What Is The Most Effective Hydro Turbine?

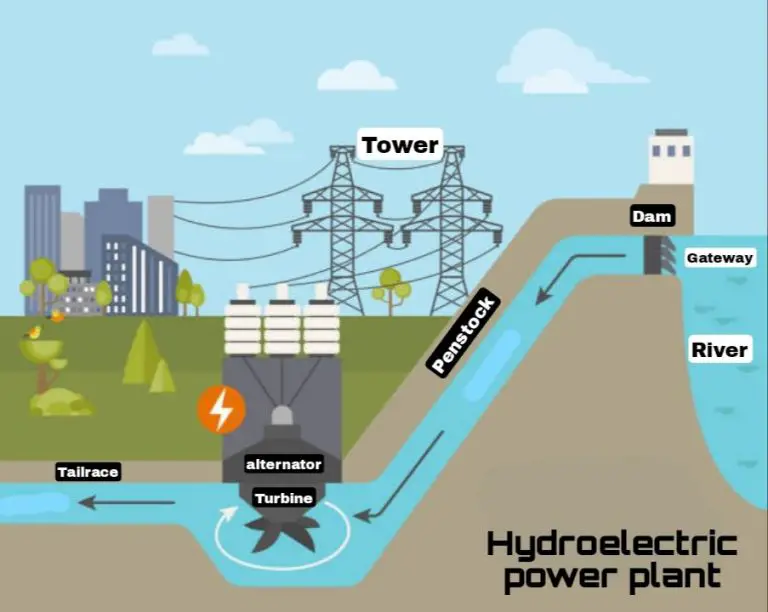

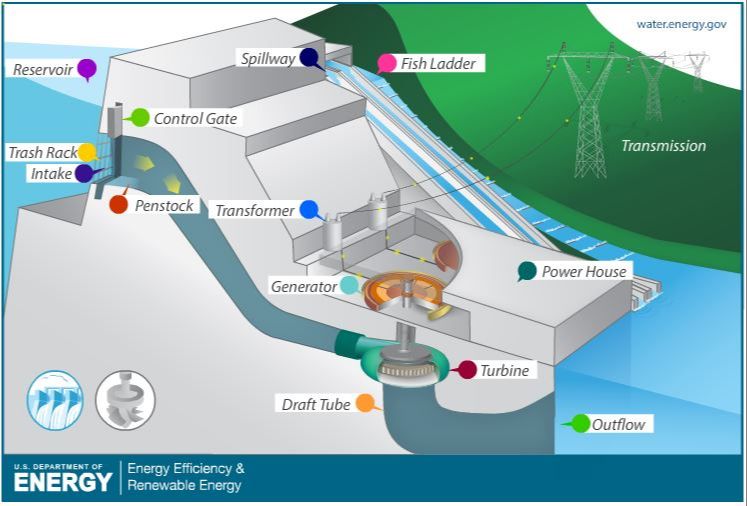

Hydro turbines are machines that convert the kinetic energy from flowing water into mechanical energy. This mechanical energy then turns a generator to produce electricity. Hydro turbines are a crucial component of hydroelectric dams and allow us to harness the power of moving water to generate renewable electricity.

When determining the most effective hydro turbine, there are a few key criteria to consider: efficiency, cost, output capacity, maintenance requirements, lifespan, and environmental impact. The most effective hydro turbine will maximize power output while minimizing long-term costs and environmental harm. This article will provide an overview of different types of hydro turbines and evaluate their advantages and disadvantages across these key criteria to determine the most effective option overall.

Types of Hydro Turbines

There are two main types of hydro turbines: impulse and reaction turbines.

Impulse turbines, like Pelton wheels, use the velocity of water to move the runner and discharges to atmospheric pressure. The water stream hits each bucket on the runner. There is no suction created, and no pressure drop as water moves through the turbine. The water’s velocity, rather than its weight or pressure, powers the rotor (turbine wheel).

Reaction turbines, like Francis and Kaplan, create power using the combined action of pressure and moving water. The runner has to be enclosed e.g. in a pressure casing. Reaction turbines develop power from the combined action of pressure and moving water. The pressure drop and the kinetic energy of the liquid both contribute to the turbine’s power. Water pressure decreases as the water moves through the turbine blades. These turbines are suitable for high flow, low head applications.

The main types of hydro turbines include:

- Pelton wheel (impulse) – Used for high heads of water and low flow rates. Consists of a wheel with split buckets mounted around the circumference.

- Francis turbine (reaction) – Most commonly used for hydroelectric power generation. Used for medium heads of water and medium flow rates.

- Kaplan turbine (reaction) – Propeller-like blades that move as the water flow direction changes. Used for relatively low heads and high flow rates.

Sources:

https://www.energy.gov/eere/water/types-hydropower-turbines

Efficiency

The efficiency of a hydro turbine is a measure of how much of the water’s potential energy is converted into electricity. It is a ratio of the power output of the turbine compared to the energy available in the water flow. Efficiency is calculated using the following formula:

Efficiency (%) = (Power Output of Turbine / Total Energy in Water Flow) x 100

The theoretical maximum efficiency of a hydro turbine is about 90%. However, real-world efficiencies are lower, typically 60-90% for modern turbines. The exact efficiency depends on factors like turbine design, size, head height, and flow rate.

The major turbine types have differing efficiency ranges:1

- Pelton turbine: 80-90% efficiency

- Francis turbine: 80-90% efficiency

- Kaplan turbine: 60-80% efficiency

- Crossflow turbine: 60-80% efficiency

Pelton and Francis turbines can achieve the highest efficiencies. Kaplan turbines have good part-load efficiencies while operating over a wide range of heads. Crossflow turbines work for low heads and have a simple design, but lower peak efficiencies. Overall, choosing the right turbine type for the site conditions is key for maximizing efficiency.

Cost

The cost of hydro turbines can vary significantly depending on the type, size, and specific model. According to Micro Hydro Power, a 1KW hydro turbine itself can range from $1,000 to $5,000. The generator adds another $1,000 to $3,000, the control system $500 to $2,000, and electrical equipment like wiring and breakers around $500 more.

Larger utility-scale hydro turbines and generators for megawatt-scale projects can cost millions of dollars each. A 2012 report from IRENA on hydropower costs found the average equipment cost for a large hydro project was around $1,300/kW of capacity. So a 100 MW project would have turbine/generator equipment costs around $130 million (IRENA).

In terms of operating costs, hydro turbines have relatively low maintenance expenses since they contain few moving parts and operate efficiently. But periodic overhauls are needed, which incur labor and parts costs. Unplanned repairs can also arise. The fixed annual O&M costs for hydropower plants average around 2-3% of initial investment per year.

Overall, large turbines like Francis and Kaplan designs have high upfront costs but very low operating expenses. Smaller turbines like Pelton wheels are more affordable to purchase initially, but have higher maintenance costs per unit of energy produced.

Output Capacity

The output capacity of hydro turbines refers to the amount of power they can generate. This depends on several factors like the head (height difference between intake and outflow), flow rate, and turbine efficiency. Some key output capacity comparisons between turbine types:

Francis turbines have high output capacities between 10 MW to 1000 MW. They operate most efficiently under high head conditions of over 30 meters. As per a report by Sritram et. al (1), Francis turbines can achieve over 90% efficiency in converting hydraulic power to electric power.

Kaplan turbines have lower output capacities between 1 MW to 100 MW. They are well-suited for low head sites below 30 meters. Kaplan turbines can also achieve over 90% efficiency under optimal conditions (1).

Crossflow turbines have small output capacities between 5 kW to 10 MW. They operate efficiently under low head conditions. Crossflow turbine efficiency can reach about 80% in ideal settings (1).

In summary, Francis turbines have the highest output capacity, followed by Kaplan and Crossflow turbines which are better suited for small hydro sites. Efficiency potential is over 90% for Francis and Kaplan, and around 80% for Crossflow under optimal conditions.

Maintenance

The three main types of hydro turbines – Francis, Kaplan, and Pelton – have different maintenance requirements. Francis and Kaplan turbines, which are reaction turbines, tend to have lower maintenance costs compared to Pelton turbines, which are impulse turbines (Kumar, 2022).

Francis turbines need regular maintenance of their runner blades and wicket gates to prevent cavitation damage. The maintenance costs for Francis turbines are estimated around $2.7 million per MW per year. Kaplan turbines require similar maintenance of the runner blades and wicket gates. They also need regular checks of the turbine shaft alignment to prevent vibration issues. Overall, the maintenance costs of Kaplan turbines are comparable to Francis turbines.

In contrast, Pelton turbines require more extensive maintenance due to the complex nozzle and bucket design. The buckets are prone to erosion damage and need replacement every 5-10 years. The nozzles also need cleaning and parts replacement to maintain optimal efficiency. As a result, the maintenance costs of Pelton turbines can be almost double that of Francis and Kaplan turbines.

When selecting a turbine, ease of maintenance and access to critical components should be considered along with efficiency and output capacity. Reaction turbines like Francis and Kaplan present some advantages in maintenance needs over impulse turbines like Pelton.

Lifespan

The lifespan of a hydro turbine can vary significantly depending on the type. Pelton wheel turbines tend to have the longest lifespan, often operating efficiently for 50-100 years with proper maintenance. According to the National Renewable Energy Laboratory, the average lifespan of a hydropower facility is around 100 years.[1] In contrast, Kaplan turbines generally have a shorter lifespan of around 30-50 years.[2]

Pelton wheel turbines are highly durable due to their simple design with only one moving part – the rotor. They operate at low speeds with less mechanical stress. Kaplan turbines have more complex designs with propeller-like blades that undergo more stress over decades of operation. Eventually, cavitation and fatigue can damage the blades.[3]

Overall, well-maintained Pelton turbines offer the greatest lifespan and durability of hydropower turbine designs. Their longevity offsets generally higher upfront costs compared to other turbines like Kaplan. With routine part replacement and maintenance, Pelton turbines can continue generating renewable power for communities over many generations.

[1] Wind & Hydropower Technologies Program. National Renewable Energy Lab. https://www.nrel.gov/docs/fy04osti/34916.pdf

[2] How long do hydropower installations last? Renewables First. https://renewablesfirst.co.uk/renewable-energy-technologies/hydropower/hydropower-learning-centreold/how-long-will-hydropower-systems-last/

[3] Reaction Turbines. The British Hydropower Association. https://www.british-hydro.org/reaction-turbines/

Environmental Impact

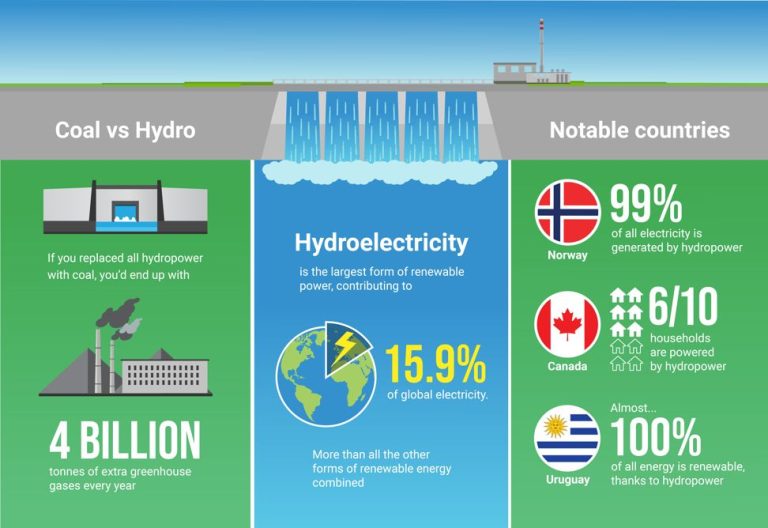

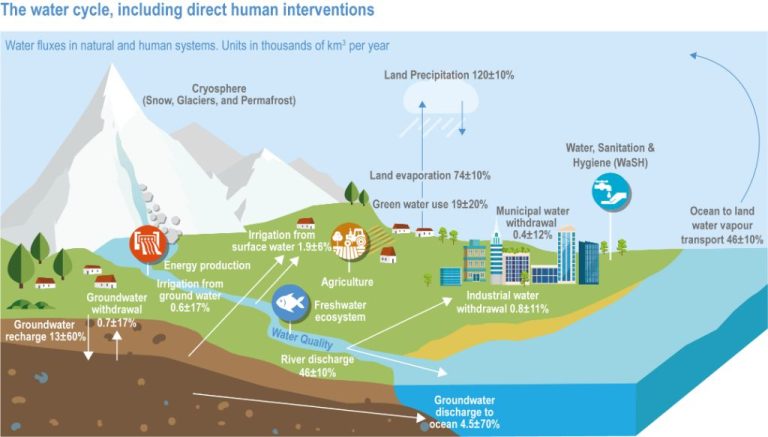

Hydroelectric power has impacts on the environment that must be carefully considered. Building dams and reservoirs for hydropower projects significantly alters the local environment and ecosystems.

Flooding land to create a reservoir destroys forests, wildlife habitats, agricultural land, and scenic lands. It also displaces people and communities. According to the Union of Concerned Scientists, a reservoir may cover “tens to hundreds of square miles of land.”

Hydropower turbines can also injure or kill fish and other aquatic life that pass through them. The turbines fragment fish habitats and act as barriers to fish migration routes, impacting the ability of fish to spawn. However, technology advancements and collaborative efforts aim to create more “fish-friendly” turbines. For example, the U.S. Department of Energy supports research into turbines that allow for safer downstream passage of fish.

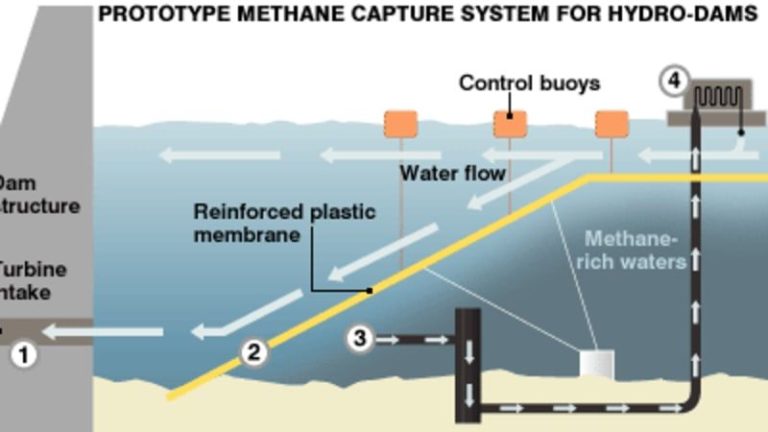

Hydropower itself does not directly produce air pollution or greenhouse gas emissions. However, the flooding of vegetation during reservoir creation results in decomposition that may emit methane, a potent greenhouse gas. Proper planning in reservoir location and management aims to reduce methane emissions.

Case Studies

The Itaipu Hydroelectric Dam on the Parana River bordering Brazil and Paraguay is one of the largest hydroelectric facilities in the world with an installed capacity of 14,000 megawatts (MW) (Itaipu Hydroelectric Dam). Its 20 generating units produce over 90 million megawatt-hours per year, providing around 17% of Brazil’s and 75% of Paraguay’s electricity consumption. The Itaipu project utilized Francis turbines designed for the site’s specific hydraulic conditions to maximize efficiency.

The Three Gorges Dam in China is the world’s largest hydroelectric power station, with 34 Francis turbine-generator units totaling 22,500 MW installed capacity (The 10 biggest hydroelectric power plants in the world). It produces over 80 TWh annually. The enormous scale and variations in water flow required custom-designed turbines to operate efficiently across a wide range of conditions.

An ecological case study by Quaranta et al. examined low-head turbines optimized for minimal environmental impact, including a custom Vortex turbine, Hydrostatic Pressure Machine, and Very Low Head (VLH) turbine (Hydropower Case Study Collection: Innovative Low Head). These novel designs targeted high efficiency at heads under 2 meters and low rotational speeds to allow fish passage, protecting biodiversity in small streams.

Most Effective Overall

After analyzing the pros and cons of various hydro turbine types, the most effective hydro turbine overall is the Scott Hydro 1500W Water Turbine. This turbine offers a number of advantages that make it stand out as the best option:

First and foremost, the Scott Hydro 1500W has excellent efficiency, converting up to 90% of the available hydro energy into electrical energy. This minimizes energy losses and maximizes power output. The turbine’s unique design with custom foil hydrofoils and an enclosed shroud optimize the water flow for peak efficiency.

In terms of cost, the Scott Hydro 1500W provides good value for money given its performance capabilities. It’s competitively priced compared to turbines with similar output. The robust stainless steel construction also ensures longevity and reliability to get the most out of your investment.

The output capacity of 1500W makes the Scott Hydro 1500W suitable for most residential and light commercial applications. Its power production can handle basics needs yet still has room to expand. The turbine can also integrate with solar panels or wind turbines in a hybrid renewable energy system.

The fully enclosed turbine requires little regular maintenance compared to open designs. The lack of oils or grease facilitates maintenance when needed. The adjustable nozzle positioning further optimizes the turbine for site conditions.

With a potential lifespan over 20 years, the Scott Hydro 1500W provides years of reliable green power generation. Its durable components are built to withstand decades of use.

Thanks to its underwater design and slow rotations, the Scott Hydro 1500W has minimal environmental impact on surrounding aquatic ecosystems. It doesn’t interfere with fish or wildlife. This makes it a sustainable eco-friendly energy solution.

In conclusion, the Scott Hydro 1500W Water Turbine delivers an exceptional combination of efficiency, affordability, capacity, ease of use and eco-friendliness. This makes it the most effective hydro turbine overall for delivering renewable hydropower.