Will Solar Panels Run Out?

Solar power consumption rose by 24% across the globe in 2021, with China bringing 54.9 gigawatts of new solar PV installations online that year alone. Solar Energy Statistics show that solar energy is continuing its rapid growth as countries seek to reduce their carbon footprints. As solar panel installations multiply, it raises the natural question of whether the materials needed to manufacture solar panels could eventually become scarce. This article examines if key resources like silicon or silver may start to dwindle given the projected growth in demand, or if solar panels are in fact sustainable long-term.

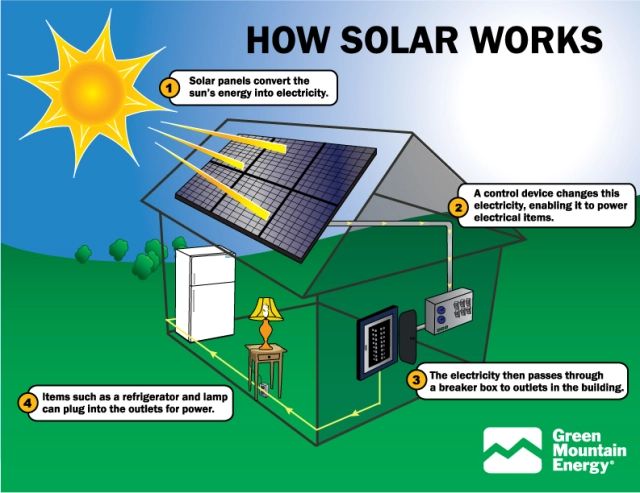

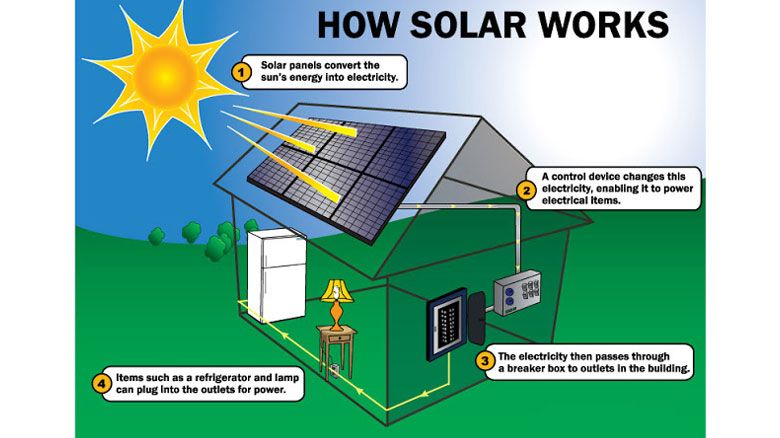

How Solar Panels Work

Solar panels work through the photovoltaic effect, where photons from sunlight knock electrons free from atoms to generate electricity. Solar cells are made up of semiconducting materials like silicon that are doped with other elements to form a p-n junction diode. When sunlight hits the solar cell, the energy from the photons excite the electrons, causing them to break free. The built-in electric field in the p-n junction separates the electrons and holes, creating a flow of current and producing DC electricity. Wires and conductive plates are attached to the positive and negative sides of the solar cell to allow the current to be drawn off for external use (EnergySage). This process allows solar panels to convert sunlight directly into electricity without any moving parts.

Solar Panel Components

Solar panels consist of a few key materials that enable them to convert sunlight into electricity. The most common solar panel types use either monocrystalline silicon or polycrystalline silicon cells. Silicon is the main active ingredient that absorbs sunlight and generates an electric current. According to Energysage, over 90% of solar panels are made of silicon.

Solar panels also require a metal frame, usually made of aluminum, to provide structure and rigidity. The cells are interconnected through thin strips of copper or silver to conduct the electricity. These conductive ribbons account for about 0.1% of a panel’s total materials. In addition, most panels have an anti-reflective coating, typically made of titanium dioxide or silicon nitride, to maximize sunlight absorption. Finally, a sheet of tempered glass protects the cells from weather and impact damage.

Other key materials in solar panels include ethylene-vinyl acetate, a polymer used to encapsulate and seal the panel, as well as various plastics for junction boxes and cables. So in summary, the main ingredients are silicon cells, a metal frame, glass casing, and small amounts of metals like silver and copper for electrical contacts and wiring.

Global Reserves of Key Resources

Solar panels require materials like silicon, silver, and copper to function efficiently. Analyzing global reserves and production of these key resources can give insight into the long-term viability of solar panels.

Silicon, a crucial material for solar cells, has abundant global reserves estimated at 120 million metric tons (MT), with China, Australia, Brazil, and the United States holding significant reserves [1]. Annual production is estimated at 7 million MT, implying silicon availability for decades of solar cell production at current rates [2].

Global silver reserves are estimated at 560,000 MT and annual production is about 27,000 MT [3]. With silver used in small quantities in solar panels, reserves are sufficient for decades of production. The leading countries for silver reserves include Mexico, Peru, China, and Australia [4].

Estimates for global copper reserves range from 830-890 million MT, with Chile, Australia, Peru, and Mexico having substantial reserves [5]. Annual copper production is around 20 million MT, implying decades of available reserves at current rates [6].

With several decades of key resource reserves available, it appears solar panel production is sustainable for the foreseeable future at current rates of global demand and technological requirements.

Resource Extraction and Processing

The extraction and processing of resources needed for solar panel production, such as silver and copper, comes with environmental costs. Silver mining involves extracting silver from mineral ores, a process that can negatively impact surrounding air and water quality (1). Copper mining also carries risks like water pollution, air quality issues, and threats to Indigenous communities (2). While solar energy itself is renewable and clean, obtaining the raw materials involves mining and refining processes that can damage local ecosystems and communities if not properly regulated. Sustainable and ethical sourcing of metals and minerals will be an important consideration as solar panel production scales up globally.

Recycling and Reuse

Solar panels contain valuable materials like silicon, glass, aluminum and copper which can be recovered through recycling. As per a 2020 U.S. Environmental Protection Agency report, around 90% of the materials in a solar panel can potentially be recovered and reused.

Instead of ending up in a landfill, these materials can be captured and fed back into production through recycling. Proper solar panel recycling requires careful handling and separation of the different components like glass, silicon, metal and plastic. The recovered silicon can be repurposed to make new solar panels. Metals like aluminum and copper are also highly recyclable.

By recycling and reusing solar panel materials, the reserves of raw materials needed for new solar panel production can be extended significantly. Recycling reduces the demand for continual mining and extraction of finite resources. In this way, material recycling and reuse helps make solar power more sustainable in the long run by conserving reserves of key materials like silicon.

Technological Improvements

There have been a number of innovations in solar panel technology that allow for more efficient use of raw materials. One such advancement is the development of thin-film solar panels, which use a thin layer of photosensitive material, like cadmium telluride or amorphous silicon, on a substrate like glass, plastic or metal [1]. Thin-film panels use about 1% of the silicon needed for conventional panels, reducing raw material requirements [2]. While less efficient, thin-film panels offset this by their lower production costs. Manufacturers are also exploring alternative semiconductor materials like perovskites that can be layered with silicon to improve efficiency.

There have also been advances in manufacturing techniques that reduce silicon waste. For example, diamond wire sawing results in less kerf loss compared to slurry wire sawing. Reclaiming and recycling silicon from manufacturing scrap and end-of-life panels also allows the reuse of materials.

Alternative Materials

As silicon and other materials used in traditional solar panels become constrained, researchers are exploring substitute materials that could replace scarce resources and reduce costs. One promising material is perovskite, which can be made from abundant low-cost starting materials like lead, tin, and organic halides (University of Rochester, 2023). Perovskites have shown solar conversion efficiencies comparable to silicon, while requiring less energy to manufacture. However, perovskites have stability issues that need to be resolved before widespread commercial use.

Thin film solar cells using amorphous silicon, cadmium telluride, and copper indium gallium selenide are other alternatives gaining traction. Amorphous silicon can be deposited on substrates like glass or plastic at lower temperatures, reducing energy usage (GAO, 2021). Cadmium telluride thin films use much less semiconductor material than silicon panels. Copper indium gallium selenide has demonstrated high efficiency and is lightweight and flexible. While still a small share of the market, thin film and perovskite solar cells show potential as more sustainable alternatives to conventional crystalline silicon panels.

Projected Demand vs Available Reserves

Solar energy demand is expected to grow substantially in the coming decades. According to the Solar Energy Industries Association (SEIA), the U.S. solar market is projected to install 69 gigawatts (GW) of new solar capacity in 2023, up 20% over 2022 installations (Solar Market Insight Report Q2 2023 | SEIA). They forecast that solar will make up over 30% of all new electricity generating capacity additions brought online in the next two years. Globally, Fortune Business Insights predicts that the solar power market will grow from $234.86 billion in 2022 to $373.84 billion by 2029, at a 6.9% CAGR (Solar Power Market Size, Share, Growth and Forecast [2029] | Fortune Business Insights).

To meet this rapidly increasing demand, adequate reserves of key solar panel materials like silicon, silver, and copper will need to be extracted and processed. Current assessments estimate global reserves for silicon at 120 million tons, for silver at 570,000 tons, and for copper at 870 million tons. At current and projected rates of solar panel production, these reserves are estimated to last for decades. However, continued growth in the solar industry will require expanding resource extraction and processing capabilities to maintain adequate supply. Higher prices or supply constraints for these materials could slow the pace of solar adoption if production cannot keep up with demand. Overall, while global resource reserves are sufficient in the near-to-medium term, ensuring adequate materials to meet long-term solar growth will require careful monitoring and management of these limited resources.

Conclusion

In summary, the long-term outlook for solar panel sustainability is cautiously optimistic. While some key resources like silicon and silver may face supply constraints down the road, improved recycling programs and new technologies can help extend reserves. The solar industry is also diversifying materials, exploring alternative semiconductor materials to silicon and reducing reliance on silver for electrical contacts. With projected increasing demand as more countries adopt solar energy, active management of resources and continued innovation will be needed to prevent shortages. But the versatility and declining costs of solar give confidence that it can remain a renewable energy mainstay for decades to come.