What Materials Are Needed For Solar Energy?

Solar energy is an increasingly important renewable energy source that harnesses the sun’s rays to generate electricity and heat. The key materials needed for solar energy technologies are photovoltaic cells, which convert sunlight directly into electricity, as well as components like glass, metal framing, wiring, and polymers for concentrating solar thermal plants.

This article will provide an overview of the most common materials used in key solar energy technologies today. We’ll look at the silicon, thin films, and organic materials that make up photovoltaic cells, as well as the mirrors, lenses, and heat transfer fluids used in concentrated solar plants. Understanding the core materials involved in solar energy systems is important for evaluating their effectiveness and environmental impact.

Silicon

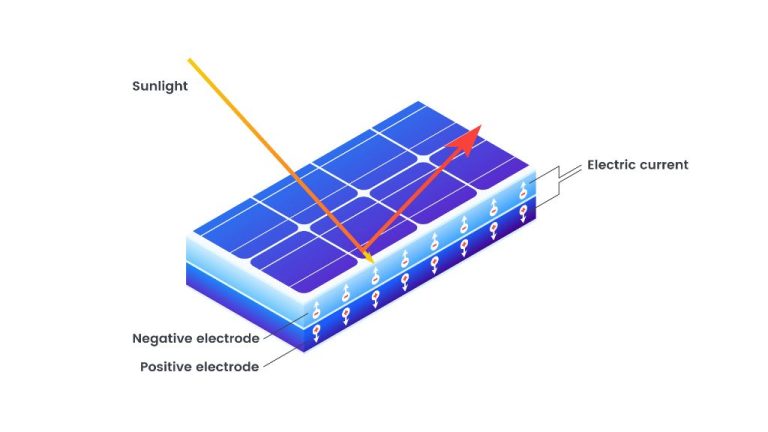

Silicon is the dominant material used for solar cells due to its abundance, non-toxicity, and excellent photovoltaic properties. Silicon is a semiconductor, which means it can conduct electricity under some conditions but act as an insulator under others. When sunlight hits the silicon cell, the photons knock electrons free from the silicon atoms, creating electron-hole pairs that generate an electric current (Solar Photovoltaic Cell Basics, n.d.).

The atomic structure and purity of silicon make it well-suited for absorbing photons and converting them into electricity. Silicon has an indirect band gap of 1.12 eV, which allows it to absorb photons across a wide energy spectrum. It also has a long minority carrier lifetime, meaning the electron-hole pairs can be separated and collected efficiently before recombining. High purity silicon with few impurities and defects is crucial for optimal solar cell performance.

The most common silicon solar cells use either monocrystalline or polycrystalline fabrication methods. Monocrystalline cells are made from cylindrical ingots of single-crystal silicon, sliced into wafers (Wikipedia, n.d.). These have the highest efficiencies but are more expensive. Polycrystalline cells are made by pouring molten silicon into a mold to form a block, which is then cut into square wafers. They are cheaper but less efficient due to more impurities and crystal boundaries.

Cadmium Telluride

Cadmium telluride (CdTe) is a thin-film photovoltaic technology that uses cadmium telluride as the light-absorbing material. CdTe solar cells have emerged as a leading thin film technology, with high conversion efficiencies and competitive manufacturing costs. Some key advantages of CdTe solar cells compared to traditional silicon cells include1:

- High sunlight absorption – CdTe absorbs light strongly, allowing it to use a very thin layer (about 1-2 microns thick) compared to silicon (150-200 microns). This reduces material usage and cost.

- Bandgap tuning – The CdTe bandgap can be tuned to be near-optimal for absorbing sunlight.

- High efficiency – CdTe solar cell efficiency has increased from 10% to over 22% in the last few decades.

- Low temperature processing – CdTe films can be deposited at low temperature (<400°C) versus silicon (>1000°C), reducing energy consumption.

The main disadvantages of CdTe compared to silicon include the toxicity of cadmium andTelluride being a rarer material. However, recycling methods for CdTe modules are being developed to mitigate environmental concerns. Overall, CdTe’s high performance, low cost, and rapid improvements make it a promising solar technology.

Copper Indium Gallium Selenide

Copper indium gallium selenide (CIGS) is a thin-film solar cell material composed of copper, indium, gallium, and selenium. CIGS has emerged as one of the most promising thin-film photovoltaic technologies due to its high absorption coefficient and adjustable bandgap energy (NREL).

Some key properties and applications of CIGS solar cells include:

- High efficiency – CIGS cells can reach up to 23.35% efficiency in lab tests, comparable to multicrystalline silicon cells (Wikipedia).

- Thin, lightweight, and flexible – CIGS absorber layers are only 1-2 microns thick, allowing lightweight and flexible module designs (Solar Magazine).

- Low toxicity – CIGS does not contain cadmium like some thin film technologies, reducing environmental and health concerns (NREL).

- Low temperature deposition – CIGS films can be deposited at low temperatures, enabling use of flexible polymer substrates (Wikipedia).

- Low cost manufacturing – CIGS cells can be produced with high throughput roll-to-roll processes, reducing costs (NREL).

With its exceptional efficiency potential and flexible form factor, CIGS is well-suited for building-integrated photovoltaics and portable/off-grid applications requiring lightweight, high-performance solar cells (Solar Magazine). Major manufacturers of CIGS modules include Solar Frontier, AVANCIS, and MiaSolé.

Organic Photovoltaics

Organic photovoltaic (OPV) solar cells use organic electronics, made of organic polymers like plastics and dyes, to absorb sunlight and convert it into electricity. Unlike traditional silicon solar cells, OPVs can be made using low-cost, high volume manufacturing techniques like roll-to-roll printing, allowing flexible and lightweight solar panels to be produced https://www.energy.gov/eere/solar/organic-photovoltaics-research. OPVs utilize the photoelectric effect to generate current when exposed to sunlight. The active layer is made of two materials – an electron donor and electron acceptor. When sunlight hits the active layer, the donor material absorbs photons and releases electrons which migrate to the acceptor material, generating an electric current. OPVs are thin, lightweight and can be made semi-transparent, offering unique advantages over rigid silicon panels. Their flexible nature allows OPVs to be integrated into curved surfaces and fabric. However, OPV efficiency tends to be lower than inorganic cells and degradation can occur over time.

Perovskites

Perovskites are a promising new material for solar cell technology. Some key advantages of perovskite solar cells include:

- High power conversion efficiencies – lab cells have reached over 25%, rivaling traditional silicon solar cells [1].

- Low production costs – perovskite films can be produced with inexpensive materials and simple techniques like spray coating or inkjet printing [2].

- Flexibility – perovskite solar cells can be made flexible and lightweight, broadening potential applications.

- Tunable bandgap – the perovskite crystal structure makes it relatively easy to engineer the bandgap by modifying the composition.

While perovskite solar cells are very promising, there are still challenges to overcome before widespread commercialization, such as improving stability and scaling up manufacturing. Overall, perovskites represent an exciting emerging photovoltaic technology.

Glass

Glass is an essential component of most solar panels. It serves as the protective front layer that allows sunlight to pass through to the solar cells underneath (Onyx Solar). Glass needs to have high light transmittance properties for use in solar panels. Most solar panels use either tempered glass or extra clear low-iron glass. Tempered glass is valued for its strength and durability. Extra clear low-iron glass maximizes light transmission by minimizing iron impurities that can absorb and reflect light (Pilkington). The optimal glass for solar panels has over 91% transmittance across the solar spectrum.

Solar glass needs to withstand weathering and potential impacts over decades outdoors. It must also withstand heating to high temperatures during manufacturing. The glass surface is textured to help minimize reflection. Special coatings are sometimes applied to further improve light capture. While glass accounts for a significant portion of a solar panel’s weight, its optical clarity and protective abilities make it an indispensable component.

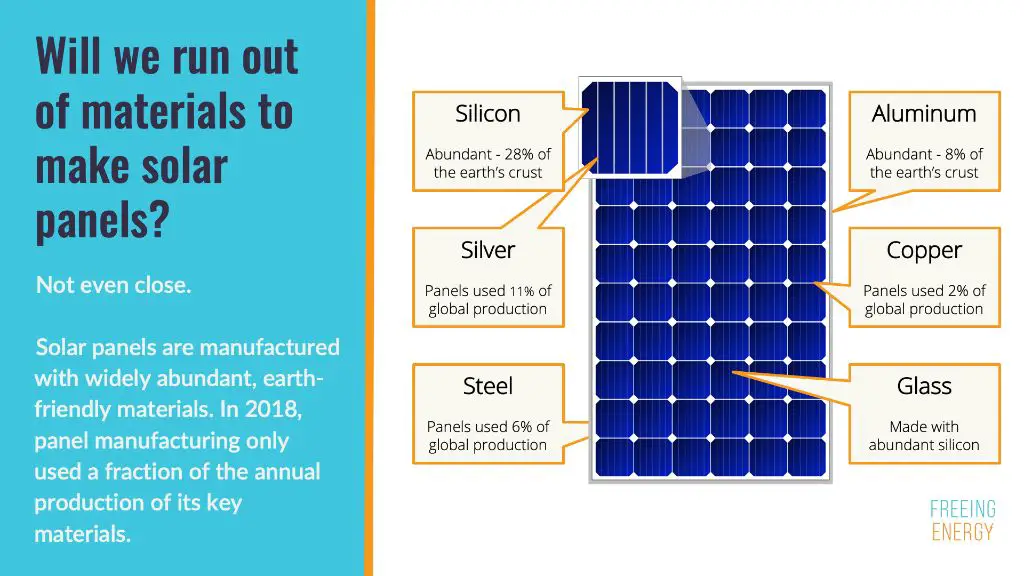

Aluminum

Aluminum is commonly used for solar panel frames and mounting systems due to its corrosion resistance, durability, and lightweight properties (https://www.aluminum.org/aluminum-key-material-renewable-energy). The metal is ideal for withstanding outdoor exposure and providing structural support without adding excessive weight to rooftop solar arrays. Aluminum framing helps protect the inner components while allowing for secure installation.

Solar panel manufacturers frequently choose aluminum for its strength, flexibility, and conductivity. Extruded aluminum rails and clamps secure and orient panels on both flat and pitched roofs (https://www.amazon.com/Aluminum-Solar-Panels/s?k=Aluminum+Solar+Panels). Adjustable mounting systems made of aluminum alloys allow for site-specific installation and maximum energy production.

Overall, aluminum plays a key role in photovoltaic module framing and racking for its corrosion resistance, strength, workability, and cost-effectiveness.

Polymers

Certain polymers are often used in solar cells for encapsulation and backing material. Polymers provide a lightweight and flexible option compared to glass. Some common polymers used include ethylene-vinyl acetate (EVA), polydimethylsiloxane (PDMS), polyvinyl butyral (PVB), polyethylene terephthalate (PET), and polyvinyl chloride (PVC) (https://www.sciencedirect.com/topics/materials-science/polymer-solar-cell).

PET is one of the most widely used polymer films for solar cell encapsulation. It offers good transparency, insulation, flexibility, and weather resistance. EVA is another popular encapsulant due to its adhesive properties, transparency, and low cost. PDMS is opted for its optical transparency down to 230 nm and flexibility. PVB and PVC are also utilized as encapsulation layers in certain types of solar cells.

The polymer materials provide protection from environmental factors like moisture, weathering, and mechanical stress. They help prevent delamination and maintain the solar cell efficiency over time. Proper encapsulation is critical for the reliability and lifespan of solar panels (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC6401826/).

Conclusion

To summarize, the key materials used in solar photovoltaic cells today include silicon, cadmium telluride, copper indium gallium selenide, organics, and perovskites. Each material has its own unique properties and advantages that make it suitable for capturing energy from sunlight and converting it into electricity.

Silicon is the most common material used in solar panels today, but newer materials like perovskites show promise for even higher efficiencies in the future. Continued innovation in materials science will be crucial for further driving down costs and improving the performance of solar technology.

The development of more efficient and affordable solar photovoltaic materials has the potential to greatly accelerate the transition to renewable energy. Solar energy offers a clean, sustainable power source that can help mitigate climate change. With the right materials, solar may one day become the world’s predominant electricity source.