What Is Biomass With Ccus?

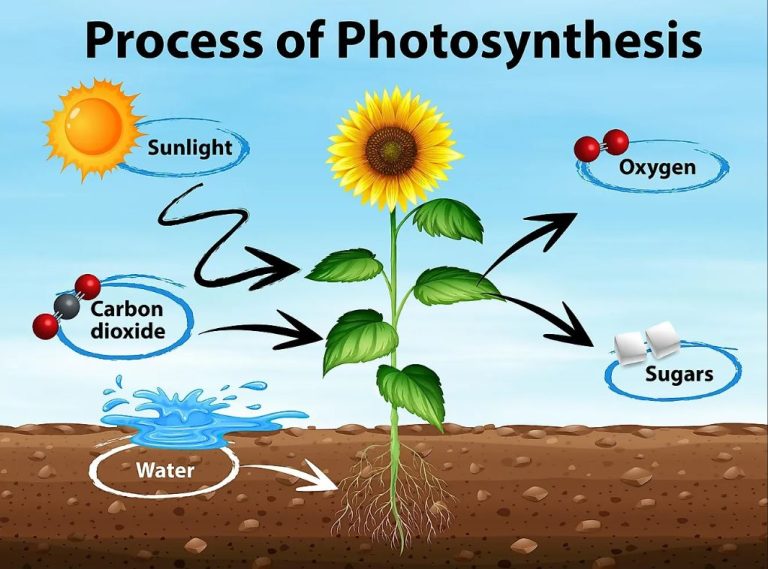

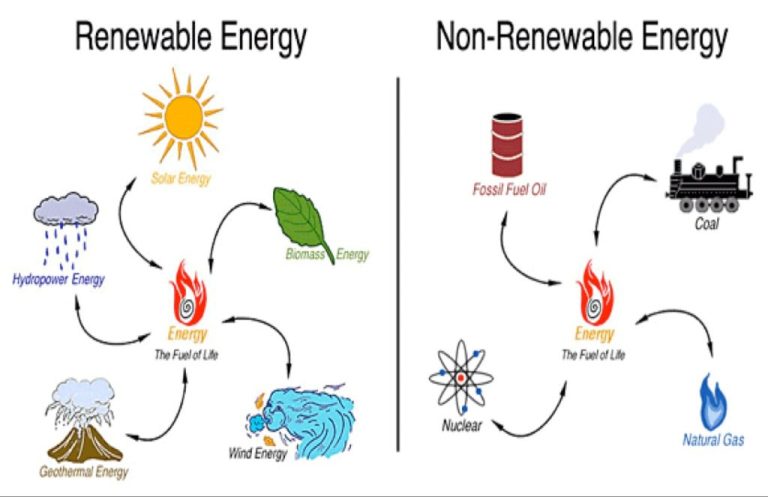

Biomass refers to organic material from plants or animals that can be used as an energy source. Common examples of biomass feedstocks include wood chips, agricultural residues like corn stover, and energy crops like switchgrass or Miscanthus. Biomass can be burned directly for heat or electricity or converted into liquid biofuels like ethanol or biodiesel. Using biomass for energy is considered carbon neutral because the carbon dioxide released when biomass is burned is balanced by the carbon dioxide absorbed as the plants grow. Biomass is an important renewable energy source and accounts for about 5% of total primary energy use worldwide.

Carbon capture and storage (CCS) refers to technologies that capture CO2 emissions from industrial processes like power generation or industrial facilities before they are released into the atmosphere. The CO2 is then compressed and transported via pipeline or ship for permanent geological storage deep underground in rock formations. CCS can capture up to 90% of CO2 emissions and is an important technology for reducing greenhouse gas emissions from fossil fuel use and hard-to-decarbonize industries like cement or steel production. According to the IEA, CCS could reduce global CO2 emissions by 15% by 2050 and is a critical technology for meeting global climate change mitigation goals.

Combining biomass energy systems with CCS, known as bioenergy with CCS (BECCS), results in net negative carbon dioxide emissions. This is because the carbon dioxide released when the biomass is burned is captured and stored underground rather than released to the atmosphere. The combination of bioenergy and CCS therefore actively removes carbon dioxide from the atmosphere. Deploying BECCS at scale has the potential to make an important contribution to reaching net zero emissions targets.

How biomass CCS works

Biomass CCS involves capturing CO2 emissions from biomass power generation and permanently storing the emissions underground to prevent them from entering the atmosphere. The key steps in the process are:

1. Biomass feedstocks like wood, agricultural residues or energy crops are combusted in a power plant to generate electricity. This results in a flue gas that contains CO2 from the combustion process.

2. The flue gas is captured before being released into the atmosphere. This is done using technologies like chemical absorption, physical adsorption, membrane separation or cryogenic Fractional distillation. Chemical absorption using amines is the most common approach.

3. The captured CO2 is compressed to turn it into a liquid for easier transportation and storage. Compression requires significant energy input.

4. The compressed CO2 is then transported via pipelines or ships to a suitable storage location. Depleted oil and gas reservoirs, deep saline aquifers and unmineable coal seams are possible storage sites.

5. The CO2 is injected deep underground into the storage formation. Over time, it gets trapped through physical and geochemical processes.

6. Monitoring of the storage site is done to track the movement of the injected CO2 and ensure permanent storage. Leakage could allow CO2 to return to the atmosphere.

By permanently storing the CO2 emissions from biomass combustion, biomass CCS results in negative emissions. The CO2 is removed from the atmosphere when the biomass feedstock grows and then permanently isolated through geologic storage after power generation.

Source: https://www.iea.org/reports/bioenergy-with-carbon-capture-and-storage

Benefits of biomass CCS

One of the primary benefits of biomass CCS is that it can reduce carbon emissions and even provide carbon-negative energy. This is because the carbon dioxide released when the biomass is burned is balanced out by the carbon dioxide absorbed as the biomass feedstock grows. As long as new biomass is grown at the same rate as it is harvested and utilized, the process results in net negative emissions.

For example, a 2018 analysis by the International Energy Agency found that deploying BECCS electricity and fuel production worldwide could enable the removal of 6 billion tonnes of CO2 per year by 2050, making a major contribution to climate change mitigation efforts [1]. The IPCC and other scientific bodies have identified BECCS as a critical technology for achieving net zero emissions across energy, industry and land-use [2].

In addition to reducing emissions, biomass CCS can provide renewable, low-carbon energy from the biofuel or biopower produced. It is also compatible with existing power plant infrastructure in many cases, allowing for an easier transition away from fossil fuels. Overall, BECCS represents a carbon removal solution that can work in tandem with clean energy generation.

Challenges of implementing biomass CCS

Despite the potential benefits, there are significant challenges involved with implementing biomass CCS on a large scale. Some of the main challenges include:

High costs – The costs of BECCS are difficult to estimate as they depend on the price of biomass feedstock, CCS components, infrastructure, operations and transportation. However, most analyses suggest the costs are very high compared to conventional bioenergy systems without CCS [1]. These high costs make it difficult to develop economically viable BECCS projects.

Lack of incentives – There are currently minimal economic incentives for BECCS in the form of carbon pricing or tax credits. More policy support is needed to make BECCS an attractive investment for developers and energy companies [2].

Storage limitations – While geological storage of CO2 is a proven technology, it is unclear if enough suitable storage sites exist to handle the volumes of CO2 captured from large-scale BECCS deployment. Developing the necessary storage infrastructure presents technical and economic challenges [3].

Examples of Biomass CCS Projects

There are several operational biomass carbon capture and storage (CCS) facilities around the world. One of the first and largest is the Illinois Industrial CCS project in Decatur, Illinois. This project started operation in 2017 and captures CO2 from the fermentation process at an ethanol plant. The CO2 is then transported via pipeline and injected deep underground for permanent geologic storage (https://www.iea.org/reports/bioenergy-with-carbon-capture-and-storage).

In Norway, the Klemetsrud waste-to-energy plant near Oslo started capturing CO2 from its biomass-fired boiler flue gases in 2020. The CO2 is liquefied and transported by ship to the Northern Lights project, which injects it into offshore geologic formations for permanent storage (https://www.drax.com/about-us/our-projects/bioenergy-carbon-capture-use-and-storage-beccs/). This was the first plant in the world to apply CCS technology to waste-to-energy.

The UK has several biomass facilities planning to add CCS in the coming years, including the Drax Power Station, which will retrofit BECCS technology to become the largest carbon capture project in the world. Other upcoming projects are planned in the US, such as the wood pellet plants in Louisiana aiming to start BECCS operation by 2024.

Biomass feedstocks for CCS

There are several types of renewable biomass sources that can be used as feedstocks for bioenergy and CCS projects. According to the IEA, the most common biomass feedstocks are:

- Agricultural residues – These include straw, bagasse, husks, cobs and nut shells. They are produced as byproducts of agricultural production. Using agricultural residues for bioenergy and CCS does not compete with food production or require additional land use change.

- Energy crops – Crops such as miscanthus and switchgrass can be purposely grown to provide biomass feedstock. They have high yields and low inputs. However, dedicating land to grow energy crops could lead to indirect land use change.

- Forestry materials – These include wood processing residues, tree trimmings, diseased trees, and thinning from sustainable forestry practices. Using forestry materials helps improve forest management.

- Biogenic waste streams – Sources include municipal solid waste, animal manure, and sewage sludge. Using biogenic waste streams for bioenergy and CCS helps manage waste while creating energy.

According to the Global CCS Institute, agricultural residues, perennial grasses and waste biomass appear to be the most promising large-scale sources of biomass for CCS. The choice of feedstock depends on cost, availability and sustainability.

Economics of biomass CCS

The costs of biomass CCS can be high compared to other renewable energy technologies. However, costs are expected to fall as the technology matures. The main cost components are biomass feedstock cultivation/procurement, conversion facility construction, CO2 capture equipment, transportation of CO2, and underground storage. According to the IEA, costs could potentially fall to $100 per tonne of CO2 stored by 2030 with sufficient deployment.

Various incentives are available to support biomass CCS projects. For example, under the 45Q tax credit in the US, developers can receive up to $50 per tonne for CO2 stored through biomass CCS. The EU Emissions Trading System provides additional revenue through issuing carbon credits for negative emissions. However, carbon prices would likely need to rise significantly for biomass CCS to be commercially viable without subsidies. More policy support is needed such as investment tax credits, loan guarantees, and funded demonstration projects.

Most projections estimate biomass CCS will play an increasing role in climate change mitigation efforts. The IEA estimates it could contribute up to 5% of total CO2 reduction needs by 2050, with many climate models requiring large scale BECCS deployment to keep global warming below 2°C. However, costs, sourcing sufficient biomass feedstocks, infrastructure buildout, public acceptance, and political will remain challenges. Significant investment and coordinated policies are required for biomass CCS to reach its emissions reduction potential.

Sources:

https://www.iea.org/energy-system/carbon-capture-utilisation-and-storage/bioenergy-with-carbon-capture-and-storage

https://globalchange.mit.edu/sites/default/files/MITJPSPGC_Rpt345.pdf

Carbon accounting for biomass CCS

There are some complexities around calculating the greenhouse gas reductions from biomass CCS projects. Unlike fossil fuel CCS which prevents emissions to the atmosphere, biomass CCS results in net negative emissions because the carbon comes from plants that absorbed CO2 as they grew. However, the timing of emissions and removals matters. Burning biomass emits CO2 immediately, while the growth of new biomass to replace what was burned takes time.

Under IPCC guidelines, bioenergy emissions are counted as zero at the point of combustion because the carbon released is considered to be balanced by the carbon absorbed during plant growth. However, some analysts argue this makes biomass appear carbon neutral when it is not. There is debate around the carbon accounting rules for biomass and whether biogenic emissions should be treated the same as fossil emissions.

Some of the key issues in greenhouse gas accounting for biomass CCS include:1

- Timing of emissions and removals from biomass growth, harvest, regrowth and avoided fossil fuel emissions

- Changes in forest carbon stocks from increased biomass harvests

- Distinguishing between byproducts, wastes, and dedicated energy crops

- Displacement of fossil fuels versus economic effects on supply and demand

- Difficulty tracking carbon flows through complex supply chains

There is active discussion around improving carbon accounting rules to better reflect the unique dynamics of biomass CCS systems. However, current guidelines provide a standardized methodology for tracking greenhouse gas reductions.

Policy landscape for biomass CCS

There has been a growing interest in policies and regulations around biomass CCS among governments as they seek ways to meet emissions reduction targets. Several key policies that have driven the development of biomass CCS include:

In the United States, the 45Q tax credit provides up to $50 per metric ton of CO2 captured and stored using qualified facilities including BECCS and direct air capture. This has made projects using BECCS more financially viable.[1]

The EU Emissions Trading Scheme allows negative emission credits for BECCS which enhances the business case for these projects. The EU’s Renewable Energy Directive also allows biomass fuels to be considered carbon neutral if sustainably sourced.[2]

The UK government has implemented contracts for difference for low carbon electricity generation including BECCS. This provides price stability and makes investment in BECCS more attractive.[3]

While regulations are evolving to enable BECCS, more policies explicitly supporting commercialization will likely be needed for significant global scale up of biomass CCS.

Future Outlook for Biomass CCS

The future outlook for biomass CCS looks promising in terms of scalability and growth potential as an important technology for climate change mitigation. According to the IEA, biomass CCS has the potential to mitigate up to 10% of total CO2 emissions by 2050 if deployed at scale[1]. However, achieving this scale will require overcoming technical and economic challenges. Key factors for scalability include developing efficient and low-cost supply chains for sustainable biomass feedstocks, optimizing capture technologies for biomass facilities, reducing costs through learning and scale, and building out transportation infrastructure for captured CO2. With supportive policies and sustained investment, costs are projected to fall and many experts see a major role for biomass CCS in reaching net zero emissions across hard-to-decarbonize sectors like industry and aviation. Overall, biomass CCS represents an exciting option in the portfolio of solutions needed to limit global temperature rise.