What Is Capacity Factor In Wind Energy?

The capacity factor of a wind turbine is an important metric that indicates how much electricity it actually produces over a period of time compared to its maximum possible output if it operated at full capacity 100% of the time. It is defined as the ratio of the actual electrical energy output over a given period of time, usually a year, to the maximum possible electrical energy output if the wind turbine operated at its full rated power capacity for the same amount of time.

Capacity factor is expressed as a percentage between 0-100%. A higher capacity factor indicates a wind turbine is producing closer to its maximum potential output. Capacity factor is crucial for wind farm operators and investors to estimate how much electricity their wind turbines will realistically generate based on the site’s wind speeds over the course of a year.

The capacity factor is affected by many variables including wind speeds, turbine reliability, availability, power curve, and grid constraints. Optimizing these factors can help increase a wind turbine’s capacity factor and energy production.

Calculating Capacity Factor

The capacity factor of a power plant is calculated as the ratio of its actual output over a period of time, divided by its potential output if it were possible for it to operate at full nameplate capacity continuously over the same period of time.

The formula for capacity factor is:

Capacity factor = Actual output / Rated (or Nameplate) Capacity

Where:

- Actual output is the total energy the plant produced over a set time period, measured in megawatt-hours (MWh).

- Rated or Nameplate Capacity is the maximum rated power output of the plant, measured in megawatts (MW).

The time period used can be a year or any other length of time. Capacity factors are typically calculated over the course of a year.

For example, if a wind farm has a Nameplate Capacity of 100 MW and it produces 87,600 MWh of electricity over the course of a year, its capacity factor would be:

Capacity factor = 87,600 MWh / (100 MW * 8,760 hours) = 0.30 or 30%

Typical Capacity Factors

The capacity factor varies widely across different types of power plants. According to the U.S. Energy Information Administration, in 2019 the average capacity factors in the United States were: https://www.eia.gov/electricity/annual/html/epa_08_02.html

- Nuclear: 92.5%

- Coal: 47.5%

- Natural gas: 56.8%

- Hydroelectric: 38.2%

- Wind: 34.8%

- Solar PV: 24.5%

For wind turbines specifically, the capacity factor depends on many factors like wind resource, turbine design, and site layout. Modern utility-scale wind turbines have capacity factors ranging from 25-50%. According to the Department of Energy, the average capacity factor for wind turbines installed today is around 42%. https://www.energy.gov/eere/wind/advantages-and-challenges-wind-energy

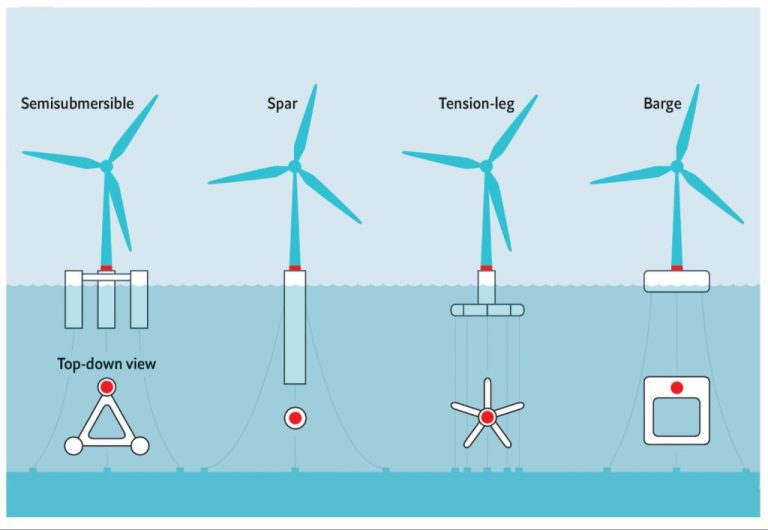

Offshore wind turbines tend to have higher capacity factors than onshore, often over 45%. This is due to stronger and more consistent winds over water compared to land. The capacity factor for offshore wind in Europe averages around 48%. https://www.irena.org/publications/2020/Feb/Offshore-wind-outlook-2020

With continued technology improvements, the capacity factors of wind turbines are expected to increase in the future.

Factors Affecting Wind Turbine Capacity Factor

There are several key factors that determine the capacity factor of a wind turbine, including:

Wind Speed – Wind speed is the most significant factor. Higher average wind speeds allow turbines to generate closer to their rated maximum capacity more often. The distribution of wind speeds at a site impacts capacity factor as well.1

Turbine Design – Advancements in wind turbine technology allow modern turbines to generate power more efficiently from lower wind speeds. Improved reliability also enables higher capacity factors. Taller towers access faster wind speeds at higher altitudes.2

Reliability – Minimizing shutdowns and operational issues helps increase capacity factor. Regular maintenance and quality components improve uptime.3

Age – Performance and capacity factors tend to degrade over a wind turbine’s lifespan as components wear out.3

Improving Wind Turbine Capacity Factor

There are several ways to improve the capacity factor of wind turbines, including advances in turbine technology, optimal site selection, and regular maintenance.

In terms of technology, newer wind turbine designs are able to operate at lower wind speeds and convert more of the wind’s energy into electricity. Larger rotors that sweep a bigger area and taller towers that access stronger winds at higher altitudes lead to increased capacity factors [1]. Additionally, improved control systems and drive train designs minimize turbine downtime and maximize energy production.

Careful site selection is also key. Areas with consistently strong winds, minimal turbulence, and few obstructions allow turbines to operate at their full potential. Offshore sites, in particular, offer vast open spaces with steady, powerful winds not disrupted by terrain or buildings [2].

Lastly, routine maintenance keeps turbines in optimal working condition. Mechanical components and sensors degrade over time, so scheduled repairs and replacements help minimize unplanned outages and maximize productive runtime [3].

Capacity Factor Trends

The capacity factor of wind turbines has steadily increased over the past few decades as technology has improved. According to a 2021 study published in ScienceDirect, the average capacity factor for offshore wind turbines in Europe increased from around 20% in 1990 to over 45% by 2010 (Carreno-Madinabeitia et al.). Onshore wind turbines have seen similar improvements, with capacity factors rising from around 10-20% in the 1980s and 1990s to around 25-40% for newly installed turbines today.

These increases in capacity factor are largely due to advances in turbine technology, such as larger rotors, taller towers, improved blade aerodynamics, and more reliable components. As wind turbine technology continues to advance, capacity factors are expected to increase further. According to the International Renewable Energy Agency, onshore wind capacity factors could reach up to 60% by 2050.

Geographic Differences

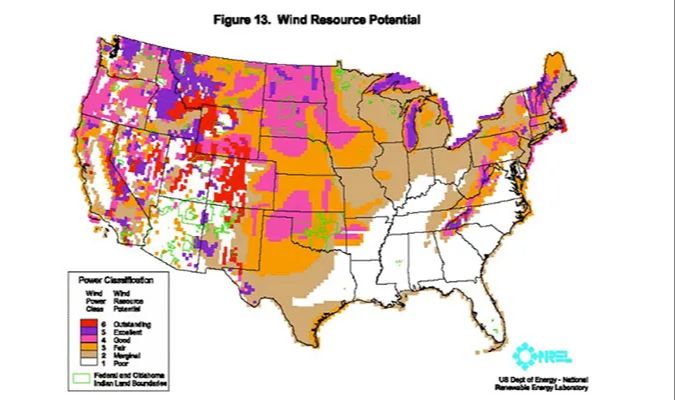

The capacity factor for solar PV can vary significantly across different regions and countries. This is largely due to differences in solar resource quality. Areas that receive more annual sunlight and have minimal cloud cover will achieve higher capacity factors. According to the National Renewable Energy Lab (NREL), the average capacity factor for utility-scale solar PV in the United States ranges from around 15% in Alaska to over 27% in California and Arizona (NREL). Parts of the Southwest United States, Middle East, North Africa, and Australia are particularly well-suited for solar power generation due to high direct normal irradiance (DNI).

An analysis by the International Renewable Energy Agency (IRENA) found that capacity factors for solar PV in 2016 ranged from 7% in Scotland to over 20% in Chile, Israel, and Saudi Arabia. The highest capacity factors were found in very sunny regions like northern Chile and Saudi Arabia. Germany had a capacity factor of 11% despite being farther north due to its large deployment of PV systems optimized for diffuse light conditions (NREL).

High-efficiency solar tracking equipment can also boost capacity factors by 25-30% compared to fixed-tilt arrays. Overall, geographic differences highlight the importance of siting solar projects in optimal locations to maximize capacity factors and energy production.

Economic Impacts

The capacity factor has a significant impact on the economics of wind energy. Lower capacity factors mean wind farms produce less electricity overall, which increases the levelized cost of electricity (LCOE). According to the National Renewable Energy Laboratory (NREL), the LCOE of land-based wind power plants ranges from $28-56 per MWh when assuming capacity factors between 35-45% [1]. Higher capacity factors within that range lead to lower LCOEs.

Areas with lower average wind speeds will have lower capacity factors, driving costs up. For example, capacity factors in the Great Plains can reach 50%, while areas in southeastern states may only achieve 20-30% [2]. This geographic variability affects wind energy’s competitiveness with other electricity sources.

Strategies like taller turbines, optimized siting, and advanced control systems can boost capacity factor and reduce costs. According to NREL data, increasing a wind plant’s capacity factor from 35% to 45% (28% higher) reduces LCOE by around 20% [1]. Therefore, capacity factor improvements are critical for the continued growth of cost-effective wind power.

Comparisons to Fossil Fuels

When comparing wind power capacity factors to fossil fuels like coal, natural gas, and oil, there are some notable differences. According to the EIA, in 2022 the average capacity factors were:

- Coal: 47.5%

- Natural gas: 56.8%

- Oil: 9.7%

Fossil fuel plants, especially natural gas and coal, tend to have higher capacity factors than wind turbines. This is because fossil fuel plants can operate continuously whenever fuel is available, while wind power depends on the wind resource which can vary. According to Stout, coal plants are designed for capacity factors between 70-85%, but average around 50% in practice. Natural gas combined cycle plants can achieve up to 90% capacity factors.

So while wind power capacity factors are improving, traditional fossil fuel plants still tend to operate at higher average capacity factors currently. However wind and solar costs have declined rapidly while fossil fuel costs fluctuate, making renewable energy more economically competitive in many markets.

Conclusion

Capacity factor is a crucial metric for assessing the productivity and economic viability of a wind energy project. It measures the ratio between the actual electrical energy output over a period of time compared to the maximum possible output if the turbine operated at full nameplate capacity.

Typically, wind turbine capacity factors range from 25-50%. Onshore wind farms generally fall on the lower end of the range, while offshore wind turbines can achieve higher capacity factors due to stronger and more consistent wind resources. Regional wind speed profiles, turbine technology, reliability, and project siting all impact capacity factor.

There are ongoing efforts across the wind industry to maximize capacity factor through improved turbine design, adaptive control systems, site selection, and operational strategies. As wind power expands its role in energy grids globally, capacity factor improvements will further increase productivity and value for wind projects.

Overall, capacity factor is a useful metric for comparing wind energy production across different projects. It provides insight into the economic viability and competitiveness of wind power. As the world continues transitioning to renewable energy, capacity factor trends will be an important indicator of progress in wind technology and adoption.