What Is A Data Plate Performance Certificate?

What is a Data Plate?

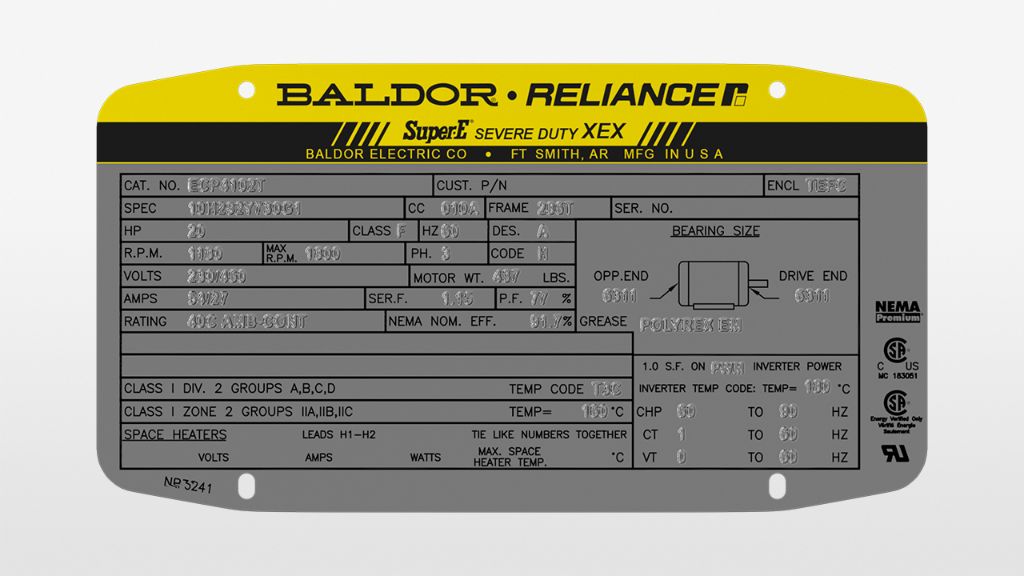

A data plate is a metal nameplate or sticker attached to equipment and machinery, which provides key information about that device. Data plates contain details such as the model number, serial number, manufacturing date, specifications, and safety certifications.

The data plate serves to uniquely identify each individual piece of equipment. It allows manufacturers, operators, and regulatory authorities to track vital statistics about that machine over its operational lifetime. The specifications on the data plate indicate the performance criteria and operational limits intended by the original equipment manufacturer.

Purpose of Data Plates

Data plates serve several key purposes for equipment and machinery. Most importantly, they identify key specifications and information needed for proper operation and maintenance.

Data plates provide details like the model number, serial number, manufacturer, voltage, amperage, horsepower, and other technical specifications. This data ensures equipment is used safely and appropriately, within the parameters and limits designated by the manufacturer.

Data plates also enable effective maintenance and service. The information allows maintenance staff to identify the right replacement parts, lubricants, and procedures for upkeep. It also aids troubleshooting when issues arise.

Additionally, data plates help owners track assets and inventory. The plates provide unique identifiers that distinguish individual units from others of the same equipment model. This allows for asset management and tracking through a facility or across an organization.

By consolidating key information in one accessible place on the equipment, data plates deliver convenience and simplify look-ups for critical specifications needed for operation, maintenance, and asset management.

Locations

Data plates are metal or plastic tags that contain important information about a piece of equipment or material. They are typically affixed to the exterior of the equipment, usually in an accessible or visible area. This allows workers, inspectors, and others to easily locate and view the data plate.

While data plates are most commonly placed on the outside of equipment, they may also be attached to the interior of certain assemblies or parts. For example, a data plate could be found inside a control panel or on the frame within a large machine. This keeps the information readily available but protects it from external damage or tampering.

The key factor is that data plates need to be positioned so they can be conveniently accessed when required. Whether on the exterior or interior, they contain vital details that must be viewable throughout the operating life of the equipment.

Information Included

Data plates contain key information about the equipment or system they are attached to. Some of the typical information included on a data plate consists of:

- Model number – The manufacturer’s model number for that particular piece of equipment. This allows you to identify the specific design and features of that model.

- Serial number – A unique serial number assigned to that individual unit, which distinguishes it from other units of the same model.

- Specifications – Technical specifications related to the operation of the equipment, such as:

- Voltage – The input voltage requirements.

- Speed – Maximum safe rotational speed for motors.

- Pressure – Maximum internal pressure for pressure vessels.

- Capacity – Maximum load capacity for structures and lifting equipment.

Having key details like model number, serial number, and operational specifications handy on the data plate makes it easy to identify the equipment and ensure it is operated within its safe limits.

Material Standards

Data plates are made from durable materials that can withstand exposure to the elements, abrasion, and corrosion. Common materials used include:

- Aluminum – Aluminum is lightweight, corrosion resistant, and easy to etch or stamp markings into. Aircraft grade aluminum alloys are often used.

- Stainless Steel – Stainless steel offers high strength and corrosion resistance. Etching or laser marking can create durable markings.

- Laminated Films – Data plate information may be printed on laminated films or plates made of materials like anodized aluminum or UV-resistant polymer.

The markings on data plates are etched, stamped, or laser engraved into the surface. This creates durable and permanent identification, rating, and certification information that will withstand wear over the lifetime of the equipment.

Certification Types

Data plates can receive different types of certifications depending on their intended function and industry regulations. The main certification types are:

Performance Certification

Performance certificates validate that the data plate meets durability and longevity standards. They ensure the plate can withstand environmental factors like weather, wear and tear, and corrosion based on testing. Performance certification provides quality assurance for manufacturers and consumers.

Safety Certification

Safety certificates verify the data plate complies with codes and standards for safe operation of the machinery or system it is installed on. This protects against potential hazards and liability issues. Safety certification is mandatory for equipment used in hazardous industrial environments.

Regulatory Compliance

Data plates must comply with government regulations for the region they are used in. Regulatory compliance certification confirms the nameplate meets labeling and identification requirements. This is necessary for legal operation in regulated industries like energy, transportation, and construction.

Performance Certificates

Performance certificates are documents that certify equipment meets its advertised specifications and performance parameters. Manufacturers have their products evaluated by independent testing facilities to validate that they perform as claimed. These evaluations focus on testing key performance metrics most important to that product type.

For example, a performance certificate for an air conditioner would validate its cooling capacity, energy efficiency ratio (EER), and airflow. A performance certificate for an electric motor would test output power, speed, torque, efficiency, power factor, and more. For electrical equipment, safety ratings are also evaluated and confirmed.

Performance testing uses industry-accepted test procedures to produce objective, measurable results that can be trusted by consumers. Any product that receives a performance certificate has demonstrated through intensive testing that it lives up to its marketed capabilities.

Getting Certified

Data plate performance certificates are obtained through accredited third-party agencies that specialize in testing and certification. Manufacturers must submit an application and provide documentation that meets the agency’s requirements.

The certification process involves thoroughly testing the performance and material standards of the product in the manufacturer’s facilities. The agency will review test reports, inspect equipment, observe testing procedures, and may conduct additional independent tests to ensure compliance.

After validating that the product meets all required standards and regulations, the agency will issue an official certificate declaring that the data plate is certified to perform as stated. This authorization permits the manufacturer to display certification marks and claims in its marketing and on the product itself.

Maintaining Validity

Data plates need to remain valid over the lifetime of the equipment they are attached to. As such, there are processes in place to maintain the validity of data plate performance certificates:

Recertification if Modifications are Made

If at any point the equipment is modified in a way that affects its performance or design specifications, the data plate will need to be re-evaluated. The performance certificate may need to be updated or reissued to account for the equipment changes.

Periodic Audits for Continued Compliance

Most data plate certifications require periodic audits to ensure the equipment remains in compliance with the original certification. During these audits, an assessor will examine the equipment and check that no unauthorized modifications were made. As long as the equipment passes the audit, the data plate remains valid. However, if non-compliances are found, the certification may be revoked until corrections are made.

Importance for Safety

Data plates provide crucial information to ensure the safe and proper operation of equipment. Adhering to the specifications and instructions on data plates helps prevent accidents and failures that could harm people or property.

By listing details like maximum load capacities, safe operating speeds, and pressure limits, data plates inform users and maintenance personnel of the acceptable parameters within which the equipment should be operated and serviced.

Exceeding the ratings stated on the data plate can overload or damage equipment. Data plates also provide maintenance specifications and intervals to follow for safe ongoing use. Adhering to data plate guidelines is essential for reducing equipment malfunctions, breakdowns or deteriorations that compromise safety.

Additionally, data plates contain identifying information that enables tracking the manufacturing and service history of equipment. This assists quality control and aids accident investigations. Overall, data plates play a vital role in equipment safety by conveying critical operating and maintenance data.