What Is Bioenergy Life Cycle Analysis?

Bioenergy life cycle analysis (LCA) is the assessment of the environmental impact of bioenergy production across its entire life cycle. The purpose of conducting a bioenergy LCA is to quantify the environmental burdens associated with producing bioenergy, from raw material extraction through processing, distribution, and final use. This allows researchers to identify opportunities to improve the sustainability of bioenergy systems.

A bioenergy LCA is generally conducted in three main phases:

1) Life Cycle Inventory – This involves creating an inventory of inputs (raw materials, energy) and outputs (emissions, waste) at each stage of the bioenergy life cycle.

2) Life Cycle Impact Assessment – The inventory data is used to calculate the potential environmental impacts in impact categories such as global warming potential, eutrophication, acidification, etc.

3) Interpretation – The results are analyzed to reach conclusions and recommendations about how to reduce environmental burdens.

Overall, bioenergy LCA provides a comprehensive view of the environmental tradeoffs associated with different bioenergy options to help inform sustainable practices and policies.

Goal of Bioenergy Life Cycle Analysis

The main goal of bioenergy life cycle analysis is to optimize the production and use of bioenergy while minimizing environmental impacts. More specifically, life cycle analysis helps with:

- Identifying opportunities to improve efficiency and reduce environmental burdens at each stage of production.

- Comparing different bioenergy systems and feedstocks in terms of sustainability.

- Informing policy and investment decisions for bioenergy.

- Quantifying environmental trade-offs between bioenergy options.

- Tracking environmental performance over time.

By taking a holistic view beyond just bioenergy production, life cycle analysis provides vital insights needed to develop an environmentally sustainable bioenergy sector. The approach helps identify the most resource and energy efficient bioenergy systems with the lowest impacts.

Key Steps in the Process

The key steps in a bioenergy life cycle analysis involve:

Goal Definition

The first step is to clearly define the goal and scope of the study. This includes setting system boundaries, establishing the functional unit, and identifying key assumptions and limitations.

Life Cycle Inventory Analysis

The inventory analysis phase involves collecting data on all inputs (raw materials, energy) and outputs (emissions, waste) across the product’s life cycle stages. This provides a comprehensive account of the system’s material and energy flows.

Life Cycle Impact Assessment

The impact assessment uses the inventory data to calculate the potential environmental impacts of the system, such as global warming potential, eutrophication, and resource depletion. Impact categories and calculation methods are selected to align with the defined goals.

Data Collection

Data collection is a crucial step in bioenergy life cycle analysis. It involves gathering all of the data needed to model the full life cycle of a bioenergy system. There are several key aspects to consider in the data collection phase:

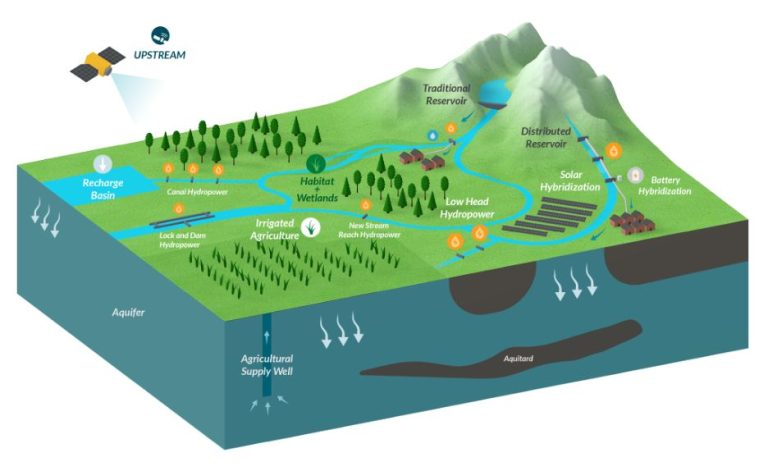

Types of data needed – The data collected depends on the goals and scope of the analysis, but generally includes details on energy and material inputs and outputs throughout the life cycle stages. For bioenergy, this may cover feedstock production, transportation, conversion processes, distribution, and end use. Data is needed on quantities of resources consumed, emissions and waste generated, energy produced, distances travelled, and more.

Sources of data – Data can come from direct monitoring and measurements, mass and energy balances, questionnaires, literature values, simulation models, and databases. Typical sources include the bioenergy company/facility itself, equipment manufacturers, government reports, academic studies, industry associations, and life cycle inventory databases.

Data quality considerations – Careful attention should be given to ensuring the data collected is high quality, including factors like representativeness, completeness, precision/uncertainty, reproducibility, and consistency. Primary data from on-site measurements is ideal, but often secondary sources must be used. Any estimates, assumptions, or data gaps should be documented.

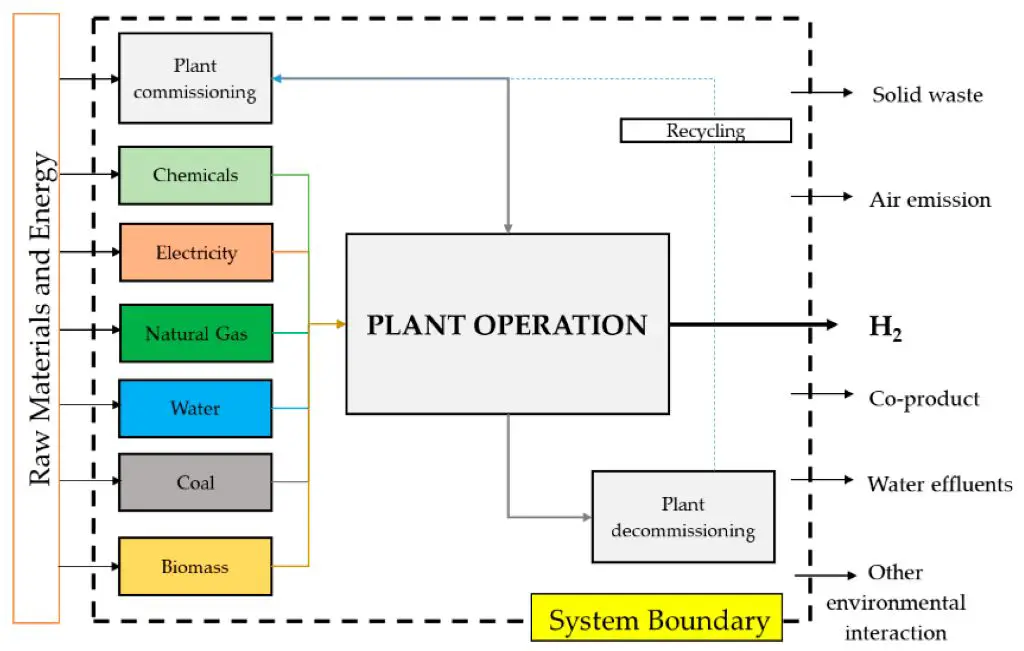

Life Cycle Inventory

The life cycle inventory step involves cataloging and quantifying all the inputs and outputs related to a product or process throughout its life cycle. This includes tracking all raw materials, energy, water used, emissions, wastes, and any other environmental exchanges at each stage. For a bioenergy process, the inventory would document things like:

- Water, fertilizers, pesticides used to grow the biomass feedstock

- Energy to harvest, collect, and transport the biomass

- Chemicals and energy consumed during conversion to biofuel

- Emissions to air, soil, water during feedstock growth, logistics, conversion and use

- Energy and material outputs generated, such as biofuels, co-products, wastes

The inventory aims to fully characterize the material/energy flows throughout the life cycle. This involves tracking inputs from nature (resources), outputs to nature (emissions) and the wastes related to making a product. The data is typically presented in tabular form with detailed mass and energy balance calculations. The completeness and consistency of this LCI step is critical for an accurate life cycle assessment.

Life Cycle Impact Assessment

The Life Cycle Impact Assessment (LCIA) phase aims to evaluate the significance of potential environmental impacts using the inventory data collected. This involves associating inventory data with specific environmental impact categories and category indicators. Some key steps in LCIA include:

– Selection of impact categories, category indicators and characterization models: Examples of impact categories evaluated include global warming potential, eutrophication potential, acidification potential, ozone depletion potential, etc. Each category has specific indicators and models used to characterize impacts.

– Classification: Inventory items are sorted and assigned to their respective impact categories.

– Characterization: Inventory data items are converted into common units and aggregated within their assigned impact category. This is done using characterization factors based on the models.

– Normalization (optional): Characterized results are related to reference values like total emissions or resource use in a region to better understand relative magnitudes across impact categories.

– Weighting (optional): Normalized results are multiplied by weighting factors reflective of priorities and value-choices to obtain single scores.

LCIA transforms the inventory data into more meaningful indicators of environmental performance in various impact categories. This aids in interpreting the impacts of processes within a bioenergy life cycle.

Interpretation

The interpretation phase is focused on analyzing the results of the life cycle impact assessment, drawing conclusions, and making recommendations. The key aspects of the interpretation phase include:

Analyzing Results

The results of the life cycle impact assessment are thoroughly analyzed to understand the implications. The relative contributions of different life cycle stages and processes to each impact category are determined. This helps identify the major hotspots for environmental impacts across the life cycle.

Statistical analysis can be applied to understand the uncertainty and sensitivity of the results. The data sources, assumptions, and methodology are critically reviewed to identify limitations and areas for improvement.

Sensitivity Analysis

Sensitivity analysis is conducted by varying model parameters, inventory data, and calculation methods to evaluate the robustness of the results. This helps determine the key parameters that influence the results and quantify the effect of parameter uncertainty.

Scenario analysis can also be done using different assumptions to understand the range of potential environmental impacts.

Conclusions

The main conclusions and recommendations from the life cycle assessment are formulated and summarized. This includes a comparative assessment of different bioenergy systems, identification of improvement opportunities, and decision-making support.

The conclusions help determine the overall environmental performance of the bioenergy system and make comparisons to other energy options. The results can be used to inform technology, process, and policy improvements.

Applications

Life cycle analysis is an important tool for evaluating the sustainability and environmental impacts of bioenergy systems. Here are some of the main ways that LCA is applied to bioenergy:

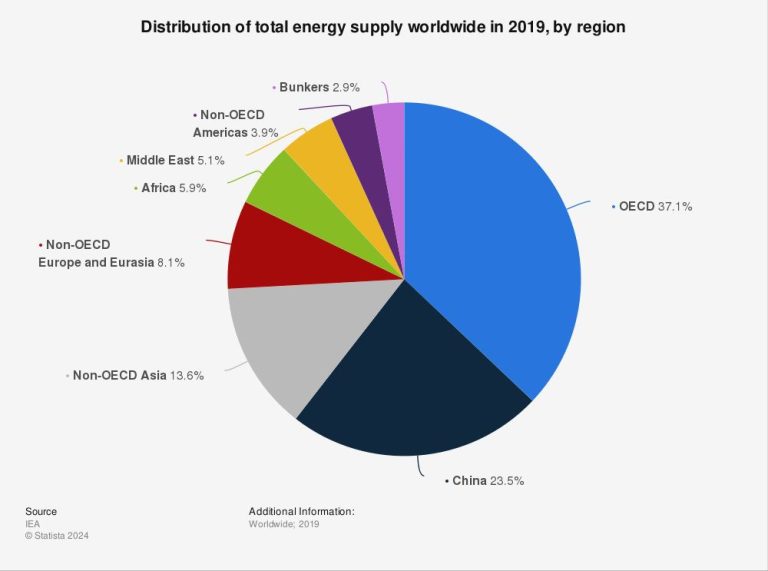

Comparing biofuels to fossil fuels – LCA allows researchers to compare the cradle-to-grave impacts of biofuels versus conventional fuels like gasoline and diesel. For example, an LCA may find that corn ethanol reduces greenhouse gas emissions by 20% compared to gasoline, but increases water usage and pollution.

Assessing different bioenergy feedstocks – LCA can compare the impacts of using different raw materials like corn, sugarcane, switchgrass or algae to produce biofuels. This helps determine the most sustainable options.

Analyzing bioenergy production pathways – LCA looks at the impacts of different production processes, such as biochemical versus thermochemical conversion technologies for biofuels.

Informing policy decisions – Governments utilize LCA findings to develop policies that promote sustainable bioenergy development, such as subsidies, mandates and sustainability standards.

Identifying environmental hotspots – LCA pinpoints parts of the bioenergy life cycle with disproportionate impacts, like fertilizer production or biomass transport, to target process improvements.

Overall, LCA provides a quantitative and science-based method to evaluate the sustainability of bioenergy systems across their full life cycle.

Limitations

Bioenergy life cycle analysis has some limitations that are important to consider:

Data constraints can be a major limitation. Collecting comprehensive data across the full life cycle requires significant time and resources. Data may not be available for all processes, especially indirect impacts across the supply chain. Using proxy data introduces uncertainty.

There is inherent variability in biological systems that makes LCA modeling difficult. Crop yields, soil conditions, climate impacts and other factors can vary greatly year-to-year and by region. Models rely on numerous assumptions to account for this variability.

Many key LCA calculations require assumptions about complex systems. For example, modeling indirect land use change requires assumptions about how increased biofuel feedstock production will impact land use globally. The resulting greenhouse gas estimates can differ greatly depending on the assumptions.

Overall, while bioenergy LCA provides valuable insights, the limitations mean results have significant uncertainty ranges. The limitations must be considered when using LCAs to guide policy and other decisions.

Future Outlook

Bioenergy life cycle analysis is an evolving field with emerging trends and innovations that aim to improve the sustainability and efficiency of bioenergy systems. Some key areas of development include:

Advances in life cycle inventory databases and impact assessment models to enable more comprehensive, accurate LCAs. There is a push to expand regionalized databases that better represent local conditions for bioenergy feedstocks.

Incorporation of socioeconomic aspects into LCAs beyond purely environmental impacts. This allows for evaluating ethics, food security, land use implications and more.

Improving characterization modeling of impacts like eutrophication, acidification, and toxicity. This helps quantify the true impacts of different bioenergy options.

Development of consequential LCAs that account for market-mediated effects over time, versus simpler attributional LCAs. This provides a more dynamic system perspective.

Increased use of uncertainty and sensitivity analysis to assess the reliability of LCA results and conclusions.

Application of LCA earlier in design processes to inform technology development and reduce environmental burdens.

Overall, the field aims to create more holistic, accurate means of evaluating bioenergy sustainability to support the transition to renewable energy.