How Much Plastic Is In Solar Panels?

Solar panels have become increasingly popular in recent years as an environmentally-friendly way to generate electricity from sunlight. The photovoltaic cells in solar panels convert sunlight directly into electricity without producing any greenhouse gas emissions or other pollutants during operation. As more homes and businesses install solar panels, the environmental benefits continue to grow.

However, some concerns have been raised over the materials used to make solar panels. Although solar energy is renewable and clean, the panels themselves contain plastic components that have lifespans of 25-30 years. With solar expanding rapidly around the world, understanding the plastic content in solar panels and developing effective recycling methods will be important for continuing the environmental advantages of solar power.

Types of Solar Panels

There are several types of solar panels used for residential, commercial, and utility-scale solar systems. The most commonly used types include:

Crystalline Silicon Panels: The majority of solar panels are made from crystalline silicon (c-Si) cells, which are cut from silicon ingots. These panels include either monocrystalline or polycrystalline silicon cells. Monocrystalline solar cells have higher efficiency but can be costly to produce. polycrystalline solar panels have slightly lower efficiency, but are cheaper. (Sources: https://a1asolar.com/types-of-solar-energy/ )

Thin-Film Panels: In thin-film solar panels, the photovoltaic material is deposited in a thin-layer onto substrates like glass, steel or plastic instead of silicon wafers. They tend to have lower efficiencies but can be cheaper and flexible. Types of thin-film solar include cadmium telluride (CdTe), copper indium gallium selenide (CIGS), amorphous silicon (a-Si), and gallium arsenide (GaAs). (Sources: https://www.quora.com/What-types-of-things-can-solar-panels-power)

Emerging Types: Some emerging solar cell technologies that are still in R&D or early commercialization include perovskite solar cells, organic photovoltaics (OPV), quantum dot solar cells, and concentrator photovoltaics (CPV). These aim to improve efficiency, flexibility or lower costs further.

Plastic Components

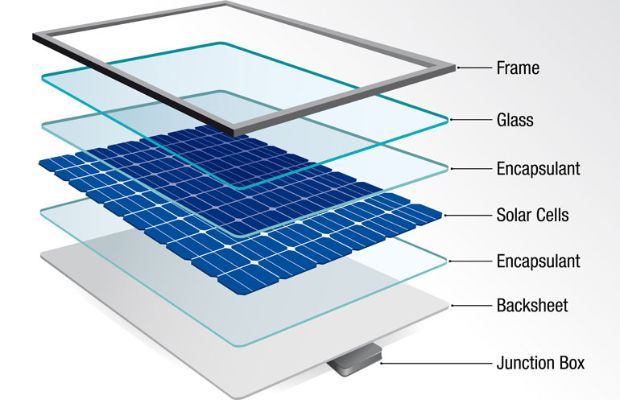

Solar panels are comprised of various plastic components that serve important functions. The main plastic components are:

Encapsulant Layer

The encapsulant layer in solar panels is a thin film of plastic that protects the solar cells from environmental damage. It is typically made of ethylene-vinyl acetate (EVA) or polyvinyl butyral (PVB). The encapsulant wraps around the solar cells and bonds the different layers of the panel together.

Backsheet

The backsheet is a protective plastic sheet on the rear of the solar panel. It insulates the panel and prevents moisture ingress. Backsheets are commonly made of polyvinyl fluoride (PVF) or polyethylene terephthalate (PET) plastics.

Frame

The frame around the perimeter of the solar panel provides structural stability. Aluminum is commonly used, but some frames utilize plastics like polycarbonate. The frames protect the edges of the panel and allow for secure mounting.

Encapsulant Layer

The encapsulant layer is a key component in solar panels. Its main purpose is to protect and cushion the solar cells, preventing moisture and environmental factors from damaging the cells over decades of exposure.

The encapsulant is commonly made from ethylene-vinyl acetate (EVA) or silicone. EVA is a soft, flexible plastic that cushions the cells well, while being transparent enough for sunlight to pass through. Silicone is more expensive but offers superior heat resistance.

The encapsulant accounts for around 8-12% of a solar panel’s total weight. It forms a critical protective barrier around the fragile silicon cells, enabling solar panels to withstand weathering effects over their 20-30 year lifespan.

Backsheet

The backsheet is a protective layer on the rear of the solar panel that shields the solar cells and other internal components from the environment. It is typically comprised of plastic polymers like polyvinyl fluoride (PVF) or polyethylene terephthalate (PET). The backsheet accounts for around 6-8% of the total weight of a solar panel.

The backsheet plays a critical role in protecting the panel from moisture, humidity, and UV radiation which could otherwise penetrate inside and degrade the performance of the solar cells over time. It ensures the internal components have a long service lifetime. The plastic polymers used for solar panel backsheets are designed to be durable and weather-resistant.

According to research, the backsheet can contribute 6-7% of the total panel weight while the frame contributes another 2%. Therefore, plastics may account for nearly 10% of a solar panel’s overall weight when factoring the protective backsheet.

Frame

The frame holds and seals the solar panels together. It is usually made of aluminum due to its durability and weather resistance properties, but some manufacturers use heavy-duty plastics like polycarbonate as an alternative frame material.

According to AluminumSolarFrame.com, aluminum is well known as the standard solar panel frame material. Plastics may account for a small percentage of the overall frame weight on some panel models.

The frame itself is a relatively small component and contributes little to the total plastic percentage. The main purpose it serves is structural integrity rather than plastic composition.

Total Plastic Percentage

By weight, the typical crystalline silicon solar panel is made of about 10% plastic polymer, while the frame and junction box contain additional plastic materials.1 Thin-film solar panels have a greater percentage of plastic, around 20-40% depending on the exact materials used.

For crystalline silicon panels, the 10% plastic polymer refers to the encapsulant layer that protects the silicon cells and the backsheet that forms the rear panel surface. The frame and junction box also contain substantial amounts of plastic.

Thin-film solar panels use amorphous silicon or cadmium telluride instead of silicon wafers. The semiconductor layer is deposited on a flexible plastic substrate, so these panels have a much greater overall plastic content in the 20-40% range.2 However, thin-film panels are becoming less common compared to crystalline silicon.

Lifespan Considerations

Solar panels typically last 25-30 years before their performance noticeably degrades (1). However, the plastic components in solar panels are susceptible to UV damage and weathering effects over time. The encapsulant layer, made of EVA plastic, can yellow and become brittle. The plastic backsheet provides protection but also degrades, developing cracks and reducing strength. Even the aluminum frame experiences corrosion (2). While solar panels are built to withstand outdoor exposure, the plastic materials gradually break down in the elements.

Regular maintenance and cleaning can maximize the lifespan of solar panels. But after 25+ years, the plastic components will likely need replacing, or the panels may need to be recycled. With good care, solar panels can operate for 30+ years, but their plastics will slowly degrade from sun and weather.

(1) https://www.forbes.com/home-improvement/solar/how-long-do-solar-panels-last/

(2) https://www.thisoldhouse.com/solar-alternative-energy/reviews/how-long-do-solar-panels-last

Recycling Challenges

Recycling the plastic components of solar panels presents difficulties. The encapsulant layer that seals and protects solar cells is made of ethylene-vinyl acetate, a composite plastic that is not widely recycled (EPA). The backsheet, which protects the rear of the panel, contains multiple layered plastics like polyvinyl fluoride and polyethylene terephthalate, which are also challenging to separate and process (Greentech Renewables).

New recycling technologies are emerging to handle solar panel plastics more effectively. Startups like Recycle PV in France use low temperatures to separate encapsulant layers from silicon cells for reuse. The project PV CYCLE in Europe coordinates collection and recycling, working with specialized plastic recycling partners (YaleEnvironment360). Such initiatives demonstrate progress in enabling solar panels to be sustainably recycled instead of going to landfills when decommissioned.

Conclusion

Though solar panels are an important technology in transitioning to renewable energy and mitigating further climate change, their manufacturing requires significant use of plastic components like ethylene vinyl acetate encapsulants, polymer backsheets, and frames. Estimates show modern solar panels contain around 6-8% plastic by weight, though new solar panel technologies are working to reduce plastic content where possible. As solar capacity is rapidly scaled up globally to meet clean energy goals, the solar industry must prioritize panel designs that minimize raw material usage, enable recycling processes, and avoid creating a new plastic waste stream at end-of-life. With proper stewardship, solar power can play a key role in building a circular economy and sustainable future.