How Much Does A Unit Of Wind Power Cost?

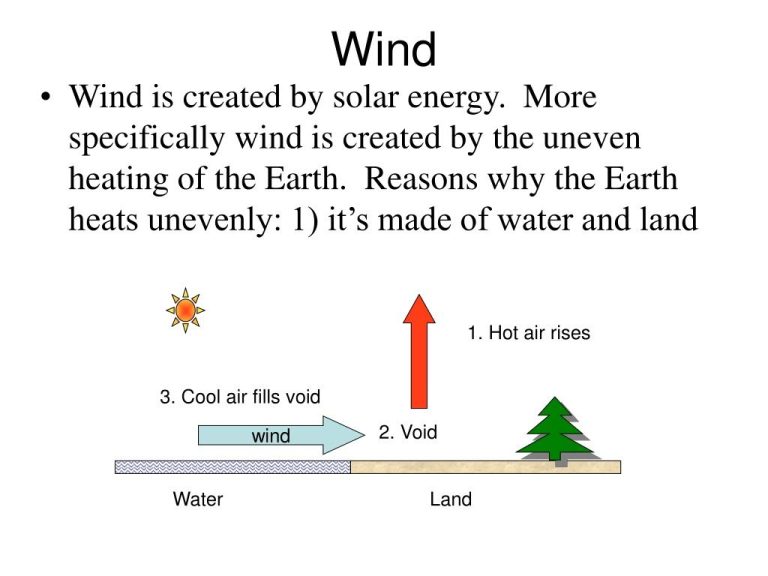

Wind power refers to the energy generated by harnessing the wind through wind turbines and generators. It is a clean, renewable, and cost-effective means of generating electricity. However, the true cost of wind power can vary greatly depending on a variety of factors. In this article, we will provide an overview of the major costs associated with wind power, including upfront costs like turbines and towers, ongoing costs like operations and maintenance, capacity factors based on wind availability, location logistics and infrastructure, available incentives and subsidies, and economies of scale. We will also discuss recent cost trends and provide comparisons to help evaluate the total cost of wind power.

Upfront Costs

The upfront costs of a wind turbine can be substantial. These costs include:

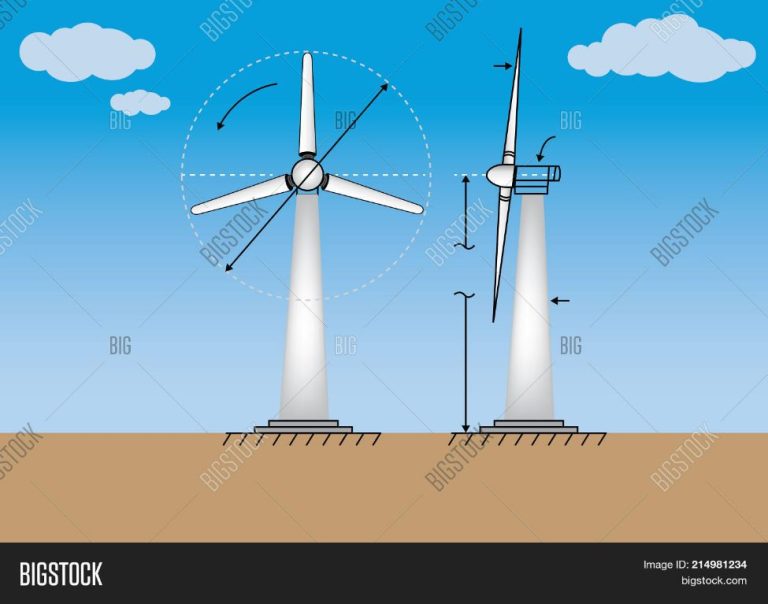

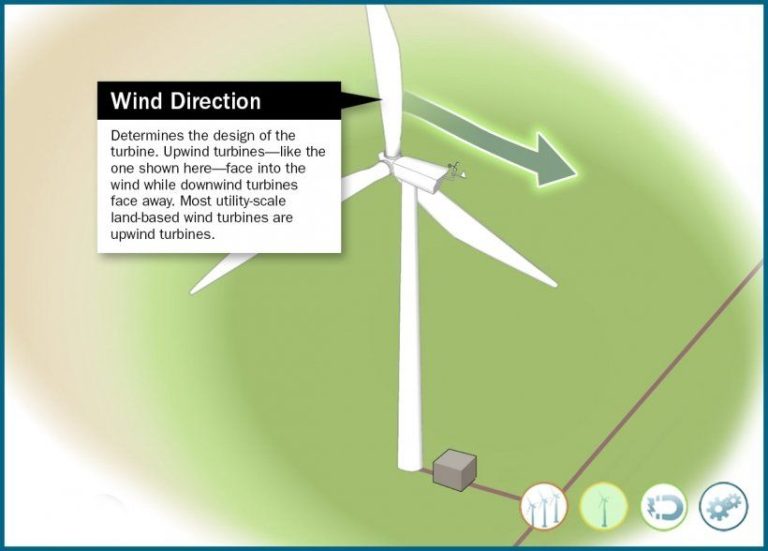

- Turbine components like the tower, rotor blades, nacelle, and other hardware (https://windexchange.energy.gov/economics)

- Transportation of the turbine components to the site

- Civil works like access roads, turbine foundations, underground cabling, and substations

- Electrical equipment like transformers, switches, monitoring equipment, and connections to the grid

- Construction and installation costs including cranes, crews, and project management

- Land acquisition or leasing costs

- Permitting and pre-construction studies

The turbine itself can cost around $1-2 million for a 2-3 MW turbine. But total installed costs for a utility-scale wind project are typically $1,500-$2,500 per kW of capacity (https://homeguide.com/costs/wind-turbine-cost). So a 100 MW wind farm may have over $150 million in upfront capital costs before generation even begins.

Ongoing Costs

The ongoing costs of operating and maintaining a wind turbine can add up significantly over the turbine’s lifetime. According to this report from Lawrence Berkeley National Laboratory, typical ongoing costs include:

- Regular maintenance and repairs – To keep turbines running efficiently, components like blades, gearboxes, generators, etc. require regular servicing, lubrication, and inspections. Maintenance costs are estimated at $20-30 per kilowatt per year.

- Insurance – Turbine owners must carry insurance policies covering damage, liability risks, etc. Premiums may cost around $10-15/kW/year.

- Land leases – For wind farms located on leased land, ongoing land lease payments must be made to property owners. These average $3-5/kW/year.

- Management fees – Wind project operators will incur annual management/administration fees. These typically run about $10/kW/year.

According to Today’s Homeowner, when you add up these ongoing costs over the typical 25-year turbine lifetime, they can total 60-80% of the initial turbine construction and installation costs. So ongoing costs are a major factor to consider when evaluating wind power project economics.

Capacity Factor

The capacity factor of a wind turbine measures how much electricity it actually generates compared to its maximum potential output. According to the Center for Sustainable Systems, the average capacity factor for land-based wind turbines in the U.S. is around 35%. This means that over the course of a year, a wind turbine will produce about 35% of the energy it could potentially generate if it operated at full capacity 100% of the time.

The capacity factor is important for estimating the overall costs per unit of electricity from wind power. Wind turbines with a lower capacity factor will produce less total annual energy, resulting in a higher levelized cost per kWh generated. Their capacity factors are constrained by the intermittent nature of wind and periods of low wind speeds. On the other hand, turbines placed in particularly windy locations can achieve capacity factors over 60%, producing more electricity and lowering the cost per kWh. Advanced turbine designs are also helping increase capacity factors through larger rotors and hub heights.

When estimating the overall costs of wind power for a potential project, the expected capacity factor based on the site’s wind resource is a key variable. A higher capacity factor directly translates into greater annual energy production from the turbines, spreading out their fixed construction and maintenance costs over more kWh generated.

Location

The geographic location and average wind speeds have a significant impact on the costs and productivity of a wind turbine project. Areas with consistently higher wind speeds allow turbines to generate more power, which improves capacity factors and returns on investment. According to the U.S. Department of Energy, the capacity factor for wind projects built in 2021 averaged 42% nationwide, but ranged from 25% to 62% depending on location 1. Higher wind speeds also reduce the number of turbines needed to generate a given amount of power, lowering overall costs.

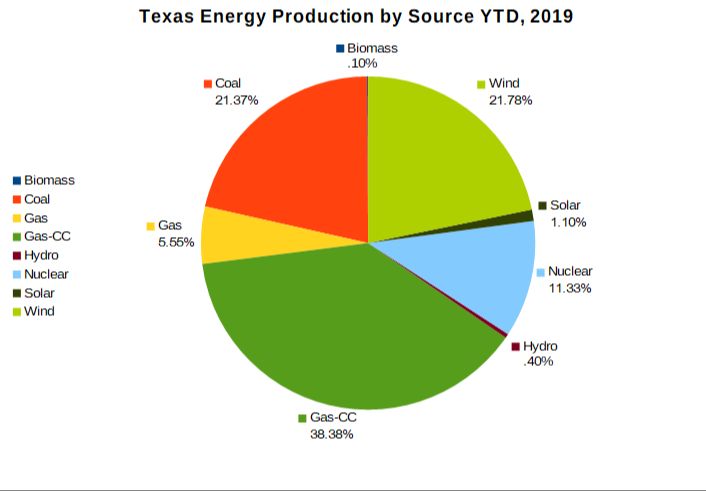

In general, wind turbine projects located in the middle of the country, from North Dakota down to Texas, have the highest wind speeds and capacity factors. Other high potential regions include coastal areas and ridgelines. Project costs are usually lowest in the windiest locations that require the fewest turbines. Turbines in lower wind speed areas may have capacity factors under 30% and cost over twice as much per unit of energy produced 2. Careful siting is crucial to maximize productivity and return on investment.

Government Incentives

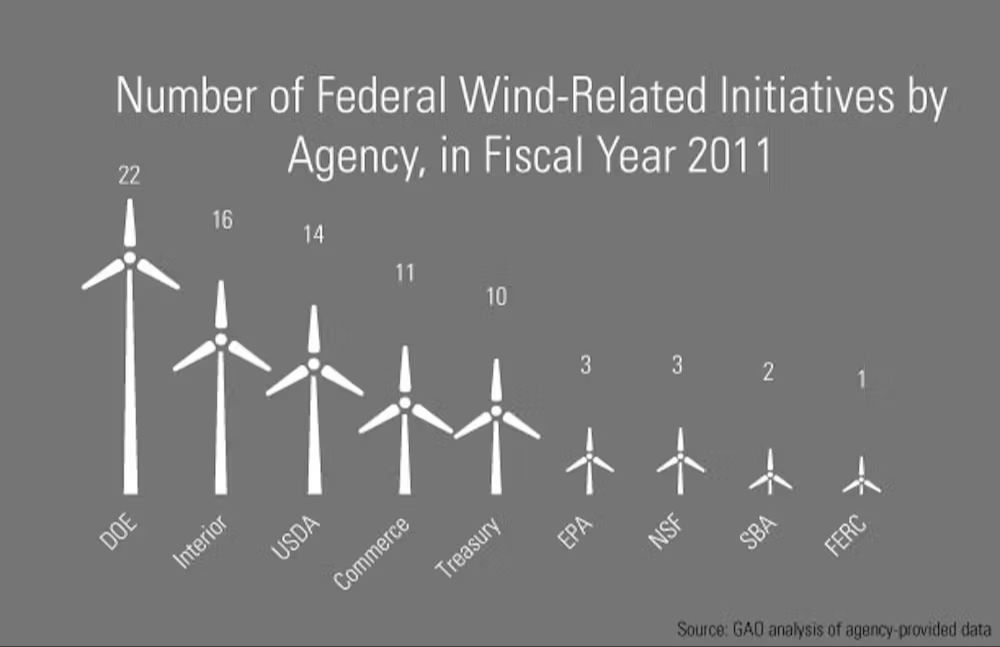

The cost of producing wind power can be significantly impacted by government incentives and policies. At the federal level in the United States, there are two main incentives that lower the cost of wind power projects (1):

- Production Tax Credit (PTC) – Provides a per-kilowatt-hour tax credit for electricity generated by qualified energy resources including wind power. This lowers the cost of producing wind power.

- Investment Tax Credit (ITC) – Provides a percentage-based tax credit applied to capital investments in renewable energy projects, which can directly reduce project costs.

The duration and level of these tax credits has fluctuated over the years, but when available they can reduce the levelized cost of wind energy by 20% or more (2). Many state governments also offer additional incentives, such as renewable portfolio standards, grant programs, rebates, and sales tax exemptions for wind projects and related equipment (3). Local policies like property tax abatements and production incentives can also impact costs.

(2) https://windexchange.energy.gov/projects/incentives

(3) https://www.energy.gov/eere/wind/other-wind-energy-funding-opportunities

Economies of Scale

As wind farms and turbines get larger, the cost per unit of energy produced decreases. This concept is known as “economies of scale”. There are several reasons that larger wind installations have lower costs:

Construction costs like roads, electrical equipment and foundations can be spread across more turbines. For example, a 100 turbine wind farm doesn’t need 100 times more roads than a 10 turbine wind farm. There are efficiencies gained with scale.

Operation and maintenance costs are lower since technicians don’t need to travel as far between turbines for routine maintenance and repairs. Larger wind farms can have dedicated on-site staff rather thancontracting out labor.

The cost of financing is lower for larger projects that can get better debt terms from banks. The ability to negotiate lower prices from suppliers is also greater with larger purchases of turbines and components.

Studies have shown that the cost per megawatt-hour for a 50 megawatt wind farm can be 25% lower than a 5 megawatt installation (The Power of Economies of Scale: A Wind Industry Case Study). Turbines themselves have also increased in size and scale over the years, with modern turbines over 100 times more powerful than early models.

Comparisons

When comparing the cost of wind power to other energy sources like fossil fuels and solar, wind is becoming increasingly competitive. According to the MIT Climate and Sustainability Consortium, the lifetime cost of wind and solar power is now cheaper than fossil fuels. This is because the fuel itself (wind and sun) is free, while fossil fuels require continuous expenditures on coal, oil, or gas.

In particular, the cost of onshore wind power ranges from $32 to $62 per megawatt-hour, significantly less than the estimated cost of coal at $65 to $150 per megawatt-hour. Offshore wind remains more expensive than onshore, but costs are falling rapidly. According to the International Renewable Energy Agency, between 2010 and 2022, the global weighted average cost of electricity from new onshore wind power fell by 15% while solar photovoltaics fell by 85%.

Compared to solar, wind energy can provide lower cost renewable electricity depending on the location and capacity factor. Solar PV ranges from $36 to $44 per megawatt-hour, comparable to onshore wind. However, wind power can generate electricity at night whereas solar cannot. With government incentives and continued innovation, wind and solar together provide a compelling alternative to fossil fuel energy.

Recent Trends

The costs of wind power have declined significantly in recent years. According to the U.S. Department of Energy’s Land-Based Wind Market Report: 2022 Edition, the average installed cost of wind projects in 2021 was $1,500/kW, down from around $1,770/kW for projects installed in 2014 and 2015. Wind turbine prices averaged $800–$950 per kW in 2021, compared to $1,510/kW for projects installed in 2009.

Power purchase agreement prices for wind have also trended downward. The Lawrence Berkeley National Lab’s 2021 Wind Technologies Market Report found PPA prices ranging from below $20/MWh to above $40/MWh depending on the region, down from a range of $20-$70/MWh in 2009. This decline in PPA pricing reflects the falling generation costs of wind power.

The overall trend shows wind power getting significantly cheaper over the last decade. Continued technological advances and economies of scale should drive costs even lower in the coming years.

Conclusion

Looking at the costs of wind power, it is clear cost per unit varies significantly based on factors like location, size of project, and access to incentives. However, recent trends show costs declining due to improved technology and economies of scale. The average cost per unit of onshore wind energy in the U.S. in 2021 ranged from $30-$60 per MWh.

To summarize, key factors driving wind energy costs include: upfront costs like turbines and transmission, ongoing maintenance and operations costs, capacity factor based on wind resources, location, available government incentives, and economies of scale for larger projects. While costs are coming down, wind remains more expensive per unit than conventional sources like coal and natural gas in most cases. However, with continuing technological improvements and scaling, wind is becoming increasingly cost-competitive.