Does Biomass Produce Gas?

What is biomass?

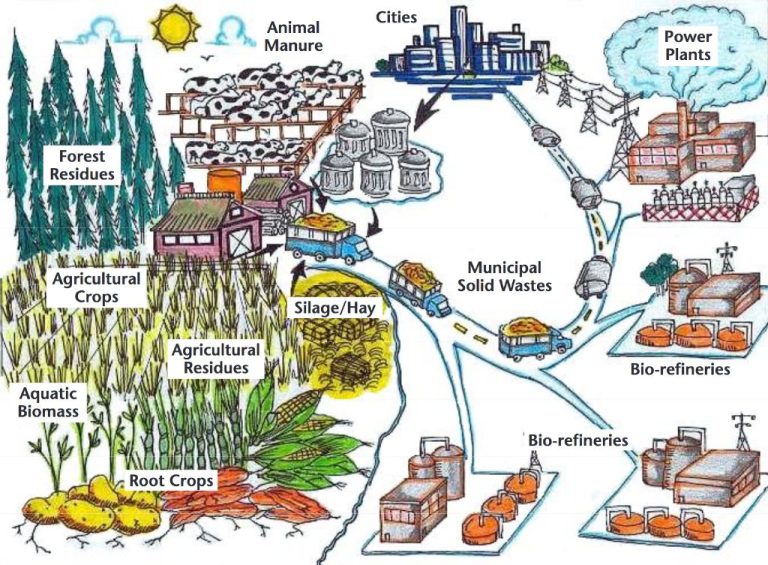

Biomass refers to organic matter that comes from plants and animals. It encompasses a wide range of materials including wood, crops, sewage, manure, and algae. More specifically, biomass is any biological material that can be used as fuel or converted into other useful products.

The most common types of biomass include:

- Wood and wood processing wastes – sawdust, timber slash, wood chips, bark, etc.

- Agricultural residues – corn stover, sugarcane bagasse, coconut husks, etc.

- Food wastes – spoiled food, restaurant leftovers, etc.

- Industrial wastes – black liquor, paper sludge, etc.

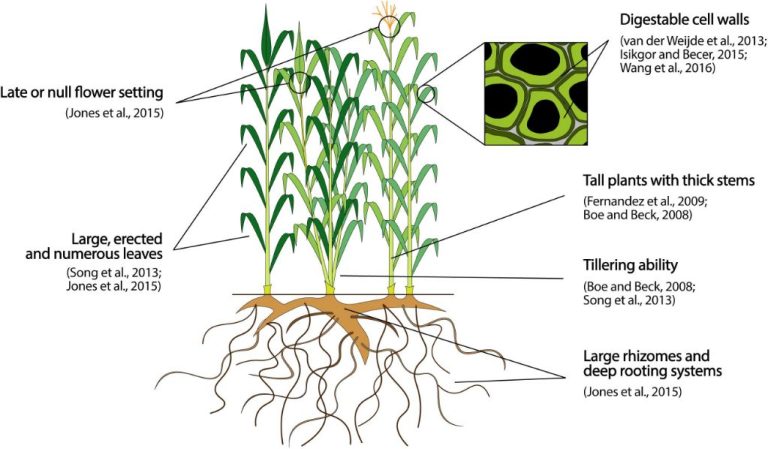

- Energy crops – fast growing trees and grasses grown specifically for energy use.

These biomass feedstocks provide renewable sources of energy and materials that can be used to produce electricity, fuels, chemicals, and heat.

Biomass gasification process

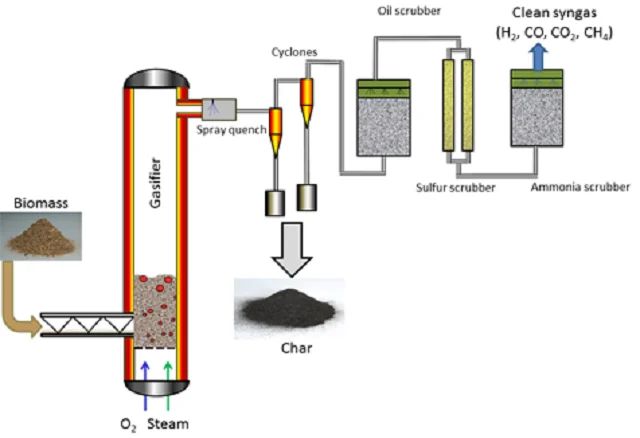

Gasification is the process of converting biomass into a combustible gas mixture known as syngas. It involves heating biomass to high temperatures with some oxygen, but not enough oxygen for full combustion. The lack of oxygen allows the biomass to break down into syngas instead of completely burning.

The gasification process consists of several key steps:

The composition of the resulting syngas depends on factors like feedstock and gasifier design. But it generally contains hydrogen, carbon monoxide, methane, and other hydrocarbons. This gas mixture can then be used for heat, power generation, or synthesizing fuels and chemicals.

Syngas produced from biomass

Syngas, also known as synthesis gas, is one of the primary gases produced from the gasification of biomass. It is a mixture of hydrogen, carbon monoxide, and some carbon dioxide. The composition of syngas depends on the biomass feedstock and the specifics of the gasification process.

Typically, syngas from biomass gasification contains 30-60% hydrogen, 25-30% carbon monoxide, 5-15% carbon dioxide as well as smaller amounts of methane and other hydrocarbons. The hydrogen and carbon monoxide in syngas have a wide range of applications.

One of the main uses of syngas is as a fuel for heat and electricity generation. Syngas can be burned directly in gas engines or turbines. The hydrogen content of syngas also makes it suitable for fuel cells. In addition, syngas can be used to produce synthetic natural gas through methanation.

Syngas from biomass provides a renewable feedstock for the production of liquid fuels via Fischer-Tropsch synthesis. The carbon monoxide and hydrogen in syngas can be catalytically converted into synthetic diesel and other transportation fuels. These “second generation” biofuels provide a sustainable alternative to petroleum-based fuels.

Syngas can also be used as a chemical building block in the synthesis of ammonia, methanol, and other chemicals. Overall, syngas offers a flexible and environmentally friendly platform for producing heat, power, fuels and chemicals from renewable biomass resources.

Other gases produced from biomass

In addition to syngas, other gases can be produced from biomass feedstocks. Two of the main ones are methane and hydrogen.

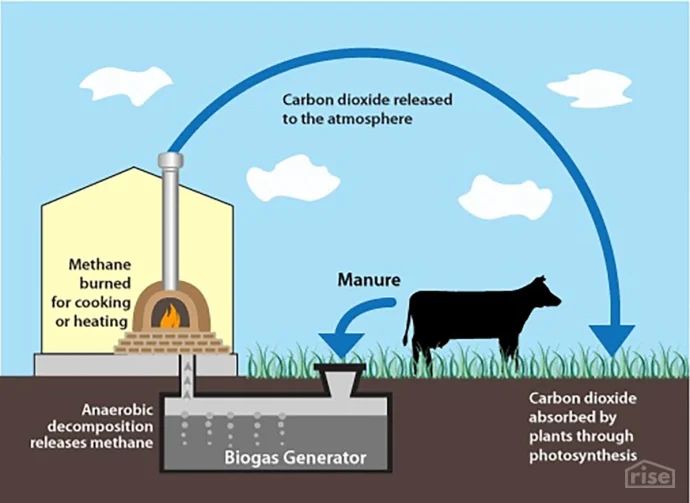

Methane can be produced from biomass through a process called anaerobic digestion. This involves the biological breakdown of organic matter by microorganisms in an oxygen-free environment. The end products are biogas, which contains around 60% methane, and digestate, which can be used as a biofertilizer.

Methane from biomass has several advantages as an energy source. It is renewable, can be used directly in gas engines and turbines for heat and power generation, and has lower emissions compared to fossil fuels. The digestate also provides benefits such as improving soil health.

Hydrogen gas can also be produced from biomass through a variety of processes like gasification, pyrolysis, fermentation and biological water-gas shift reaction. This is known as biohydrogen. The potential environmental benefits of biohydrogen include reduced greenhouse gas emissions compared to conventional hydrogen production. Biohydrogen also has use as a transport fuel and energy storage medium.

Research is ongoing to improve biohydrogen production technology and economics. Key challenges include increasing gas yields and purity while lowering costs. But in the future, biohydrogen could play a role in sustainable energy systems.

Benefits of biomass gasification

Biomass gasification offers several important benefits that make it an attractive renewable energy technology:

Renewable energy source – Biomass is considered a renewable energy source because plants and organic waste can be regrown relatively quickly compared to the time it takes to form fossil fuels. Gasifying biomass provides a sustainable way to generate energy and reduces dependence on non-renewable fossil fuels like coal and natural gas.

Reduced waste – Biomass gasification offers an efficient waste management solution by using agricultural residues, forest debris, and urban waste as feedstocks for energy production. This diverts biomass waste from landfills and gives it a productive purpose.

Lower greenhouse gas emissions – Using sustainably sourced biomass for energy avoids the high levels of greenhouse gases emitted from burning fossil fuels. While biomass does release CO2 when gasified, this is offset by the CO2 absorbed as the biomass feedstock grows. So the overall net emissions are lower compared to conventional fossil fuel power plants.

Challenges of biomass gasification

While biomass gasification offers many benefits, it also comes with some challenges that need to be addressed for its widespread adoption. Three main challenges are:

High capital costs – Building a biomass gasification plant requires significant upfront capital investment. The gasifier units, gas cleaning and conditioning systems, and pipelines all add to the costs. This can make financing difficult, especially for smaller scale distributed plants.

Feedstock limitations – Not all types of biomass feedstock are suitable for gasification. The feedstock needs consistent composition and energy content. Supply logistics at adequate volumes can also be an issue. Pre-treatment of feedstocks may be needed to make them usable.

Technical expertise required – Designing, building and operating a biomass gasification plant requires specialized technical skill and expertise which is still limited. The technology itself is also continuously evolving. Lack of trained personnel can deter adoption.

While these challenges exist, they are not insurmountable. As the technology matures and gets more investment, costs should come down. Supportive policies and incentives can further accelerate adoption. Overall, the benefits of clean, renewable energy from biomass gasification outweigh the current limitations.

Biomass Gasification Applications

Biomass gasification has several key applications that make use of the combustible gases it produces:

Electricity Generation

The syngas produced from biomass gasification can be used to generate electricity. The syngas is combusted to create heat that produces steam. This steam then spins a turbine which drives a generator to produce electricity. Biomass gasification for electricity production provides a renewable and often carbon-neutral source of power generation.

Transportation Fuel

Syngas from biomass can also be converted into liquid fuels, like ethanol and methanol, to power vehicles. Biomass gasification produces syngas made up of hydrogen and carbon monoxide which can be catalytically converted into alcohols through a Fischer-Tropsch process. These alcohol fuels can directly replace gasoline and diesel for transportation.

Heating and Cooking

The combustible gases produced from biomass gasification can also provide heat directly for cooking and heating purposes. The gas can be burned directly for cooking similar to liquified petroleum gas (LPG). Biomass gasifiers that produce wood gas or producer gas can provide heat for industrial heating needs as well as residential space heating.

Commercial viability

Biomass gasification is becoming increasingly commercially viable as demand for renewable energy continues to grow. The gas produced from biomass gasification can be used for heating, power generation, transportation fuel, and as a chemical feedstock. While capital costs for biomass gasification plants are still high compared to options like natural gas, costs are coming down as the technology matures.

When factoring in the lower price volatility and environmental benefits of biomass compared to fossil fuels, biomass gasification is an attractive option for many applications. Electricity from biomass gasification can be cost competitive with grid electricity in some markets, especially when combined heat and power systems are utilized to increase efficiency.

Transportation fuels like renewable natural gas from biomass are becoming more cost effective due to government incentives and the low carbon fuel standard in places like California. Chemical and industrial companies are also investing in biomass gasification to produce syngas to meet sustainability goals.

While natural gas currently retains a significant cost advantage, as demand grows and biomass gasification technology improves, it is likely that many applications will cross the threshold to commercial viability over the next decade.

Environmental Impact

The environmental impact of biomass gasification is complex and depends on the scale of operations as well as specific feedstocks and processes used. However, some key considerations around air and water emissions as well as effects on the carbon cycle are important.

In terms of air emissions, gasification can produce pollutants like particulate matter, nitrogen oxides, carbon monoxide, volatile organic compounds, and other hazardous air pollutants if not properly controlled. Emissions controls like gas cleaning systems are often needed to limit environmental impact. Water discharges may also contain organic compounds, oils, tars, and other suspended solids. Proper wastewater treatment is required.

Regarding the carbon cycle, biomass itself is considered carbon neutral because it absorbs CO2 during growth. However, there can still be net carbon emissions at various steps of production, harvest, processing and transport. The net emission impact depends on the specific biomass feedstocks and supply chain. Sustainable harvesting and minimal processing is required to maximize net carbon benefit.

Future Outlook

The future outlook for biomass gasification is focused on improving efficiency and reducing costs. Researchers are working to optimize the gasification process in order to increase gas yields and quality, as well as improve the reliability and adaptability of gasification systems. Key goals are to make biomass gasification more economically competitive with fossil fuel alternatives.

There is also interest in integrating biomass gasification into renewable energy systems. Syngas from biomass can be used to generate electricity, produce renewable natural gas for injection into gas grids, or converted into liquid biofuels. With the growth in renewable power, biomass gasification may play an increasing role as a dispatchable and flexible technology to complement variable sources like wind and solar. Gasification enables long-term storage of biomass feedstocks and on-demand production of syngas. This allows renewables generation to be smoothly managed over hours or seasons.