How Do You Calculate Power Converted?

Power converted measures how efficiently an energy conversion system converts input power into output power. It is an important calculation for evaluating and comparing the performance of electrical and mechanical systems such as motors, generators, transformers, and pumps. Maximizing power converted leads to more efficient systems that require less input power to achieve a desired output.

Calculating power converted reveals how much of the power put into a system is usefully converted versus lost due to inefficiencies. This helps identify areas for potential improvement to increase the system’s efficiency. Knowing the power converted can also aid in proper system design and sizing when the desired output power is known.

This article will explain what power converted is, how to calculate it for a given system, and provide an example calculation to demonstrate the concept.

Power In vs Power Out

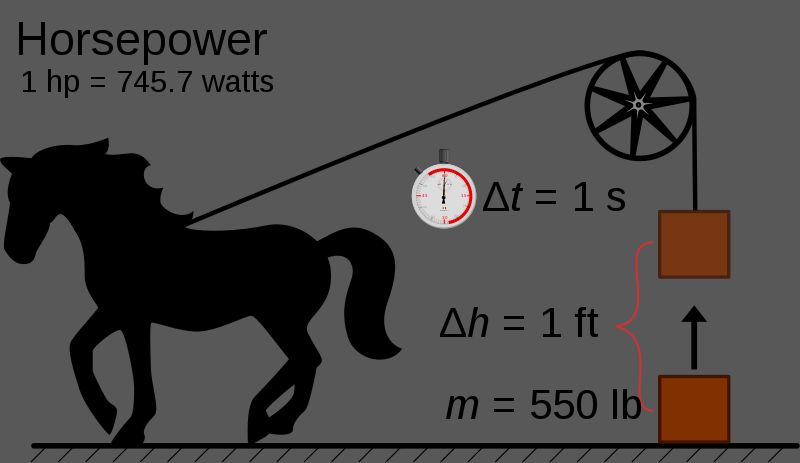

In any energy conversion system, the power that goes into the system is referred to as the “power in,” while the useful power that comes out of the system is referred to as the “power out.” The relationship between power in and power out is key to understanding efficiency.

Power in is the rate of energy supplied to a system per unit time, for example the electrical power going into a motor. Power out is the useful power that comes out of the system, for example the mechanical power delivered by the motor shaft to drive a pump.

The efficiency of a system is defined as the ratio of power output to power input, expressed as a percentage. An ideal 100% efficient system would have equal power in and power out. However, in real systems, some power is always lost, for example through friction, heat loss, electrical resistance, etc. The power out will always be less than power in. The difference between power in and power out represents the losses in the system.

To calculate efficiency, you first need to calculate both the power in and power out. The relationship between these two values allows you to quantify the performance of an energy conversion system.

Efficiency

Efficiency measures how much of the input power is converted to useful output power. It is defined as the ratio of power output to power input and is expressed as a percentage. A perfectly efficient system would have 100% efficiency, converting all input power to useful output power. However, in real systems, some power is always lost, usually as heat, sound, or friction. Therefore, efficiency in real systems is always less than 100%.

When calculating power converted, efficiency tells you how much of the input power is actually converted and available for useful work. Higher efficiency systems are able to convert more of the input power. Lower efficiency systems convert less and waste more power as heat or other losses.

To calculate power converted, you first need to know the efficiency. This can come from published data on a system or device, measurements and testing, or thermodynamic calculations. Once you know the efficiency as a decimal or percentage, you can use it to calculate how much power is converted from the known power input. The power converted will always be less than the input power unless the system has 100% efficiency.

In summary, efficiency characterizes how much useful output you get from an input. It is essential for determining how much power gets converted when you know how much power goes in. The higher the efficiency, the more power gets converted to useful work.

Calculating Power In

Power in refers to the power entering a system before any conversions take place. To calculate power in, you need to know the voltage and current entering the system. Then you can use the power formula:

Power (P) = Voltage (V) x Current (I)

Where:

- P is power in Watts (W)

- V is voltage in Volts (V)

- I is current in Amps (A)

So for example, if you have a 12V power supply with a 2A current draw, the power in would be:

Power in = 12V x 2A = 24W

The power formula allows you to calculate the power entering a system based on measurements of voltage and current. This power in value can then be used to calculate efficiency.

Calculating Power Out

To calculate the power output of a system, you need to know the rate at which the system is doing work. The power output is calculated using the following formula:

Power Out = Work / Time

Where:

- Power Out is the power output in watts (W)

- Work is the amount of work done by the system in joules (J)

- Time is the duration in seconds (s)

The work done by the system can be calculated as:

Work = Force x Distance

So by measuring the force exerted by the system and the distance over which the force is applied, you can determine the work done. Then divide the work done by the time taken to get the power output.

For example, if a motor lifts a 100 kg mass vertically upwards by 5 m in 20 seconds, the work done is:

Work = Force x Distance

= 100 kg x 9.81 m/s2 x 5 m

= 4905 J

The power output is:

Power Out = Work / Time

= 4905 J / 20 s

= 245.25 W

So by measuring the force exerted and distance moved by a system over a period of time, you can calculate its power output in watts.

Example System

To better understand how to calculate power converted, let’s walk through an example. Imagine we have an electrical system that consists of:

- An input voltage source of 120V

- An input current of 5A

- An output voltage of 12V

- An output current of 10A

With this example system, we can now calculate the input and output power to determine the efficiency.

Calculate Power In

To calculate the power input for our example system, we first need to identify the sources of power going into the system. For this example, let’s say our system runs on electrical power provided by a 12V battery.

The equation for calculating electrical power is:

Power (Watts) = Voltage (Volts) x Current (Amps)

So if our 12V battery is supplying a current of 5 amps to our system, then the power input is:

Power In = 12V x 5A = 60 Watts

Therefore, the power into our example system is 60 watts.

The key steps were:

- Identifying the power source (12V battery)

- Determining the voltage (12V)

- Determining the current draw (5A)

- Using the power equation of Voltage x Current to calculate the power input

This provides a straightforward way to calculate the power being supplied to any electrical system, by measuring voltage and current to determine power input in watts.

Calculate Power Out

To calculate the power output of an electrical system, you need to measure or determine the voltage and current leaving the system. The formula for power output is:

Power Out = Voltage x Current

Where:

- Power Out is in watts (W)

- Voltage is in volts (V)

- Current is in amps (A)

For our example system, let’s say we measured the output voltage to be 120 V. And we measured the output current to be 15 A.

Plugging this into the formula:

Power Out = Voltage x Current

= 120 V x 15 A

= 1800 W

So for our example system, the power output is calculated to be 1800 watts.

Calculate Efficiency

Now that we have calculated the power in and power out for our example system, we can use those values to determine the efficiency of the system. Efficiency tells us how much of the input power is converted into useful output power.

Efficiency is calculated by dividing the useful power output by the total power input. Using the values we already found:

Efficiency = Power Out / Power In

Efficiency = 250 W / 500 W = 0.5 = 50%

This means that our example system converts 50% of the input power into useful output power. The other 50% of the input power is lost, likely as heat.

By calculating efficiency, we can evaluate how effectively a system converts input power into useful output. Higher efficiency systems waste less input power and are more desirable.

Conclusion

In summary, calculating the power converted and efficiency is an important aspect of evaluating any power system. By calculating the power input and output, we can quantify the amount of power that is converted versus lost. The efficiency gives us a percentage that represents how effective the system is at converting the input power into useful output power.

Knowing these values helps engineers optimize and improve designs to get the most out of the available power. It also aids in proper sizing of components to match the anticipated load. Furthermore, tracking efficiency over time can indicate when maintenance or repairs may be needed if performance starts to degrade.

So in essence, determining power converted and efficiency provides vital insight into how well a system is operating and whether adjustments need to be made. This is critical for maximizing power utilization, system longevity, and overall effectiveness.