What Is Hydro Foundation?

What is Hydro Foundation?

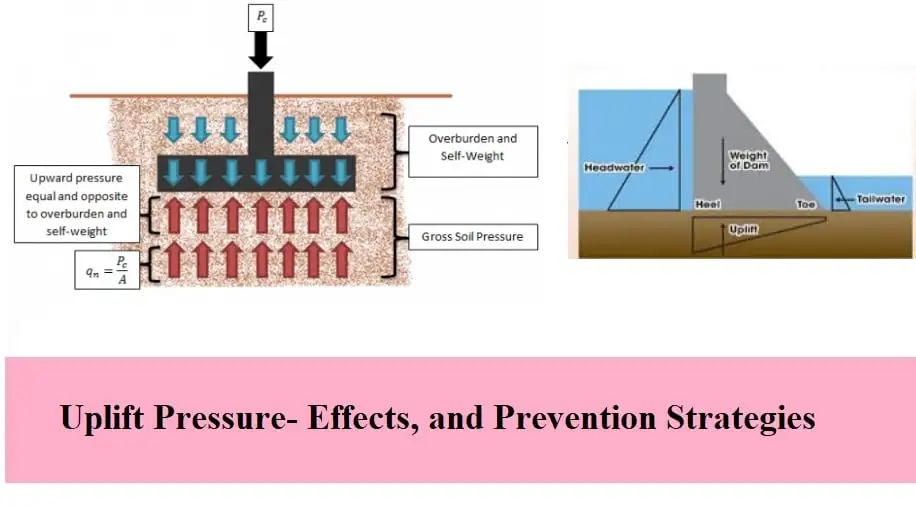

Hydro foundation is a type of foundation used in construction that utilizes water or fluid pressure to stabilize the foundation (Kett Hydro Foundation). It is a foundation system designed to resist uneven settling and earth movements.

The main purpose of hydro foundation is to provide a stable base for structures, especially in areas with poor soil conditions or seismic activity. The fluid pressure evenly distributes the weight of the structure and allows the foundation to “float” slightly. This helps prevent uneven settling issues.

Hydro foundations utilize high-pressure hydraulic jacks filled with water or hydraulic fluid to pressurize the foundation (Kett Hydro Foundation Ruby). The jacks are placed under the concrete foundation slab and are designed to expand and contract as the pressure changes. This creates a cushioning effect.

Materials commonly used in hydro foundation systems include concrete slabs, hydraulic jacks, high-pressure hoses and valves, and water or non-compressible fluid such as glycol solutions.

Types of Hydro Foundations

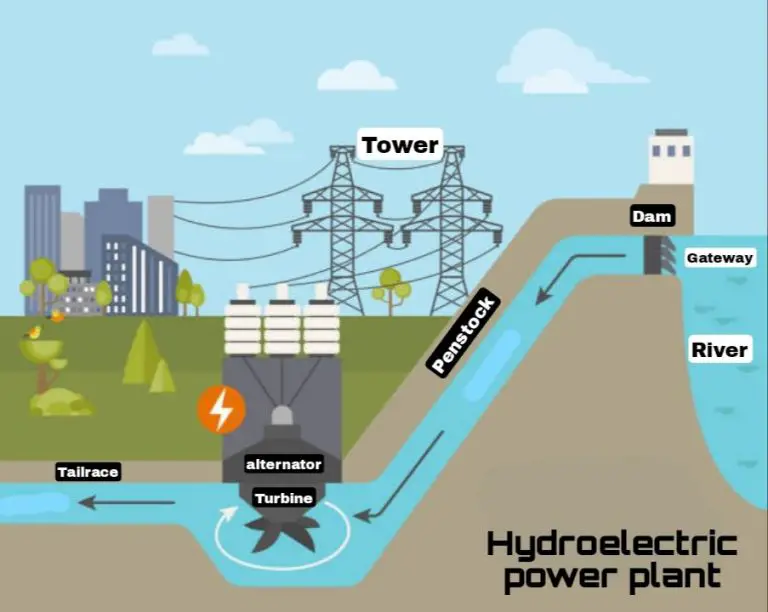

There are three main types of foundations used for hydroelectric power plants:

Mat Foundation

A mat foundation is a large concrete slab that covers the entire area underneath a structure (https://www.energy.gov/eere/water/types-hydropower-plants). It provides a stable, uniform foundation and distributes the weight of the structure over a large area. Mat foundations are commonly used for hydroelectric dams and powerhouses located on rock or other stable soil.

Raft Foundation

A raft foundation, also called a floating foundation, is a concrete slab that floats on the soil rather than being anchored into bedrock. It is typically used when bedrock is too deep or the soil is too soft to support a traditional foundation. Raft foundations can adapt to subsidence and shifts in the soil without cracking (https://www.energy.gov/eere/water/types-hydropower-plants).

Pile Foundation

A pile foundation consists of long concrete, steel, or timber piles driven deep into the ground to transfer the weight of the structure through weak or unstable soil to firmer ground or bedrock below. Piles provide support and uplift resistance. They are often used for hydroelectric structures adjacent to rivers or in areas with soft soils (https://www.energy.gov/eere/water/types-hydropower-plants).

Advantages of Hydro Foundations

Hydro foundations offer a number of benefits that make them advantageous for supporting structures built over water or unstable soil conditions. Some of the key advantages include:

High load bearing capacity – Because they displace water and silt to reach firmer soil underneath, hydro foundations are able to withstand very heavy structural loads. This high load bearing capacity makes them well-suited for large buildings and infrastructure projects.

Durable and long-lasting – Properly installed hydro foundations can last for decades with little or no maintenance required. The materials such as concrete and steel casings provide stability and durability over many years of service.

Resists erosion – Unlike shallow footings, the deep supports of a hydro foundation extend well below the level of any water flow or soil shifts. This helps them maintain their position and prevent erosion or undermining from currents, tides or flooding.

Sources:

https://www.energy.gov/eere/water/benefits-hydropower

https://www.enelgreenpower.com/learning-hub/renewable-energies/hydroelectric-energy/advantages

Challenges with Hydro Foundations

Hydro foundations present some key challenges that must be addressed in the planning and construction process. Three major challenges include:

Expensive

Hydro foundations are significantly more expensive than conventional foundations. The materials, equipment, and construction processes required drive up costs substantially. According to the American Made Challenges Prize competition, hydro foundation expenses can account for 5-15% of major hydropower project budgets. Proper planning and cost estimation is critical when budgeting for hydro foundations.

Require Extensive Site Preparation

Because hydro foundations rely on materials like concrete being injected or poured underwater, the construction site requires extensive preparation. Cofferdams must be erected to create a dry work environment. The riverbed needs to be leveled and cleared of debris. Access roads and equipment pads need to be constructed. This site preparation adds time and complexity to hydro foundation projects.

Not Suitable for All Soil Conditions

The soil and bedrock characteristics of the dam site must be carefully evaluated. Loose soils and fractures in bedrock can lead to concrete leakage and stability issues. Hydro foundations perform best in dense, impermeable soil or solid bedrock. Extensive subsurface exploration is needed to assess suitability.

Sources:

https://www.linkedin.com/pulse/challenges-hydropower-development-amit-pokhrel-mieaust-p-eng-m-s-

https://americanmadechallenges.org/challenge/ground-breaking-hydro

Materials Used

Three of the most commonly used materials for hydro foundation construction are reinforced concrete, steel, and timber:

Reinforced concrete is one of the most widely used building materials for hydroelectric dams and powerhouses. It provides excellent durability and strength needed to withstand the massive hydrostatic loads exerted by dams holding back large reservoirs. Reinforcing bars, also known as rebars, are embedded within the concrete to provide added tensile strength.

Steel is also commonly used in hydro foundations, particularly steel sheet piles driven into the ground to form retaining walls for excavation support. Steel materials provide high strength and ensure stability of structures. Steel beams, pipes, and plates are other steel components used.

Timber cribbing made of interlocking wooden beams is an economical option for supporting excavations during hydro foundation construction. The void spaces between beams are filled with granular backfill material. While not as strong as steel or concrete, timber provides adequate temporary support if designed properly.

Construction Process

The construction process of a hydro foundation generally involves the following key steps:

Site preparation involves clearing and leveling the site. Tree stumps and topsoil need to be removed (The Foundation Construction Process).

Excavation involves digging out the area for the foundation. The depth and layout depends on the building design and soil conditions (https://theconstructor.org/geotechnical/foundation-construction/1392/).

Formwork refers to the wooden or steel molds into which the concrete will be poured. Rebar or steel rods are fixed inside the formwork to reinforce the foundation (Pouring a Foundation).

Concrete pouring involves placing the concrete mix inside the prepared formwork. The concrete is poured in sections and vibrated to remove air bubbles.

Curing refers to allowing the concrete time to set, harden and gain strength. Curing takes at least 28 days and concrete must be kept moist during this period.

Cost Breakdown

Hydro foundations can be expensive to construct due to the materials, labor, equipment rental, permits and other costs involved. Some of the major cost components include:

Materials: Concrete, steel rebar, formwork, and other materials needed to build the foundation can be a significant expense. Materials may account for 25-40% of total costs, according to some estimates (Source).

Labor: Paying construction crews to excavate, pour concrete, install rebar, and complete other labor-intensive tasks contributes to costs. Skilled labor can account for 30-50% of the total (Source).

Equipment Rental: Large machinery like cranes, excavators, concrete pumps and generators need to be rented. Equipment rental and fuel can be 5-15% of total expenses.

Permits: Environmental permits, building permits, zoning approvals and other regulatory costs may be required. These permits and fees can sometimes tally 2-5% of overall costs.

Maintenance

Regular maintenance and inspection of hydro foundations is crucial to ensure they remain in good condition. Some key maintenance tips include:

Inspect the foundation walls and floor slab for any cracks or damage. Even small cracks can allow water to enter and lead to larger issues over time. Check for cracks along the walls, corners, and where the slab meets the foundation walls. Use a flashlight to inspect all surfaces thoroughly. Refer to this source for more on inspecting for foundation cracks.

Make repairs as soon as possible when any cracks or flaws are detected. Seal cracks with hydraulic cement or epoxy injections. For larger repairs, consult a professional foundation repair company. The sooner cracks are repaired, the less chance of water intrusion and further deterioration.

Conduct thorough inspections at least twice per year. Inspect in the spring after the ground thaws and again in late summer/early fall when the ground begins drying out. These seasonal changes in moisture are when cracks are most likely to open up.

In addition to regular inspections, address any signs of foundation damage immediately. Symptoms like sticking doors/windows, cracks in walls or ceilings, or sloping floors could indicate foundation problems. Don’t delay in contacting a professional for an assessment.

Proper maintenance helps extend the lifespan of hydro foundations and prevents costly repairs down the road. Following these best practices will help keep a hydro foundation in optimal condition for decades.

Safety Considerations

Hydro foundation construction involves several hazards that require safety precautions. According to the Clarification on the foundation for Passively Safe Lighting Columns document by Hydro, trench safety is a major concern. Trenches for foundations can be over 5 meters deep, requiring proper shoring or sloping to prevent collapse. Additionally, employees working in trenches may require fall protection to prevent injuries.

The Neutrogena Hydro Boost Hydrating Tint document by SkinSafe Products emphasizes the importance of proper equipment for foundation work. Workers should wear hard hats, safety glasses, and steel-toe boots at minimum. Jobsite safety measures like marking excavations and keeping heavy machinery away from trench edges are also critical. Proper training on equipment like excavators and following all applicable OSHA regulations can help mitigate risks.

Applications of Hydro Foundations

Hydro foundations have some key applications in large infrastructure and construction projects:

Bridges

Hydro foundations like caissons are commonly used to support bridge piers and abutments built over water. The caisson is sunk down through soft riverbed deposits until a suitable foundation material like bedrock is reached. This provides a solid base to build upon in water crossings. Some famous bridges built using caisson foundations include the Brooklyn Bridge and Golden Gate Bridge.

Dams

Concrete and masonry gravity dams often utilize hydro foundations. The dam structure is built on top of a prepared foundation of sound rock or coarse granular deposits. Grouting is applied to fill cracks and voids in the foundation material, and drainage galleries may be incorporated. This creates a watertight connection to handle the immense forces exerted by the reservoir. The Hoover Dam is a well-known example constructed on a complex hydro foundation system.

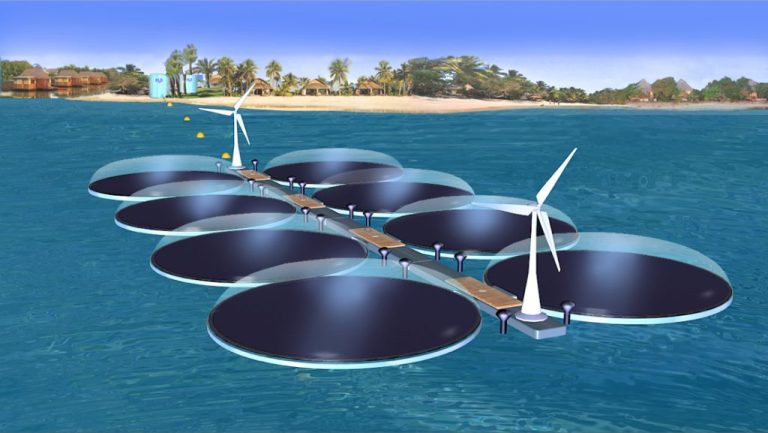

Offshore Structures

Hydro foundations enable offshore oil platforms, wind turbines, docks, and other structures to be anchored in the seafloor. Subsea caissons, monopiles, gravity bases, and other designs are employed. Grout or concrete is used to fill the foundations and provide stability against waves, currents, and seabed conditions. Offshore hydro foundations must withstand salty, corrosive conditions.