What Is The Biochemical Conversion Process Of Biomass?

Biomass refers to organic matter from plants and animals, and can include agricultural residues, municipal solid waste, industrial waste, and crops grown specifically for energy production 1. It is considered a renewable energy source because plants and trees can be replanted to replace those that are used. The conversion of biomass into usable forms of energy and other products is important for several reasons:

1. Provides a sustainable source of energy – Biomass can be replenished, so it provides a renewable alternative to fossil fuels.

2. Reduces waste – Agricultural, forestry, and municipal waste can be converted into useful forms of energy instead of being landfilled.

3. Mitigates climate change – Since biomass absorbs CO2 as it grows, energy from biomass can have lower lifecycle carbon emissions compared to fossil fuels.

4. Supports domestic energy production and rural economies – Biomass feedstocks are abundant domestically, reducing reliance on imported fossil fuels while creating economic opportunities in agricultural communities.

There are multiple processes that can be used to convert biomass into energy and products, including direct combustion, thermochemical conversion, biochemical conversion, and more recently, hybrid conversion processes combining thermochemical and biochemical techniques 2. This article provides an overview of the major biomass conversion processes and their applications.

Types of biomass

Biomass feedstocks can be broadly categorized into three main types: plant biomass, animal biomass, and municipal waste biomass (ResearchGate).

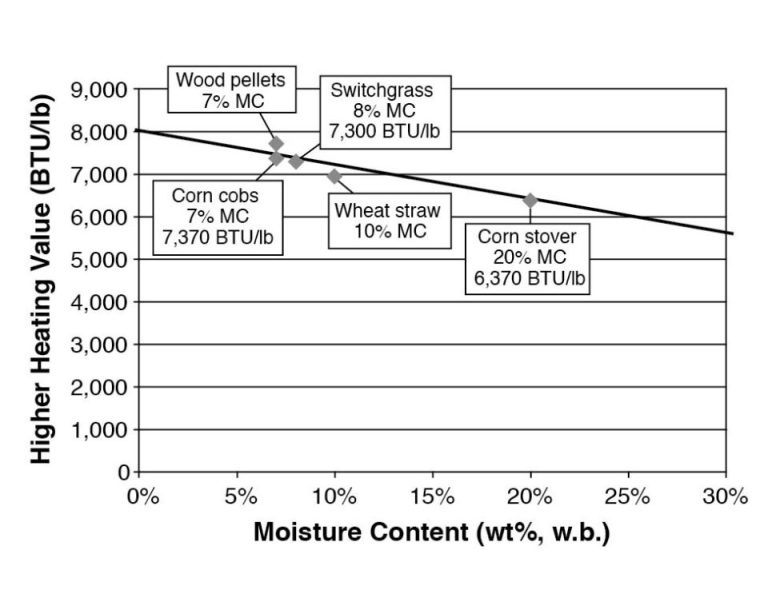

Plant biomass includes dedicated energy crops like corn, sugarcane, and oilseed crops that are rich in starch, sugar, oils, and cellulose. It also includes agricultural residues like corn stover, wheat straw, rice husks, and bagasse. Forestry materials like wood, logging residues, thinnings, tree branches, and sawdust are other common plant biomass sources (UWSP).

Animal biomass comprises animal manure, poultry litter, meat and bone meal, fats, greases, and other animal processing wastes. These contain proteins, fats, cellulose, and hemicellulose that can be converted into biofuels (ETIP Bioenergy).

Municipal solid waste like food waste, paper, plastics, leather, textiles and garden waste represent another significant biomass resource. Sewage sludge from waste water treatment is also included in this category (UWSP).

Pretreatment

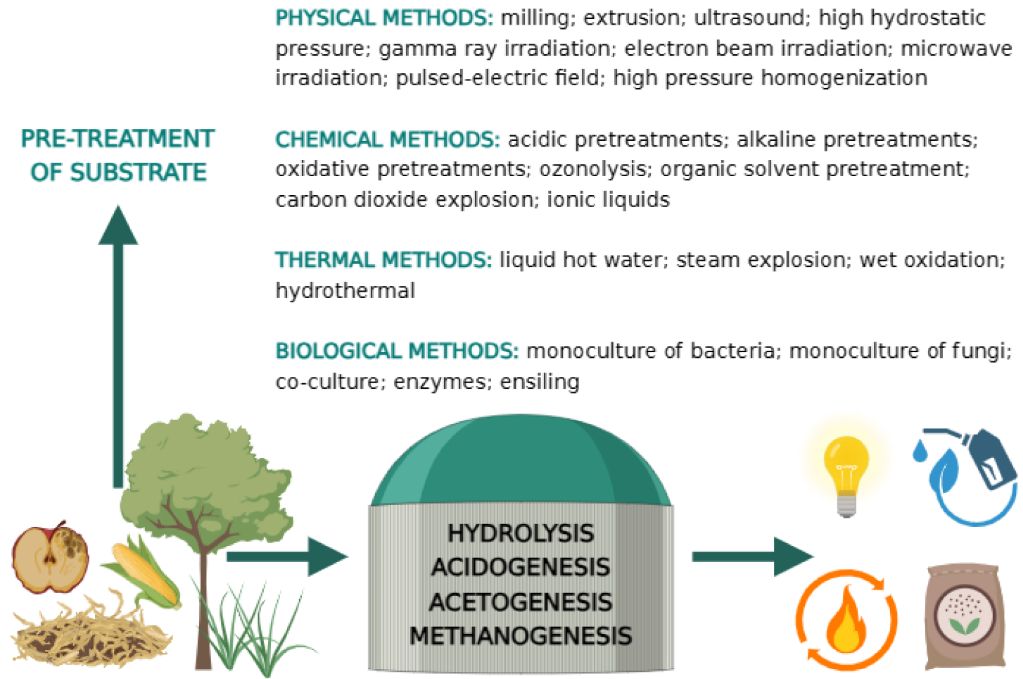

Pretreatment is an essential step in the biomass conversion process as it helps to break down the rigid structure of lignocellulosic biomass and make the cellulose and hemicellulose more accessible for hydrolysis. The main goal of pretreatment is to remove lignin and hemicellulose, reduce cellulose crystallinity and increase porosity of the biomass. There are several pretreatment methods including mechanical, thermal, chemical and biological pretreatment.

Mechanical pretreatment involves physical disruption of the biomass structure using methods like milling, grinding and chipping to reduce particle size and increase surface area. This helps improve enzyme access and increase efficiency in downstream processes.[1]

Thermal pretreatment uses heat to break lignin and hemicellulose bonds. Methods like steam explosion, liquid hot water, and microwave irradiation are used. High temperatures help solubilize hemicellulose and alter lignin structure.[2]

Chemical pretreatment employs acids, alkalis, oxidizing agents or organic solvents to fragment the biomass structure. Dilute acid hydrolysis is commonly used to solubilize hemicellulose. Alkaline pretreatment helps remove lignin and a portion of the hemicellulose.[3]

Biological pretreatment uses microorganisms like brown, white and soft-rot fungi to degrade lignin and hemicellulose in the biomass.

Hydrolysis

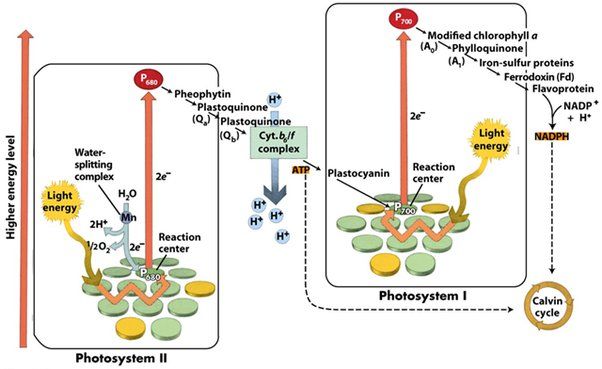

Hydrolysis is a key step in the biochemical conversion of biomass, which breaks down the polymers in biomass into fermentable sugars that can then be converted into biofuels and chemicals. This is primarily done through acid hydrolysis, using acids like sulfuric acid, or enzymatic hydrolysis, using cellulase enzymes [1]. The main components of lignocellulosic biomass that need to be hydrolyzed are cellulose and hemicellulose polymers.

During acid hydrolysis, dilute acids break the glycosidic bonds between the glucose monomers that make up cellulose and hemicellulose, releasing C5 and C6 sugar monomers. High temperature and pressure are required. Enzymatic hydrolysis uses cellulase enzymes to break these bonds under milder conditions. However, pretreatment is first required to open up the structure of lignocellulosic biomass so the enzymes can access and hydrolyze the cellulose and hemicellulose. After hydrolysis, the resulting sugar monomers like glucose and xylose can be fermented by microbes into products like ethanol or butanol [2].

Optimization of hydrolysis conditions like temperature, acid concentration, and enzyme loading can improve sugar yields. Since hydrolysis is often the most costly step, ongoing research aims to make this process more efficient through enzyme engineering and process integration.

Fermentation

Fermentation is a key step in the biochemical conversion of biomass. It involves the microbial conversion of sugars derived from the hydrolysis process into alcohols, organic acids, gases, and other compounds [1]. The most common fermentation process transforms the 5-carbon and 6-carbon sugars from biomass hydrolysates into ethanol. This is done through fermentative microorganisms such as yeasts and bacteria [2].

The yeast Saccharomyces cerevisiae is commonly used to ferment biomass sugars into ethanol. Native strains of S. cerevisiae can ferment both hexose (6-carbon) and pentose (5-carbon) sugars derived from lignocellulosic biomass. Genetic engineering approaches have further optimized microbial biocatalysts for efficient ethanol production. Other microbes like Zymomonas mobilis bacteria have also been studied for biomass fermentation due to their high sugar uptake and ethanol productivity.

In addition to ethanol, fermentation of biomass sugars can yield other alcohols like butanol. It also allows for the production of organic acids such as lactic acid, acetic acid, succinic acid which have commercial applications. Microbial fermentation provides a renewable means of transforming sugars in plant biomass into higher-value products.

Anaerobic digestion

Anaerobic digestion is a process in which microorganisms break down biodegradable material in the absence of oxygen. It is used to convert biomass such as animal manure, food waste, and crop residues into biogas, which consists primarily of methane and carbon dioxide. Anaerobic digestion occurs naturally in landfills, wetlands, and the digestive systems of ruminant animals. Engineered anaerobic digesters optimize the process to maximize biogas production.1

In an anaerobic digester, biomass undergoes four key biological and chemical stages: hydrolysis, acidogenesis, acetogenesis, and methanogenesis. In the first stage, complex organic polymers like carbohydrates, proteins, and lipids are broken down into simple, soluble monomers by hydrolytic bacteria. Acidogenic bacteria then convert these monomers into volatile fatty acids, alcohols, hydrogen, and carbon dioxide.

Next, acetogenic bacteria convert these products into acetic acid, carbon dioxide and hydrogen, which are used by methanogenic Archaea to produce methane in the final stage. The chemical reaction for the overall digestion process can be represented as:2

(C6H10O5)n + nH2O → 3nCH4 + 3nCO2

Anaerobic digestion provides a renewable source of biogas fuel while diverting organic waste from landfills and reducing greenhouse gas emissions. It is a core technology for recovering energy from wet biomass resources.

Catalytic conversion

Catalytic conversion of biomass primarily utilizes thermochemical processes like pyrolysis, gasification, and liquefaction to convert biomass into useful biofuels and chemicals. These processes involve heating biomass in the absence of oxygen (pyrolysis), partial oxidation (gasification), or at high pressures with catalysts (liquefaction) to break down the biomass structure and produce an intermediate bio-oil or syngas product.

Pyrolysis breaks down biomass at temperatures typically between 300-600°C to produce bio-oil, syngas, and biochar. Fast pyrolysis optimizes bio-oil yields up to 75% by rapidly heating the biomass and then quickly cooling the vapors. Catalytic pyrolysis uses catalysts to increase selectivity towards certain chemicals or improve bio-oil properties. Gasification converts biomass at 700-1000°C using steam and limited oxygen/air to produce syngas composed primarily of hydrogen and carbon monoxide. Catalysts can be used to increase syngas yields or adjust its composition. Hydrothermal liquefaction uses water at high pressures (5-20 MPa) and temperatures (280-370°C) to liquefy wet biomass into bio-oil.

Overall, thermochemical conversion provides a flexible way to produce different biofuels and chemicals from biomass feedstocks. Catalysts and operating conditions can be tailored to optimize yields of desired products. Key challenges include improving catalyst longevity, bio-oil stability, and overall process economics.

Upgrading and refining

After biomass has been converted into intermediate bio-oil products through processes like pyrolysis, hydrotreating can be used to upgrade these crude outputs into finished products like transportation fuels. Hydrotreating involves reacting the bio-oil with hydrogen under elevated temperature and pressure in the presence of catalysts. This serves to stabilize the bio-oil by removing oxygen and saturating double bonds. Common catalysts used include sulfided NiMo and CoMo supported on alumina or silica [1].

Hydrodeoxygenation (HDO) is an important hydrotreating process for deoxygenating bio-oils. HDO removes unstable oxygen-containing compounds, resulting in a higher heating value and improved stability. Typical HDO conditions involve temperatures of 300-450°C at 5-20 MPa hydrogen pressure with sulfided NiMo or CoMo catalysts [2]. The products can be further separated into naphtha, diesel, and gas fractions.

Additional catalytic cracking and reforming steps can be utilized to optimize the hydrocarbon composition. Mild hydrocracking and isomerization may also be employed. The resulting hydrocarbons are very similar chemically to petroleum-derived fuels.

Applications

Biomass conversion technologies have a wide range of applications. Some of the major ones include:

Biofuels – Bioethanol and biodiesel are the most common biofuels produced from biomass conversion. Bioethanol is made by fermenting sugars from biomass feedstocks like corn, sugarcane and cellulosic materials. Biodiesel is produced by transesterification of oils from sources like soybean, canola and algae (https://medium.com/@chiragreportprime3/biomass-conversion-and-biorefinery-market-trends-and-market-analysis-forecasted-for-period-2fef4c390c3a).

Bioplastics – Biomass can be converted into biodegradable plastics like PLA, PHA, etc. which have applications in packaging, textiles, automotive components, electronics, etc. (https://onlinelibrary.wiley.com/doi/pdf/10.1002/9780470694954.ch69).

Biochemicals – Platform chemicals like succinic acid, itaconic acid, lactic acid, etc. can be produced through fermentation of sugars from biomass. These find uses in plastics, resins, coatings, pharmaceuticals, etc.

Bioenergy – Solid biomass like wood pellets, bio-oil and biogas can be used to generate electricity, heat and biofuels for transportation.

Challenges and future outlook

While biomass conversion shows immense promise, there are still challenges that need to be addressed for it to reach its full potential. Some of the main challenges are economic, sustainability, and process optimization.

Economically, biomass conversion processes can have high capital and operating costs. The logistics of collecting and transporting bulky biomass feedstocks also add to costs (Source). More research is needed to improve conversion efficiency and scale up processes to benefit from economies of scale. Public policies that support renewable energy development can help improve the economics.

Sustainability concerns revolve around using food crops as feedstocks, which could compete with food supply. However, research shows non-food crops and waste biomass can provide substantial amounts of feedstock. Land use change is another concern that needs to be responsibly managed. Overall, experts believe sustainability risks can be mitigated through strategic policies and practices as the industry matures (Source).

There are also opportunities to optimize biomass conversion processes. Advances in genetic engineering can tailor biomass crops to improve conversion efficiency (Source). New catalysts are also being developed to make conversion faster and more selective (Source). Integrating processes like pretreatment, saccharification, and fermentation into one step (consolidated bioprocessing) could also cut costs.

Overall, experts are optimistic the field will continue to innovate and mature, overcoming limitations to make biomass conversion widely available and economically sustainable.