How Much Water Is Needed For A Micro Hydro Generator?

What is a Micro Hydro Generator?

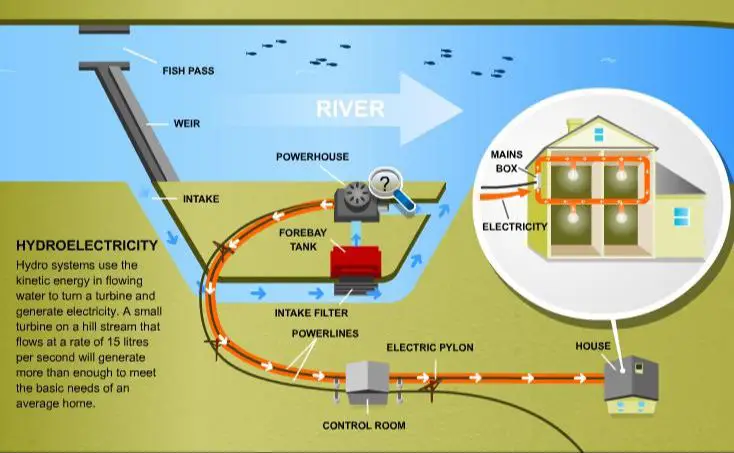

A micro hydro generator is a small-scale hydropower system that converts the energy of flowing water into electricity. According to atlasenergy.com, it typically has a power output of up to 100 kW. The system uses the natural flow of water in streams, canals, or small rivers to spin a turbine connected to an electrical generator (DTL – Micro Hydro Generator).

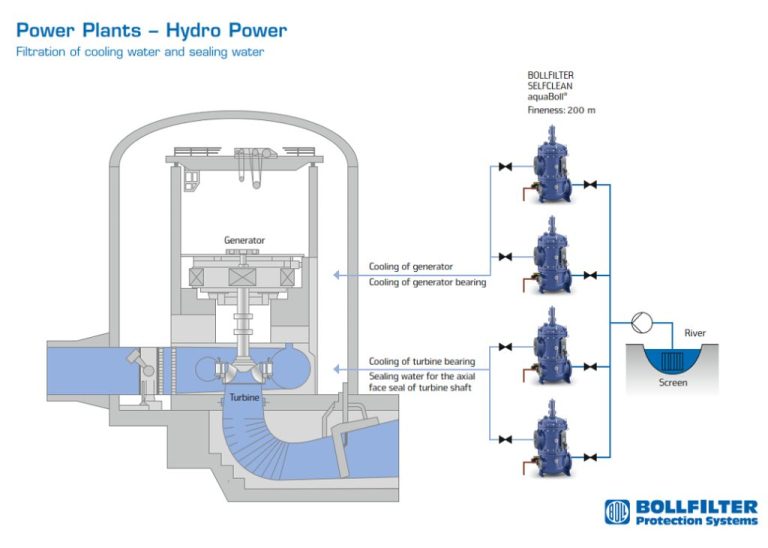

Water flowing through the turbine causes it to rotate, which then turns the rotor in the generator to produce electricity. The components needed for a micro hydro system include a water turbine, generator, controller, and civil works like a weir, pipeline, and powerhouse (Micro hydro systems and Renewable energy). The electricity can be used directly or fed back into the grid.

Micro hydro systems provide clean, renewable power and are often used in rural or remote areas that lack connection to the main electrical grid. They can also provide a backup energy source for homes or businesses.

Key Components

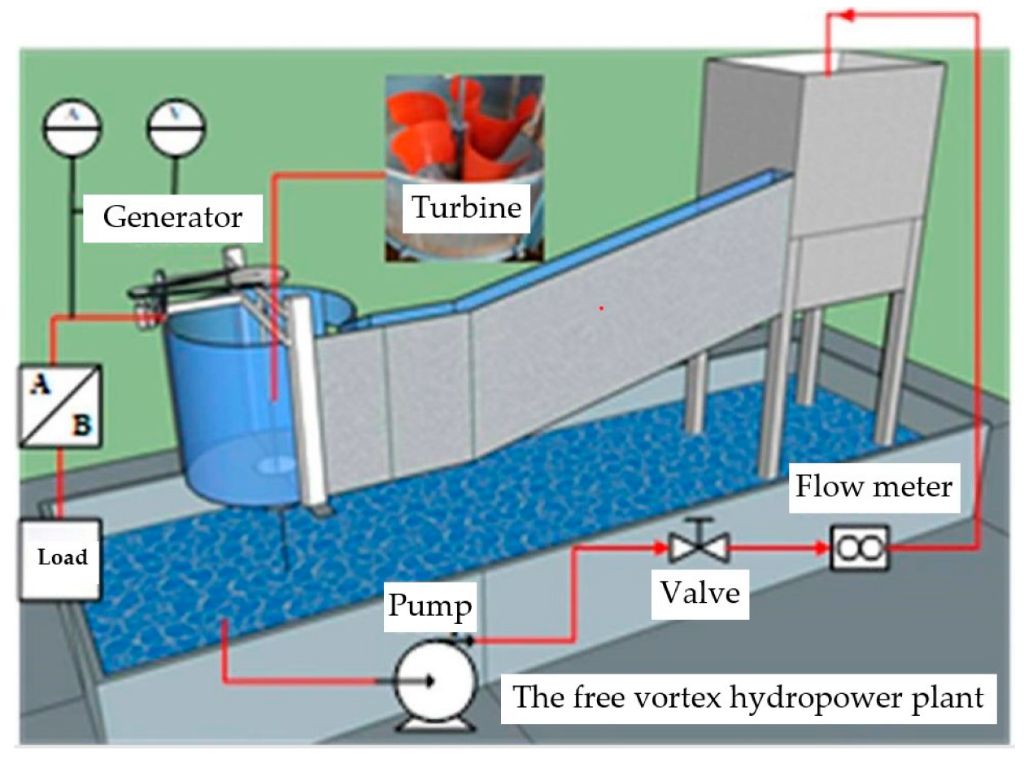

The key components of a micro hydro generator include the turbine, alternator/generator, controls, and pipes/penstock that control the water flow:

The turbine is the component that converts the energy of moving water into rotational mechanical energy. Common turbine types used in micro hydro systems include Pelton wheels and Francis or propeller turbines. The optimal turbine type depends on factors like head height and flow rate. Pelton wheels are often used for high heads while propeller turbines work best for low heads (Energy.gov).

The alternator/generator converts the mechanical rotation energy from the turbine into electrical energy. It is coupled to the turbine’s rotating shaft. Alternators designed for variable speed operation are often used in micro hydro systems (Micro-hydro-power.com).

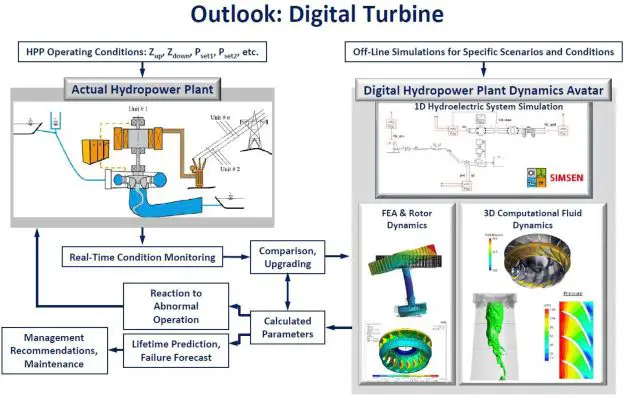

The control system monitors and regulates the generator, turbine, and water flow to ensure smooth and efficient operation.

Finally, pipes and penstock carry water from the intake to the turbine. The penstock pipe directs water downhill at an incline optimized for the system’s head height.

Factors That Determine Water Needs

There are three main factors that determine the water needs for a micro hydro generator:

Head (Vertical Drop)

The head refers to the vertical distance the water falls from the intake to the turbine. More head means more gravitational potential energy that can be converted into electricity by the turbine. Typical head heights for micro hydro systems range from 2 to 200 meters (https://www.energy.gov/energysaver/planning-microhydropower-system). More head allows for greater power output.

Flow Rate

The flow rate is the volume of water that runs through the system over time. More water flow means more kinetic energy that can turn the turbine. Required flow rates depend on factors like the head height and power output goals, but a rough estimate is 9-90 liters per second for micro hydro systems (https://attra.ncat.org/publication/micro-hydro-power-a-beginners-guide-to-design-and-installation/). Higher flow rates allow for more power.

Power Output Goals

The desired power output capacity will influence water needs. More power requires greater head heights and flow rates. Micro hydro systems generally produce up to 100 kW, but 5-20 kW is more common for residential use (https://ressupply.com/micro-hydro-power-basics). The water resource must support the head and flow rate needed for the power goals.

Typical Head Heights

Micro hydro systems are broadly classified as either low head or high head based on the vertical fall of water. “Head” refers to the height between the water intake and where it is discharged back into the stream. As explained by Energy.gov, low head refers to a change in elevation of less than 20 meters (66 feet). Ultralow head refers to a change of less than 3 meters (10 feet). High head sites have a vertical drop greater than 30 meters (100 feet).

While micro hydro systems can work with heads as low as 1 meter, typical head heights often fall within these ranges:

- Low head – 2 to 20 meters

- Medium head – 20 to 100 meters

- High head – 100 to 300 meters

The optimal head height depends on factors like the site terrain, available flow rate, and desired power output. Lower heads of 5-20 meters are common for many residential and small commercial micro hydro projects. Sites with heads above 50 meters may be better suited for more powerful turbine systems.

Required Flow Rates

The flow rate, measured in gallons per minute (GPM), is a critical factor in determining the viability of a micro hydro system. Generally, a minimum flow of 200 GPM is needed for a small residential system, while 500-1000 GPM is optimal for producing enough electricity to power a home or small business.

According to Estimating WaterHead and WaterFlow, a flow rate of around 4 cubic meters per second (4 m3/s), equivalent to 1059 GPM, is reasonably good for a micro-hydro system. The higher the flow rate, the more electricity that can be generated.

However, there is no single ideal flow rate. The optimal flow depends on the head height available, the size of the turbine, and the power output needed. With a high head and an efficient turbine, a lower flow rate in the 300-500 GPM range may suffice. But for maximum power generation, most experts recommend having at least 1000 GPM of flow if possible.

Power Output Capabilities

Micro hydro systems are capable of generating anywhere from a few hundred watts to 100 kilowatts of electricity. The maximum power output of a micro hydro system depends on several key factors:

The amount of hydraulic head, which refers to the vertical distance the water falls. More head means more power potential.1

The flow rate of the water source. Higher flow rates allow more water volume to pass through the turbines.2

The efficiency of the turbine and generator equipment. More efficient components will convert a greater percentage of the available power into electricity.

For a typical micro hydro system with a moderate head height and flow rate, power outputs usually range from 1 to 100 kilowatts. With optimal conditions, outputs of 100 kilowatts or more are possible. Generally, micro hydro systems are designed based on the specific head and flow parameters of a site.

Calculating Water Needs

The amount of water needed for a micro hydro system depends on the head height and flow rate. The head is the vertical distance the water falls. The flow rate is the volume of water that moves past a point over time. These two factors help determine the power output potential.

The basic formula for calculating power is:

Power (in watts) = Head (in meters) x Flow Rate (in liters/second) x Gravitational Constant (9.81)

For example, if the head height is 5 meters and the flow rate is 15 liters/second:

Power = 5 x 15 x 9.81 = 735.75 watts

So with a 5 meter head and 15 liter/second flow, the micro hydro system could potentially generate around 736 watts of power. The higher the head and greater the flow, the more potential power can be produced.

Typical micro hydro systems operate with heads from 2 to 200 meters and flow rates from 0.2 to 15 liters/second. Larger heads and flows at the higher end of those ranges allow micro hydro systems to produce up to 100 kilowatts of power (REF: https://www.energy.gov/energysaver/planning-microhydropower-system).

When sizing and planning a micro hydro system, it’s important to calculate the specific head and flow rate available at the site. These measurements along with the power output goal will determine how much water is needed to generate the desired amount of electricity.

Real-World Examples

There are a number of real-world case studies that provide examples of actual micro hydro installations, their head heights, flow rates, and power produced:

A case study by Penn State University found a 5kW micro-hydro turbine in India with a head height of 49 feet and flow rate of 5-6 cubic feet per second. It provided enough electricity for 35 families.

According to a paper by Swati Sachan, a 50 kW micro-hydro project in Uttarakhand, India had a design head of 200 meters and flow rate of 0.3 cubic meters per second. This system powers a rural industrial estate.

The YouTube channel Off Grid with Doug and Stacy installed a small micro-hydro system on their property with a head height of 18 feet and flow rate of 20 gallons per minute. It produces 300-500 watts of power.

These real-world examples demonstrate how micro-hydro systems can be customized for different head heights, flow rates, and power needs. The key factors are measuring the available head and flow at a site to determine the potential power output.

Considerations for Implementation

There are several key factors to consider when implementing a micro hydro generator:

Assessing Site Suitability

The most critical aspect is assessing if your site has the necessary flowing water resources to power a micro hydro system. According to the Department of Energy, your property needs a flowing stream or creek with a sufficient vertical drop and flow rate (https://www.energy.gov/energysaver/planning-microhydropower-system). The vertical drop, known as head height, and the flow rate will determine the potential power output.

Environmental Impacts

It’s important to evaluate any environmental impacts of diverting water flow and building infrastructure. Consult local regulations and ensure proper fish passages are maintained. Proper site selection and system design can minimize ecosystem disruption (https://attra.ncat.org/publication/micro-hydro-power-a-beginners-guide-to-design-and-installation/).

Costs/Incentives

While micro hydro can provide cost savings over time, the upfront system costs can be prohibitive for some. Grants, tax credits, and other incentives may help offset the installation expenses. Maintenance costs should also be accounted for.

Conclusions

The optimal amount of water needed for a micro hydro generator depends on several key factors, including the head height, flow rate, power output, and efficiency of the turbine. While the calculations may seem complex, it is important to properly estimate water resources and generator requirements to ensure a successful project.

Accurately measuring the head height and available flow at your site provides the baseline for selecting appropriate generator components and calculating power production capabilities. Remember that flow rates tend to fluctuate seasonally, so examine historical patterns when estimating average flow.

The power output calculations help determine the feasibility of the project and size the various components like turbines, generators, and penstocks. Striving for maximum efficiency is ideal to optimize energy production from the available water source. Overestimating resources can lead to system underperformance, while underestimating can mean missed potential.

With careful planning using the calculations and variables outlined here, a properly designed micro hydro system can provide clean, renewable electricity for decades to come. Paying close attention to the details will lead to long-term energy independence and sustainability.