What Is The Basic Design Of A Hydropower Plant?

Hydropower is a form of renewable energy that harnesses the power of flowing water to generate electricity. The term hydropower refers to the process of using the energy of moving water to produce mechanical force that can then run electric generators (“Hydropower Facts”, 2022).

Humans have been harnessing the power of water for thousands of years, with early water wheels used by ancient Greeks for grinding grain. The first known use of water to generate electricity was in the late 1800s, when the first hydroelectric power plants were built in North America and Europe (https://www.energy.gov/eere/water/history-hydropower).

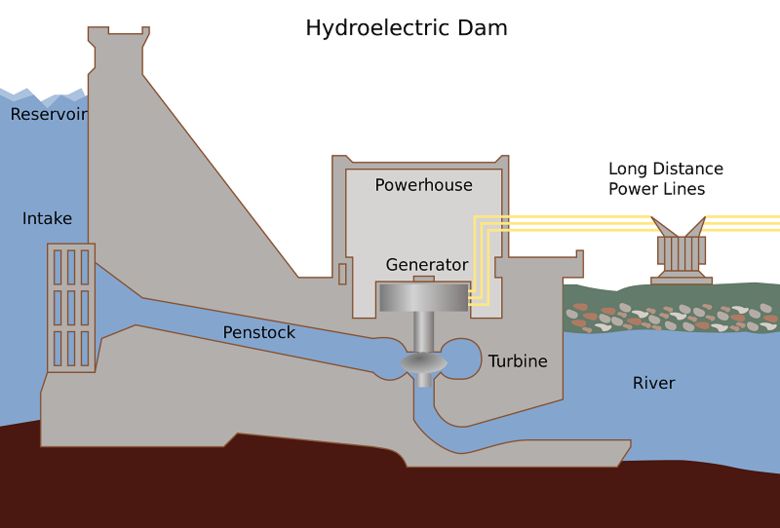

Hydropower is considered a renewable energy source because it relies on the water cycle, which is continuously renewed by the sun. As an emissions-free energy source, hydropower provides clean and reliable electricity. Hydropower plants also offer flexibility to meet peak power demands. The major components involved in hydropower generation include the dam, turbine, generator, and transformer.

Water Intake

The water intake structure is one of the most important components of a hydropower plant. It collects and diverts river or reservoir water into the intake canal or penstock that will carry it to the turbines (Guidelines for Design of Intakes for Hydroelectric Plants). The intake is usually an open channel or submerged structure made of concrete, steel, or wood.

Intake structures contain screens to filter out debris like logs, leaves, and sediment that could damage equipment downstream. The screens are designed to allow an optimal water flow rate while minimizing clogging (Water intake structures for hydropower). The filtered water then travels through tunnels, canals or penstocks to the turbine room.

The intake design must balance hydraulic performance, structural integrity, and environmental factors. Poor intake design can negatively impact plant efficiency and aquatic life. Careful engineering is required to allow sufficient water flow while screening debris and minimizing fish entrainment.

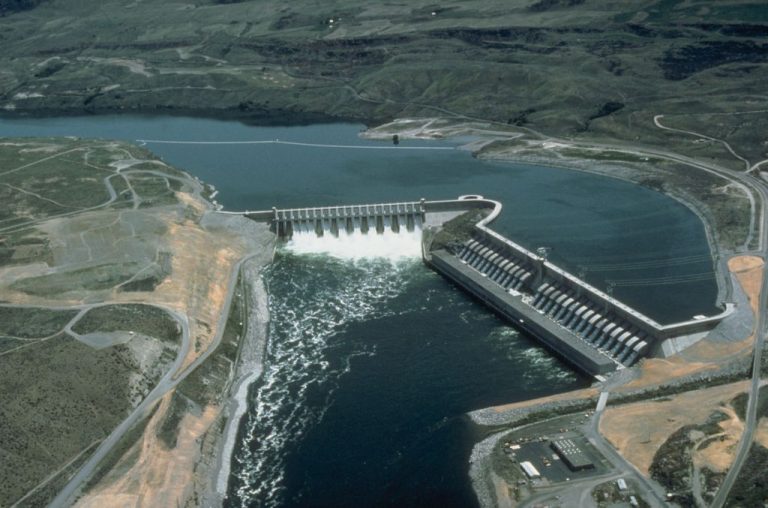

Dam

The dam is a critical component of most hydropower plants. Its purpose is to store and control water for power generation. There are several main types of dams used in hydropower facilities:

Gravity dams use their own weight and concrete structure to resist the massive water pressure from the reservoir. They are well suited for narrow gorges or canyons. Arch dams are curved masonry dams that transfer water pressure and weight to the canyon walls. Arch dams can be built in wider canyons than gravity dams.

Embankment dams are made of earth, rock, or tailings and rely on their sheer mass to resist water pressure. They are well suited for wide valleys with shallow rock foundations. Cofferdams are temporary watertight structures used during construction. They divert water flow and allow the dam foundation to be built in dry conditions.

The dam type and size depends on topography, geology, and project purpose. Dams store many months’ worth of water to ensure consistent electricity generation during seasonal changes in water flow.

Turbine

The turbine is the component that is turned by the moving water to rotate a shaft, converting the kinetic energy of water into mechanical energy. There are different types of turbines used in hydropower plants:

The Kaplan turbine is a propeller-type turbine that has adjustable blades. It is used in low head hydropower sites. According to the U.S. Department of Energy, Kaplan turbines are well-suited for relatively low heads of 3-130 ft. They are adjustable to allow efficient operation under a wide range of head and flow conditions (Types of Hydropower Turbines, n.d.).

The Francis turbine is the most common type used in hydropower plants today. It is a reaction turbine that uses water pressure by guiding the flow through a runner with fixed vanes. Francis turbines operate under heads of 50-500 ft. According to Enel Green Power, Francis turbines provide high efficiency and operate well under variable load conditions (Hydroelectric turbines, n.d.).

The Pelton turbine is an impulse turbine that uses the velocity of water to move a wheel with split buckets. Pelton turbines are used for high heads of typically over 500 ft. The jet of water is directed tangentially onto the buckets, causing the wheel to turn. Pelton turbines can operate at high efficiency in a very wide range of flow conditions (Types of Hydropower Turbines, n.d.).

Generator

The generator is the component that converts the mechanical energy from the turbine into electrical energy. It works through the principles of electromagnetism. The turbine causes a rotor inside the generator to spin, which then rotates a series of wire coils within a magnetic field. This motion of the coils induces an electric current according to Faraday’s law of electromagnetic induction.

The main components of a generator include:

- Rotor – The rotating part of the generator. The turbine shaft is connected to the rotor to spin it.

- Stator – The stationary part that contains the wire coils.

- Exciter – Provides DC current to the rotor to induce a magnetic field.

- Cooling system – Cools the generator to prevent overheating.

- Housing – Encloses and protects the generator components.

By optimizing these components, generators can achieve efficiency levels of over 90% in converting mechanical energy into electrical energy.

Transformer

The transformer is a critical component of the hydroelectric plant. Its role is to step up the voltage of the electricity generated by the plant before it is transmitted over long distances on the transmission lines. As the University of Lehigh notes, “The electricity goes to the transformer in the powerhouse.” (https://ei.lehigh.edu/learners/energy/hydroelectric3.html)

Transformers allow the voltage to be increased to very high levels like 345,000 volts for efficient transmission over long distances. This is done through the principle of electromagnetic induction between the transformer’s primary and secondary windings. The ratio between the number of turns in each winding determines the voltage transformation ratio.

There are different configurations of transformers used in hydroelectric plants. Corefficient outlines some of these: “In hydroelectric power plants – where electricity is generated by waterpower – transformers play a key role in stepping up voltages to enable long-distance transmission as well as stepping down voltages for distribution to homes and businesses.” (https://corefficientsrl.com/electrical-transformers-assist-hydroelectric-energy/)

Transmission

When electricity is first generated at the hydropower facility, it is in the form of high voltage electricity. This means the electricity is at a very high power level – too high to be used directly by consumers. High voltage transmission lines are needed to carry the electricity from the hydropower facility to electrical substations located near population centers.

These high voltage transmission lines can be either overhead power lines or underground cables. Overhead lines are the most common, consisting of aluminum conductor cables suspended between tall steel towers. Underground cables are insulated cables buried below the surface in conduit. They are more expensive to install but provide some aesthetic advantages.

The distance from hydropower facilities to substations can be many miles. The high voltage allows the electricity to travel long distances before power is lost. The transmission lines must be properly maintained to deliver electricity efficiently and avoid any power outages along the grid.

Substation

Substations are an essential component of hydropower plants, as they step down and regulate the voltage generated by the plant for safe distribution on transmission lines and eventually to customers (1). The main components of a hydropower substation include transformers, switchgear, capacitor banks, and protective relays (2).

Transformers are used to step down the higher voltage electricity produced at the generator to lower distribution voltages. This allows the electricity to be transmitted efficiently over long distances. Switchgear and circuit breakers help route and control power flow, as well as isolate and de-energize equipment for maintenance. Capacitor banks help provide reactive power compensation to optimize transmission capacity and voltage levels. Protective relays monitor system conditions and can quickly isolate faults when issues occur (1).

Substations play a critical role in transmission and distribution from hydropower plants. Their design, safety, and reliability are paramount to delivering clean electricity to homes and businesses (3). Key considerations in substation design include equipment ratings, fault protection, physical and cyber security, and redundancy.

[1] https://www.ingeteam.com/en-us/sectors/hydroelectric-energy/p15_50_230/hydropower-substations.aspx

[2] https://www.penlight.org/hydropower-101-transmission-from-dam-to-doorstep/

[3] https://www.zuken.com/us/blog/designing-for-safety-and-reliability-in-hydropower-substations/

Environmental Considerations

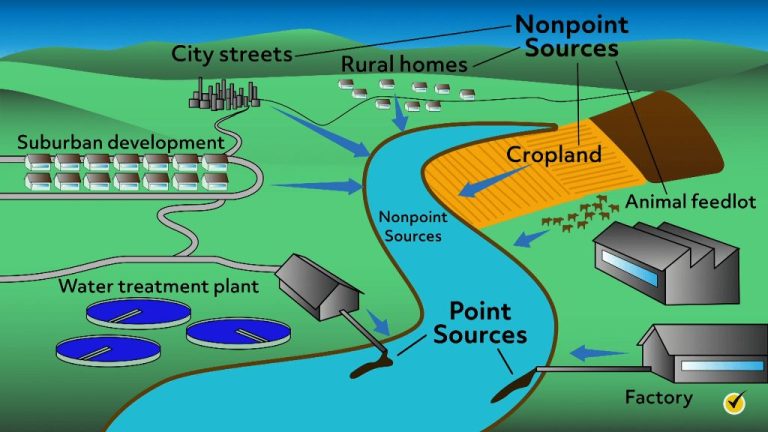

Hydropower dams can cause various environmental impacts, particularly related to fish migration and sediment flow downstream. To mitigate the impacts on fish, most hydropower dams now include fish ladders and screens, which give fish a route to migrate upstream and downstream past the dam. Minimum flow levels are also maintained in the river downstream, to sustain aquatic ecosystems.

Sediment buildup behind dams is another issue, as it reduces a river’s ability to transport nutrients downstream. Methods of sediment control and reducing erosion include sediment bypassing, sluicing, and dredging. Overall, careful facility design, adaptive management, and environmental monitoring can reduce the impacts of hydropower dams on local ecosystems.

Conclusion

In summary, the main components of a hydropower plant include the water intake, dam, turbine, generator, transformer, transmission lines, and substation. Water from a river or reservoir flows through the intake and turns the turbine, which spins a generator to produce electricity. The power output is stepped up by the transformer before being sent via transmission lines to a substation for distribution. Hydropower is a major source of renewable electricity globally, providing around 17% of the world’s electricity generation. It offers the benefits of being renewable, flexible, and able to store energy via pumped storage. Hydropower capacity and generation have grown steadily in recent years and are projected to continue growing 3-4% annually to help meet decarbonization goals while also providing grid stability and energy security.