What Is Meant By Pv Cell?

A photovoltaic (PV) cell is an electronic device that converts sunlight directly into electricity. PV cells are made from semiconducting materials that exhibit the photovoltaic effect, causing them to absorb photons from sunlight and release electrons. This flow of electrons generates an electric current that can be captured and used as electricity.

The photovoltaic effect was first observed by French physicist Alexandre-Edmond Becquerel in 1839. The first silicon PV cell was developed in 1954 by scientists at Bell Labs. Since then, PV technology has continued to advance and solar panels made from interconnected PV cells have become a popular renewable energy source around the world.

PV cells are often referred to as solar cells because most capture energy from sunlight. However, they differ from solar thermal collectors, which absorb heat from sunlight to heat water or another fluid. PV cells directly convert photons from sunlight into electricity through the photovoltaic effect.

How PV Cells Work

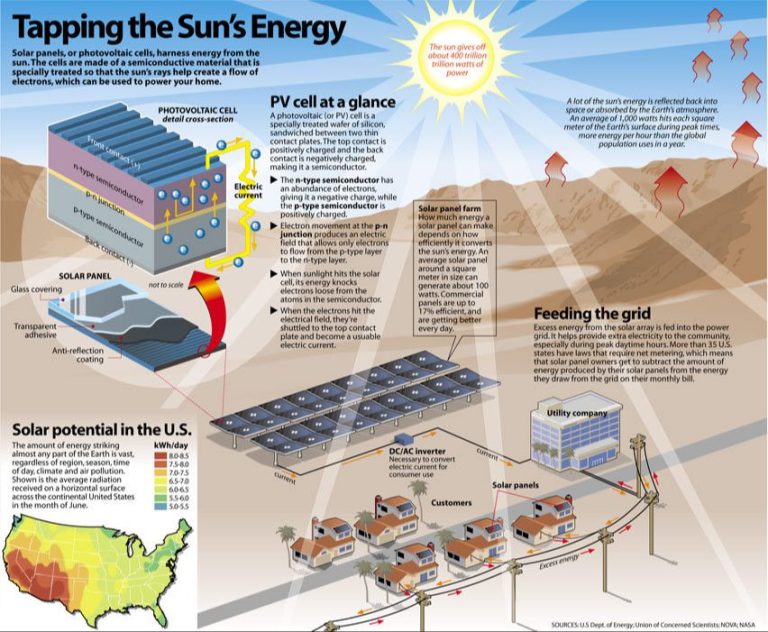

Photovoltaic (PV) cells, also known as solar cells, convert sunlight directly into electricity through the photovoltaic effect. PV cells are made of semiconductor materials like silicon that absorb photons from sunlight when exposed. The energy from these absorbed photons causes electrons in the PV cell to break free of their atomic bonds and flow as electricity.

The photovoltaic effect occurs when light shining on a PV cell creates an electric field across the layers of a semiconductor material. Photons from the sunlight hit the electrons in the semiconductor, giving them enough energy to move around. The PV cell has an electric field that forces the excited electrons in one direction, creating an electrical current. This current is captured and delivered through an electrical circuit.

Silicon is one of the most common semiconductors used in PV cells to produce electricity from sunlight. When silicon absorbs photons, its electrons gain energy allowing them to flow freely. PV cells contain a p-n junction between a positive layer (p-type) and a negative layer (n-type) to create the electric field. This allows the newly freed electrons to flow in one direction, generating electricity.

PV Cell Efficiency

Photovoltaic cell efficiency refers to the percentage of sunlight energy that hits the cell and gets converted into electricity. Typical efficiency ranges vary depending on the type of PV cell technology:

- Monocrystalline silicon PV cells – 15-20% efficient

- Polycrystalline silicon PV cells – 13-16% efficient

- Amorphous silicon PV cells – 5-7% efficient

- Cadmium telluride PV cells – 7-13% efficient

- Copper indium gallium selenide PV cells – 10-12% efficient

There are several factors that can affect the efficiency of PV cells:

- Purity of the semiconductor material – Higher purity translates to higher efficiency

- Reflection off the cell surface – Anti-reflective coatings can improve efficiency

- Temperature – Higher temperatures degrade efficiency

- Quality of manufacturing – Precise manufacturing optimizes efficiency

- Amount of sunlight exposure – Low light conditions reduce efficiency

Ongoing research aims to push the boundaries of PV cell efficiency even higher through advanced materials and novel cell designs.

Types of PV Cells

There are several main types of photovoltaic (PV) cells in use and development today:

Silicon Cells

Silicon PV cells are the most common type used today. They can be divided into two main categories:

- Mono-crystalline silicon cells – Made from single crystalline silicon ingots. They have the highest efficiency rates, typically 15-20%, but are more expensive to produce.

- Poly-crystalline silicon cells – Made from cast square ingots that are composed of many different silicon crystals. They are cheaper to produce but have a lower efficiency of around 12-18%.

Thin Film Cells

Thin film PV cells are made by depositing extremely thin layers of photosensitive materials onto surfaces like glass, stainless steel or plastic. Types of thin film cells include:

- Amorphous silicon

- Cadmium telluride (CdTe)

- Copper indium gallium selenide (CIGS)

Thin film cells are cheaper to manufacture but less efficient, typically around 7-13%.

Emerging Technologies

Some emerging PV cell technologies aiming to improve efficiency and lower costs include:

- Perovskite cells

- Quantum dot cells

- Dye-sensitized solar cells

- Organic PV cells

These new types of cells are still in early research and development stages but show promise for the future.

Manufacturing PV Cells

The manufacturing process for PV cells involves several key steps including purification, doping, slicing, and assembly. It all starts with ultra-pure silicon, the basic material for most PV cells. The raw silicon is purified through a series of chemical processes to remove impurities which might hamper performance.

Next, the silicon is “doped” by introducing very small amounts of other elements like phosphorus or boron. This gives the silicon semiconducting properties needed to produce electricity from sunlight. The front and back sides of the wafer are differently doped to form an electric field across the cell.

The ultra-pure silicon is then formed into nearly round ingots and sliced into very thin wafers about 0.2mm thick using specialized saws. Many cells are then wired together and encapsulated between sheets of glass or plastic to make a PV module.

The manufacturing process continues to become more efficient and cost-effective through automation and new techniques. For example, some companies are transitioning to diamond wire saws which waste less silicon during the slicing step. Overall, PV cell and module manufacturing has become a highly sophisticated large-scale industry.

PV Cell Durability

The durability and reliability of PV cells are critical factors that determine their lifespan and long-term performance. Understanding degradation mechanisms and conducting reliability testing allows manufacturers to improve the robustness and longevity of PV cells.

The key considerations around PV cell durability include:

Lifespan – PV modules are typically warrantied for 25-30 years. The actual lifespan can exceed this with proper design, manufacturing and installation. Temperature, humidity, mechanical stress and UV exposure are key factors affecting lifespan.

Degradation Mechanisms – PV cells experience light-induced degradation, thermal degradation, corrosion, delamination, microcracks and photodegradation over time. Light exposure especially in the blue spectrum and heating during operation accelerate degradation.

Reliability Testing – Accelerated lifetime testing exposes PV cells to extreme light, heat, moisture, mechanical stress and voltage to simulate aging and identify failure modes. Manufacturers use results to improve encapsulation, optimize materials selection and enhance overall robustness.

Understanding PV cell degradation mechanisms through testing allows manufacturers to develop robust product designs and validating long lifespans, instilling confidence in consumers.

PV Cell Costs

The costs of photovoltaic cells and solar panels have declined significantly over the past few decades. This is mainly due to improvements in manufacturing and economies of scale as the PV market has grown.

The main indicator used for PV cost is dollars per watt ($/W). In the 1970s, PV modules cost around $76 per watt. By 2019, costs had dropped to around $0.25 per watt. The Department of Energy has set a goal to reduce PV costs further to $0.05 per watt by 2030.

Some key factors that affect PV cell and module costs include:

- Efficiency – Higher efficiency cells generate more electricity for the same surface area, reducing overall system costs.

- Manufacturing – Improvements in manufacturing techniques and automation reduce production costs per watt.

- Economies of scale – As production volumes increase, fixed costs are spread over more units reducing per unit costs.

- Raw materials – Polysilicon is the main raw material for crystalline silicon cells and accounts for around 15-20% of costs.

- Balance of system costs – In addition to the cells/modules, wires, inverters and other BOS costs account for a major part of a full PV system.

Overall, the dramatic cost reductions have made solar photovoltaics one of the most affordable and rapidly deployed energy technologies globally.

PV Cell Applications

PV (photovoltaic) cells have a wide variety of applications, from small scale off-grid uses to large utility-scale solar farms.

Off-Grid

Off-grid PV systems are not connected to the electrical grid. They are typically used in remote areas where extending power lines is difficult and expensive. Off-grid PV systems store solar energy in batteries and are commonly used to power lighting, appliances, telecommunications equipment, water pumps, and small electronic devices.

Residential

Rooftop solar PV systems are installed on homes to generate electricity and offset purchases from the grid. Any excess solar energy produced can be fed back to the grid. Residential PV systems typically range from 2-10 kilowatts in size. The electricity generated is used to power home appliances, lighting, electronics and electric vehicle charging.

Commercial

Commercial PV systems are installed on the rooftops or grounds of businesses and public buildings like offices, factories, warehouses, schools etc. The solar energy produced serves the electric needs of the buildings and reduces grid purchases. Commercial PV systems are usually sized between 10-500 kilowatts.

Utility-Scale

Utility-scale solar farms can range from 1 to over 1,000 megawatts in size. At this massive scale, solar PV systems feed power directly into the transmission grid, supplying electricity to utilities for distribution to customers. Large utility-scale PV projects may cover hundreds or thousands of acres of land.

PV Market Trends

The solar PV market has experienced exponential growth over the past decade. Total global solar PV capacity reached over 600 GW by the end of 2018, supplying over 2% of global electricity demand. The International Energy Agency (IEA) projects that solar PV capacity could grow to over 4,500 GW by 2050 under its Sustainable Development Scenario.

China continues to dominate the global solar PV market, accounting for around 30% of total installed capacity. Other leading markets include the United States, Japan, Germany and India. Emerging markets with significant growth potential include Brazil, Mexico, Chile, Australia, Turkey, the Middle East and North Africa.

Key factors driving growth include declining costs, supportive government policies, and increased demand for clean energy sources. However, grid integration challenges, policy uncertainty and subsidy reductions in some markets could impact the pace of solar PV expansion going forward.

Overall, most analysts project strong continued growth for solar PV installations globally, with solar expected to play a major role in the transition to renewable energy across both developed and developing markets worldwide.

Future of PV Cells

The future looks bright for photovoltaic technology. Here are some key areas of innovation and growth on the horizon:

Improving Efficiency

Researchers continue to find new ways to improve the efficiency of PV panels, including using new materials, nanostructures, and solar cell designs. Perovskites, multijunction cells, and concentrator PV technology hold promise for pushing efficiency rates even higher.

Perovskites

Perovskite solar cells have emerged as a highly promising PV technology, with lab cell efficiencies already exceeding 25%. Perovskites are inexpensive to produce and can be printed or coated onto flexible substrates. However, durability issues remain a challenge. Once the stability of perovskites improves, they have the potential to outcompete silicon as the dominant PV material.

Building Integrated PVs

Integrating PV directly into building materials is an exciting area of innovation. Building-integrated photovoltaics (BIPV) can be embedded into roof shingles, window glass, exterior paints, and other building facades. Widespread adoption of BIPV could help solar power seamlessly blend into infrastructure and the electricity grid.