What Is Pv In Terms Of Solar?

What is PV?

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials. PV uses the photoelectric effect to generate electric current when sunlight hits the semiconducting material in a PV cell. The most common semiconducting materials used in PV cells are silicon and thin-film materials such as cadmium telluride.

There are three main types of PV cells:

- Monocrystalline – Made from a single crystal of silicon, these cells are the most efficient but also the most expensive.

- Polycrystalline – Made from many silicon crystals melted together, these cells are less efficient but cheaper than monocrystalline.

- Thin Film – Made by depositing layers of photosensitive materials on surfaces like glass or plastic. Thin film cells are less efficient but inexpensive to manufacture.

When sunlight hits the semiconducting material, photons knock electrons loose, allowing them to flow freely and generate an electric current. PV modules are made up of interconnected PV cells that can be used together to form solar arrays and turn sunlight into usable electricity.

History of PV

The photovoltaic (PV) effect was first discovered in 1839 by French physicist Edmond Becquerel. He found that certain materials would produce small amounts of electric current when exposed to light. The first solar cell made from selenium was constructed in 1883 by Charles Fritts.

In the early 1900s, Albert Einstein won the Nobel Prize for his work explaining the photoelectric effect, which laid the foundation for solar cell technology. The first silicon photovoltaic module was built by Bell Laboratories in 1954. It was billed as a solar battery and was mostly just a curiosity as it was too expensive to gain widespread use.

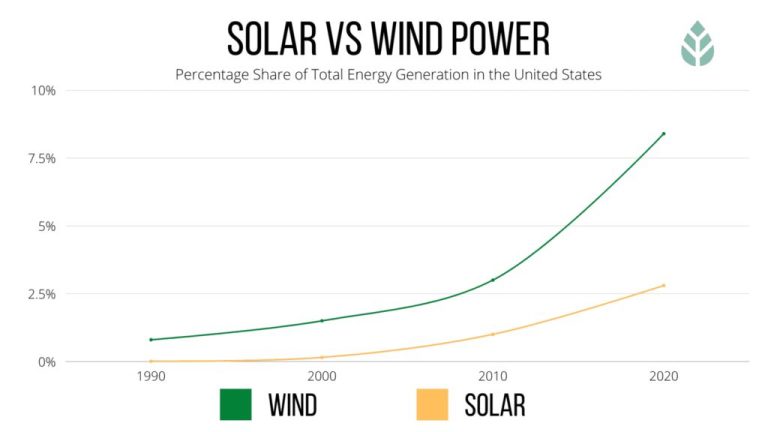

The space industry began using PV technology in the 1950s to provide power aboard spacecraft. Through the space programs, research into solar cells gained momentum because the technology was essential for power generation where conventional electricity sources were unavailable. This drove efficiencies higher and costs lower.

During the energy crisis in the 1970s, photovoltaic technology gained recognition as a source of power for non-space applications. As oil prices rose, PV became more cost competitive, and solar panels were installed in remote locations without access to an electric grid. Though still expensive, PV started being used for small scale commercial and residential applications like powering calculators, watches and off-grid homes.

From the 1990s onward, PV technology has improved dramatically, with solar cell and module efficiencies increasing and costs decreasing. Economies of scale led to further cost reductions. Now PV power is one of the lowest cost energy sources and continues to expand around the world.

How PV Cells Work

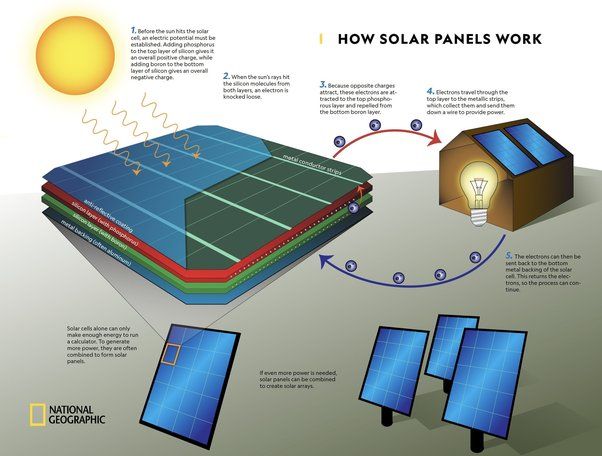

Photovoltaic cells are made of semiconductor materials like silicon that have a unique crystalline structure. When light photons strike the cell, they transfer their energy to electrons in the material. This causes the electrons to break free from the atoms they are bonded to and flow through the material.

The displaced electrons leave behind holes that also act as charge carriers. The result is one side of the cell becomes negatively charged as electrons accumulate, while the other side becomes positively charged due to holes. This creates an electric field across the cell, which causes electrons to flow from one side to the other when the PV cell is connected to an external circuit.

The electron flow in the external circuit is the electricity produced by the photovoltaic cell. Sunlight energy is first converted to electrical energy when electrons are knocked loose. The static electric field built into the cell structures this generated electricity into a current and voltage. More photons entering the cell equals more electricity being produced.

PV Cell Efficiency

The efficiency of a photovoltaic (PV) cell refers to how much of the sun’s energy striking the cell is converted into usable electricity. There are several factors that affect PV efficiency:

Spectrum of sunlight: Sunlight contains a range of wavelengths, but PV cells only convert certain wavelengths into electricity. Cells are designed and optimized to convert wavelengths most prevalent in sunlight.

Temperature: Conversion efficiency decreases as cell temperature increases. Cooler cells operate more efficiently.

Light intensity: Efficiency peaks at a certain light intensity and declines at lower and higher intensities.

Surface reflectance: Reflection of light off the cell surface reduces light absorption and efficiency. Anti-reflective coatings help maximize absorption.

Quality of semiconductor material: Defects in the crystal lattice reduce efficiency. Higher quality manufacturing improves efficiency.

In lab tests, record cell efficiencies now exceed 47%. However, mass-produced commercial modules operate in the 15-22% efficiency range. Real-world operating conditions limit efficiency compared to peak laboratory results. But advances in materials and manufacturing continue to improve commercial PV efficiency over time.

Types of PV Cells

There are three main types of photovoltaic cells used in solar panels: monocrystalline, polycrystalline, and thin film.

Monocrystalline Cells

Monocrystalline cells are made from a single cylindrical crystal of silicon. These cells have the highest efficiency rates, typically around 15-20%, but are more expensive to produce than other types.

The benefits of monocrystalline cells are:

- Highest efficiency rates (15-20%)

- Perform better in low light conditions

- Have a sleek uniform appearance

The drawbacks are:

- More expensive to manufacture

- Waste more silicon in production

- Can be prone to cracking and damage

Polycrystalline Cells

Polycrystalline cells are made from multiple silicon crystal fragments melted together. The efficiency rate is typically 13-16%. These cells are cheaper to produce than monocrystalline.

The benefits of polycrystalline cells are:

- Cheaper manufacturing costs

- Less silicon waste in production

- Can have slightly better warm weather performance

The drawbacks are:

- Slightly lower efficiency (13-16%)

- Appearance isn’t as uniform

- Larger surface area is required

Thin Film Cells

Thin film cells are made by depositing photovoltaic material onto substrates like glass or plastic. The efficiency rate is typically 7-13%. They are easier and cheaper to manufacture than crystalline silicon cells.

The benefits of thin film cells are:

- Very cheap production costs

- Can be flexible when mounted on plastics or metals

- More effective in warm weather

The drawbacks are:

- Lower efficiency rates (7-13%)

- More prone to damage and defects

- Toxic materials can be used like cadmium

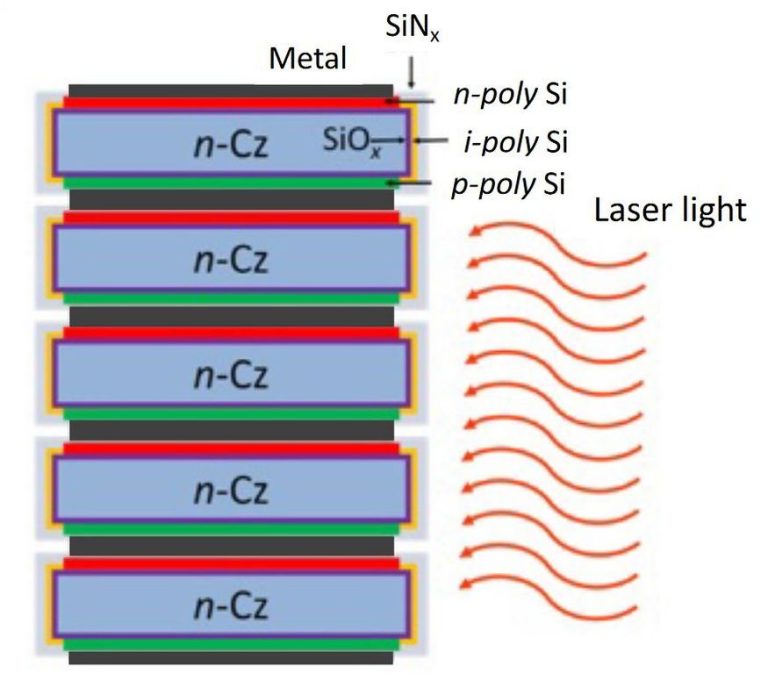

PV Cell Manufacturing

The manufacturing process of PV cells starts with the purification of silicon. Metallurgical grade silicon contains many impurities and must be refined to increase purity levels to those suitable for solar cells. This is done through chemical vapor decomposition to convert silicon to trichlorosilane gas which can be distilled at different boiling points to extract high purity silicon.

The purified silicon is then melted and cast into ingots. As the ingots cool, they form a single crystal structure ideal for making PV wafers. Ingots are sliced into thin wafers about 200 microns thick using wire saws. The edges of each wafer are rounded to prevent chipping.

Wafers then undergo chemical etching and texturing to form a rough surface that helps trap light. An anti-reflective coating is applied to further reduce light reflection. Dopant atoms are diffused into the wafers at high temperature to form the p-n junction and electrical contacts are screen printed onto the surface using metal pastes.

The wafers are then fused together into a full cell through lamination. An anti-reflective glass cover is added to the top surface. Testing takes place at each step of the process to ensure quality and performance meet specifications. The finished solar cells are sorted, tested again, and assembled into PV modules ready for installation.

PV Modules

Photovoltaic or PV modules are created by connecting multiple PV cells together electrically and encapsulating them between a transparent front sheet and a backing material to form a weatherproof and durable package. The front surface of a PV module is designed to be transparent to allow sunlight to reach the PV cells inside. The most common front sheet material is glass, but plastic films like ETFE can also be used.

PV cells are very thin, only around 0.2mm thick, so connecting many cells together helps build modules of a usable size. Typically 60 or 72 PV cells are connected together in a grid pattern and laid out between the front sheet and backing material. The cells are connected via thin ribbons or wires, usually made of copper or silver. Connecting cells in this way builds up the current and voltage output to useful levels for power generation.

Encapsulating the PV cells protects them from mechanical damage and the effects of moisture and air. The encapsulant is usually ethylene vinyl acetate (EVA) which fills in between the cells and bonds to the front sheet and backing material under heat and pressure. The backing material, also called the backsheet, is usually a polymer material like polyvinyl fluoride (PVF) or polyvinylidene fluoride (PVDF) which are designed to be weather resistant.

Bypass diodes are also connected across sections of PV cells during module construction. These diodes provide an alternate current path around any shaded or damaged cells, preventing those cells from acting as an energy dissipating load on the rest of the module.

PV Array Installation

There are two main types of PV array installations: rooftop arrays mounted on top of buildings, and ground-mount arrays installed directly on the ground or poles. The scale of the array and type of mounting depends on whether it is a residential or commercial installation.

Rooftop Arrays

Rooftop solar arrays are commonly installed on residential homes, commercial buildings, and industrial facilities. For residential homes, the PV panels are mounted on top of the roof, either flush with the roof or tilted at an angle. The roof must have proper orientation and minimal shading to maximize solar production. Rooftop arrays for commercial buildings are much larger in scale, with panels covering most of the roof surface area.

Ground-Mount Arrays

Ground-mount PV arrays are installed directly on the ground rather than on rooftops. The PV racks and modules are anchored into the ground and angled up towards the sun. Ground mounts allow the panels to be oriented for optimal sunlight, regardless of rooftop direction. They are commonly used for larger utility-scale systems in open fields or on agricultural land. Ground-mount residential systems are also an option when rooftops have improper orientation or shading.

Residential vs Commercial Scale

A residential roof array is usually between 3-10 kilowatts and mounted on sloped rooftops. For commercial and industrial buildings, rooftop arrays can range from 10 kilowatts up to the megawatt scale, with panels covering nearly the entire rooftop. Ground-mount utility-scale PV projects are over 1 megawatt and can cover hundreds of acres of land with many rows of panels.

PV System Components

In addition to the PV modules, complete PV systems require other components such as inverters, charge controllers, batteries, wiring, and mounting equipment. These balance of system components are what allow the PV modules to effectively deliver power for real world applications.

The inverter is one of the most important parts of a PV system. Its job is to convert the DC electricity generated by the PV modules into AC electricity that can power lights, appliances, and feed into the utility grid. Most inverters connect to the utility grid so that the PV system can feed excess power back to the grid. Inverters must provide various safety features and utility interconnect protections.

Charge controllers regulate the voltage and current coming from the PV modules to safely charge batteries. They prevent overcharging and may have load control capabilities. Some charge controllers also have MPPT (maximum power point tracking) to maximize the power output.

Batteries provide storage so that the PV system can provide power when the sun isn’t shining. Deep cycle lead acid batteries are commonly used, but lithium-ion batteries are becoming more popular. However, not all PV systems require batteries.

PV systems require wiring to interconnect the components. Electrical codes and standards govern the types of wiring and installation methods. Proper grounding, conductor sizing, disconnects, and overcurrent protections are vital for safety.

The PV modules and other components must be securely mounted. Rack mount systems on rooftops or ground mounts are common for larger systems. Pole mounts, lag bolts, or even adhered laminate products can be used for smaller residential systems.

PV Applications

PV systems can be installed for various applications depending on the need and location. Some of the main PV applications include:

Grid-tied Systems

In grid-tied systems, the PV array is connected to the electricity grid via an inverter and metering system. The PV system supplies power to the grid during the daytime when the sun is shining and draws power from the grid when needed at night. The main advantages of grid-tied systems are net-metering which allows sending excess PV electricity back to the grid to offset costs, and not requiring batteries for energy storage.

Off-grid Systems

Off-grid PV systems operate independently of the electricity grid. They require batteries to store energy for use at night. Off-grid systems are commonly used in remote areas without grid access. The main advantage is independence from the grid, but disadvantages include higher costs for energy storage.

Distributed Generation

Distributed generation refers to PV systems installed on rooftops or small ground mounts on homes, commercial buildings or industrial facilities. Power is generated at the point of use, lowering transmission losses. Distributed PV reduces the burden on central power generation and transmission infrastructure.

Solar Farms

Solar farms or solar parks involve large-scale deployment of PV modules over a large land area to generate bulk power. The power is fed into the electricity grid rather than being consumed locally. Solar farms allow centralized renewable energy generation but require substantial land areas.

In summary, PV can provide renewable electricity in both decentralized distributed setups as well as centralized utility-scale solar farms. The choice depends on the application need and location.