What Are Two Works Using Mechanical Energy?

What is Mechanical Energy?

Mechanical energy is the energy possessed by an object due to its motion or position. There are two types of mechanical energy:

Kinetic energy is the energy an object possesses due to its motion. For example, a moving car has kinetic energy. The faster the car moves, the more kinetic energy it has.

Potential energy is the energy an object possesses due to its position or shape. For example, a book sitting on a shelf has potential energy that could be released if it falls off the shelf. A compressed spring also contains potential energy.

We encounter mechanical energy everyday. Some examples include:

- The motion of a rollercoaster

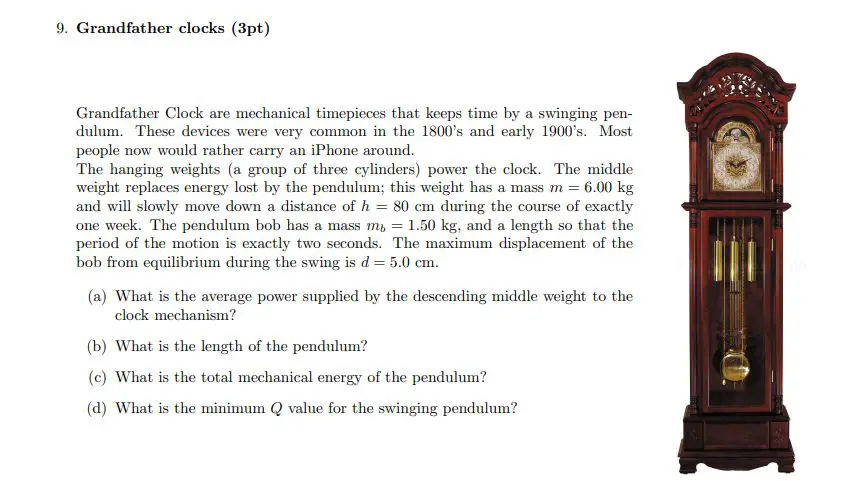

- A grandfather clock’s swinging pendulum

- The tension in a drawn bow before firing an arrow

- The spring inside a jack-in-the-box

Understanding mechanical energy allows us to predict the behavior of objects and build useful machines.

Kinetic Energy

Kinetic energy is the energy of motion. An object that has motion – whether it is vertical or horizontal motion – has kinetic energy. Some examples of kinetic energy include:

- A car driving down the road

- A bouncing ball

- The wind blowing

- A person walking

Kinetic energy depends on the mass and velocity of an object. The faster an object moves and the more mass it has, the more kinetic energy it possesses. Kinetic energy is directly proportional to mass and velocity squared. For example, if you double the velocity of an object, its kinetic energy will increase four times.

When objects slow down and stop moving, the kinetic energy transforms into other forms like potential energy or heat energy through friction. Understanding and harnessing kinetic energy has allowed humans to invent and utilize many machines and devices that have become integral to our lives.

Potential Energy

Potential energy is the stored energy an object possesses due to its position or state. For example, a book sitting on a shelf has potential energy due to the force of gravity acting on its mass. When it falls, this potential energy gets converted to kinetic energy – the energy of motion. Other examples of potential energy include:

– Water held behind a dam. The water has potential energy that can be converted into electricity as it flows through turbines.

– A compressed or stretched spring. The deformation of the spring gives it potential energy that can be released as kinetic energy.

– A pendulum at the top of its swing. The pendulum has gravitational potential energy that will convert into kinetic energy as it swings down.

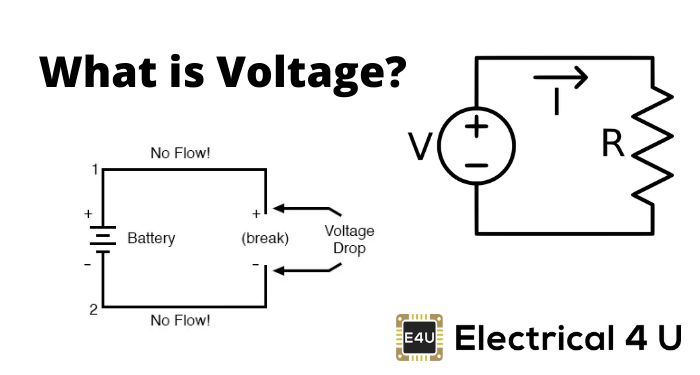

– Chemical potential energy stored in batteries. This can be released as electrical energy.

Potential energy is stored in an object by virtue of its position or arrangement of parts. This stored energy has the potential to be released and do work. Understanding potential energy is key to designing devices and systems that can effectively harness and utilize mechanical energy.

Mechanical Energy Conversion

Mechanical energy can be converted between potential energy and kinetic energy. Potential energy is stored energy based on an object’s position or shape. For example, a ball held at the top of a ramp has potential energy due to gravity. Kinetic energy is energy of motion. When the ball is rolled down the ramp, the potential energy is converted to kinetic energy as the ball gains speed. Other examples of potential energy converting to kinetic energy include a pendulum swinging, a spring uncoiling, and a roller coaster going downhill. The conversion also works in reverse – kinetic energy can be converted into potential energy. For instance, as a pendulum swings upwards, it slows down as the kinetic energy is converted back into potential energy. Understanding mechanical energy conversion allows engineers to design mechanisms and machines that use this principle to do work.

Using Mechanical Energy

Mechanical energy is essential for operating many machines and devices that we use every day. By converting one form of mechanical energy into another, these mechanisms are able to perform useful work. There are numerous examples of machines that harness the power of mechanical energy:

Wind turbines are a prime example of utilizing mechanical energy. The kinetic energy of the wind is converted into rotational kinetic energy to spin the turbines. This spinning turbine then converts the mechanical energy into electrical energy through an electrical generator.

Watches and clocks also rely on mechanical energy to keep time. A mainspring or weight provides potential energy that is slowly released over time. This is converted into kinetic energy through gears and pendulums, keeping the clock hands moving. Older grandfather clocks exemplify the clever use of mechanics and weight to accurately tell time.

Many other mechanical systems also depend on the conversion of potential and kinetic energy. Hydropower stations use falling water to spin turbines. Jack-in-the-boxes convert the potential energy of the spring into kinetic energy. Roller coasters rely on gravity and momentum as their cars travel up and down the hills and loops.

Understanding mechanical energy allows us to invent and build these types of useful machines. By harnessing natural forces like wind, water, springs, and gravity, the principles of mechanics enable the everyday functioning of modern society.

Hydraulic Machines

Hydraulic machines utilize the principles of hydraulic fluids and pressure physics to perform mechanical work. They operate through the use of an incompressible fluid, typically a type of oil, which transfers energy from one part of the system to another. The fluid transfers power quickly and efficiently through small diameter pipes, enabling hydraulic machines to produce large amounts of force.

Some common examples of hydraulic machines include:

- Hydraulic presses: Used for stamping, forging, punching, flattening, and shaping of metal parts. A hydraulic cylinder applies downward force to a platform.

- Hydraulic jacks: Portable tools used to lift heavy loads. The hydraulic cylinder extends under hydraulic pressure to raise the lifting arm.

- Hydraulic brakes: Found on automobiles and bicycles. When the brake pedal is pressed, it forces hydraulic fluid through valves which then squeeze the brake pads against a rotating disc or drum.

- Hydraulic door openers: Used on large doors like those on aircraft hangars. Hydraulic cylinders open and close the doors using fluid power.

Hydraulic machines allow for the controlled transfer of force to accomplish significant mechanical work with precision and efficiency. Their principles demonstrate the useful application of hydraulics in machinery of all scales.

Spring Operated Machines

Springs are elastic objects that can store mechanical energy when compressed, stretched, or bent. This energy gets released when the spring returns to its original shape. Many machines utilize springs to operate different functions and motions.

One common example is the pogo stick. This toy uses a large spring to propel the rider up and down. When the rider lands, their weight compresses the spring. As the spring decompresses, it provides an upward force that lifts the rider. Other spring-powered toys like jack-in-the-boxes and popup toys also utilize this compress-and-release action.

Springs are often used in tools and hardware. For example, automatic retractable tape measures contain a coil spring that draws the tape back in. Spring-loaded door hinges allow doors to close automatically. Springs also provide the closing force in latch mechanisms like padlocks and ratchet wrenches.

Vehicles use leaf springs, coil springs, and torsion bars to absorb shocks from bumps in the road. These spring suspensions smooth out the ride and prevent damage to the chassis. Springs also return the vehicle to its normal ride height after a bump.

In industry, springs can act as shock absorbers and vibrational dampeners in heavy machinery. They are also important components in pressure relief valves, which use springs to regulate fluid flow in pipes and tanks. Overall, springs are a versatile way to store and release mechanical energy for all kinds of mechanical tasks.

Flywheel Mechanisms

Flywheels are mechanical devices used for storing rotational energy by spinning a mass around an axle. They work by accumulating kinetic energy when torque is applied to accelerate the flywheel. This kinetic energy is then converted back into rotational force which powers the connected mechanism when the flywheel slows down.

Flywheels are useful when an energy source delivers power intermittently while power needs to be constant. For example, a potter’s wheel uses a flywheel to maintain constant rotation for shaping clay. The potter provides torque to the wheel intermittently by kicking a pedal. The flywheel stores this energy and feeds it back steadily to the wheel. Other manual flywheel mechanisms are found in toys like yo-yos, spinning tops and diabolos.

Clockwork Mechanisms

Clockwork mechanisms are devices that use the controlled release of mechanical energy to power functions in a precise and regulated manner. They typically incorporate gears and springs to store potential energy and transmit kinetic energy in a contained system.

The most common example of a clockwork mechanism is the clock. Clocks use gears, springs, and escapements to regulate the release of energy from a wound spring or descending weight to turn hands at a constant speed. This allows clocks to keep accurate time. Other examples of clockwork devices include music boxes, wind-up toys, mechanical watches, and mechanical timers.

In a basic clockwork mechanism, the mainspring or weight stores potential energy. The escapement mechanism controls the release of this energy to turn gears at a constant speed. The gears connect to indicators that move at regulated intervals, like the hands on a clock face. The precise nature of these mechanisms allows them to automate timed functions.

Clockwork represents an early ingenious solution for controlling the release of mechanical energy to produce consistent automated motion. Before electronics, clockwork mechanisms enabled complex machines powered by springs and gears. They are still admired today for their intricate craftsmanship.

Importance of Mechanical Energy

Mechanical energy plays a vital role in many areas of science, technology, and everyday life. Its unique properties have enabled groundbreaking innovations and powered human civilization through the ages.

In physics and engineering, mechanical energy principles govern everything from simple machines like levers and pulleys to complex systems like internal combustion engines, turbines, and rocket engines. Understanding how to harness mechanical energy allows us to convert one form, like fuel or moving water, into useful motion and work.

Throughout history, mechanical energy has been a driving force behind human progress. The transition from animal power to water wheels and windmills enabled industrialization. Steam engines sparked the First Industrial Revolution by powering factories, trains, and ships. Gasoline and diesel engines then propelled vehicles and equipment that transformed transportation, manufacturing, and infrastructure.

Today, mechanical energy continues to be indispensable. Almost all vehicles, heavy machinery, and power generation rely on principles of mechanical energy and conversion between kinetic and potential energy. Appliances, tools, toys, and countless other everyday items also leverage basic mechanical physics to function.

Looking ahead, innovations in mechanical energy storage, such as flywheels and compressed air, may help enable cleaner and more sustainable energy solutions. After centuries at the heart of human technology, mechanical energy remains a versatile and vital asset for addressing our future needs.