Is Wind Power Cheap To Maintain?

Wind power has seen rapid growth in recent years as a renewable energy source. According to RenewableUK, statistics show that introducing 35GW of onshore wind power capacity in the UK could provide benefits such as lower energy bills and reduced carbon emissions. With the continuing expansion of wind farms across the world, questions around the costs of maintaining wind turbines have become increasingly important.

Wind Turbine Maintenance Costs

According to research on wind turbine operational cost, the average operation and maintenance runs an additional $42,000-$48,000 per year per turbine. This includes regular preventative maintenance as well as any unplanned repairs or replacements that may be required. Factors like the turbine model, age, location, and weather conditions can impact the costs. But in general, wind turbines require routine maintenance including inspections, component replacements, and lubrication to keep them running efficiently.

Turbine Lifespan

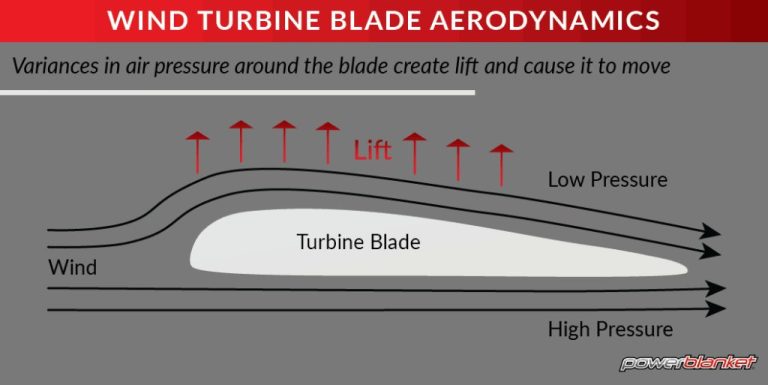

The lifespan of a wind turbine can vary greatly depending on the size, usage, and environmental factors. According to Choose Energy, the average wind turbine lifespan is up to 25 years.1 However, the blades themselves often need replacement sooner than that. This is because the blades experience a lot of wear and tear from the wind. As reported by The Naked Scientists, the turbine blades typically need replacement every 10 to 15 years.2

So while the turbines themselves can operate for 20-25 years, the blades are more likely to need servicing or replacement around the 10-15 year mark. This lifespan can be extended through preventative maintenance and repair as issues arise.

Land Leasing

One of the expenses associated with building and operating a wind farm is leasing the land required for the wind turbines and access roads. According to a 2019 analysis, the cost of leasing land for wind farms in the Middle West is typically lower than leasing land on the east or west coasts. In Iowa, for example, land leases range from $4000 to $6000 per megawatt of capacity. This works out to around $8000-12,000 annually for a 2 megawatt turbine. In contrast, land lease rates on the east coast can be 50-100% higher. The variability in land lease costs across different regions of the U.S. depends on factors like land values, wind resources, permitting processes, and tax incentives.[1]

Transmission Lines

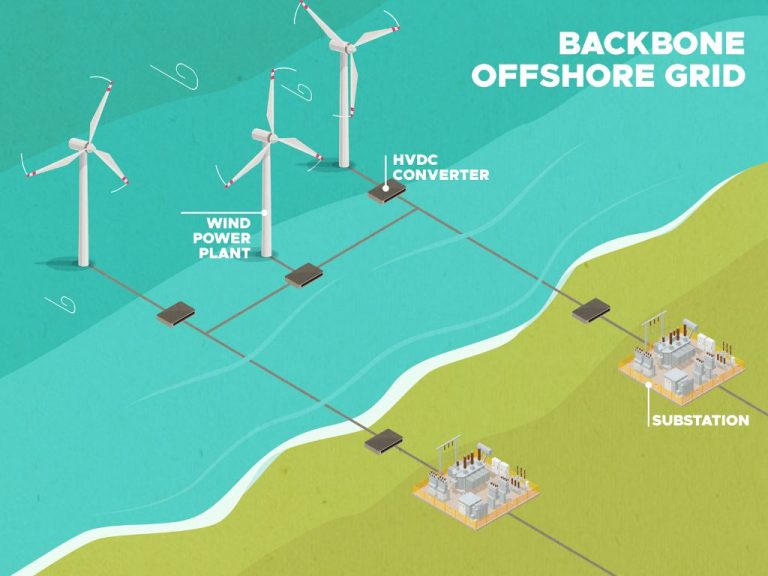

A significant cost of wind power is building transmission lines to connect wind farms to the electric grid. Long distance high voltage lines are often needed, especially for large-scale wind farms built in remote areas with strong wind resources. According to a 2009 study, transmission costs can range from $2 to $12 per MWh for wind power. More recent research from the Lawrence Berkeley National Lab in 2019 estimates average transmission capital costs of $1 to $10 per MWh for renewables.

Transmission line expenses include the costs for poles, cable, right-of-way acquisition, and labor for construction and maintenance. Upgrading the grid and building sufficient transmission capacity for new wind capacity is often cited as a key barrier for scaling up renewable energy.

Repowering Costs

When wind turbines reach the end of their operational lifespan, usually around 20-25 years, wind farm owners face the decision of whether to “repower” the site with newer, more advanced turbine models or decommission the site entirely. Repowering involves replacing old turbines with more efficient, often larger turbines that can generate more electricity from the same site. This repowers the wind farm and extends its productive life.

Repowering comes with considerable capital costs, as new multimegawatt turbines can cost $3-4 million each. However, wind experts estimate repowering can boost a wind farm’s energy output by 10-25% due to technology improvements. Newer turbine designs extract more energy from the same wind resource. Some project owners may also be able to expand the number of turbines onsite. The significant gains in energy production make repowering attractive financially, more than offsetting the upfront capital expenses over the long run.

Ultimately, experts advise wind farm owners to carefully weigh the costs and benefits of repowering against alternatives like decommissioning. With strategic planning and smart site selection, repowering can be a cost-effective way to maintain and even boost wind power returns over decades.

Tax Credits

Government subsidies and incentives play a major role in supporting wind power development. In the United States, the main incentive is the production tax credit (PTC), which provides a tax credit per kilowatt-hour of electricity generated by qualified energy sources like wind power. The PTC has been crucial for the growth of wind power in the US, but it requires periodic renewal from Congress, causing boom-bust cycles in the industry (1).

The PTC makes wind power projects more financially viable by offsetting some of the upfront capital costs. However, opponents argue that the PTC distorts energy markets in favor of wind. There is also debate around whether subsidies should go towards more emerging renewable energy technologies instead of mature sources like wind (2).

Recent legislation like the Inflation Reduction Act extended the PTC for wind projects that begin construction before 2025. This may spur another wave of wind development, especially since project costs have decreased (3). However overall, the uncertain future of wind tax credits makes it difficult for the industry to have stable long-term growth.

Sources:

(1) https://www.bloomberg.com/news/articles/2024-01-23/us-climate-law-to-refuel-onshore-wind-energy-developments

(2) https://energy5.com/the-pros-and-cons-of-wind-energy-tax-credits

Comparisons

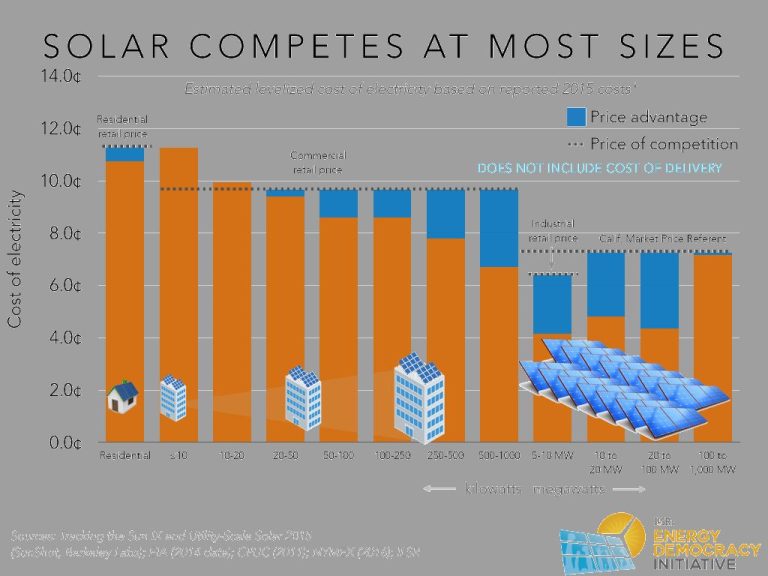

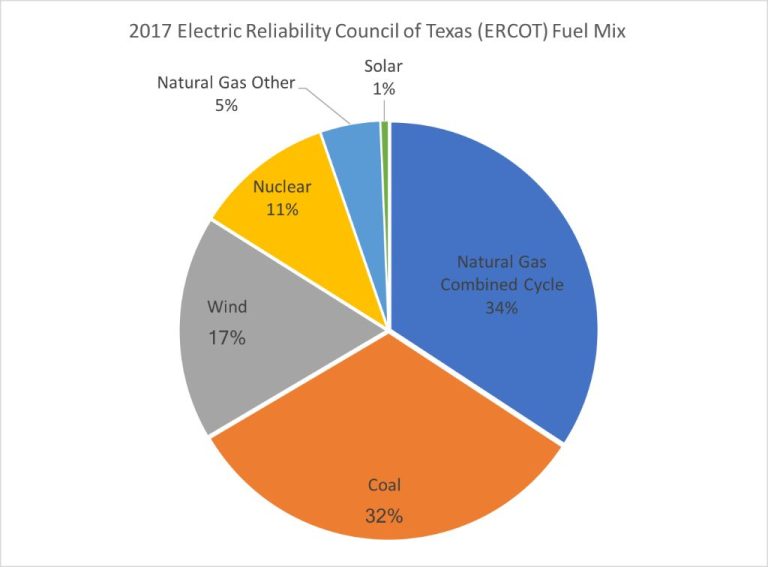

When evaluating cost, it’s important to compare wind power to other energy sources. According to Lazard’s Levelized Cost of Energy Analysis, in 2023 the levelized cost of energy for onshore wind ranges from $26-50 per MWh, compared to $31-44 for utility-scale solar photovoltaics, $37-81 for coal, $41-74 for natural gas combined cycle, and $131-198 for nuclear. This indicates that onshore wind costs are competitive with other conventional energy sources.

Offshore wind costs more ranging from $83-115 per MWh, but prices are rapidly decreasing as the offshore industry matures and becomes more efficient. According to the same Lazard report, offshore wind costs have fallen 67% since 2014. With economies of scale and technology improvements, experts expect offshore wind costs to approach onshore costs in the coming years.

Based on levelized costs, wind power is now one of the most affordable options for new electricity generation capacity when compared to fossil fuels or nuclear power. Continued cost declines for wind bolster the economic argument for utilizing this renewable resource.

Recent Trends

There has been a clear downward trend in wind turbine maintenance costs in recent years. According to the National Renewable Energy Laboratory, wind O&M costs have declined by 7-18% every time the installed capacity doubles (https://www.osti.gov/servlets/purl/1544993). This is largely a result of economies of scale, technology improvements, and increased competition among service providers. In 2019, average O&M costs ranged from $13-$25/MWh, down from over $30/MWh a decade earlier.

One major factor driving down costs is that turbines have become more reliable through better engineering and design. Unplanned maintenance has dropped from an average of 2-3% of operating time in 2005 to less than 1% today (https://www.wind-energy-the-facts.org/operation-and-maintenance-costs-of-wind-generated-power.html). More predictable maintenance allows providers to optimize labor and manage inventories more efficiently.

There is also greater consolidation and professionalization of the wind O&M sector. Larger third-party operators and original equipment manufacturers are investing in data analytics, sophisticated monitoring systems, and preventative tech upgrades. This focus on proactive maintenance versus reactive repairs reduces costs over the long run.

Conclusion

In summary, wind power maintenance costs are relatively low compared to other energy sources. Modern wind turbines have lifespans of 20-25 years and require routine maintenance like lubricating parts and inspecting blades. Land leasing fees are minimal, and connecting to transmission lines accounts for a small portion of operating expenses. Repowering turbines after their lifespan by replacing old equipment with new systems helps reduce maintenance costs. Wind farms enjoy tax credits that keep expenditures low. Overall, wind is one of the most affordable and cost-effective energy sources to maintain over the long run.

Looking ahead, maintenance costs for wind power are likely to go down as technology improves. Larger and more reliable turbines will require less frequent repairs and replacement parts. Remote monitoring and predictive analytics will enable more efficient maintenance scheduling. Improvements in blade coatings, gearbox designs, and other components will extend turbine lifespans. With economies of scale and maturation of the wind industry, operations and maintenance costs as a percentage of total expenses will continue falling. Wind energy is already cheap to maintain compared to fossil fuels, and those competitive advantages will likely grow in the future.