the way for the mass production of silicon photovoltaic cells.

The first practical photovoltaic module was built in 1958 by American inventor Daryl Chapin utilizing silicon solar cells created by Bell Labs researchers Calvin Fuller and Gerald Pearson. This module was able to produce enough power to run everyday electrical equipment. Space programs in the 1960s and 1970s drove further advances, leading to the production of more efficient and cost-effective silicon solar modules. With the energy crisis of the 1970s, focus turned to developing solar technology for terrestrial applications. The first commercial solar PV plants were built in the 1980s, and solar panel adoption has steadily increased since then as manufacturing costs have declined and efficiency has improved.

How Solar Panels Work

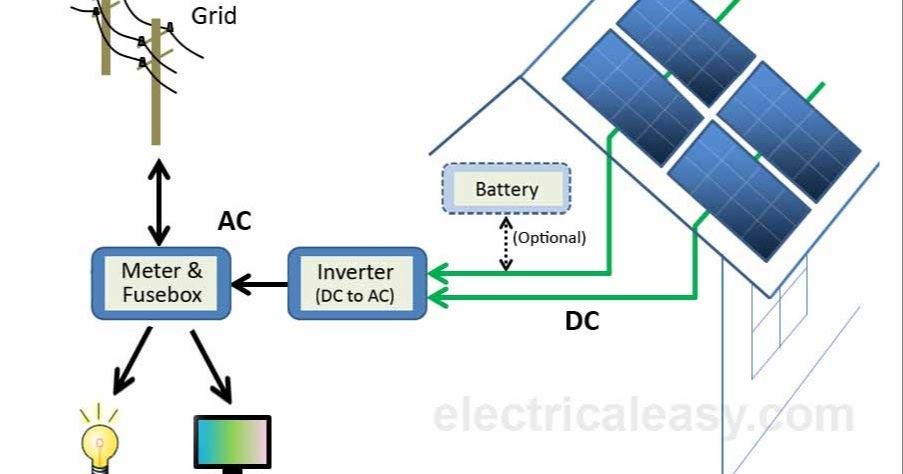

Solar panels convert sunlight into electricity through the photovoltaic effect. At the heart of a solar panel are semiconductors, which enable this conversion. When photons from sunlight hit the solar panel, they get absorbed by the semiconductors, causing electrons to break free. This generates an electric current as the electrons start moving through the semiconductor material. The current gets channeled into the electrical wiring of the solar panel, where it can then be used to power electrical devices and equipment.

Solar panels are made up of many individual solar cells wired together. Each solar cell is made from silicon, which is the semiconductor material that exhibits the photovoltaic effect. When sunlight hits the silicon atoms, the photons dislodge electrons from their positions around the silicon atoms, allowing them to flow freely. The movement of these electrons generates a DC electric current.

The photovoltaic effect was first discovered in 1839 by French physicist Edmond Becquerel. It wasn’t until 1954 that researchers at Bell Labs created the first practical photovoltaic cell, which was made of silicon. Silicon remains the most common semiconductor used in solar cells today due to its widespread availability and efficiency at converting sunlight into electricity. Other semiconductors like gallium arsenide and cadmium telluride are also used in some solar panels.

References:

[1] https://www.eia.gov/energyexplained/solar/photovoltaics-and-electricity.php

[2] https://www.energy.gov/eere/solar/how-does-solar-work

Solar Cell Design

Solar cells are made from semiconductors such as silicon that are specially treated to form an electric field across the material. When light shines on the solar cell, the energy from the photons of light excites electrons in the semiconductor materials, causing them to flow and produce electricity.

A solar cell contains two layers of semiconductor material, typically silicon. On the top is an n-type silicon layer that has extra electrons. On the bottom is a p-type silicon layer that lacks electrons, leaving holes where electrons can go. In between the two layers is an electric field formed by the imbalance of electrons.

When sunlight hits the solar cell, photons with enough energy knock electrons loose in the n-type silicon layer. If the photon hits the p-type layer, it may free an electron from the nearby electrically neutral atom and leave a hole behind. The electrons want to flow from the n-type side to the p-type side due to the electric field, so they travel through an external circuit to get there, generating an electric current. Holes flow in the opposite direction from the p-type to the n-type to unite with electrons.1 This flow of electrons and holes produces usable electric power in the external circuit.

The n-type and p-type silicon layers have different crystalline structures that are crucial in helping the electrons flow in one direction. The two layers provide both the electric field for electron flow and the medium for light absorption that starts the flow.

Silicon as a Semiconductor

Silicon is the most commonly used semiconductor material for solar cells due to its ideal semiconductor properties. Though silicon is abundant in nature, it needs to be extremely pure to be useful as a semiconductor. Impurities in the silicon can interfere with its electrical properties. So silicon used for solar cells typically has a purity of 99.99999%

Silicon is an intrinsic semiconductor, meaning it conducts electricity better than an insulator but not as well as a metal. To improve its conductivity, silicon goes through a process called doping where small amounts of other elements are intentionally added. Adding atoms like phosphorus provides extra electrons, creating an n-type semiconductor. Adding boron creates vacancies for electrons called holes, forming a p-type semiconductor. The junction where the n-type and p-type silicon meet is called a p-n junction, which is critical for converting sunlight into electrical current in a solar cell.

Sources:

[1] https://www.energy.gov/eere/solar/solar-photovoltaic-cell-basics

[2] https://www.wevolver.com/article/silicon-semiconductor-a-comprehensive-guide-to-silicon-and-its-use-in-semiconductor-technology

Silicon as the Key Ingredient

Silicon is the predominant material used in solar panels for several reasons:

Abundance – Silicon is the second most abundant element in the Earth’s crust after oxygen. This makes it readily available and affordable as a raw material.

Manufacturing – The technology for manufacturing silicon solar cells is well-established. The processes for purifying, crystallizing, and doping silicon are now highly optimized for efficient large-scale production.

Efficiency – Silicon has excellent semiconductor properties. The purity and crystallinity of silicon can be well controlled to optimize efficiency at converting sunlight to electricity.

Silicon solar cells typically have energy conversion efficiencies between 15-20%. While other semiconductor materials may have higher theoretical efficiencies, silicon strikes the best balance between high-performance and manufacturability.

History – Silicon has been used as the semiconductor for solar cells since the invention of the modern solar cell in 1954. Decades of research have optimized silicon solar cell technology.

In summary, silicon is the predominant photovoltaic material today because it provides an abundant, manufacturable, efficient, and time-tested solution for solar energy.

Other Semiconductor Materials

While silicon is the most common semiconductor material used in solar panels, researchers have explored other materials like gallium arsenide (GaAs), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS). Each material has its own advantages and disadvantages compared to silicon.

GaAs has a higher efficiency than silicon, with lab cell efficiencies over 30% compared to around 26% for silicon (ResearchGate, 2022). However, GaAs is more expensive to manufacture than silicon. CdTe has lower efficiencies than silicon, around 22%, but is cheaper to produce. CIGS falls in the middle with efficiencies around 23% and lower manufacturing costs than silicon.

Overall, silicon remains the dominant material for commercial solar panels because of its abundant supply, well-understood properties, and balance of efficiency and cost. But researchers continue improving other semiconductor designs to increase performance and lower prices further.

Improving Efficiency

There are several ways to improve the efficiency of silicon solar cells. One method is tuning the crystal structure of silicon. Monocrystalline silicon, which has a continuous crystal lattice, is more efficient than polycrystalline silicon, which has a more interrupted lattice structure. Going a step further, researchers are developing silicon with an ordered crystal structure that enables lower rates of defects and higher efficiency. According to the U.S. Department of Energy, this approach has enabled experimental mono-Si cells to achieve over 26% efficiency. [1]

Another approach is using anti-reflection coatings on the surface of solar cells to reduce reflective loss of sunlight. Typically made of silicon nitride or titanium dioxide, these coatings can improve efficiency by up to 2%. Texturing the surface of silicon cells also helps minimize reflection and trapping more light. Pyramid-shaped textures on mono-Si cells can further boost efficiency. [2]

Additional methods like using back-surface fields, surface passivation, and impurity dopingoptimization are also being researched to reduce electrical losses. Multijunction cells that stack materials with different bandgaps can achieve higher efficiencies by absorbing a broader spectrum of wavelengths. While more complex and expensive, tandem cells using three or four junctions have reached over 47% efficiency in lab settings. [3]

Future Outlook

There are several emerging solar cell technologies that show promise for improving the efficiency and lowering the costs of solar panels in the future:

-

Perovskite solar cells – These use a class of materials called perovskites that can be solution processed, potentially enabling low cost production. Perovskite solar cells have seen rapid increases in efficiency, now over 25%, though challenges with stability remain. Research is ongoing to improve perovskite stability for commercial applications.

-

Organic photovoltaics – Solar cells using organic materials, like organic polymers and small molecules, offer potential for low-cost, flexible solar panels. Efficiencies are currently lower than inorganic cells but research to improve organic PV efficiency and stability is active.

-

Quantum dot solar cells – These utilize semiconductor nanocrystals known as quantum dots to absorb sunlight. Quantum dots can be tuned to absorb specific wavelengths of light. Combining different quantum dots can potentially enable solar devices that exceed the efficiency limits of single junction silicon cells. However, commercial application currently lags lab demonstrations. Ongoing research aims to enable low-cost quantum dot solar panels.

While silicon is likely to remain dominant in the near future, these emerging technologies may become more prominent in years to come.

Conclusion

In conclusion, silicon remains the dominant semiconductor material used in solar cells today. Its natural abundance, mature processing technology, suitable bandgap, and affordable cost have cemented its status as the key ingredient in most solar panels.

Silicon makes up over 90% of the solar cell market, far surpassing any other materials. While alternatives like gallium arsenide show promise for niche applications, silicon will likely continue its dominance for mainstream solar panels in the foreseeable future.

The decades of research into improving silicon solar cell efficiency will enable ongoing incremental gains. But more dramatic advances may ultimately come from novel designs like multi-junction tandem cells that incorporate silicon. Silicon’s central role looks assured thanks to its unique combination of practical and technical advantages.