Who Is The Largest Solar Manufacturer In India?

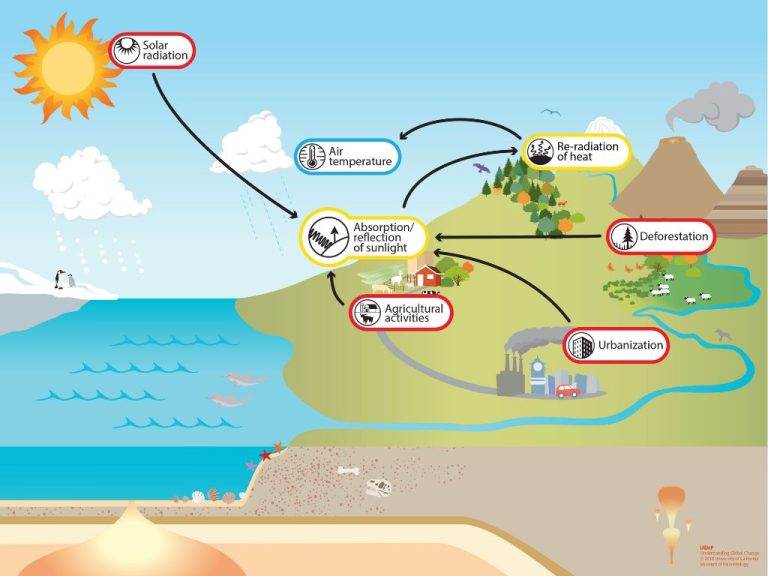

The solar manufacturing industry in India has experienced rapid growth in recent years, driven by the country’s rising energy demands and a push to increase renewable energy capacity. India is aiming to install 175 GW of renewable energy capacity by 2022, of which 100 GW is set to come from solar energy. As of January 2021, India had installed over 41 GW of solar capacity, making it the third largest solar market globally. With the demand for solar expected to continue rising, there is a need to ramp up domestic manufacturing capabilities. Currently, Indian solar manufacturers account for only a small portion of the market, with Chinese companies supplying the bulk of solar panels and equipment. However, the government aims to boost local manufacturing through supportive policies like production-linked incentives. As India looks to meet its ambitious renewable targets and energy needs in a clean and sustainable manner, the growth of the domestic solar industry will be key.

Leading Solar Manufacturers

India has seen rapid growth in solar manufacturing in recent years. Some of the major solar manufacturers in India include:

Adani Solar (https://www.adanigroup.com/businesses/solar-manufacturing) – Part of the Adani Group conglomerate, Adani Solar has an annual module production capacity of 1.2 GW and cell production capacity of 1 GW. The company manufactures mono and multi crystalline solar modules at its manufacturing facility in Mundra, Gujarat.

Vikram Solar (https://www.vikramsolar.com/about/) – Vikram Solar is one of the leading solar panel manufacturers in India with over 1 GW annual production capacity. The company offers solar PV modules, rooftop EPC services, and floating solar solutions. Its manufacturing facilities are located in Falta, West Bengal.

Tata Power Solar Systems (https://www.tatapowersolar.com/) – Part of India’s Tata Group, Tata Power Solar has an annual module manufacturing capacity of 1.1 GW. It produces solar cells and modules and also provides EPC services for utility-scale solar projects. Its factories are located in Bangalore.

Waaree Energies (https://www.waaree.com/) – Waaree is one of India’s oldest and largest solar module manufacturers with over 1.5 GW of annual production capacity. The company has factories in Surat and Tumb and offers mono and multi crystalline PV modules for various applications.

Largest by Production Capacity

According to India: solar PV module manufacturing companies 2023, Waaree Energies is the largest solar photovoltaic module manufacturer in India by production capacity. As of March 2023, Waaree had an annual production capacity of over 12 gigawatts (GW).

Waaree Energies was founded in 1989 and is the flagship company of the Waaree Group. Headquartered in Mumbai, Waaree has India’s largest module manufacturing facility located in Surat, Gujarat. This state-of-the-art facility has the capacity to produce over 2,700 modules per day. Waaree also has manufacturing plants in Nalagarh (Himachal Pradesh) and Umbergaon (Gujarat).

In addition to having the highest production capacity in India, Waaree Energies exports solar PV modules to over 350 customers in 80+ countries. It is one of the top solar brands worldwide, with certifications from leading test labs for quality and performance.

Largest by Market Share

The largest solar company in India by market share is Adani Green Energy. According to ElectronicsandYou, Adani Green Energy has the dominant market share in India’s solar industry at 19%, significantly higher than competitors like Azure Power and Renew Power who have around 5% market share each.

Adani Green Energy is part of the larger Adani Group conglomerate and has established a leading position in solar project development, construction, operations, and maintenance. The company has focused aggressively on large-scale solar parks and has over 5,000 MW of operational solar projects, the most of any company in India. Adani has been able to utilize the financial and infrastructure backing of the larger Adani Group to scale up rapidly and capture market share.

Some key advantages for Adani Green Energy include having strong relationships with government agencies, access to cost-efficient financing, extensive industry expertise and technical capabilities, and an end-to-end solar platform spanning manufacturing to generation. The company is now aiming to reach 25 GW of renewable energy capacity by 2025, cementing its market leading position in India.

Growth Trends

The Indian solar energy market has experienced rapid growth in recent years. According to Ember’s research, India’s solar capacity grew over 18 times from 2.6 GW in March 2014 to 60 GW by March 2022. The country is expected to reach 100 GW of solar capacity by 2022 and 266 GW by 2026, as part of its commitment to increase adoption of renewable energy.

The major solar manufacturers in India have benefited from strong domestic demand. The top three companies – Adani Green Energy, Reliance Industries, and Tata Power Solar – have all announced major expansion plans to increase production capacity over the next few years. For example, Adani Green Energy, the current market leader, aims to expand from 5 GW annual production in 2022 to 25 GW annual capacity by 2025. Reliance plans to scale up from under 1 GW per year to 10 GW annual capacity in the same timeframe.

Foreign solar manufacturers have also invested heavily in India due to the country’s solar growth potential and policies supporting domestic manufacturing. Major companies like Longi, Trina Solar, and Jinko have either set up or announced new factories in India. With strong government support through initiatives like the Production Linked Incentive scheme, India is projected to become a major global solar manufacturing hub.

Domestic vs. Foreign Companies

The solar manufacturing industry in India has historically been dominated by foreign companies, especially from China. However, recent years have seen a major push by the Indian government to promote domestic manufacturing through initiatives like the Production Linked Incentive (PLI) scheme. This is part of India’s aim to be self-sufficient and reduce dependence on imports.

According to market research, in 2021 six major Chinese companies – Jinko Solar, Trina Solar, LONGi Solar, JA Solar, Canadian Solar and GCL-SI accounted for nearly 70% of module supplies to India. The top domestic suppliers were Adani Solar, Vikram Solar and Tata Power Solar with a combined market share of just 10-15%. [1]

However, India aims to flip this dynamic and capture 80% of the domestic solar market with local manufacturing by 2026. With PLI incentives and an enabled ecosystem, the market share of domestic companies is projected to expand significantly. Leading Indian firms like ReNew Power and Adani Group are making major investments to ramp up production capacity.

The rise of domestic manufacturing will reduce import dependence, create jobs and support the growth of India’s solar sector. It remains to be seen if domestic companies can match the scale and cost competitiveness of Chinese suppliers, but the long-term outlook is positive.

Challenges

The solar manufacturing industry in India faces several key challenges. One major issue is cost and transmission & distribution (T&D) losses. As per EAI, solar PV is still not as cost competitive as conventional power in India, and T&D losses remain high, reducing the appeal of solar power plants that may be located far from demand centers [1].

Another challenge is lack of research and development (R&D). Enphase notes India lacks modern manufacturing facilities and infrastructure for solar panels, equipment and inverters [2]. This restricts technological development and innovation.

Furthermore, India depends heavily on imported solar equipment per LinkedIn [3]. Boosting domestic manufacturing and reducing imports is an ongoing struggle.

There are also challenges around project costs, land acquisition, grid integration, policy uncertainty and lack of skilled manpower that the solar industry must tackle.

Government Support

The Government of India has implemented various policies and initiatives to boost domestic solar manufacturing in the country. Some of the key government efforts include:

Production Linked Incentive (PLI) Scheme – Launched in April 2021, the scheme aims to add 10,000 MW of integrated solar PV manufacturing plants and provide incentives of Rs 4,500 crores over 5 years (Schemes | Ministry of New and Renewable Energy | India).

Approved Lists of Models and Manufacturers (ALMM) – Introduced in 2022, ALMM makes it mandatory for solar project developers to source modules and cells from approved domestic manufacturers to avail government incentives (Govt plans to register only India-made solar panels under ALMM – RK Singh).

Basic Customs Duty – Import duties on solar cells and modules have been raised to 40% and 25% respectively to encourage local manufacturing and reduce imports.

Other incentives – Subsidized land, power, water supply and exemption from electricity duties provided in Solar Parks. Concessional finance and priority sector lending provided for solar manufacturers.

Future Outlook

India has ambitious solar energy targets, with a goal to reach 100GW of solar capacity by 2022 as part of its commitment to the Paris Climate Agreement. To meet these targets and continue the rapid growth of solar, India will need a strong domestic solar manufacturing industry.

According to a report by Bridge to India, domestic solar cell and module manufacturing capacity is expected to reach around 20-25 GW by 2025. However, India is still reliant on imports for 80% of its solar module demand.

The government aims to implement policies to nurture domestic manufacturing, including the Approved List of Models and Manufacturers (ALMM) and Production Linked Incentives (PLI) scheme. If successful, these measures could enable India to domestically produce over 50 GW of solar equipment by 2030.

Domestic manufacturers will need to focus on technology upgrades, economies of scale, vertically integrated production, and bringing costs down. This could allow Indian companies to compete with cheaper imports. However, manufacturers will still face challenges like inconsistent policy support and financing constraints.

Overall, the outlook for Indian solar manufacturing is optimistic but achieving scale while remaining cost-competitive will be critical. With supportive policies and manufacturing innovations, India is poised to boost domestic production and reduce reliance on imports in the future.

Conclusion

To summarize, India’s solar manufacturing industry has grown rapidly over the past decade, fueled by supportive government policies and falling costs. The largest solar module manufacturer in India is currently Adani Solar, part of the Adani Group conglomerate. With a production capacity of 2 GW per year, Adani has established itself as India’s solar manufacturing leader.

Foreign companies like China’s Longi Solar and Trina Solar have also set up manufacturing bases in India, attracted by India’s market growth and policies supporting domestic manufacturing. Going forward, India is expected to add significant solar capacity to meet its renewable energy goals. Its domestic solar manufacturing industry will play a key role in supplying modules and cells for these projects.

If current growth trends continue, India could become one of the world’s major solar manufacturing hubs in the coming years. However, challenges around financing, infrastructure and competing with cheaper imports remain. With the right policy support and technology improvements, India’s solar manufacturers can establish a strong global presence.