What Do You Mean By Pv?

Definition of PV

PV stands for photovoltaics. PV cells, also known as solar cells, are electronic devices that convert sunlight directly into electricity. This process of converting light (photons) into electricity (voltage) is called the photovoltaic effect. When sunlight shines on a PV cell, the energy from the photons in the sunlight is transferred to the electrons in the atoms of the PV cell. This energy causes the electrons to move, creating an electrical current. The PV cell has electric field that forces the current to flow in a singular direction, allowing us to capture the electricity for external use.

PV cells do not require any external power to function, they simply generate electricity whenever exposed to a light source. This makes them highly versatile for power generation. As long as sunlight is available, PV systems can produce clean, renewable electricity. The amount of electricity generated depends on how much sunlight strikes the PV cell surface. PV systems are extremely scalable as well. PV cells can be linked together to form modules and panels, which can then be combined in PV system configurations ranging from a few watts to hundreds of megawatts.

How PV Cells Work

PV cells are made of semiconducting materials like silicon that can absorb photons from sunlight and release electrons. When sunlight hits the PV cell, the energy from the photons knocks electrons loose in the cell. This allows the electrons to flow freely, generating an electric current. The PV cell has electric fields built in that force the current to flow in one direction, allowing us to harness it for external use.

So in summary, PV cells can convert sunlight directly into electricity through the photovoltaic effect. The photovoltaic effect causes electrons in the cell to be emitted and flow due to the energy absorbed from photons in the sunlight that hits the cell. This electron flow is captured as electric current that we can then utilize.

PV Cell Components

The key components that make up a photovoltaic (PV) cell are the semiconductor material, metal contacts, anti-reflective coating, and encasing.

Semiconductor Material

The semiconductor material, usually silicon, forms the base of the PV cell. Silicon atoms are modified or “doped” with other elements to form an n-type semiconductor with extra electrons, and a p-type semiconductor with extra holes where electrons can go. The n-type and p-type semiconductors are placed together to form a p-n junction with an electric field. When sunlight hits the PV cell, the energy frees electrons in the semiconductor to flow through the electric field, generating electricity.

Metal Contacts

Metal contacts are attached to the front and back of the PV cell to collect the current. The n-type semiconductor is connected to the negative contact, and the p-type to the positive. When the PV cell is exposed to sunlight, the electric field causes current to flow from the positive to the negative metal contacts.

Anti-Reflective Coating

An anti-reflective coating is applied to the top of the PV cell to reduce reflection off the cell’s surface so more sunlight can enter and be absorbed by the semiconductor. This improves the cell’s efficiency.

Encapsulation

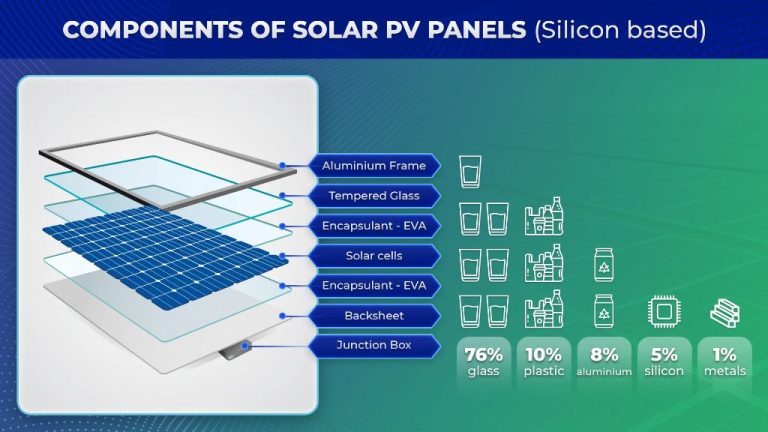

The PV cell is encased between sheets of material, such as glass or plastic, to protect the cell from impact and environmental damage. The encapsulation seals and insulates the cell.

PV Cell Efficiency

PV cell efficiency refers to the ratio of electrical output versus solar energy input. It measures how effectively a solar cell can convert the energy in sunlight into usable electricity. Most commercial PV cells today have efficiencies between 5-22%.

A key factor determining PV efficiency is the type of semiconductor material used in the cell. Monocrystalline silicon cells typically have the highest efficiencies, around 15-22%. Polycrystalline silicon cells are a bit lower, around 13-16%. Thin-film technologies like cadmium telluride (CdTe) tend to have lower efficiencies, around 5-13%.

Researchers continue working to maximize PV efficiencies through new materials and cell designs. The highest efficiency achieved for a research-level solar cell is around 47%. But such cutting-edge lab cells are still expensive to manufacture compared to commercial cells. The focus is on raising the efficiency baseline for mass-produced PV panels.

PV Cell Types

There are several main types of photovoltaic cells used in solar panels today:

Monocrystalline Silicon

Monocrystalline silicon PV cells are made from pure crystalline silicon and have a distinctive uniform black color. They are cut from a single cylindrical silicon ingot and have the highest efficiency rates, typically around 15-20%. However, they are more expensive to produce than other types.

Polycrystalline Silicon

Polycrystalline silicon PV cells are made from melted and recrystallized silicon fragments and have a speckled blue color appearance. They are less expensive to manufacture than monocrystalline cells but also slightly less efficient, around 13-16%.

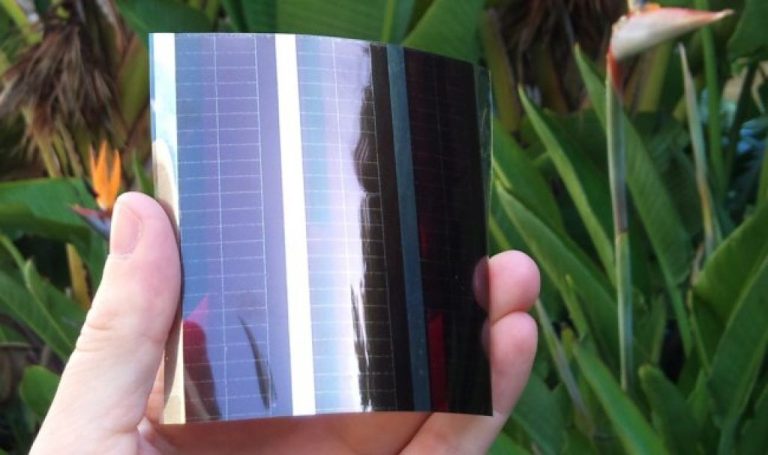

Thin Film

Thin film PV cells are made by depositing very thin layers of photosensitive materials like amorphous silicon, cadmium telluride, or copper indium gallium selenide onto a substrate. They have lower efficiencies of around 7-13% but allow more flexible applications.

Perovskites

Perovskite solar cells are an emerging technology made from inexpensive materials using simple manufacturing techniques. Their power conversion efficiency has increased rapidly from 3% to over 25% in just a few years of research and development. However, work is still needed on their stability and durability.

Connecting PV Cells

PV cells can be connected together in different configurations to produce the desired current and voltage output for a PV system. The two main ways to connect PV cells are in series and in parallel.

When PV cells are connected in series, the voltage of each cell is added together, but the current stays the same. For example, connecting two 12V PV cells in series produces 24V. This method is used when a higher voltage is needed from the PV system.

Connecting cells in parallel combines the current of each cell, while the voltage remains the same. For instance, two PV cells rated at 1A each can be paralleled to produce 2A total at the same voltage. This method is used when more current is required from the PV system.

PV panels are made up of many PV cells connected in series and parallel to deliver the desired electrical output. Panels can then be wired together in series or parallel to form PV arrays sized to meet the particular system’s voltage and power needs.

PV Panels and Arrays

PV cells are interconnected and encapsulated to form PV modules, or solar panels. These solar panels contain a number of PV cells wired in a series to achieve a desired voltage and output. The PV cells within a module are electrically connected to metal contacts and wiring, and then laminated between protective layers, framed, and sealed from the environment.

PV panels are designed to supply electricity at a certain voltage, such as a 12 volt system. Multiple solar panels can be wired together to form a PV array, which is a complete power generating unit. Solar arrays are designed and sized to meet specific electric load requirements for a home, business, or grid-connected system. The number of solar panels in an array depends on the size of the system and amount of electricity needed.

When solar panels are mounted together in an array, they are wired in series to increase voltage, and in parallel to increase current. The direct current (DC) electricity generated by the array is fed through an inverter to convert it to alternating current (AC) for usage or to tie into the electric grid.

Balance of System

PV systems require more than just solar panels to function. The components that enable the full system to operate are known as the balance of system (BOS). The main elements of the BOS include:

-

Inverters – These convert the DC electricity from the solar panels into AC electricity that can be used to power homes and businesses or exported to the grid.

-

Batteries – Battery storage allows excess solar energy to be stored for use at night or during cloudy weather. Batteries also enable an off-grid solar system.

-

Wiring – This connects all of the PV system components together into a working whole.

-

Mounting equipment – Racking, frames and mounts securely attach the solar panels and position them at the proper angle.

-

Monitoring – Sensors and meters allow remote monitoring of system performance and output.

-

Safety gear – Equipment like fuses, disconnects and grounding hardware help ensure safe and reliable operation.

Properly integrating the balance of system allows a PV system to effectively collect solar energy and convert it into useful electricity.

PV Applications

Photovoltaic systems have a wide variety of applications at residential, commercial and utility-scale levels. PV systems can be installed to connect with the utility grid or operate off-grid, providing greater flexibility and options based on power needs.

For residential homes, small grid-tied PV systems are commonly installed on rooftops to offset electricity usage. Excess solar power generated during the daytime can be fed back to the grid. Homeowners with net metering can get credit for this which helps offset costs and their utility bill. Off-grid PV systems with batteries allow homes complete energy independence.

For commercial buildings, larger roof or ground mounted PV systems help provide supplemental or even 100% of their energy needs during daylight hours. Grid-tied systems with net metering help reduce peak demand charges. Some warehouses install systems on shade structures over parking lots which provides covered parking space too.

At utility-scale, large ground mounted PV farms can generate hundreds of megawatts of solar power. These centralized plants help feed into the utility grid, offsetting fossil fuel generation during peak daylight hours. Solar plants are increasingly competitive with traditional power plants as PV costs fall.

Future of PV

The future looks bright for photovoltaics. Much of the ongoing research is focused on improving efficiency and lowering costs through new materials and manufacturing methods.

Companies are investing heavily in developing new high-efficiency solar cell designs that can absorb more of the sun’s energy and convert it into electricity. Some emerging technologies like perovskite solar cells and organic PV show great promise to push efficiencies above 30%.

There is also a lot of work being done on new ways to manufacture solar cells that are simpler and require less energy-intensive processes. This could significantly reduce production costs. Some examples include printable solar cells, quantum dot solar cells, and solutions that use less or no silicon.

We may also see increased use of hybrid systems that combine multiple solar technologies, like silicon cells with thin-film layers. This allows the strengths of each material to be leveraged.

With supportive policies and continued innovation, solar PV will keep advancing and make an increasingly larger contribution to clean energy production globally.