What Transformation Is The Turbine Turning To Make Electricity?

A turbine is a device that harnesses the kinetic energy of a fluid, such as water, steam, combustion gases, or air, and converts that energy into rotational mechanical energy. The rotational mechanical energy generated by the turbine is used to spin a generator shaft and produce electricity.

Turbines are a critical component of power plants that generate electricity. Within a power plant, the turbine extracts energy from pressurized steam and converts it into useful mechanical work. This rotational mechanical energy produced by the turbine is used to spin magnets within an electrical generator. The generator then converts the mechanical rotation into electrical energy that can be transmitted and distributed for residential, commercial, and industrial use.

Mechanical Energy

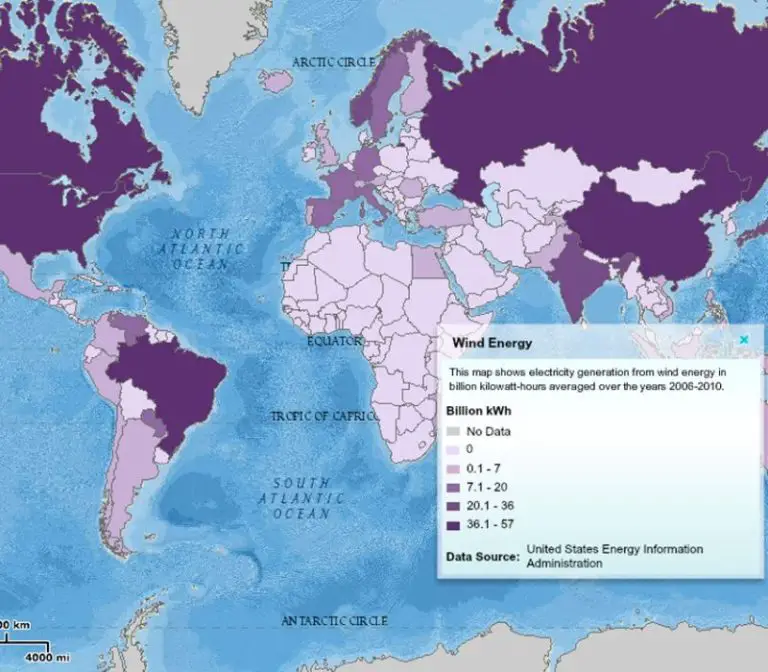

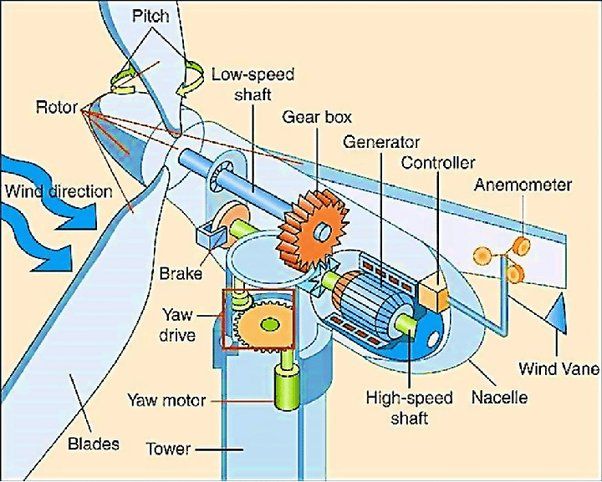

The process of generating electricity in a turbine generator begins with mechanical energy. This is the energy of motion that comes from the kinetic energy of wind, falling water, or pressurized steam. Large wind turbines capture the kinetic energy of wind using their massive blades that rotate as wind blows over them. At hydroelectric dams, the potential energy of water held behind the dam is converted into kinetic energy as water falls down through the penstocks, turning the turbines at high speeds. In coal, gas, nuclear or geothermal power plants, heat is used to convert water into high-pressure steam that rushes against the blades of steam turbines, causing them to spin rapidly.

In each case, the captured mechanical energy from these moving sources results in the rotation of a turbine shaft. The faster the speed of the shaft rotation, the greater the amount of mechanical energy that can be converted into electricity by the generator.

Rotating Shaft

The turbine has many blades mounted on a shaft. When water hits the blades, they capture the kinetic energy of the flowing water and start rotating. This rotational motion spins the shaft that the blades are connected to. So the moving water causes the turbine blades to rotate, which then spins the attached shaft.

The shaft acts as a mechanical linkage between the turbine blades and the generator. It is able to transfer the rotational kinetic energy of the spinning blades into the generator. So the turbine converts the water’s energy into mechanical rotation, and the spinning shaft passes that rotational energy on to the generator.

Electromagnetic Induction

The rotational kinetic energy generated by the spinning turbine blades is transferred to the generator shaft, causing it to spin. Inside the generator are coils of conductive wire surrounded by magnets. As the shaft spins the coils of wire, they rotate through the magnetic field, inducing a flow of electrons in the wire. This process is known as electromagnetic induction.

According to Faraday’s law of induction, when a conductor moves relative to a magnetic field, it causes electrons in the conductor to move, generating an electromotive force (EMF). The faster the conductor cuts through the magnetic field lines, the greater the induced EMF. Therefore, the high-speed rotation of the turbine shaft and wire coils creates a strong EMF – an alternating current of electricity.

Electricity Generation

The rotational kinetic energy of the turbine shaft is converted into electrical energy inside the generator. The generator contains magnets and conductors (usually copper wire coils). As the turbine spins the shaft, it rotates the magnets around a stationary set of conductors. This motion of the magnets around the conductors induces a current flow in the conductors. This is called electromagnetic induction. The induced current flows through the conductors and electricity is generated. The faster the rotational speed, the greater the motion between the magnets and conductors, which creates larger voltage and current to generate more electricity. Therefore, the rotational mechanical energy is transformed into electrical energy inside the generator.

Step-Up Transformer

The electricity generated by the turbine starts out at a low voltage level. Before it can be efficiently transmitted long distances over the electrical grid, the voltage must be stepped up to a much higher level using a device called a step-up transformer. Essentially, a transformer consists of two coils of wire separated by an iron core. When AC from the generator passes through the first coil, it creates a magnetic field in the core which induces a current in the second coil. By carefully selecting the number of turns in each coil, the transformer can increase (or step up) the voltage in the second coil to whatever level is desired. Typical generators may output electricity around 25,000 volts. After passing through the step-up transformer, this voltage could be increased to as high as 500,000 volts for long distance transmission over high voltage power lines. Without this essential step-up, transmitting electricity over long distances would be highly inefficient due to resistive losses in the wires. The step-up transformer enables practical, efficient power transmission over hundreds of miles.

Transmission Lines

After the electricity is stepped up to high voltage levels by the transformer, it must be transported long distances to substations near populated areas. This is done via overhead transmission lines. Transmission lines consist of aluminum conductors strung between tall steel lattice towers. Aluminum is used because it is an affordable conductor that is both lightweight and corrosion resistant.

The spacing between the conductors and the height of the towers are designed to ensure adequate insulation and avoid short circuits. Higher voltages allow for more efficient long-distance transmission with lower line losses. Therefore, transmission voltages are typically 115 kV or higher. The high voltage enables the current to be transmitted at lower currents, which reduces resistive heating losses in the conductors. This allows the power to be transmitted over hundreds of miles to reach load centers.

Step-Down Transformer

After the electricity has traveled through the transmission lines over long distances, the voltage must be reduced again for safe distribution to homes, businesses, and other end users. Step-down transformers are used for this final reduction in electricity voltage before delivery. The incoming transmission lines bring the electricity to the step-down transformer at very high voltages of 155,000 to 765,000 volts. The transformer then converts it to a lower voltage between 120 to 25,000 volts that is safer for distribution.

Step-down transformers work on the same principles of electromagnetic induction as step-up transformers, just in reverse. The number of turns in the coils helps determine the change in voltage. By having fewer turns of wire in the secondary coils than the primary coils, the voltage is stepped down to a lower level before being sent to the distribution lines.

This final voltage reduction makes the electricity safe for consumer use and prevents hazards from such high voltages. After the step-down transformer lowers the voltage, the distribution lines can safely and efficiently deliver the electricity to homes, businesses, factories and anywhere else it is needed.

Distribution

Once the electricity has been stepped down to a lower voltage by the step-down transformer, it enters the distribution system. This system of overhead lines and underground cables brings the electricity to homes, businesses, and other end users in the utility’s service area.

The distribution lines, also called “feeders,” branch out from the substation and distribute power to different neighborhoods and communities. Distribution lines carry voltages ranging from 4kV to 33kV, depending on the distance and number of customers served.

For residential customers, the distribution lines connect to the service drop, which brings power from the nearest utility pole to the home. The service drop attaches to the meter, which records how much electricity the home uses. Past the meter, another set of wires brings the electricity into the home’s breaker box, where it can then be distributed to outlets and appliances.

Large commercial and industrial customers often take electricity delivery at higher voltages between 2.4kV and 35kV. The electricity is stepped down at a transformer near the facility before entering the building.

Distribution systems include components like switches, fuses, lightning arrestors, capacitor banks, and voltage regulators to control and regulate the electricity flow. Monitoring and control devices report data back to the utility to help balance loads and isolate issues.

Conclusion

Electricity generation through turbine systems is an important process that makes modern life possible. The transformation of mechanical rotational energy into electrical energy via electromagnetic induction allows turbines to convert the kinetic energy of wind, water, steam, or combustion into usable electricity. This electricity powers homes, businesses, industries, and infrastructure across the world.

Understanding how a generator turbine works provides insight into how one of the most essential utilities is created. The spinning turbine shaft is able to induce a magnetic field in surrounding coils, generating an AC electric current. This current is then transformed to higher and lower voltages as needed for efficient transmission and distribution. Turbine generators harness natural forces or heat to sustain reliable electricity production.

In summary, the turbine generator allows the transformation of mechanical rotation into widespread electrical power. This technology is critical for supplying electricity safely and effectively to the modern world.