How Is Biomass Converted To Bioenergy?

Biomass refers to organic materials that comes from plants and animals. It includes agricultural crops and waste, wood products, aquatic plants, animal waste, municipal waste, and other waste streams. Bioenergy refers to renewable energy produced from biomass feedstocks. Common examples of bioenergy include biofuels like ethanol and biodiesel, biogas, and solid biomass that can be burned directly for heat and electricity generation.

The conversion of biomass to bioenergy offers many benefits, such as reducing dependence on fossil fuels, mitigating greenhouse gas emissions, and making use of waste materials. There are two main pathways for converting biomass into bioenergy: thermochemical conversion and biochemical conversion. The most common thermochemical methods are combustion, gasification, and pyrolysis. The most common biochemical method is anaerobic digestion.

Sources of Biomass

Biomass refers to organic materials from plants and animals that can be used as an energy source. The main sources of biomass include:

-

Plant materials – This includes trees, grasses, crops, algae and other plants. Fast growing trees like poplar and willow are commonly used. Crop residues like corn stalks and sugarcane waste are also important sources.

-

Agricultural waste – Leftover materials from farming operations like husks, stems, pruning and food waste can provide biomass. Common examples are peanut shells, rice husks, coconut husks, and waste from livestock operations.

-

Forest residue – This refers to the unused materials left over from logging and forest thinning like tree tops, branches and bark. These residues can be sustainably collected without impacting the forest.

-

Animal waste – Manure from cows, pigs, chickens and other livestock is high in organic matter. It can be used directly or converted to biogas which is a form of bioenergy.

These renewable organic sources provide a versatile feedstock for generating energy and power.

Benefits of Biomass Energy

Biomass energy offers many benefits that make it an attractive renewable energy source. Firstly, biomass is renewable as it comes from plants and organic waste materials. As long as crops, trees, and organic waste are replenished, a constant supply of biomass is available. This makes biomass an alternative to finite fossil fuels.

Secondly, biomass energy converts waste materials into useful energy. Agricultural residues, municipal solid wastes, industrial wastes, and even sewage sludge can be sources of biomass. Using these waste materials as an energy source reduces waste volumes.

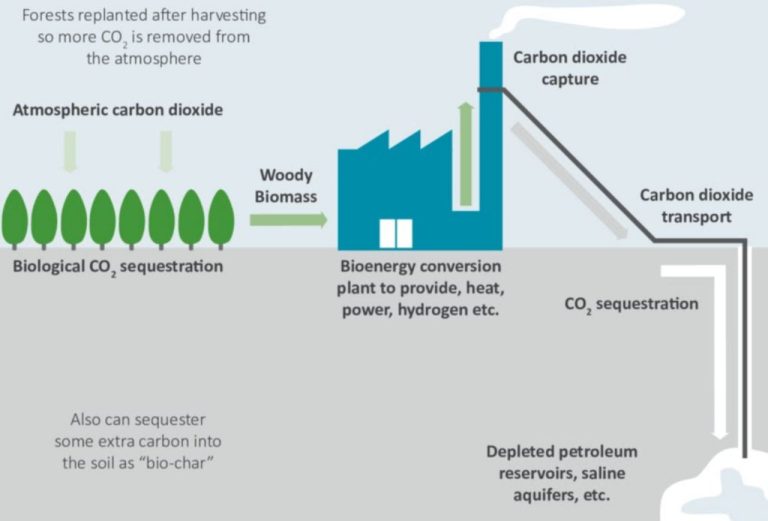

Finally, biomass energy has lower emissions compared to fossil fuels. Since biomass absorbs carbon dioxide while growing, combustion releases less net carbon dioxide than fossil fuels. Biomass emits about the same amount of carbon during generation as is absorbed during plant growth. This gives biomass a neutral carbon footprint.

Thermochemical Conversion

Thermochemical conversion uses heat and chemical reactions to convert biomass into forms of energy. The three main thermochemical processes are combustion, gasification and pyrolysis.

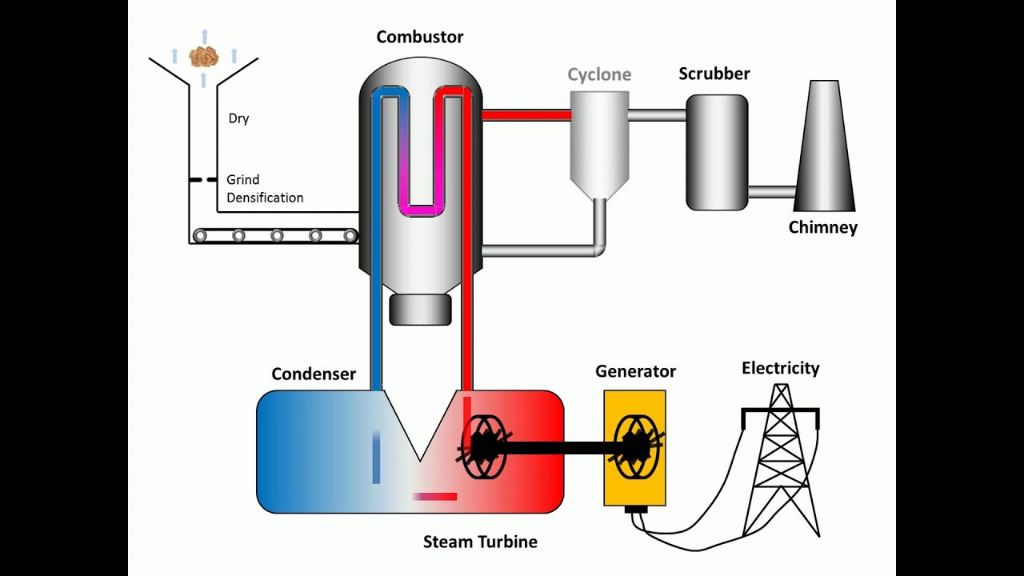

Combustion involves burning biomass directly to produce heat and electricity. The biomass fuel is burned in an oxygen environment, releasing the chemical energy. The heat can be used to boil water and drive a steam turbine to generate electricity.

Gasification uses high temperatures and a controlled amount of oxygen to convert biomass into a mixture of carbon monoxide, hydrogen and methane called syngas. The syngas can be burned directly for heat and power or further processed into transportation fuels.

Pyrolysis heats biomass in the absence of oxygen, breaking down the material into bio-oil, syngas and biochar. The bio-oil can be refined into fuels, while the syngas can generate electricity. Biochar can improve soil fertility as a soil amendment.

Biochemical Conversion

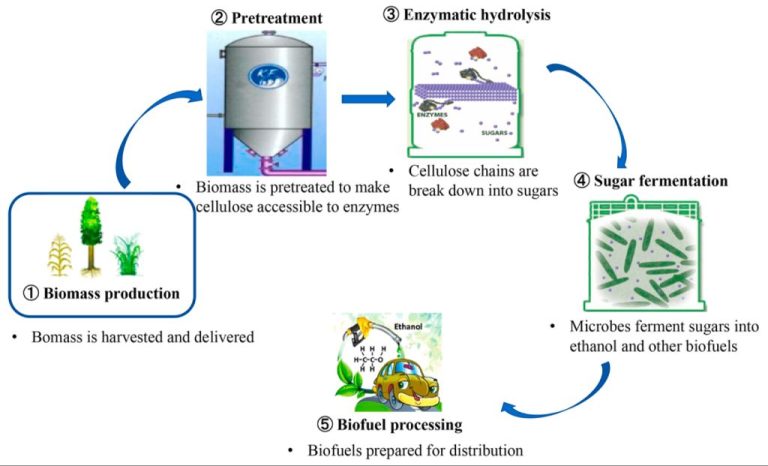

Biochemical conversion involves the use of bacteria, enzymes, and other biological agents to break down biomass into useful energy products. The two main biochemical conversion methods are anaerobic digestion and fermentation.

Anaerobic digestion uses bacteria in an oxygen-free environment to break down organic material into biogas. This biogas is composed mainly of methane and carbon dioxide and can be used to generate electricity and heat. Animal manure, food waste, and sewage sludge are common feedstocks for anaerobic digesters at farms, wastewater treatment plants, and landfills. The nutrient-rich digestate left over after digestion can also be used as fertilizer.

Fermentation uses yeasts and bacteria to convert biomass sugars into ethanol fuel. The feedstocks are often high-sugar or starchy crops like corn, sugarcane, wheat, and sorghum. After pretreatment to unlock the sugars, the biomass slurry is inoculated with cultures of microorganisms that metabolize the sugars into ethanol. Fermentation is a popular biofuel production method in many countries. Cellulosic ethanol using non-food plant sources is also an emerging area of fermentation research.

Combustion

Combustion is the most established and commonly used technology for converting biomass to energy. It directly produces heat as well as electricity using boilers and steam turbines, and still accounts for over 90% of biomass-based power generation. It involves the direct burning of biomass feedstocks in a controlled amount of air to produce heat.

The technology is relatively simple and straightforward. The process begins by loading biomass fuel like wood chips, agricultural waste, or municipal solid waste into a combustion chamber. The fuel is then burned at high temperatures, ranging from 800 to 1100°C. As the biomass burns, it generates hot gas which fire up boilers to produce high pressure steam. The steam then propels turbines which in turn drive generators and produce electricity. The heat from combustion can also be utilized directly for applications like cooking and heating.

In addition to heat and electricity, combustion generates fly ash and flue gases as byproducts. Pollutants like carbon dioxide, carbon monoxide, sulfur oxides, nitrogen oxides, particulates and ash emissions must also be controlled and managed. Hence combustion plants utilize various pollution control technologies like electrostatic precipitators and flue gas desulfurization systems. Additionally, operating parameters like temperature, pressure and air flow are optimized to maximize efficiency and control emissions.

Gasification

Gasification is a process that converts biomass into a gaseous fuel called syngas. It involves the partial oxidation of biomass at high temperatures (900-1000°C) with a controlled amount of oxygen and/or steam. During gasification, the biomass breaks down into hydrogen, carbon monoxide, and methane gases which form the main components of syngas.

The amount of oxygen present during gasification influences the quality of syngas produced. With less oxygen, gasification leads to higher methane content in syngas. Whereas increased oxygen results in more hydrogen and carbon monoxide. The ratio of these gases in syngas determines its energy content and suitability for different applications.

After syngas is produced, it goes through a cleanup process to remove impurities like ash, sulfur, nitrogen compounds, and particulate matter. The clean syngas can then be utilized as a fuel for heat, electricity generation, transportation, and even for producing synthetic fuels and chemicals.

Gasification offers an efficient way to convert solid biomass into a clean-burning gaseous fuel. It also provides more flexibility in applications compared to directly combusting solid biomass. Overall, gasification serves as an important thermochemical process for unlocking the energy potential of biomass.

Pyrolysis

One of the thermochemical conversion techniques is pyrolysis, where biomass is converted to bioenergy in the absence of oxygen. During pyrolysis, the biomass feedstock is heated to temperatures between 400-800°C. The heating happens in an oxygen-limited environment, so combustion does not occur. Instead, this heating breaks down the biomass into different components.

The biomass breaks down into biochar, bio-oil, and syngas. Biochar is similar to charcoal and has soil amendment properties. Bio-oil is a dark brown liquid composed of different oxygenated hydrocarbons and water. It can be refined further into biofuels. Syngas is composed of hydrogen, carbon monoxide, carbon dioxide, methane, and other gaseous products. It can be used to generate electricity directly in engines or turbines.

The distribution between biochar, bio-oil, and syngas depends on the operating parameters of the pyrolysis process. Fast pyrolysis at high temperatures maximizes bio-oil production, which can make up 75% of the products. Slow pyrolysis at lower temperatures maximizes biochar production. Overall, pyrolysis provides an efficient thermochemical pathway for generating bioenergy from biomass.

Anaerobic Digestion

Anaerobic digestion is a process that converts biomass to biogas through bacterial decomposition in an oxygen-free environment. Organic material such as agricultural waste, manure, municipal waste, plant material, sewage, green waste or food waste are placed inside a closed tank called a digester. Inside the digester, anaerobic bacteria break down the organic matter and produce biogas, which consists mainly of methane and carbon dioxide.

The anaerobic digestion process involves three key steps:

- Hydrolysis – Complex organic polymers like carbohydrates are broken down into simple sugars, amino acids, and fatty acids with the addition of water.

- Acidogenesis – The simple sugars, amino acids and fatty acids are further broken down by acidogenic bacteria into carbon dioxide, hydrogen gas, ammonia, and organic acids.

- Methanogenesis – The organic acids are broken down further by methanogenic bacteria into methane and carbon dioxide gas which makes up the majority of the biogas produced.

Factors like digestion temperature, pH, carbon/nitrogen ratio, organic loading rate and retention time impact the microbial activity and biogas generation. The nutrient-rich digestate left after anaerobic digestion can be used as fertilizer.

The biogas produced can be upgraded to pure methane, which is similar to natural gas, and used to generate electricity and heat. Overall, anaerobic digestion provides an efficient waste management solution while also producing renewable energy.

Conclusion

There are several key methods for converting biomass into usable bioenergy. Direct combustion involves burning biomass to produce heat and generate electricity. Gasification heats biomass to produce a combustible gas called syngas. Pyrolysis also heats biomass but does so in the absence of oxygen to generate bio-oil, syngas, and biochar. Finally, anaerobic digestion uses microorganisms to break down biomass and release biogas containing methane and carbon dioxide.

Each of these thermochemical and biochemical conversion processes have their own advantages and applications. Combustion is simple and widely used for combined heat and power. Gasification and pyrolysis can produce higher value fuels and products. Anaerobic digestion offers benefits such as waste reduction. Overall, the multitude of conversion methods provides flexibility in utilizing the energy stored in biomass.