What Happens When A Diode Fails In A Solar Panel?

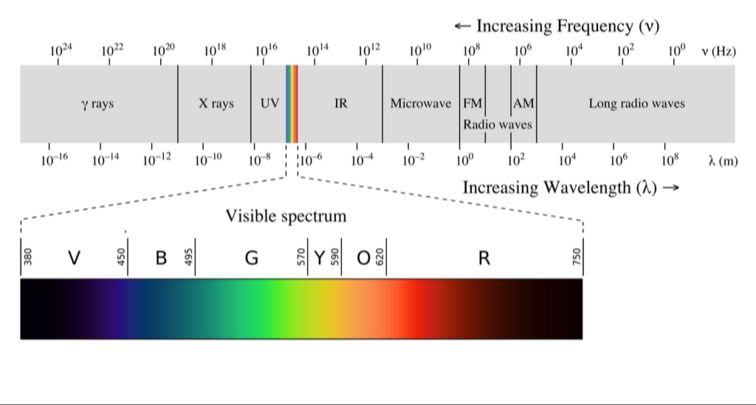

Solar panels generate electricity from sunlight using photovoltaic (PV) cells. PV cells are made of semiconductor materials like silicon that absorb photons from sunlight and convert them into electrons. This flow of electrons generates a DC electric current. Solar panels connect PV cells together in series to produce higher voltages and power output. The more sunlight that hits the PV cells, the more electricity they can produce. When sunlight energy strikes the PV cells, light particles called photons knock electrons free from the cell’s atoms. The freed electrons can then flow through the cell and create electricity. The voltage and current produced depends on factors like the type and number of solar cells as well as the intensity of sunlight hitting them.

“How do solar panels work? Simply put, a solar panel works by allowing photons, or particles of light, to knock electrons free from atoms, generating a flow of electricity.” (Source)

Solar panels produce clean, emissions-free renewable power from the sun and don’t require any external mechanical power to run. They’re a sustainable way to generate electricity and reduce reliance on fossil fuels.

Diode Function

Bypass diodes play a critical role in solar panels by preventing reverse current flow and protecting panels from damage due to shading. When a solar cell or portion of a panel is shaded, it can become reverse biased and start drawing current from the rest of the unshaded cells. This reverse current flow can heat up the shaded portion and cause damage over time. Bypass diodes are connected in parallel across groups of cells within a panel, usually 12 to 18 cells per diode. When a cell group becomes shaded and starts to develop a reverse bias, the diode becomes forward biased and starts conducting electricity around the shaded cells. This prevents overheating and hot spots from developing. By routing current around shaded areas, bypass diodes allow solar panels to tolerate some shading without suffering catastrophic failure. They keep the overall panel operating even if small portions are shaded.

Sources:

Diode Failure Modes

Diodes can fail in solar panels due to several common failure modes:

Thermal fatigue is a major cause of diode failure. Repeated heating and cooling cycles can cause mechanical stress and eventual cracking or detachment of the diode inside the solar panel. Overheating is especially damaging and can quickly lead to diode burnout. Maintaining proper operating temperatures is critical to prevent thermal diode failures.

Electrostatic discharge (ESD) can instantly destroy diodes. Built-up static electricity rapidly discharges through and fries the delicate electronics. Proper grounding, surge protection, and handling procedures help mitigate ESD risks.

Manufacturing defects also contribute to early diode failures. Imperfections in materials, contamination, poor connections, and assembly errors can make diodes prone to premature breakdowns. Quality control in the production process aims to minimize these defects.

Additionally, overcurrent and reverse bias conditions can degrade and short diode junctions over time. Careful system design, monitoring, and maintenance helps prevent damage from occurring.

Effects of Diode Failure

When a bypass diode fails in a solar panel, the main effect is a drop in power output from that panel. Solar panels contain strings of solar cells connected in series. If one cell is shaded or damaged, it can act as a resistor and dissipate power rather than pass it on. Bypass diodes are placed in parallel across each cell string to provide an alternate current path around any shaded or damaged cells.

When a bypass diode fails, the cell string it was protecting is forced to pass current through the underperforming cell rather than around it. This causes that string to operate at the current level of the weakest cell, dropping the output of that string sometimes by 50% or more. With multiple cell strings in each panel, the overall power loss may be less but can still be significant. According to one source, “The failure of a bypass diode in a module usually results in the switching-off of one of three cell strings. The result is a sudden drop in performance by up to 50 percent” (https://www.pv-magazine.com/2017/11/08/what-happens-when-bypass-diodes-fail/).

In addition to power loss, a failed bypass diode can lead to damage of the solar cells in that string. Forcing current through a shaded or faulty cell causes overheating that can further degrade performance. It also puts more stress on the good cells as they try to compensate. This added load can shorten the life of the remaining cells in the string.

Identifying Failed Diodes

There are a few methods for identifying which diode has failed in a solar panel. The most common testing methods are:

-

Measuring voltage – Using a multimeter, measure the voltage coming out of each individual solar cell or string of cells connected to a diode. A cell or string with low/zero volts indicates the diode is not bypassing current, and is likely failed.

-

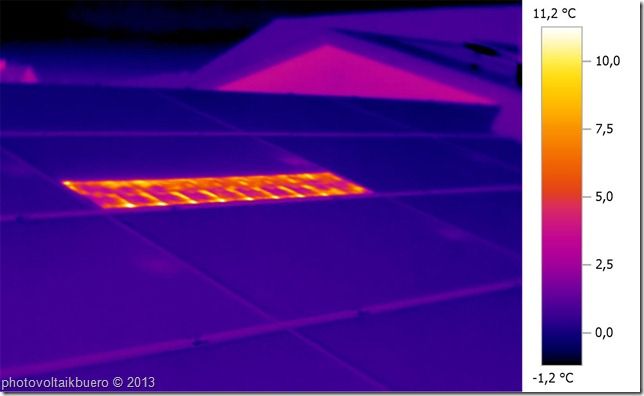

Thermal inspection – Visually inspect the back of the panel for hotspots, which indicate a cell/string is not contributing energy and heating up. The associated diode is likely faulty.

-

Dark IV curve testing – Use a specialized IV curve tracer to measure current/voltage while the panel is covered/dark. Abnormal curves pinpoint faulty diodes.

Visual inspection is the simplest method. Closely examine the back of the panel for hotspots, seen as areas that are significantly warmer than surrounding cells. This heat is caused by reverse current leakage through a failed diode.

Precisely locating the hotspot will identify which diode is faulty and needs replacing. Take care not to touch overheated areas, as they can cause burns.

Replacing Failed Diodes

When a diode fails in a solar panel, the most direct fix is to replace it with a new diode. This typically involves desoldering the failed diode and soldering a replacement diode onto the solar cell tabs or busbars. It’s important to use a diode with an equal or higher current rating as the original.

To replace a failed bypass diode, first remove the junction box cover and disconnect the panel from the system. Use a voltmeter to confirm the diode is failed by checking for continuity across it in both directions. Once verified, use desoldering tools and a soldering iron to remove the bad diode and clean the solder pads. Solder the new diode in place, matching the orientation of the original. Reassemble the junction box when finished.

The process requires some electrical skill and good soldering technique. Arc flashes are a risk if mishandled. Due to the complexity, most system owners rely on solar professionals or panel manufacturers to replace faulty diodes. Repair shops can diagnose issues and swap out individual failed diodes in otherwise functional panels. Complete panel replacement may be recommended if multiple diodes have failed.

According to one source, “Use a very sharp blade to cut a rectangular area around the diode, then use a soldering iron to heat up each of the two connections and pull the diode out with tweezers. Solder in a new diode with the same specifications in the same direction” (Fixing solar panel diodes – Sealed junction box). Professional solar technicians follow a similar diode replacement process using specialized tools.

Preventing Diode Failure

Proper handling, installation, and maintenance of solar panels can help prevent diode failure. Solar panels should be handled carefully during transportation and installation to avoid mechanical damage. Panels should be securely mounted and wiring properly connected to avoid stress and loose connections. Wires should have strain relief and slack to account for thermal expansion. The installation should follow manufacturer guidelines and industry best practices.

Regular inspections, cleaning, and maintenance can also help extend diode and overall system lifetime. Inspect electrical connections for corrosion and tightness. Check for discoloration, delamination, and cracking of panels that can allow moisture intrusion. Remove any accumulated dirt, dust, snow, etc. that can cause overheating. Check bypass diode functionality during routine IV curve testing. Replace any damaged wiring or parts. Follow manufacturer maintenance recommendations.

Environmental factors like extreme temperatures, moisture, and lightning strikes contribute to diode failure. Proper system design is important, including surge protection, insulation, weather sealing, and temperature management. Avoiding shading and oversizing arrays can help minimize hot spots and overcurrent. Following best practices in panel selection, installation, and maintenance can maximize diode and system longevity.

Safety Risks

Diode failures in solar panels can present electrical and fire safety hazards that should not be underestimated. According to this article, failed diodes can create both fire and shock risks.

When a diode fails, it can cause arcing, sparks, and extreme heat inside the solar panel. This poses a serious fire hazard, as the sparks can ignite flammable materials near the solar installation. Failed diodes also undermine the panel’s intrinsic protection against electric shocks. Healthy diodes help prevent current from flowing backwards into the panel. But when diodes are damaged, this safety mechanism is compromised, raising the risk of dangerous shocks.

Installers and homeowners should therefore take care when handling panels with suspected diode failures. Arc faults and ground faults become more likely, so precautions are necessary. Regular inspection, testing, and replacement of aged or damaged diodes can mitigate many of these safety risks.

System Design Factors

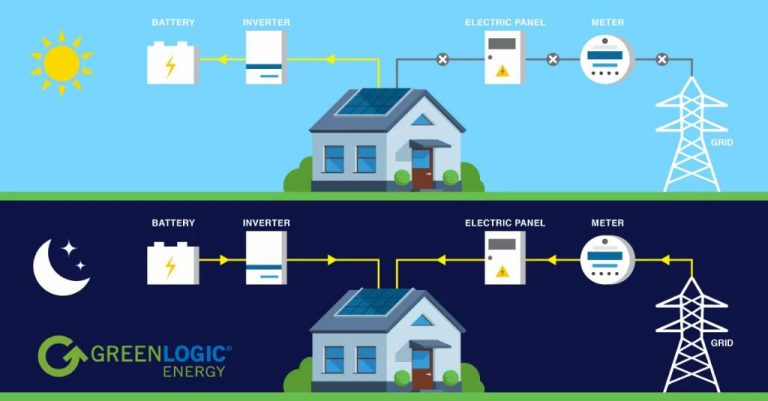

Solar panel system designers carefully consider wiring configurations and connections to help minimize the chances of diode failure. One key strategy is using a series-parallel arrangement for connecting the solar cells and panels. This involves wiring solar cells in series within each panel, and then connecting multiple panels together in parallel. The series connections protect against reverse currents within each panel, while the parallel connections provide redundancy so that a single failed panel or diode won’t shut down the whole system.

Another technique is to use separate sub-arrays for each row of panels, with blocking diodes protecting each sub-array. This helps contain any reverse currents or faults to just one section of the overall array. Designers may also specify higher-rated bypass diodes than technically required, to provide an extra margin of safety and redundancy. Proper sizing of overcurrent protection devices like fuses or circuit breakers is also important to prevent excessive currents that could damage diodes.

Overall, thoughtful solar array designs utilize methods like redundant parallel connections, blocking and bypass diodes, segmented sub-arrays, and appropriately rated overcurrent protection to help minimize the likelihood of diode failures. This both improves safety and maximizes the system’s overall power output. For more details, see the informative article from Sinovoltaics (https://sinovoltaics.com/learning-center/off-grid/blocking-diode-bypass-diode-solar-panels/).

Conclusion

In summary, diodes play a critical role in solar panels by preventing reverse current flow and protecting the panels. When diodes fail, it can lead to hot spots, power loss, and other issues. Careful installation, maintenance, and monitoring can help prevent diode failure. Replacing failed diodes promptly is important to maximize solar panel productivity and longevity.

Proper installation and regular maintenance are key to avoiding diode failure in solar panels. Installers should carefully follow manufacturer guidelines, use high-quality components, and double check connections. Preventative maintenance like visual inspections, electrical tests, and cleaning can catch issues early. Tightening connections and replacing worn parts proactively reduces the chances of diode failure down the road.

Diode failure is a significant concern for any solar installation. But being mindful of diode function, failure modes, and preventative care can help maximize the performance and lifetime of solar panels.