What Is A Pv System Made Of?

Photovoltaic (PV) systems are solar power systems that use solar panels to convert sunlight into electricity. They allow homes and businesses to harness the sun’s energy for power generation, helping reduce reliance on the electrical grid. PV systems are modular, versatile, and increasingly affordable, making solar energy more accessible.

PV systems come in a variety of configurations but primarily consist of solar panels (with PV cells), inverters, and mounting equipment. Residential systems may also include batteries for energy storage. PV systems can range from small rooftop arrays that provide a few kilowatts to massive solar farms that generate tens or hundreds of megawatts. They provide clean renewable electricity from an abundant free fuel source – the sun.

Solar Panels

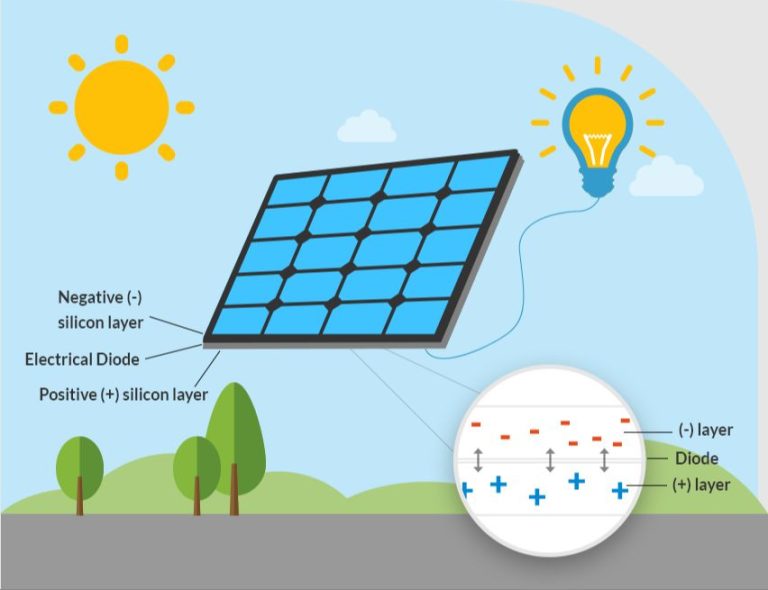

Solar panels, also known as photovoltaic (PV) panels, are a key component of any PV system. They are responsible for converting sunlight into direct current (DC) electricity. The main components and materials of solar panels include:

Solar Cells – Solar panels are made up of many individual solar cells. These cells are typically made from monocrystalline silicon or polycrystalline silicon, which are semiconducting materials that generate electricity when exposed to sunlight. The silicon cells are protected by a glass casing and framed in aluminum.

Junction Box – The junction box collects the DC current from each of the solar cells and combines them into one electrical output. This aggregated electricity then runs through cables out of the junction box.

Backsheet – The backsheet forms the rear protective layer of the solar panel. It is usually made of tedlar or polymers and protects the panel from weather damage.

Encapsulant – The encapsulant seals and holds the solar cells in place. It is commonly made of ethylene vinyl acetate.

Frame – The frame, typically made of aluminum, surrounds and helps support the solar cells while allowing secure mounting of the panels.

Inverters

Inverters play a critical role in photovoltaic (PV) systems by converting the direct current (DC) electricity generated by the solar panels into alternating current (AC) electricity that can be used to power homes and businesses. The conversion process allows the solar-generated electricity to be compatible with standard electrical infrastructure and equipment.

PV panels produce DC power, but most appliances and devices used in homes and buildings require AC power. Inverters act as the bridge between the DC output of the solar panels and the AC input required to run lights, appliances, electronics and anything else connected to the electrical system.

Inverters monitor and adapt to the variable DC output from the solar panels as conditions like cloud cover and sunset cause fluctuations. The inverter’s circuitry converts the DC into standardized, steady AC power that smoothly integrates into the electrical network.

High quality inverters from reputable brands are a key component in any PV system. They ensure the system’s power production is optimized and the electrical output is safe, reliable and compatible with infrastructure and devices. Selecting the properly sized inverter with enough capacity for the panels being installed improves efficiency and provides long-term performance.

Batteries

Batteries play an important role in solar PV systems by storing excess electricity generated from the solar panels. This stored energy can then be used to power electrical loads when solar production is low, such as at night or on cloudy days. There are several battery options available for home solar energy storage:

Lead-Acid Batteries

Lead-acid batteries are the most common type used in home PV systems. They contain lead electrodes and sulfuric acid as the electrolyte. Lead-acid batteries are a mature technology that is inexpensive, widely available, and reliable. However, they are large, heavy, and require ventilation. Lead-acid options include flooded, gelled, and absorbed glass mat (AGM) batteries.

Lithium-ion Batteries

Lithium-ion batteries have become popular for solar storage in recent years. They are lighter, smaller, and have a longer lifespan than lead-acid. However, lithium-ion batteries are more expensive. Different lithium-ion battery types include lithium iron phosphate (LFP), lithium nickel manganese cobalt oxide (NMC), and lithium titanate oxide (LTO).

Flow Batteries

Flow batteries are an emerging technology for large-scale energy storage. They store energy directly in the electrolyte liquid. Flow batteries have a long lifespan, can discharge for very long durations, and can be scaled up easily. However, they are currently expensive and less efficient than lithium-ion batteries.

When selecting a battery for a home PV system, key factors to consider are the battery chemistry, size, lifespan, performance, and cost. Proper battery maintenance and operation are also critical for safety and longevity.

Charge Controllers

A charge controller is a key component of most PV systems. It regulates the voltage and current coming from the solar panels going to the battery to prevent overcharging. Charge controllers protect batteries from overcharging by limiting the rate at which they are charged, preventing damage and prolonging their lifespan. They track the battery’s state of charge, and reduce or stop the flow of electricity from the panels to the battery when it reaches a certain set point, around 80-85%.

Charge controllers come in different sizes and types. Simple controllers just prevent overcharging, while more advanced MPPT controllers can maximize power transfer efficiency from solar panels to batteries. Controllers may be PWM (pulse-width modulation) or MPPT (maximum power point tracking). MPPT controllers are more efficient and can harvest up to 30% more power from panels.

Overall, charge controllers play a vital role in regulating and optimizing electrical flow in PV systems. By preventing overcharging and damage, they ensure batteries last longer and operate safely at maximum capacity.

Wiring

The wiring is a critical component that ties together all the parts of a photovoltaic system. Proper wiring ensures efficient operation and helps prevent issues like power loss and fires.

PV panels generate DC electricity which needs to be converted to AC for use in homes and businesses. This requires running wires from the panels to one or more inverters. Thicker wires are used for runs over longer distances to minimize resistance and loss of power.

For off-grid systems, additional wiring is needed between the inverter, batteries, and charge controllers. The batteries store energy for use when solar panels aren’t generating, so large gauge wires help maintain voltage over variable distances.

All wiring should be run through weatherproof conduit to protect against UV rays, moisture, and insects. Proper grounding wires are also essential for diverting stray electrical current and preventing shock or fire hazards.

Clearly labeled disconnects and overcurrent devices are wired into the system to allow safe shutdown for maintenance. Monitoring systems may also be wired to track system performance.

Hiring a qualified solar installer is highly recommended to ensure the right wire types, gauges, and connections are used in the system.

Racking

Racking refers to the mounting systems used to affix solar panels in place. There are a few main options for racking PV systems:

Rooftop racking – For rooftop solar, panels can be mounted flush with the roof or on racks tilted at an angle. Flush mounting is simpler and less expensive but tilted racking increases energy production. Tilted racking can be installed parallel or perpendicular to the roofline.

Ground mount racking – For ground mount systems, racking holds panels in the desired orientation. This allows angling panels to maximize sun exposure. Ground mounting is more complicated but offers more flexibility in panel placement.

Tracking racking – Tracking rack systems move panels to follow the sun’s path during the day. Single-axis tracking tilts panels east to west and dual-axis also tracks the sun’s elevation. Tracking maximizes energy output but increases system costs.

Racking must be properly engineered to withstand wind, snow loads, and other environmental factors. Aluminum and galvanized steel are common racking materials that resist rust and corrosion.

Safety Components

Safety is critical for any electrical system, but especially for solar PV systems which produce high amounts of DC electricity. There are several key components that help ensure safe operation of a PV system:

Disconnect Switches – These switches allow sections of the system to be safely disconnected for maintenance and repairs. Having multiple disconnect switches allows isolating parts of the system like the inverter or solar panels.

Overcurrent Protection – Devices like fuses and circuit breakers protect against overcurrents that could damage equipment or cause fires. Properly rated overcurrent protection should be included for modules, batteries, and other system components.

Ground Fault Protection – Ground faults occur when current flows unintentionally through the grounding system. Ground fault detectors and interrupters shut down the system when a ground fault is detected before damage or injury can occur.

Lightning and Surge Protection – Surges caused by lightning strikes or grid fluctuations can damage a PV system. Surge protectors and lightning arrestors divert this excess energy to prevent equipment damage.

Warning Signs – Warning signs indicate electrical hazards and alert people to take proper precautions around the solar system.

Paying attention to key safety components improves the safe operation of a PV system for installers, homeowners, and utilities.

Monitoring

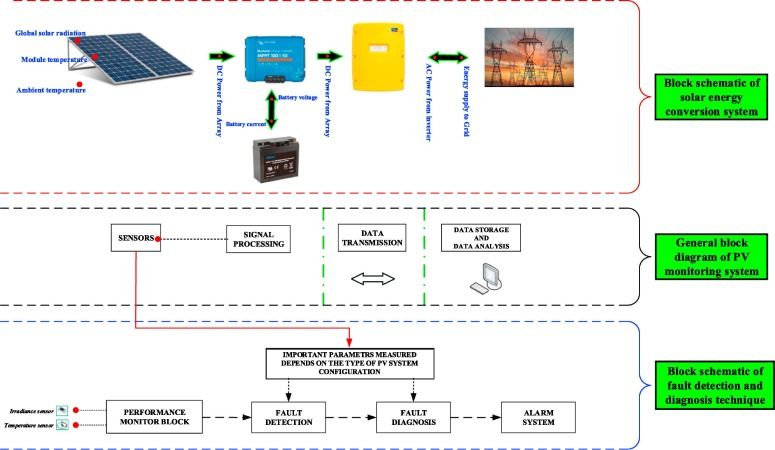

Monitoring is an important part of any photovoltaic (PV) system installation. Monitoring hardware and software allow system owners and installers to track system performance and identify any issues that may arise. There are several key components involved in PV system monitoring.

Monitoring hardware includes meters, sensors, and data loggers. Meters track and record energy production data. Sensors monitor environmental conditions like irradiance and temperature. Data loggers aggregate data from meters and sensors and transmit it to monitoring software. Data loggers may communicate wirelessly or through a wired connection.

Monitoring software analyzes performance data and presents it in an accessible interface. It can detect underperformance, faults, and other issues. Monitoring software may provide real-time insights or compile historical performance data. It allows users to view system production, consumption, efficiency, and more. Some monitoring platforms also include remote troubleshooting capabilities.

By keeping close tabs on PV system performance, owners can ensure their system is operating optimally. Monitoring maximizes uptime and gives advance warning about potential problems. It also aids in maintenance and can help validate energy savings and return on investment. As solar expands globally, robust monitoring is essential for managing and optimizing solar assets.

Conclusion

In summary, a photovoltaic or PV system is made up of several key components that work together to convert sunlight into usable electricity. The main components are the solar panels, which contain photovoltaic cells to absorb sunlight and generate DC power. This power is sent to one or more inverters, which convert the DC power into AC power for home use. Batteries store excess power generated for use when needed. Charge controllers regulate power flow into and out of the batteries to prevent overcharging. The system requires wiring to connect the components, racking to mount the solar panels, safety devices like disconnect switches, and monitoring hardware and software to track performance. When assembled together into an integrated system, these components allow a PV system to cleanly and sustainably generate electricity from the sun. Understanding what makes up a PV system is important for determining the right system design and specifications to meet energy needs.