Why Is Solar Installation So Expensive?

Solar power has experienced rapid growth in recent years as more homes and businesses adopt renewable energy. The main appeal of solar is that it can generate electricity from sunlight without producing greenhouse gas emissions. However, the upfront costs of installing solar panels remain expensive compared to other energy sources. On average, solar installation costs $2 to $4 per watt in the U.S., so a typical 6 kW system runs between $12,000 and $24,000 before incentives. What factors make solar installation so costly despite the environmental and long-term financial benefits?

Cost Breakdown

The total cost of a solar installation can be broken down into several main categories: solar panels, inverters, racking & mounting equipment, permitting fees, labor, marketing/customer acquisition costs, and more. According to EnergySage, here’s a typical cost breakdown for residential solar installation:

- Hardware equipment (solar panels, inverters, etc.) – ~25% of total cost

- Marketing and customer acquisition – ~20%

- Overhead costs – ~20%

- Labor – ~10%

- Permits and inspections – ~5%

- Other soft costs – ~20%

The largest single expense is the solar panels themselves. High-efficiency monocrystalline panels from premium brands generally cost $2.50-$3.50 per watt. The supporting inverters, racking, and wiring add to the hardware costs as well (source).

The “soft costs” like permits, labor, marketing and overhead represent a significant portion too. Streamlining regulations and permitting has helped reduce these soft costs in recent years, but there’s still room for improvement (source).

Solar Panels

Solar panels account for around 25-30% of the total cost of a solar system, not including installation and labor (Source). The high cost of solar panels is largely driven by the manufacturing process and materials involved.

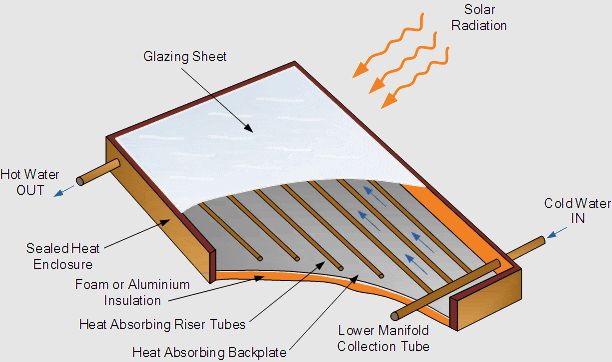

Solar cells, which make up solar panels, are typically made from monocrystalline or polycrystalline silicon. Producing high purity silicon is energy intensive and requires costly materials and equipment. The silicon must be refined, melted, crystallized into ingots, cut into wafers, and further processed before being assembled into solar cells and encapsulated into panels (Source).

In addition, solar panel supply chains can lack economies of scale compared to fossil fuels, keeping costs elevated. Most solar panel production is located in China and other parts of Asia, so transportation and import costs also contribute to the price (Source). While costs have dropped dramatically in the last decade, the complex manufacturing process required for high efficiency solar panels makes them inherently expensive components.

Inverters

Inverters play a critical role in solar installations as they convert the DC power generated by solar panels into usable AC power for homes and businesses. The cost of inverters makes up 10-15% of the total price of a solar system (Solar Inverters: Types, Benefits, Cost(2023 Guide)). In recent years, the cost of inverters has been coming down thanks to advancements in power electronics and increased competition among manufacturers. However, inverters still represent a significant portion of overall system costs.

According to industry experts, the average cost per watt of solar inverters ranges from $0.20-0.40 (Inverter price vs Panel price: Which is cheaper?). The size of the inverter, its features, warranty length, and the complexity of the overall system design all impact the final price. Larger string inverters used in commercial solar farms are more affordable on a per watt basis compared to smaller microinverters used in residential rooftop systems. While inverter technology has improved greatly, power electronics remain one of the more expensive components in solar energy systems.

Racking & Mounting

Racking and mounting refers to the materials and hardware needed to securely attach solar panels to rooftops or ground mounts. This includes rails, clamps, fasteners, and anchors. According to Solar Power World, mounting costs can account for up to 7% of the total cost of a residential solar installation.

The mounting system must be strong enough to withstand wind, snow, and seismic loads over the system lifetime of 20-25 years. Aluminum and galvanized steel are common mounting materials, chosen for their strength, durability, and corrosion resistance. Labor costs are also a factor, as installing a mounting system requires technical expertise.

There are a few ways installers can reduce racking and mounting costs. Streamlining the installation process with integrated mounting solutions can cut labor time and costs. Sourcing high-quality but lower-cost mounting hardware can also make installations more affordable without sacrificing safety or longevity.

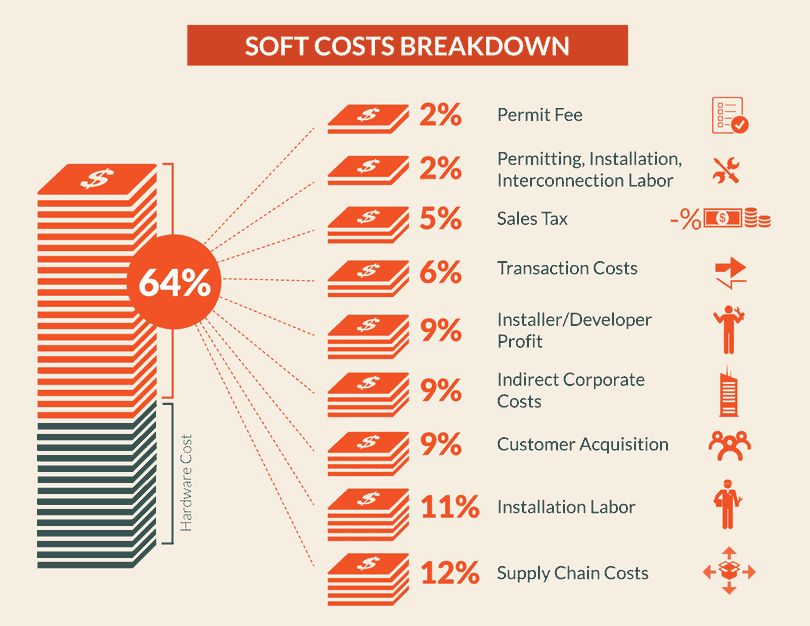

Soft Costs

Soft costs refer to the non-hardware costs associated with solar installation, such as labor, permitting, inspection, financing, customer acquisition, supply chain, and overhead costs. These costs can account for over half of the total price of residential solar installation. For example, according to an analysis by the National Renewable Energy Laboratory (NREL), soft costs represented 64% of the total price of a residential solar system in the United States in 2015 [1].

High soft costs are one of the major factors that make solar expensive compared to other energy sources. Streamlining permitting and inspection processes could accelerate solar adoption and reduce costs. Software tools that automate processes like system design, permitting, and customer acquisition can also help lower soft costs [2]. Programs like the Department of Energy’s SolSmart initiative work with local governments to standardize and expedite solar permitting and inspection, reducing soft costs [3].

Supply Chain Issues

Global supply chain disruptions have significantly contributed to increased solar costs in recent years. Manufacturing and transportation bottlenecks at nearly every point along the solar supply chain mean higher costs to acquire key hardware components like solar panels, racking systems, and inverters.

A boom in solar demand, coupled with shutdowns during the Covid-19 pandemic, has led to shortages of key polysilicon and solar panel components. Facilities have struggled to ramp up production as demand outstrips supply (1). Port congestion and container shortages have also challenged efforts to ship components in a timely and cost-effective manner. For example, shipping container rates from China to the U.S. West Coast quintupled from 2019 to 2021, directly increasing hardware costs (2).

Furthermore, recent policy changes have disrupted supply chains. New tariffs on Chinese solar manufacturers were intended to boost U.S. panel production but instead reduced supply and increased costs as U.S. manufacturing could not fill the gap (1). Ongoing regulatory uncertainty around the Uyghur Forced Labor Prevention Act has also jeopardized access to low-cost polysilicon from the Xinjiang region of China (3).

As key inputs face manufacturing delays and mounting transportation expenses, installers have little choice but to pass those higher hardware costs on to residential and commercial solar customers.

(1) https://pv-magazine-usa.com/2022/03/16/making-sense-of-solar-supply-chain-issues/

(2) https://www.renewableenergyworld.com/solar/solar-supply-chain-issues-could-contribute-to-energy-shortfalls-in-california-this-summer/

(3) https://www.youtube.com/watch?v=H7R-e-rvxEI

Lack of Economies of Scale

One major factor that increases the cost of solar installation is the lack of economies of scale. Unlike mass-produced consumer products, most residential solar systems are custom designed and installed. This means that there are fewer opportunities to reduce costs through bulk manufacturing, standardized parts, and streamlined installation processes.

Each home has a unique roof type, angle, and solar access. So solar companies cannot take a one-size-fits-all approach. The custom measurements, design work, and tailored mounting and wiring add labor and logistical costs compared to large utility-scale solar farms. Without replicating thousands of identical systems, it’s hard to achieve the cost savings from purchasing components in bulk or developing specialized installation equipment and techniques.

According to a report by the National Renewable Energy Laboratory (NREL), soft costs like customer acquisition, system design, permitting, and installation labor account for over 60% of the total price of residential solar in the US. Streamlining and standardizing these processes could significantly reduce costs, but it requires a massive scale of installations nation-wide. So the relative small scale and customized nature of most residential solar systems makes it hard to reach the cost efficiencies that come with economies of scale at this time.

Permitting & Regulations

Permitting fees and regulatory requirements can add significantly to the overall cost of a solar installation. According to the Solar Energy Industries Association (SEIA), permitting fees alone can range from $500 to $2,000 on average nationwide [1]. These costs are especially high in states like California that have more stringent rules and regulations around solar. In California, permitting fees can be over $1,000 on average and the process takes longer compared to other states [2]. The long and complex permitting process requires trained inspectors, plan reviews, and inspections which all cost time and money. Simplifying and standardizing the permitting process could help streamline solar installations and lower costs.

Apart from permitting, regulations like tariffs on imported solar equipment and restrictions on selling excess energy back to the grid can also drive up costs. There is opportunity to reform regulations to encourage more solar adoption while still maintaining safety and reliability.

Conclusions

In summary, there are several key factors that make solar installation expensive. The high upfront costs of solar panels, inverters, and racking contribute significantly to the overall cost. Soft costs like permitting, installation labor, and customer acquisition also add major expenses. Supply chain issues and lack of economies of scale in the solar industry prevent costs from falling further.

There are opportunities to reduce costs in the future through technological improvements, streamlining regulations and permitting, increasing solar deployment and manufacturing scale, and bringing down soft costs. Key ways the industry could lower expenses include developing more efficient solar panels, simplifying the permitting process, expanding solar manufacturing capacity, and reducing customer acquisition costs. As the solar industry matures and solar deployment expands globally, prices are likely to decrease further. But regulatory and policy support will be crucial to enabling the solar industry to achieve economies of scale and drive down costs.