Why Are Solar Panels Not Recyclable?

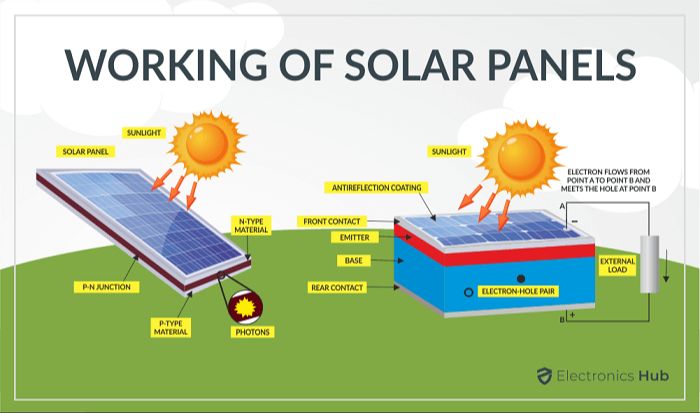

Solar panels are devices that convert sunlight into electricity using photovoltaic (PV) cells made of materials like silicon and other semiconductors. The popularity of solar panels has skyrocketed in recent years, with global installed capacity rising from under 10 gigawatts in 2007 to over 760 gigawatts in 2020.[1] This exponential growth is expected to continue as solar energy becomes more affordable and countries aim to transition away from fossil fuels.

However, there is a looming issue. Solar panels have lifespans of around 25-30 years, after which their performance declines. By 2050, it is estimated that there will be 78 million metric tons of solar panel waste globally.[2] So why are these increasingly common devices not recyclable? This article will examine the various factors that make recycling photovoltaic solar panels difficult and expensive.

[1] https://www.irena.org/Statistics/View-Data-by-Topic/Capacity-and-Generation/Statistics-Time-Series

[2] https://www.pv-magazine.com/2018/10/01/iea-releases-first-estimate-of-pv-waste-at-78mt-by-2050/

Solar Panel Materials

Solar panels are primarily composed of silicon, metal, and glass. The photovoltaic cells that convert sunlight into electricity are typically made from monocrystalline or polycrystalline silicon https://www.energysage.com/solar/what-are-solar-panels-made-of-list-of-solar-pv-materials/. Silicon has semiconducting properties that allow it to absorb photons from sunlight and release electrons, generating an electric current. The silicon is doped with other elements like phosphorus and boron to improve its conductivity. Thin-film solar panels may also use cadmium telluride or copper indium gallium selenide instead of silicon https://www.azom.com/article.aspx?ArticleID=21383.

The silicon cells are protected from the environment by sheets of glass on the sun-facing side. On the reverse side, the cells are encased in materials like polymers and aluminum. Solar panel frames are commonly made of anodized aluminum. Wires and junction boxes made of metals like copper transport the generated electricity outside the panel.

Difficulty Separating Materials

Solar panels are constructed by fusing various layers of materials together, making them challenging to recycle and separate. The silicon cells which convert sunlight into electricity are surrounded by glass, polymer and aluminum frames (Riech, 2021). The layers are tightly bound and fused together through heat and pressure, creating durable panels that can withstand harsh weather for decades.

However, this tight fusion of materials creates major difficulties when trying to recycle solar panels. Unlike materials loosely bound or screwed together, the fused solar panel components cannot easily be taken apart and separated at recycling facilities. According to research, “delamination and separation of different layers in the PV module remains a technical challenge” (Riech, 2021). The layers have different melting points and properties, preventing easy separation through heat, shredding or chemicals.

Manual dismantling and shredding can damage the recoverable silicon and metals. Chemically dissolving the resins and polymers leaves a contaminated sludge requiring further processing. The components tightly fused in solar panels therefore create technical and economic challenges for recycling facilities hoping to recover usable materials.

Small Amounts of Recoverable Materials

One key challenge with recycling solar panels is that only small percentages of the materials can actually be recovered and recycled. According to the Washington Post, currently only about 10-15% of a solar panel’s materials by weight are being recycled at end of life

(1). This is because solar panels are complex composite products made up of many different materials like glass, aluminum, silicon, copper, and silver embedded in plastics. It is technologically difficult to separate and extract all of these valuable materials in a cost effective way.

Researchers estimate that a typical crystalline silicon solar panel is made up of 70% glass, 10% polymer, 8% aluminum, 5% silicon, 5% copper, 1% silver, and less than 0.1% of materials like tin, lead, and cadmium

(2). While materials like aluminum and copper can be readily recycled, it is much harder to extract and purify the silicon and silver. As a result, current recycling processes are only able to recover a fraction of the total material value.

(1) [https://www.washingtonpost.com/climate-solutions/2023/07/05/solar-panel-recycling-microwave-technology/]

(2) [https://www.technologyreview.com/2021/08/19/1032215/solar-panels-recycling/]

High Recycling Costs

Recycling solar panels is an expensive process due to the costs of transport, labor, and facilities. According to Bloomberg Law, recycling one solar panel costs $15 to $45 – significantly more than the $1 to $5 per panel cost of sending it to a landfill (https://news.bloomberglaw.com/environment-and-energy/states-weigh-making-industry-pay-millions-for-solar-panel-waste). The Empire Center notes that it costs $20 to $30 to recycle each panel, while only recovering $3 to $12 in materials, leaving a substantial net cost (https://www.empirecenter.org/publications/renewable-solar-comes-with-recurring-waste-costs/).

Transporting end-of-life solar panels to specialized recycling facilities generates significant logistics expenses. Panels must be carefully handled to avoid breakage during loading, shipping, and unloading. Recycling plants have high capital costs for equipment like shredders, separators, and furnaces to break down and process all the solar panel components. Skilled technicians are needed to operate the recycling machinery and handle hazardous materials appropriately. Strict safety and environmental regulations also drive up operational overhead for solar panel recycling sites.

Lack of Financial Incentive

One major reason that solar panels are not widely recycled is the lack of financial incentive to do so. Solar panels are primarily made of glass, polymer plastics, and aluminum, which have low scrap value compared to materials like copper or gold. A typical solar panel may contain only $5 worth of recoverable material, while the cost to disassemble and process it for recycling can be $20-30.[1]

This means recycling companies lose money for every solar panel they accept and process. With such low yields and high costs, there is little profit motive to scale up solar panel recycling. Additionally, there is not much demand for the reclaimed low-value materials, as vergin materials are still relatively inexpensive.[2] Unless new technologies emerge to improve material recovery and lower recycling costs, or until reclaimed material demand rises, recycling solar panels will remain economically unviable for businesses.

Toxic Materials

Many solar panels, especially older models, contain hazardous materials such as lead and cadmium that can leach out and contaminate soil and waterways if the panels break or are improperly disposed of. According to the EPA, cadmium telluride (CdTe) thin film solar panels may contain cadmium, a heavy metal that is highly toxic and may pose risks if not handled properly.[1] Lead solder and lead-acid batteries are also commonly found in solar panels.[2]

When solar panels are damaged or improperly disposed of in landfills, the toxic materials can leach into the soil and contaminate groundwater. Cadmium exposure, even at low levels over a long period, can lead to kidney, bone, and lung diseases.[3] Furthermore, there is potential for toxic materials to accumulate up the food chain and contaminate fish and wildlife when released into the environment.

Proper end-of-life recycling is crucial to prevent the release of toxic chemicals from solar panels. While the amount of toxic materials in an individual panel may be small, the large and increasing number of solar panels reaching end-of-life globally makes their responsible disposal an important environmental issue.

[1] https://www.epa.gov/hw/end-of-life-solar-panels-regulations-and-management

[2] https://scdhec.gov/sites/default/files/Library/OR-1695.pdf

[3] https://www.americanexperiment.org/solar-panels-produce-tons-of-toxic-waste-literally/

Recycling Techniques and Research

Current recycling methods for solar panels focus on separating and recovering valuable materials like silicon, silver, and copper. Panels are first manually dismantled to remove aluminum frames, junction boxes, and cables. The remaining materials are then crushed and subjected to mechanical processes like shredding, grinding, and sieving to break them down further.

One common technique is pyrometalurgical processing which involves melting panel materials at high temperatures to separate metals like silver and copper. However, this process loses the silicon in the panels. Hydrometallurgical techniques using chemical baths to dissolve materials are better at recovering silicon, but require more complex steps (EPA).

Ongoing research is looking into improving recycling yields while reducing costs and environmental impacts. Methods being studied include using microwave energy, electrochemical processes, and biological processes with microbes and plant extracts. Researchers are also working on better panel designs to facilitate disassembly and material separation.

While current recycling is limited, innovations in processes, robotics, and solar panel design show promise for making solar panel recycling more economically viable and efficient in the future.

Recommendations

To improve solar panel recycling, there are several recommendations that can be made:

Proper disposal of solar panels at end-of-life is critical. Consumers need more education on how and where to recycle solar panels instead of sending them directly to landfills. Implementing policies requiring proper solar panel disposal at specialized recycling facilities would divert more panels from landfills.

New policies and regulations could also incentivize solar panel recycling. Governments can implement laws requiring manufacturers to collect and recycle a certain percentage of solar panels sold. Tax credits or rebates could be given to companies investing in solar panel recycling research and infrastructure.

Design improvements to solar panels could also boost recycling rates. Manufacturers can use standardized designs and fewer composite materials which are easier to separate. Adding QR codes to panels would enable better tracking and sorting for recycling. Panels designed for easy disassembly at end-of-life would also aid the recycling process.

Investing in more recycling facilities and research for solar panels is critical. Improved recycling techniques to efficiently separate and recover solar panel materials need further development. With more recycling plants available, transport costs could also be reduced.

Conclusion

As solar panel installations continue to grow exponentially, the lack of recycling options presents a serious problem. With current solar panels not designed for disassembly and recycling, we are creating massive amounts of electronic waste that contains toxic materials. While research is underway to develop new solar panel materials and recycling techniques, solutions are still years away from being widely adopted. There is an urgent need for manufacturers, policymakers, and the solar industry to prioritize recyclability and establish infrastructure, regulations, and incentives that enable proper solar panel recycling. If we don’t address this issue soon, we are heading towards a solar waste crisis in the coming decades as early solar installations reach end-of-life. The environmental and health impacts would undermine the sustainability benefits of solar power. Creative solutions encompassing technological innovation, industry standards, government policy and public-private collaboration are needed to make solar panels recyclable and build a circular economy around photovoltaic products.