What Component That Changes To Electrical Energy To Light Energy?

Introduction

Lightbulbs are an essential part of modern life that most people take for granted. At the most basic level, a lightbulb converts electrical energy into light energy that allows us to illuminate interior spaces. Understanding how this process works provides insight into physics, engineering, and the ways that technology has shaped society.

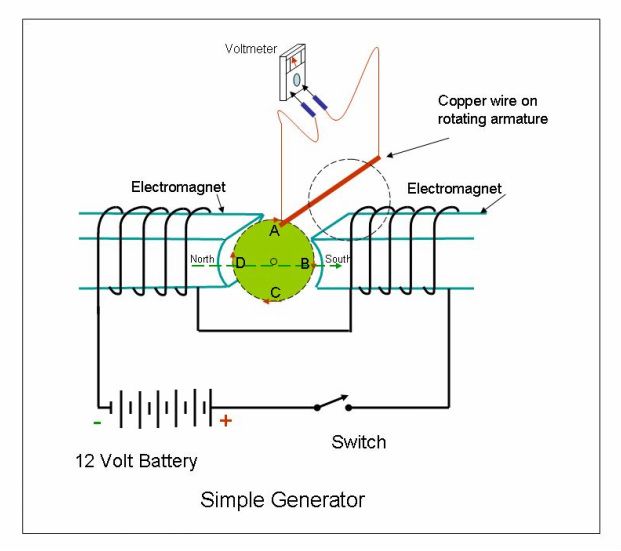

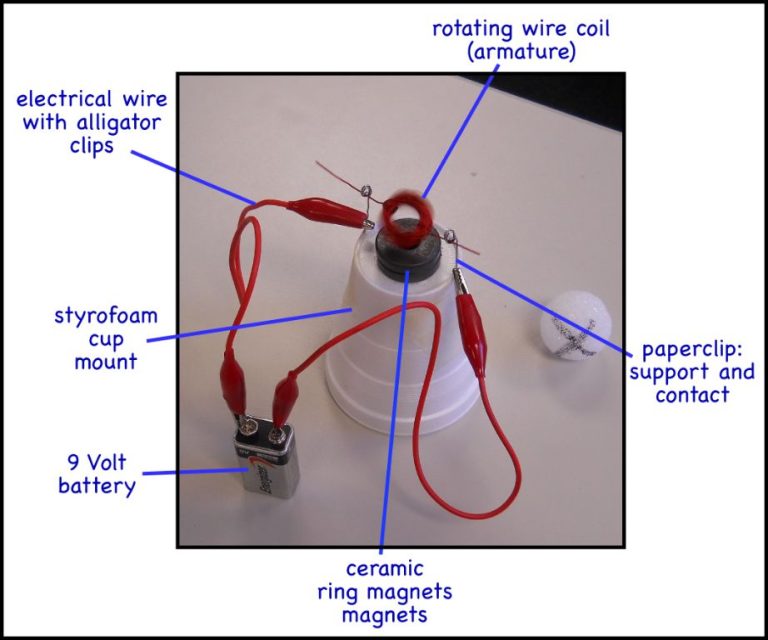

Electrical energy refers to the movement of electrons or electric charge. Generators at power plants produce an electric current by rotating coils of wire inside large magnets. This current then flows through transmission lines to bring electricity into homes and buildings. The standard unit of electrical energy is the kilowatt hour (kWh).

Light energy is a form of radiant energy that is created through electromagnetic radiation. This radiation is emitted when charged particles such as electrons interact. The particles accelerate and release energy in the form of photons. The wavelength and frequency determine the color and properties of the resulting light. Measured in lumens, light allows us to see objects that would otherwise be invisible in darkness.

Exploring the journey of electrical energy powering lightbulbs provides insights into fields like physics, engineering, chemistry, and the history of technology. It also reveals how a simple invention profoundly impacted society and human progress.

The Role of the Lightbulb

A lightbulb’s primary role is to convert electrical energy into light energy that provides illumination. This conversion occurs through several key components inside the lightbulb. At the heart of the lightbulb is a thin wire filament. When electricity passes through the filament, it heats up to an extremely high temperature, causing the filament to glow brightly. This glowing filament produces the visible light.

The glass bulb encasing the filament contains a vacuum or inert gas, which prevents the hot filament from oxidizing or burning up immediately. The glass bulb also allows the visible light to pass through. Additionally, the base of the lightbulb connects the electrical contacts that power the filament. Other components like the lamp socket provide an interface between the lightbulb and electricity supply.

So in summary, the filament converts the electrical energy into intense heat energy, and this heat produces visible light emission, allowing the lightbulb to convert electricity into illumination. The glass bulb, base, and lamp socket enable this process to occur reliably and safely.

History of the Lightbulb

The story of the lightbulb begins in the early 1800s when British chemist Humphry Davy created an electric arc lamp by connecting two wires to a battery. While impractical for everyday use, this pioneering invention established the principle of electric lighting. Over the next several decades, many inventors experimented with different designs trying to create a lasting, reliable electric light source.

In the 1870s, British physicist Joseph Swan developed an incandescent lamp using carbonized paper filaments that could glow for hours at a time. Thomas Edison built on Swan’s work to create longer lasting carbon filament bulbs as well as the first electrical distribution system needed for practical use. Edison is widely credited with the invention of the lightbulb as we know it today. However, his success was really thanks to the groundwork laid by Swan and other earlier inventors.

By the late 1800s, incandescent lightbulbs using carbon filaments were being commercially produced and installed in buildings, allowing electric indoor lighting to become commonplace. Later on, tungsten filaments replaced carbon, increasing efficiency further. While the basic lightbulb has remained largely unchanged, new technologies like fluorescent, LED, and halogen bulbs have since been invented to increase efficiency and meet the lighting needs of the modern world.

How Electrical Energy is Converted to Light

Inside a lightbulb is a thin filament made of tungsten metal. When electrical current flows through this filament, the filament heats up and starts to glow. This process of heating up a metal to the point where it glows is called incandescence. The hotter the filament gets, the brighter it glows.

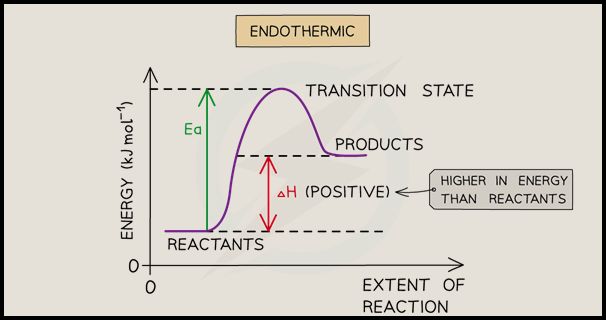

The physics behind this light emission has to do with the electrons within the filament. The electrical current provides energy to the electrons in the metal filament, putting them into a higher energy state. As the electrons return to their original energy state, energy is released in the form of light photons. The color of the light is determined by the temperature of the filament. Higher temperatures result in bluer light.

So in summary, the electrical current heats the tungsten filament to incandescence, and the heated filament emits photons in the visible spectrum, resulting in the bright glow that provides illumination. The entire process is based on the principles of incandescence and electron excitation/relaxation within the filament material.

The Life Cycle of a Lightbulb

The life cycle or lifespan of a lightbulb refers to how long it will operate before burning out and needing to be replaced. There are several factors that affect the lifespan of a bulb.

Most standard incandescent bulbs are rated for 750-1,000 hours, while halogen incandescent bulbs may last 2,000-4,000 hours. Compact fluorescent lamps (CFLs) typically last 6,000-15,000 hours, and light emitting diodes (LEDs) can have lifespans over 25,000 hours.

A bulb’s operating life depends on the number of on/off cycles. Frequent switching on and off can create wear and reduce longevity. Keeping bulbs turned on for long periods is better than turning them on and off multiple times per day.

Higher wattage bulbs tend to burn out faster than lower wattage versions. Bulbs that get very hot operate at high temperatures that can accelerate the rate at which the filament degrades. Using lower wattage bulbs when possible extends the operating life.

Quality of manufacturing also affects lifespan. Bulbs made with higher standards and more durable components will last longer. Cheaply made bulbs are more prone to early failures. Purchasing reputable brands from reliable retailers helps maximize the usable life of bulbs.

Operating lightbulbs within the proper voltage range and avoiding fluctuations that can damage the filament also preserves longevity. Dirt buildup on the glass or bulb can reduce light output over time. Regular cleaning can prolong usable life.

With typical usage of 3-5 hours per day, most standard bulbs last 6-12 months. Following the manufacturer’s recommendations and choosing the right bulb for an application is key to maximizing the operating lifespan.

Types of Lightbulbs

There are several major types of lightbulbs used in homes and businesses today:

- Incandescent bulbs – These bulbs have been around for over 100 years. They work by heating a filament inside the bulb until it glows. They are inexpensive to produce but inefficient, converting only 10% of energy into light.

- CFL bulbs – CFL stands for compact fluorescent light. These bulbs use 25-35% less energy than incandescent bulbs and last 6-10 times longer. They contain mercury so need to be disposed of properly.

- LED bulbs – LED stands for light-emitting diode. These bulbs use only about 10% of the energy of an incandescent. They can last over 20 years. They contain no mercury or other hazardous materials.

- Halogen bulbs – Halogens are a subset of incandescent bulbs with halogen gas added. This allows them to be more efficient while maintaining a similar light quality. They last longer than regular incandescents.

When choosing a lightbulb, factors like light quality, energy efficiency, lifespan, and environmental impact should be considered. LED and CFL bulbs offer the best efficiency, while old-fashioned incandescents are very energy intensive but provide a warm, familiar light.

Lightbulb Efficiency

The efficiency of a lightbulb refers to how much light (measured in lumens) it produces per unit of energy consumed (measured in watts). More lumens per watt means greater efficiency. Incandescent lightbulbs tend to be very inefficient, producing only 10-20 lumens per watt. Fluorescent bulbs are more efficient at around 60-70 lumens per watt. LED bulbs are the most efficient today, with some producing over 100 lumens per watt.

There have been major efforts in recent decades to increase the efficiency of lighting. This is done through advancing technologies like compact fluorescents and LEDs. It also involves setting higher efficiency standards and phasing out inefficient incandescent bulbs. The average efficiency of installed bulbs in U.S. homes improved from about 15 lumens per watt in 2001 to over 45 lumens per watt in 2010. Increased efficiency means lower energy consumption for the same brightness.

Going forward, further improvements in LED technology will continue driving gains in efficiency. LED bulbs already match or exceed the light quality of incandescents while using a fraction of the energy. Government policies are also helping accelerate the adoption of efficient bulbs. As outdated incandescent bulbs are phased out worldwide, the lumens per watt rating for installed lighting is projected to keep rising – reducing energy usage and costs.

Environmental Impact

The environmental impact of lightbulbs depends on the materials and manufacturing processes used to make them. Incandescent bulbs are relatively simple, containing a tungsten filament inside a glass bulb filled with inert gas. This makes them easy to manufacture. However, they are very inefficient, wasting over 90% of energy as heat. This excess energy use contributes to air pollution from power plants. Incandescents also have a short lifespan of 1,000 hours, so they must be replaced frequently, creating more waste.

CFLs and LEDs are much more efficient, using around 75% and 85% less energy than incandescents, respectively. This greatly reduces their environmental impact from energy use. However, they contain electronics and materials like mercury (CFLs) and rare earth metals that require more complex manufacturing. The extraction and refinement of these materials can damage the environment. At end of life, CFLs and LEDs should be recycled to prevent the release of mercury and other heavy metals into landfills. Overall, energy efficient bulbs have a lower carbon footprint across their lifecycle despite their more complex manufacturing and materials.

Halogen bulbs are similar to incandescents in relying on a tungsten filament, but contain halogen gas instead of inert gas to increase efficiency. This makes them last longer than incandescents, but they are still very inefficient, wasting 85-90% of energy as heat. Ultimately, LED bulbs offer the best combination of efficiency, long life, and eco-friendly materials, while incandescent and halogen bulbs have the highest environmental impact.

The Future of Lightbulbs

In recent years, there have been significant innovations in lighting technology and the future looks bright for new types of efficient, long-lasting, and environmentally-friendly lightbulbs. LED and OLED technology continues to improve, providing lighting solutions that use a fraction of the energy of traditional incandescent bulbs. Smart lightbulbs with integrated WiFi allow for creative new features like voice control, scheduling, and integration with other smart home devices. Engineers are also developing more sustainable materials and manufacturing processes to reduce the environmental impact of lighting products. Several promising technologies on the horizon include:

- Organic LEDs (OLEDs) – Thinner, more energy-efficient, and longer-lasting than traditional LEDs.

- Flexible and foldable LEDs – Allowing for new shapes and applications.

- Nano-crystal coatings – For improved LED efficiency and light quality.

- Solar-powered LEDs – Eliminating the need for batteries or wiring.

- Human-centric lighting – Mimicking natural light cycles for health and productivity.

While incandescent bulbs are now largely obsolete, lighting technology will continue advancing in exciting ways. The future is bright for more efficient, customizable, and intelligent lighting solutions that meet diverse needs while minimizing environmental impacts.

Conclusion

In summary, the component that converts electrical energy to light energy in a lightbulb is called the filament. We’ve covered the history of how lightbulbs were invented, starting with early designs like arc lamps and incandescent bulbs made with carbonized bamboo fibers. Modern incandescent lightbulbs use tungsten filaments to glow white-hot when electrical current passes through, producing visible light. Other types of lightbulbs like CFLs and LEDs use different methods to generate light.

Understanding how lightbulbs work and their environmental impact is key. Traditional incandescent bulbs are inefficient, wasting most energy as heat. More energy-efficient options like CFLs and LEDs have become popular, reducing electricity usage and costs. Ongoing research aims to improve lightbulb lifespan and efficiency even further.

Lightbulbs play an essential role by allowing us to illuminate our homes and workplaces with the flip of a switch. As this content has shown, there are complex processes and tradeoffs involved in converting electricity into light. Appreciating this technology that is easy to take for granted can help guide better choices and innovations for the future.