Is Renewable Hydrogen Safe?

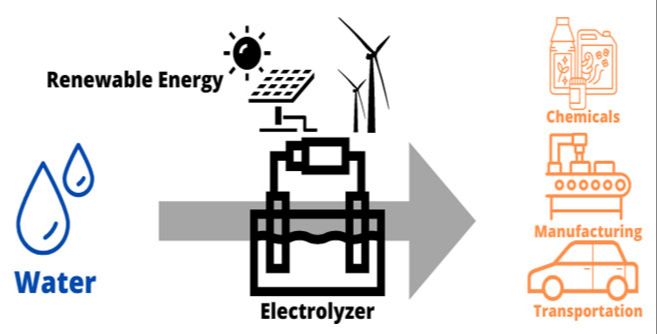

Renewable hydrogen is hydrogen produced through electrolysis powered by renewable electricity such as wind or solar power. Unlike hydrogen produced from fossil fuels, renewable hydrogen emits no greenhouse gases. With growing interest in decarbonization, renewable hydrogen is gaining attention as a clean energy source that can be used for electricity production, heating, transportation fuel, and industrial processes.

As countries aim to transition to net-zero emissions and renewable energy, there is increasing focus on renewable hydrogen as a versatile energy carrier and storage medium. The European Union recently adopted delegated acts to define renewable hydrogen and outline sustainability criteria for its production, with the goal of scaling up renewable hydrogen capacity to 10 million metric tons per year by 2030.1 With major investments and policy support, renewable hydrogen is poised to play a key role in decarbonizing hard-to-abate sectors.

Hydrogen Production Methods

Hydrogen can be produced through various methods, the most common being steam-methane reforming and electrolysis.

Steam-methane reforming is a thermal process that extracts hydrogen from natural gas. This involves reacting natural gas with high-temperature steam in the presence of a catalyst. The process breaks down the methane in natural gas into hydrogen and carbon monoxide. Further reactions can convert the carbon monoxide into carbon dioxide and produce more hydrogen. Steam reforming accounts for nearly all of the hydrogen produced in the United States today. According to the U.S. Energy Information Administration, 95% of the hydrogen produced in the U.S. comes from natural gas via steam-methane reforming. This method is currently the cheapest way to produce large quantities of hydrogen.

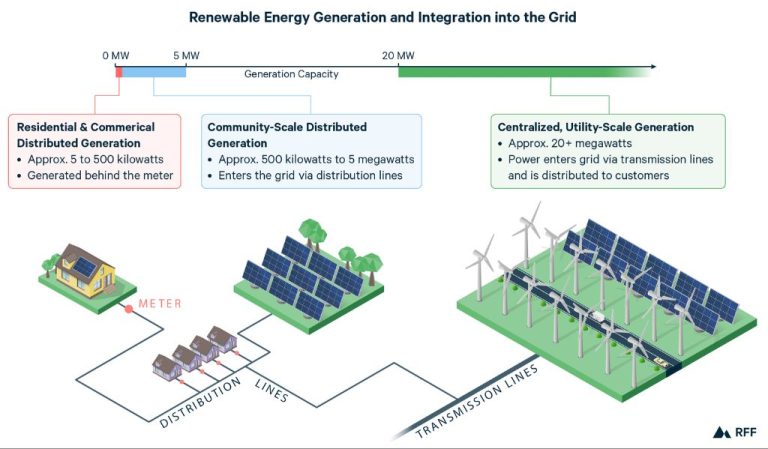

Electrolysis uses electricity to split water into hydrogen and oxygen. This reaction takes place in a unit called an electrolyzer. Electrolyzers can range in size from small, appliance-size equipment to large-scale, central production facilities. There are different kinds of electrolyzers, but all use electric current to separate the bonds between hydrogen and oxygen in water. Electrolysis accounts for a very small portion of current hydrogen production but has the potential to provide clean hydrogen from renewable electricity sources like wind and solar.

Other less common methods of hydrogen production include biomass gasification and partial oxidation of oil and coal. But steam-methane reforming and electrolysis are by far the predominant methods used today.

Safety Concerns

One of the major safety concerns with renewable hydrogen is its flammability. Hydrogen gas is highly flammable when mixed with air at concentrations between 4% and 75% (NRDC, 2021). This wide flammability range means even small leaks of hydrogen could lead to fires or explosions if an ignition source is present. Compared to gasoline, which is only explosive at oxygen concentrations between 1.4% and 7.6%, hydrogen’s flammability range is much wider (NRDC, 2021).

Proper handling, storage, and leak detection are critical to prevent accidental ignition of hydrogen. Materials used to handle hydrogen must be appropriate as well. Hydrogen causes embrittlement in some metals, which can lead to cracks and component failures over time (Energy.gov, n.d.). Proper selection of hydrogen compatible materials is essential.

Lastly, hydrogen is odorless, colorless, and leaks are not visible. Leak detection equipment and procedures are necessary to identify hydrogen leaks before concentrations reach hazardous levels (OSHA, n.d.). With proper safety measures for handling, storage, and leak detection, the risks of hydrogen can be minimized.

Handling and Storage

Hydrogen requires safe handling and storage practices due to its high flammability. According to the Occupational Safety and Health Administration (OSHA), hydrogen storage areas must be permanently placarded with the warning “HYDROGEN – FLAMMABLE GAS – NO SMOKING – NO OPEN FLAMES” (https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.103). Additionally, the U.S. Department of Energy’s (DOE) Hydrogen Safety Best Practices Manual provides guidelines for safe hydrogen storage and handling, including:

- Storing hydrogen outdoors or in well-ventilated environments

- Using proper containment and storage vessels designed for hydrogen use

- Avoiding ignition sources like flames, sparks, or static electricity buildup

- Implementing proper grounding and bonding

- Establishing safe distances from other equipment and operations

- Using gas detectors and ventilation as needed

- Having certified equipment inspected regularly

- Providing training for personnel handling hydrogen

Following best practices, codes, and standards for hydrogen storage and handling is critical to mitigate safety risks like leaks, fires and explosions (https://www.energy.gov/eere/fuelcells/safety-codes-and-standards). With proper precautions, the flammability concerns posed by hydrogen can be effectively managed.

Transportation

Transporting hydrogen presents unique challenges due to its physical properties. According to the NRDC article “Hydrogen Safety: Let’s Clear the Air,” hydrogen is very lightweight and rises quickly, meaning any leaks dissipate rapidly (https://www.nrdc.org/bio/christian-tae/hydrogen-safety-lets-clear-air). However, hydrogen is also highly flammable, so leaks could lead to fires or explosions if an ignition source is present. Proper handling and storage procedures are critical.

The article “Review article Safety of hydrogen storage and transportation” on ScienceDirect discusses regulations around hydrogen transportation. Compressed hydrogen is commonly moved by truck and trailer in high-pressure tubes. Stringent codes govern every aspect, including tank design, maximum pressures, automated sensors, and driver training (https://www.sciencedirect.com/science/article/pii/S2352484722008332). With the right precautions, compressed hydrogen can be safely transported by road, rail, sea or pipeline.

Residential Use

Hydrogen has several potential applications within homes, including cooking, heating, and powering fuel cell vehicles in home garages. Fuel cell vehicles like the Toyota Mirai passenger car can be refueled at home using a hydrogen station. These stations use an electrolyzer to produce renewable hydrogen from water and electricity from rooftop solar panels or the grid (NationalGrid).

For cooking and heating, prototype hydrogen boilers and cooktops have been developed. These use fuel cells to generate heat and electricity from hydrogen, producing only water as a byproduct. Field tests of these appliances in real homes have shown positive results, with users reporting an experience comparable to natural gas appliances in terms of function, heat output, and ease of use (TheEarthAndI).

However, hydrogen does come with safety considerations for residential use. Since hydrogen is flammable and leaks can lead to explosions, rigorous standards must be met for any hydrogen appliances and fueling systems used in homes. Proper ventilation, hydrogen sensors, automated shut-off valves, and impact-resistant materials help mitigate risks (Sciencedirect). With responsible engineering and adherence to building codes, renewable hydrogen can be safely utilized in homes.

Commercial Use

Hydrogen has many industrial and commercial applications. It is used in oil refining to remove impurities from fuels and as a reactant in chemical production of compounds like ammonia. According to the U.S. Energy Information Administration, hydrogen is currently used in various industrial processes, as rocket fuel, and in fuel cells for electricity generation and powering vehicles.

Hydrogen’s potential as an emissions-free fuel source has led to rapid growth in fuel cell applications in recent years. Fuel cells combine hydrogen and oxygen chemically to generate electricity without combustion. This makes them highly efficient and environmentally friendly. Fuel cells are now used to power vehicles, provide backup power, and generate electricity in commercial and industrial facilities, according to the Fuel Cell & Hydrogen Energy Association.

As the demand for clean energy continues to rise globally, hydrogen is poised to play an integral role powering everything from data centers to transportation fleets. With its versatility, hydrogen has the potential to decarbonize a wide range of industries and processes.

Environmental Impact

The environmental impact of hydrogen depends greatly on how it is produced. Currently, most hydrogen is produced from fossil fuels like natural gas, which emits carbon dioxide and contributes to climate change. However, renewable hydrogen from sources like wind and solar has near zero emissions

According to the U.S. Department of Energy, “Hydrogen can be produced from diverse domestic resources with the potential for near-zero greenhouse gas emissions.” (afdc.energy.gov)

Compared to alternatives like gasoline and diesel, hydrogen fuel cells emit only water vapor and warm air, producing no greenhouse gases or air pollutants. Fuel cell vehicles powered by renewable hydrogen could greatly reduce emissions from transportation.

However, hydrogen does have the potential to leak and contribute to climate change. According to the Environmental Defense Fund, “But when emitted into the atmosphere, hydrogen contributes to climate change by increasing the amounts of other greenhouse gases such as methane and tropospheric ozone.” Proper handling, storage, and transportation is key to minimizing leaks.

Overall, renewable hydrogen has the potential to be a sustainable fuel source with minimal environmental impact compared to fossil fuel alternatives, if leaks can be minimized through proper regulations and practices.

Regulations and Codes

There are a number of codes and standards that regulate the safe handling and use of hydrogen. According to the U.S. Department of Energy’s Fuel Cell Technologies Office, the primary model codes for hydrogen are NFPA 2 Hydrogen Technologies Code and the International Fire Code (IFC). The NFPA 2 provides fundamental safeguards for the generation, installation, storage, piping, use, and handling of hydrogen in compressed gas or cryogenic liquid form.

The IFC includes general fire safety requirements for hydrogen facilities. Many jurisdictions have adopted and amended these model codes to regulate hydrogen locally. For example, California adopted NFPA 2 under its state fire code. Some states like Massachusetts also reference NFPA 55 for hydrogen storage. Beyond the model codes, the Department of Energy has also developed a number of recommended practices for hydrogen such as NFPA 2.0.

There are also equipment standards from organizations like CSA, UL, ANSI, and ASME that provide technical requirements for hydrogen system components. Compliance with codes and standards ensures hydrogen systems are designed, installed, and operated safely. As hydrogen usage increases, these codes and standards will continue to evolve.

The Future of Renewable Hydrogen

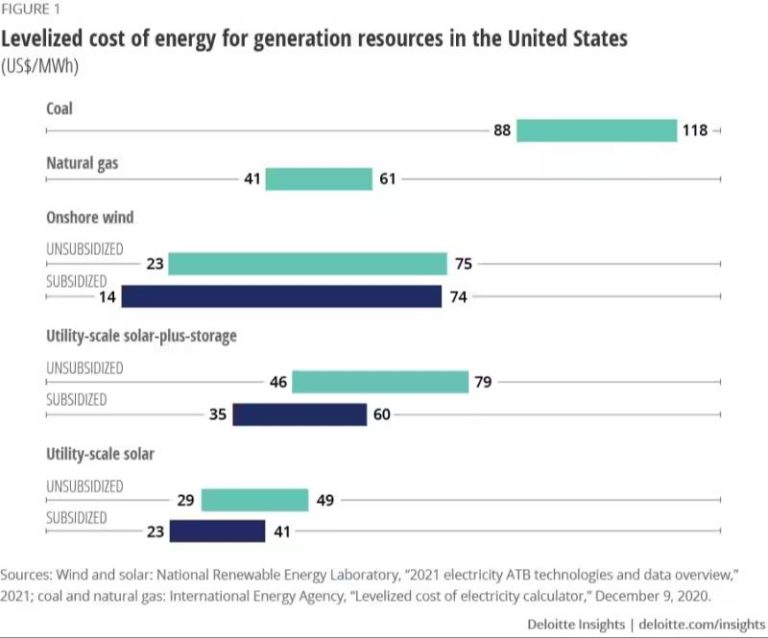

There has been growing interest and investment in renewable hydrogen as a sustainable energy source for the future. According to the International Energy Agency (IEA), hydrogen produced from renewable electricity has the potential to play a major role in the global energy transition towards net zero emissions by 2050 (https://www.iea.org/reports/the-future-of-hydrogen). The IEA analysis finds that the costs of producing renewable hydrogen could fall 30% by 2030 as renewable energy costs decline. They predict renewable hydrogen could account for up to 12% of global energy consumption by 2050.

Hydrogen provides unique benefits as an energy carrier and can enable the decarbonization of traditionally hard-to-abate sectors like heavy industry and long-distance transport. It can also enhance grid flexibility and resilience as more intermittent renewable electricity comes online. The development of a global hydrogen market could also boost economic growth and create new jobs and export opportunities.

However, there are still challenges to scale up renewable hydrogen production and build out supporting infrastructure. Governments need to implement policies and incentives to spur investment and bring down costs. Public acceptance and safety regulations around hydrogen use will also need to be addressed. If these hurdles can be overcome, renewable hydrogen has excellent potential to help enable a zero-emissions future.