What Is A Situation In Which Electrical Energy Is Converted Into Heat?

Electrical energy is energy carried by moving electrons, typically in the form of an electric current. Heat energy, also known as thermal energy, is the energy that an object possesses due to the vibration of its molecules and atoms. There are many situations in everyday life where electrical energy gets converted into heat energy.

Some common examples of electrical energy being converted into heat energy include electric heaters, stoves, ovens, kettles, clothes dryers, showers, power tools like drills, electric motors, and incandescent light bulbs. In all of these devices, the electrical current flows through a resistor, which causes the electrons to collide with the metallic atoms. These collisions cause the atoms to vibrate faster, resulting in heat production. So the ordered energy carried by the electrons gets converted into the disordered kinetic energy of microscopic particles, heating up the resistor and its surroundings.

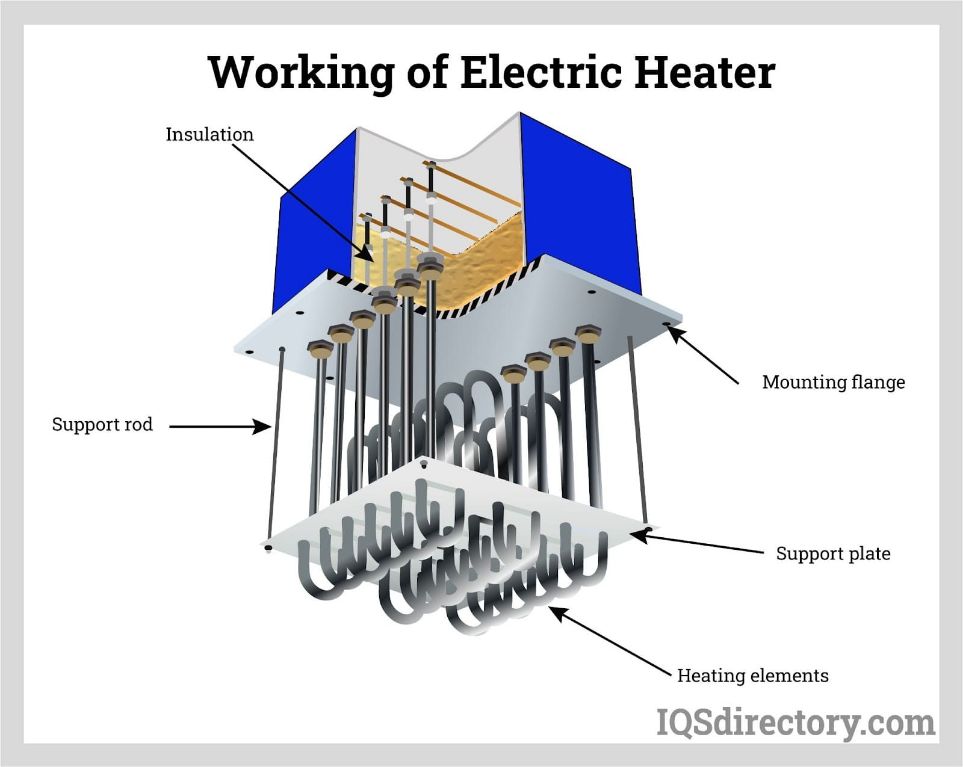

Electric Heaters

Electric heaters are devices that convert electrical energy into heat through the process of resistive heating. Resistive heating occurs when an electric current passes through a conductor, in this case a heating element or coil, which has electrical resistance. As the current passes through the resistance, electrons collide with the atoms of the conductor, generating thermal energy in the form of heat.

Some common types of electric heaters that rely on resistive heating include space heaters, electric blankets, electric heating pads, and portable radiant heaters. In a space heater, the heating element warms up when electricity passes through it, and a fan blows the warmed air into the surrounding space. Electric blankets and heating pads contain wires through which an electric current flows to produce heat. Infrared or radiant heaters use heating elements that emit infrared radiation to warm people and objects directly.

Electric heaters are prevalent in many households worldwide. According to statistics, over 40 million American households use portable electric space heaters. Electric blankets and heating pads are also popular, with over 50 million sold annually in the United States. Approximately 22 million electric radiant heaters are in use across Europe. With their ease of use, affordability, and customizability, electric heating devices continue to be a convenient way to convert electricity into targeted heat.

Electric Stoves/Ovens

Electric stoves and ovens use resistive heating elements to convert electrical energy into heat for cooking food. Inside an electric oven or stove, electricity passes through resistive coils made of materials like nickel-chrome wire. As the current flows through the coils, they heat up due to resistance and begin emitting thermal heat.

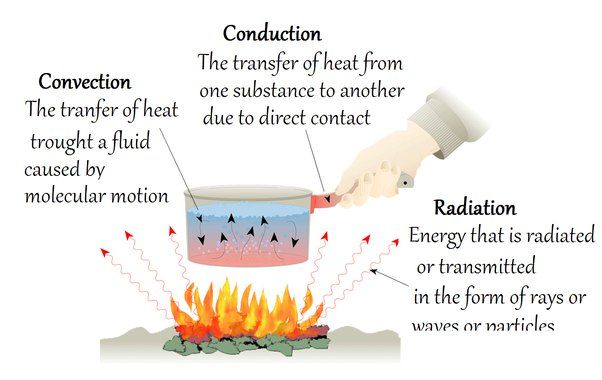

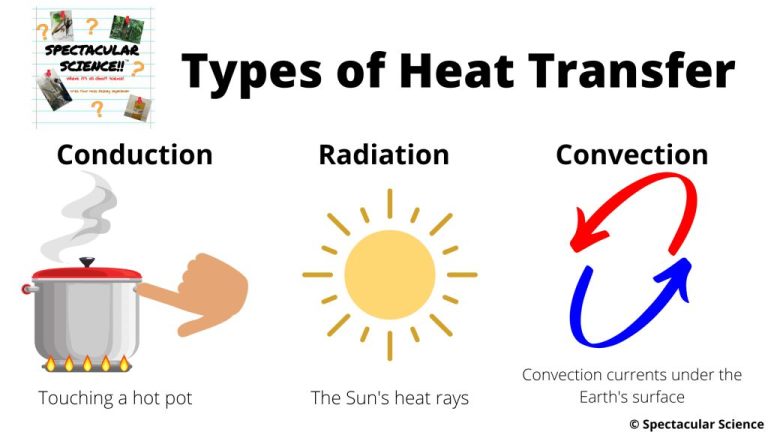

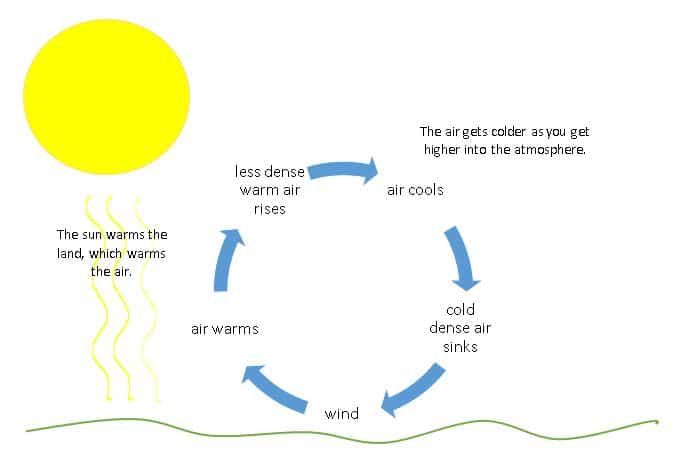

This heat is then transferred to the air and surfaces inside the oven or stove. For electric stovetops, the coils heat up and transfer heat directly to the pots and pans sitting above them. For electric ovens, the heat builds up inside the insulated oven box and cooks the food by convection.

Compared to gas stoves, electric stoves tend to heat up and cool down slower. However, they provide more even, consistent heating. Electric stoves are also generally easier to clean. In terms of energy efficiency, there is debate around whether electric or gas stoves are better. Gas stoves are often more energy efficient for cooking tasks that need quick, intense heat like boiling water. However, for baking and roasting, electric ovens can be more efficient.

Light Bulbs

One of the most common examples of electrical energy being converted into heat is in incandescent light bulbs. These bulbs consist of a thin tungsten filament enclosed in a glass bulb filled with an inert gas. When electricity flows through the filament, it heats up to incandescence, glowing white-hot and emitting visible light. However, most of the energy is actually converted into heat, not light. Incandescent bulbs are highly inefficient, converting only about 5-10% of the input electricity into visible light. The rest is wasted as heat.

This contrasts with LED light bulbs which convert most of the electricity into light, making them far more efficient. LED bulbs use semiconductors and electroluminescence to emit light, without generating nearly as much excess heat. This allows LED bulbs to produce a similar brightness while consuming a fraction of the energy compared to traditional incandescent bulbs. The reduced heat output also makes LED bulbs safer and longer-lasting. So while incandescent bulbs rely heavily on converting electricity to heat to produce light, LED technology has reduced this inefficient thermal process.

Electric Kettles

Electric kettles are a common household appliance used to heat water. They work by using a heating element, usually a coiled wire, that sits at the bottom of the kettle. When the kettle is plugged in and turned on, an electric current passes through the heating element, causing it to heat up rapidly. This heat energy is transferred to the water, quickly bringing it to a boil.

Electric kettles are prevalent all over the world but are especially popular in the UK, Ireland, and Australia where tea drinking is common. According to market research, electric kettles are found in about 95% of British households. They offer a quick and convenient way to boil water for tea, coffee, instant meals, and more. Their speed and efficiency make them a staple appliance in many kitchens.

Clothes Dryers

Clothes dryers are a common household appliance that use electricity to generate heat and dry wet clothes. Inside an electric clothes dryer is a motor, fan, heating element, and a drum that rotates to tumble the clothes. When activated, the motor turns the drum and the fan circulates air. The electricity powers the heating element, which heats up to very high temperatures. As the hot air blows into the rotating drum, it comes into contact with the wet clothes and absorbs moisture. The heat helps evaporate the water in the clothes, effectively drying them over the course of the cycle.

The heating element is typically a long coiled wire made from nickel and chromium alloy. It can reach surface temperatures of 300-400°F. As the current passes through the heating element, the resistance causes it to heat up. A thermostat and sensors control the temperature to prevent overheating. The hot dry air gets blown around the drum and dries the clothes through convective heat transfer. The evaporation of the moisture also has a cooling effect that keeps the temperature in check. This conversion of electrical energy into heat via resistance makes clothes dryers an effective and convenient way to dry laundry.

Electric Showers

Electric showers are a common way that electrical energy is converted into heat for the purpose of showering. An electric shower works by passing cold water through an electric heating element which rapidly heats the water before spraying it out through the shower head. The heating element contains electric resistive coils that heat up when electrical current passes through them. As the cold water passes over and around these hot coils, the water absorbs the thermal energy and gets heated up very quickly before exiting the shower.

Inside an electric shower unit, the heating element and water pipes are contained within an enclosed chamber. There is often a thermostat or dial to control the temperature of the heated water. When the shower is turned on, cold water enters this chamber and passes across the electric heating coils. The thermostat senses the water temperature and controls the electric current flowing through the coils to heat the water to the desired temperature. The rapid heating that occurs allows an endless supply of hot water on demand without needing a separate hot water heater tank.

Electric showers are able to quickly heat a stream of water due to the high power rating on the heating element, often ranging from 8 to 10+ kilowatts. This allows a high rate of electrical energy to be converted into heat energy. The conversion of electrical energy to thermal energy occurs across the resistive coils as current passes through them, making electric showers a prime everyday example of joule heating.

Power Tools

Power tools like drills, sanders, grinders, and saws are common examples of devices that convert electrical energy into heat energy. Modern power tools use electric motors powered by electricity to spin or oscillate cutting surfaces, grinding wheels, or sanding discs at high speeds.

In a power drill, an electric motor spins a chuck that grips the drill bit. As the fast-spinning drill bit grinds against a material, friction converts the drill’s rotational kinetic energy into heat. The drilling action produces significant heat, which is why drill bits become hot during use. The motor itself also heats up from electrical resistance as current passes through its coiled windings. Ventilation slots in the drill housing allow air circulation to cool the motor.

Similar principles apply for other power tools. Sanders use spinning pads to heat and wear down material surfaces through friction. Grinders rotate grinding wheels that generate extreme heat when applied to materials like metal. Saws employ serrated blades that get hot from friction with the material being cut.

So in all these power tools, the conversion of electrical energy into mechanical energy also inevitably produces heat as a byproduct. The higher the power and torque required by the tool, the more heat that will be generated during operation.

Electric Motors

Electric motors convert electrical energy into mechanical energy, but they also inevitably produce heat as a byproduct of inefficiency. All motors have some level of energy loss during operation, usually in the form of heat. This wasted energy is due to several factors:

– Friction: There is always some friction in the motor’s moving parts that causes heat. Bearings, bushings, and brushes all experience friction that is dissipated as heat.

– Electrical resistance: The conductors in the motor have inherent electrical resistance that also generates heat. The currents flowing through the windings produce I2R losses.

– Eddy currents: These swirling currents induced in the iron cause additional energy losses, heating the core.

– Hysteresis losses: The reversing magnetic field in the motor leads to energy loss through magnetizing and demagnetizing the core.

– Stray load losses: Leakage fluxes and other stray effects dissipate energy as heat.

– Inefficiencies: Imperfections in design and manufacturing mean the motor cannot fully convert input power into mechanical output.

In summary, these multiple sources of loss during the energy conversion process generate waste heat in electric motors. Engineers work to minimize losses, but some level of heat dissipation is inherent to their operation. Proper cooling and ventilation is necessary to avoid overheating motors.

Conclusion

In summary, there are many common household appliances and devices that convert electrical energy into heat energy. Electric heaters, stoves, ovens, kettles, clothes dryers, showers, power tools, motors, and light bulbs all produce heat as a result of electrical current flowing through resistive elements like heating coils or filaments.

Understanding where and how these electrical to thermal energy conversions take place is important for designing efficient appliances and systems. For example, reducing wasted heat in devices like motors and light bulbs through improved insulation or LED technology can lower energy consumption. Knowing how electrical energy gets turned into heat also helps explain how many everyday items in our homes actually work to provide useful services like cooking, drying clothes, or warming rooms.