What Is Wind Power Classified?

Types of Wind Turbines

There are two main types of wind turbines classified by the orientation of their axis of rotation – horizontal axis wind turbines (HAWT) and vertical axis wind turbines (VAWT).

Horizontal axis wind turbines have a main rotor shaft and electrical generator mounted at the top of a tower, with the rotor blades facing into the wind. The shaft is parallel to the ground. Nearly all utility-scale wind turbines today are HAWTs. HAWTs have higher efficiency than VAWTs, can produce more rotation energy at peak efficiency, and operate optimally when pointed into the wind. There are two types of HAWTs:

- Upwind turbines – The rotor faces the wind upstream. They do not experience turbulence from the tower interference.

- Downwind turbines – The rotor is on the downstream side, facing away from the wind. They experience turbulence created by the tower.

Vertical axis wind turbines have the main rotor shaft arranged vertically and the generator located at the base of the tower. There are two types of VAWTs:

- Darrieus turbines – Shaped like an eggbeater with airfoils as the blades. The rotation of the blades is due to lift.

- Savonius turbines – S-shaped and drag-type with scooped blades. Rotation results from the difference in drag force on each side.

VAWTs operate independently of wind direction, have lower efficiency than HAWTs, and are better suited for small-scale applications.

Wind Turbine Components

Wind turbines are made up of many important components that all work together to convert wind energy into electricity. The main components include:

Blades

The blades are the large fins that catch the wind. Most modern wind turbines have three blades, though some have two or one. The blades are made of composite materials like fiberglass reinforced plastic. Their aerodynamic shape helps maximize energy capture.

Rotor

The rotor is formed by the blades and hub together. It spins when the wind blows over the blades. The rotational speed is controlled for optimal energy production.

Nacelle

The nacelle sits atop the tower and contains the key electrical components like the generator, gearbox, controller, and brake. It is designed to be weatherproof and protect the inside components.

Tower

The tower supports the nacelle and rotor high up where wind speeds are greater. Towers are made of steel or concrete and can be over 300 feet (100 meters) tall for large turbines.

Foundation

The foundation anchors the wind turbine system firmly to the ground. Foundations vary based on location, but commonly include concrete slabs or piers dug deep into the earth.

Wind Turbine Sizes

Wind turbines come in a variety of sizes depending on their intended application and power output. Generally, wind turbines are classified into the following size categories:

Small Wind Turbines

Small wind turbines, sometimes called micro or mini turbines, produce up to 100 kW of power. They typically have rotor diameters of 6-20 meters and stand up to 30 meters tall. Small turbines are well suited for residential, farm, and small business applications.

Medium Wind Turbines

Medium wind turbines produce 100 kW to 1 MW of power. They generally have rotor diameters of 20-60 meters and tower heights around 40-80 meters. Medium turbines work well for business, institutions, and industrial applications.

Large Wind Turbines

Large wind turbines generate 1-3 MW of power. They have rotor diameters of 70-130 meters and tower heights up to 140 meters. Large turbines are ideal for wind power plants and wind farms.

Utility-Scale Wind Turbines

Utility-scale wind turbines are massive in size, producing over 3 MW of power each. Their rotor diameters exceed 130 meters and their towers reach heights over 140 meters. Utility-scale turbines are designed for large wind farms to feed into the grid.

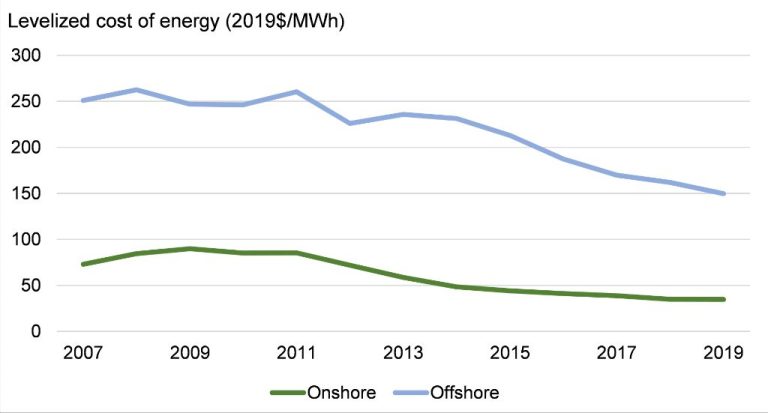

Onshore vs Offshore

Wind turbines can be broadly classified as either onshore (land-based) or offshore (ocean or lake-based). Each has its own advantages and disadvantages.

Onshore wind farms are located on land, usually in rural or agricultural areas. They are cheaper and easier to construct, transport, and maintain compared to offshore wind. However, there are fewer suitable onshore sites available, and residents sometimes oppose construction of onshore wind farms due to concerns over noise pollution and impact on views.

Offshore wind farms are built in bodies of water, usually in coastal regions. They benefit from stronger and more consistent winds, allowing them to generate more electricity. However, offshore wind turbines are much more expensive to build and maintain due to the complex logistics of transporting and installing equipment at sea. Corrosion from seawater also poses engineering challenges.

Overall, onshore wind is currently more mature and cost-effective, representing the bulk of installed wind power globally. But offshore wind holds great potential, especially as costs continue to fall. Both onshore and offshore wind will play important roles in the ongoing transition to renewable energy.

Distributed vs Centralized

Wind power systems come in two main configurations – distributed and centralized. Distributed systems consist of smaller wind turbines that are installed across many sites, such as homes, farms or small businesses. Centralized systems consist of large wind farms made up of dozens or even hundreds of utility-scale wind turbines.

Distributed wind turbines are usually smaller, under 100 kW in size. They can be installed on the property of homeowners, businesses, schools, and other facilities to provide electricity on-site. Excess power can be sold back to the grid. Distributed turbines provide a local source of clean energy and reduce reliance on the grid. However, they produce less total power than large wind farms.

Centralized wind farms consist of many large, utility-scale wind turbines, usually over 1 MW in size each. These massive turbines are clustered together in optimal windy locations to maximize energy production. The electricity feeds into transmission lines that carry the power over long distances to where it will be used. Wind farms can harness stronger, steadier winds and generate much greater total power output. However, long transmission is required to get the electricity to end users.

In summary, distributed systems allow localized, on-site wind power generation while centralized wind farms maximize total energy output. An integrated approach using both configurations is likely needed to fully transition our energy system to renewable sources.

Grid-connected vs Off-grid

Wind turbines can be classified as either grid-connected systems or off-grid systems. Grid-connected wind turbines are connected to the main electricity grid to feed electricity into the grid. Off-grid wind turbines are not connected to the main grid and are used in isolated locations to provide electricity locally.

Grid-connected wind turbines are the most common type. They operate in conjunction with the main grid, feeding electricity into the grid. The grid acts as a battery, storing electricity when the wind turbines produce excess power and supplying power when the wind turbines cannot meet demand. Grid-connected turbines require less storage capacity and are more cost-effective overall.

Off-grid wind turbines operate independently of the main electricity grid. They are installed in remote locations where connection to the grid is not possible or cost-effective. The electricity generated is used locally or stored in batteries. Off-grid systems require storage capacity to handle variability in wind. They are more complex and costly to operate than grid-connected systems. Off-grid turbines are useful for remote power needs, but have limitations in storage and transmission of excess power.

In summary, grid-connected wind turbines integrate wind power into the main grid whereas off-grid turbines operate independently to serve isolated loads. The type of application and location determines whether grid-connection or off-grid operation is most suitable.

Fixed Speed vs Variable Speed

Wind turbines can be classified as either fixed speed or variable speed designs. Older wind turbines typically used a fixed speed design. In a fixed speed wind turbine, the rotor spins at a constant speed regardless of the wind speed. The rotational speed is determined by the frequency of the grid power so that it rotates in sync with the grid AC frequency.

Fixed speed wind turbines have several downsides. They cannot optimize energy capture in fluctuating wind conditions. The constant spinning of the rotor also creates instability and mechanical stress on the turbine. Lastly, fixed speed turbines require reactive power compensation equipment to help stabilize grid integration.

Newer wind turbines use a variable speed design to overcome the limitations of fixed speed turbines. Variable speed turbines allow the rotor to speed up or slow down based on changing wind speeds. This maximizes energy capture from the wind across a range of wind speeds. Variable speed operation also reduces mechanical stress and noise. Power electronics convert the variable frequency power from the generator into fixed frequency power that can be synced to the grid.

Overall, variable speed wind turbines are technologically superior and more efficient than older fixed speed turbines. That’s why modern utility-scale wind farms overwhelmingly use variable speed turbines.

Wind Power Ratings

When assessing the potential electricity generation from a wind farm or turbine, there are a few key power ratings to consider:

Nameplate Capacity

This refers to the maximum rated output of a turbine or wind farm under optimal wind speed conditions. For example, a 2 MW turbine has a nameplate capacity of 2 megawatts (MW). Nameplate capacity represents the upper limit of potential generation.

Capacity Factor

The capacity factor represents the average power generated over a period of time divided by the nameplate capacity. Wind turbines typically have a capacity factor between 25-50%. This means a 2 MW turbine with a 35% capacity factor would produce an average of 0.7 MW (2 MW * 0.35) over a year.

Actual Output

The actual output is the real amount of electricity generated over a period of time, measured in megawatt-hours (MWh). This depends on the turbine’s nameplate capacity, capacity factor, and the number of hours in the period. The actual output provides the clearest sense of how much electricity a turbine or wind farm contributes to the grid over time.

Understanding nameplate capacity, capacity factor, and actual output is important for estimating and evaluating the potential power production from wind energy projects.

Environmental Impact

Wind power can have both positive and negative effects on the environment. Some of the main environmental concerns related to wind turbines include:

Avian Mortality

Birds and bats can be killed by collisions with wind turbines. However, compared to other human-related causes of avian mortality, wind turbines account for a relatively small percentage. Proper placement and design of wind farms can help minimize bird and bat impacts.

Noise Pollution

The mechanical noise from wind turbine blades can negatively impact people living close by. Advances in blade design and insulation around turbines have helped reduce noise. Turbines are often set back at adequate distances from homes to help mitigate noise.

Visual Pollution

Some people find wind turbines visually unappealing and feel they detract from natural landscapes. Opinions vary greatly on this topic. Proper siting can help reduce visual impacts. Offshore wind farms installed far from shore also minimize visual pollution.

Land Use

Wind farms require large areas of land. The actual footprint is relatively small but there must be sufficient spacing between turbines. This can compete with other land uses. However, wind turbines can often coexist with agriculture. With proper planning, land use impacts can be minimized.

Economic Considerations

The economics of wind power must be carefully evaluated when considering it as an energy source. There are several key economic factors to analyze:

Capital Costs

The upfront costs of constructing a wind farm are significant. These include expenses such as permitting, turbines, towers, land acquisition, roads, grid connections, and more. Installing just one utility-scale wind turbine can cost over $3 million.

Operating Costs

Once built, a wind farm has ongoing operation and maintenance costs. These include repairs, insurance, spare parts, staffing, and regular maintenance. Operating costs are much lower than for fossil fuel plants.

Cost Per kWh

A key metric is the levelized cost of energy (LCOE) per kilowatt-hour for wind power. This factors in all costs over the system’s lifetime. The U.S. Department of Energy reported an average LCOE of $37/MWh for wind in 2019.

Incentives

Government incentives like production tax credits have helped make wind energy more affordable in the U.S. These incentives bring down the cost per kWh produced. However, wind remains competitive even without subsidies in some cases.