What Is An Energy Consuming Process?

An energy consuming process is any activity that requires input of energy in order to accomplish a desired task or purpose. Energy is necessary to drive virtually every mechanical process and physical or chemical transformation. Some common examples of energy consuming processes include:

- Operating heavy machinery such as drills, pumps, and conveyor belts in factories

- Powering home appliances such as refrigerators, washing machines, and ovens

- Fueling transportation methods including cars, trucks, planes, and ships

- Heating or cooling buildings through HVAC systems

- Charging batteries and powering electronics like computers and mobile devices

- Enabling chemical reactions to produce materials, chemicals, fuels, food, and pharmaceuticals

These processes require energy input in the form of electricity, fuel combustion, mechanical force, or other forms. The energy is used to generate motion, apply force, change matter from one state to another, or enable chemical transformations. Without adequate energy input, the desired process would not be able to proceed.

Types of Energy Consuming Processes

Energy consumption occurs in many forms across various industries and applications. Broadly speaking, there are three main types of energy consuming processes: mechanical/physical, chemical, and electrical.

Mechanical/Physical Processes

Mechanical or physical processes involve the use of mechanical power to perform work. Examples include transportation, manufacturing, construction, mining, agriculture, and materials handling. Energy is consumed to power physical movement and mechanical operations like pumping fluids, excavating materials, assembling products, and moving people or goods from one place to another.

Chemical Processes

Chemical processes consume energy through chemical reactions and phase changes. The chemical industry, including petrochemicals, polymers, fertilizers, and pharmaceuticals, relies heavily on chemical processes that require significant energy input. Other examples include metal refining, food processing, and pulp and paper production. Heating substances to high temperatures to induce chemical reactions is an energy-intensive process.

Electrical Processes

Electrical processes use electricity to power operations, equipment, and devices across the commercial, industrial, and residential sectors. Lighting, electronics, appliances, machinery, and industrial equipment all require electrical energy to function. High intensity processes like electrolysis and electrical discharge machining consume large amounts of electrical power. Information and communication technology infrastructure also necessitates major electrical energy use.

Mechanical/Physical Processes

Mechanical and physical processes involve the application of mechanical force or work to perform tasks like milling, grinding, cutting, pumping fluids, compression, and conveying/transport. These processes require energy to overcome friction, resistance, and other forces.

Milling and grinding use rotary cutters to cut, shape, and finish materials like metals, plastics, and lumber. Milling can involve removing material with a spinning multiple-tooth cutter whereas grinding usually removes small amounts of material with an abrasive wheel or disc. Both require considerable energy to spin the cutting tools and overcome the resistance of the material being cut.

Cutting processes like sawing, shearing, and slicing also consume energy to operate the cutting tools and overcome the strength of the material. The energy required depends on the toughness, hardness, and thickness of the material being cut.

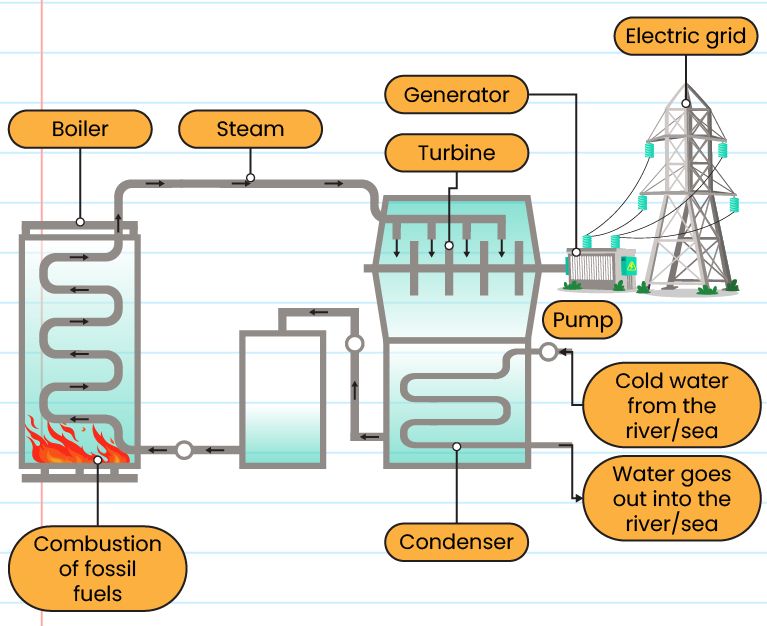

Pumping fluids like water, oil, or chemicals consumes energy to overcome gravity, friction, and pressure to raise, transfer, or pressurize liquids. Centrifugal, positive displacement, and rotary pumps all require energy input to move fluid against resistance. Compressing gases also requires energy to reduce volume against atmospheric pressure.

Conveying and transporting raw materials, parts, or finished products with conveyor belts, elevators, cranes, and automated guided vehicles also consumes energy to overcome friction and move weight horizontally or vertically. Energy use depends on weight, speed, and distance travelled.

Chemical Processes

Chemical processes are energy consuming processes that involve chemical reactions resulting in the rearrangement of atoms. These reactions can absorb or release energy as bonds between atoms are broken and formed. Some examples of chemical processes include:

- Combustion – This is an exothermic chemical reaction between a fuel and an oxidant that produces energy in the form of heat and light. Combustion requires an ignition source to initiate the reaction. Examples include burning of fossil fuels and biomass.

- Electrolysis – This process involves passing an electric current through a medium to drive a chemical reaction. Electrolysis is used for processes like smelting of metals from their ores.

- Synthesis reactions – Chemical synthesis combines simpler compounds to form more complex products. Many polymers, fuels, fertilizers, pharmaceuticals and other chemicals are produced through synthesis reactions.

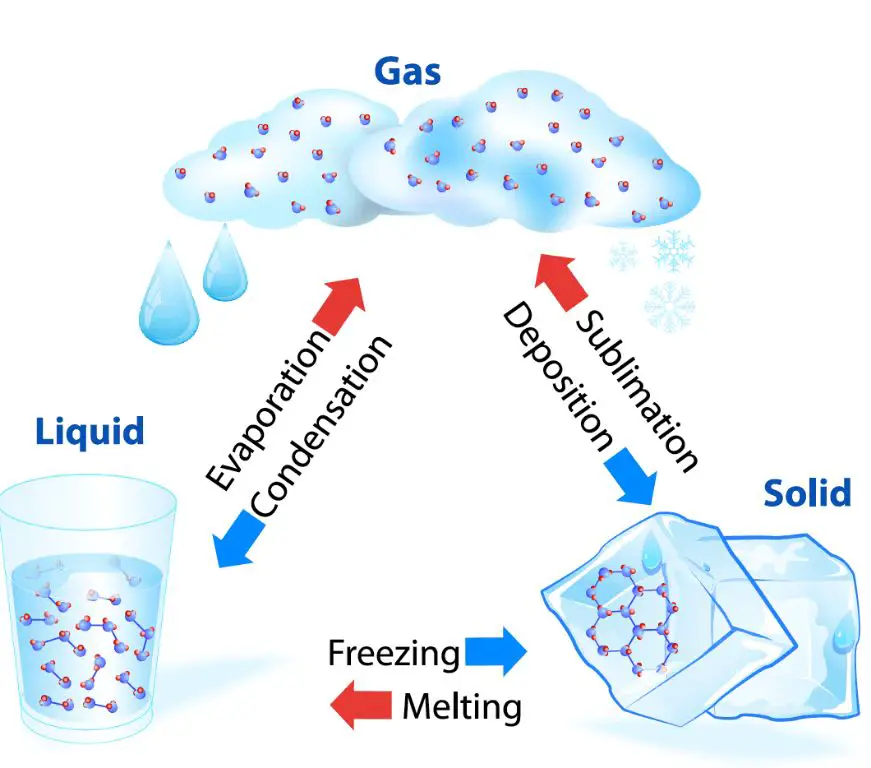

- Phase changes – Transition of a substance between liquid, solid and gaseous states require absorption or release of energy. Examples include melting, freezing, evaporation, condensation.

- Mixing – When two or more substances are combined, energy may be needed to overcome molecular interactions. Exothermic or endothermic heat may also be released or absorbed during mixing.

Careful control of parameters like temperature, pressure, and concentrations is needed to manage the energy requirements of chemical processes.

Electrical Processes

Electricity is used in many industrial processes as a source of energy for heating, electrolysis, electric motors, and more. Some major electrical energy consuming processes include:

Resistive Heating

Resistive heating converts electricity into heat through the resistance of conducting materials. As electric current passes through a resistive material, it encounters friction that generates heat. Common examples of resistive heating include electric stoves, space heaters, hair dryers, and strip heaters used in industrial processes.

Electrolysis

Electrolysis uses electricity to drive chemical reactions that would not occur spontaneously. A key example is the electrolysis of water, which separates water into hydrogen and oxygen gases. Electrolysis is also used for electroplating, metal refining, and producing chemicals like chlorine and sodium hydroxide.

Arc Furnaces

Arc furnaces use very high currents and voltages to generate an electric arc to melt and refine metals. The intense heat from the arcing can reach over 3,500°C. Arc furnaces are commonly used in steelmaking to melt scrap metal and remove impurities before casting.

Electrical energy powers processes vital to modern industry and daily life. But electricity generation also constitutes a major share of global energy consumption and carbon emissions. Improving efficiency of electrical processes can provide environmental and economic benefits.

Major Energy Consuming Industries

There are several key industries that consume large amounts of energy through their day-to-day operations. The manufacturing, transportation, and commercial building sectors in particular account for a huge portion of energy usage.

The manufacturing industry uses energy for operating heavy machinery and heating and cooling large facilities. Energy is consumed during every step of manufacturing processes, from the extraction of raw materials to assembly of final products. The specific energy needs of manufacturing plants depend on what they produce and how they produce it. Overall, this sector accounts for about 30% of global energy consumption.

Transportation consumes around 20% of total global energy use. This includes energy used to power cars, trucks, ships, planes, trains, and other vehicles that transport people and goods. Transportation relies heavily on petroleum products like gasoline and diesel. As economies grow, transportation energy usage rises due to increasing movement of goods and services.

Commercial buildings such as offices, hospitals, schools, stores, and other facilities consume around 10% of global energy. Heating, cooling, lighting, appliances, electronics, and other services require significant energy in commercial buildings. As cities expand and economies develop, the floorspace and energy needs of commercial buildings continue to grow. Energy efficiency improvements in lighting, HVAC systems, building shells, and other areas can help constrain this rapid growth in energy consumption.

Targeting energy efficiency in the manufacturing, transportation, and commercial building sectors through advanced technologies, optimized processes, and strategic policies can lead to major energy savings worldwide. Given their large collective energy footprints, these industries present prime opportunities for improving overall energy productivity.

Improving Efficiency

There are several ways that energy consuming processes can be optimized to improve efficiency and reduce waste:

Process Optimization

Analyzing each step of a process and finding ways to reduce unnecessary energy use, lower temperatures and pressures, and minimize idle time can lead to significant energy savings. Simple changes like improving insulation, maintenance, and scheduling can also optimize energy efficiency.

Waste Heat Recovery

Capturing and reusing waste heat from industrial processes is an effective way to improve efficiency. This might involve installing heat exchangers, heat pumps, or organic Rankine cycles. Recovered waste heat can be used to preheat materials, generate electricity, or meet facility heating needs.

Switching to Renewable Energy

Transitioning to renewable energy sources like solar, wind, geothermal, or bioenergy can drastically reduce the environmental footprint of energy consuming processes. On-site renewable generation also improves energy security and insulation from utility rate volatility.

Case Studies

Industrial and manufacturing processes can significantly reduce energy consumption through optimization and efficiency improvements. Here are some real-world examples:

Efficient Pumping Systems

Pumps are used extensively in industrial applications for moving liquids. Optimal pump selection, right-sized pumps, and variable speed drives can dramatically cut energy use. For example, an automotive plant installed variable frequency drives on cooling water pumps, reducing energy consumption by 75% while still meeting operational needs.

Recovering Heat from Furnaces

Furnaces produce large amounts of wasted heat. Capturing and reusing this heat, through heat exchangers or heat recovery systems, improves efficiency. A steel producer recovered waste heat from a furnace exhaust system to preheat combustion air, cutting fuel use by over 20%.

Optimized Motor Systems

Electric motors are ubiquitous in factories. Upgrading to premium efficiency models, properly sizing motors for the load, and adding variable speed drives can save significant energy. One manufacturer optimized the motors in a paper mill, reducing overall motor system power demand by 30%.

Environmental Impact

Transitioning to more energy efficient processes can have a significant positive impact on the environment. Some of the main benefits include:

Reducing carbon emissions – Many industrial processes rely heavily on the burning of fossil fuels, which generates greenhouse gases like carbon dioxide. By improving efficiency, less fuel is needed to complete the same tasks, leading to lower emissions. This helps mitigate climate change.

Lower pollution – Increased efficiency also reduces other byproducts like sulfur dioxide, nitrogen oxides and particulate matter. This decreases smog, acid rain, and health hazards associated with pollution.

Sustainability – Efficient energy use reduces strain on nonrenewable resources like oil, gas and coal. This prolongs the lifetime of existing reserves. It also gives more time to transition to renewable energy sources like solar, wind and geothermal.

Overall, greener industrial processes are vital for protecting the environment while still allowing economic growth and human development. The incentives for energy efficiency are both ecological and economical.

Conclusion

In summary, an energy consuming process is any system that requires input of energy to operate and perform useful work. The three main categories are mechanical/physical processes, chemical processes, and electrical processes. Examples include manufacturing, transportation, heating and cooling systems, and appliances.

Improving the efficiency of these processes is crucial for reducing energy consumption and environmental impacts. Even small optimizations add up, and adopting the best available technologies and practices can lead to major energy savings over time. Efficient processes allow us to maintain production and services while consuming less energy. This benefits the environment through lower emissions and reduced resource depletion.

More work is still needed to maximize efficiency across all sectors. Through continued research, investment, and an emphasis on sustainability, energy consuming processes can be refined to use only the energy that is absolutely necessary. The payoff will be well worth the effort.