What Are The Parts Of A Solar Panel Cell?

Solar panels are an increasingly important source of renewable energy. Understanding the different parts that make up a solar panel allows us to better design, produce, maintain, and utilize this technology. This article will provide an overview of the main components that comprise photovoltaic solar panels.

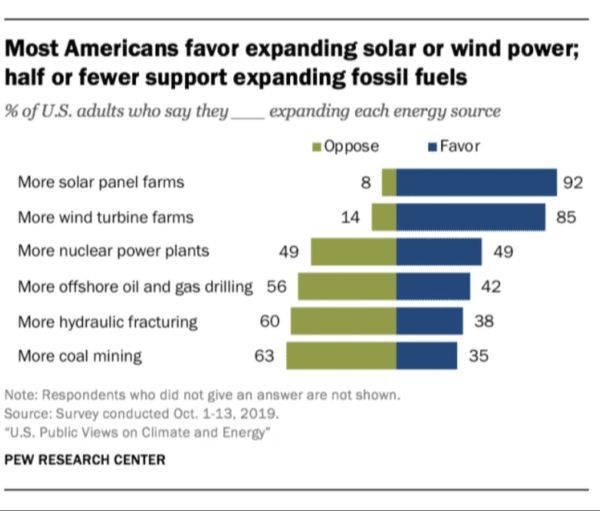

The motivation for covering the parts of a solar cell is to gain a deeper knowledge of how this technology works at a fundamental level. With this understanding, we can continue to make advances in solar technology and deploy it more broadly to reduce reliance on fossil fuels.

We will examine the photovoltaic cells that absorb sunlight and generate electricity, the electrical contacts that transmit power, the protective glass cover and casing, and other elements that enable solar panels to function.

Photovoltaic Cells

A photovoltaic cell, also known as a solar cell, is the basic unit of a solar panel that converts sunlight into electricity. Photovoltaic comes from the words photo, meaning light, and voltaic, meaning voltage or electrical potential. Solar cells are made from semiconductor materials that exhibit the photovoltaic effect.

When sunlight hits the solar cell, the photons are absorbed by the semiconductor material, causing electrons to break free from their atoms. This generates electron-hole pairs, which produce an electric field across the cell. The electrons want to reunite with the holes, but they are forced to travel through an external circuit, generating electricity. Thin wires on the surface of the cell collect the electrons and transport them to the external circuit.

Solar cells are specially treated to form an electric field, with a positive charge on one side and a negative charge on the other. This causes the electrons and holes to travel in opposite directions when the cell is exposed to sunlight. This flow of electrons generates electricity that can then be used to power electrical devices or fed into the electricity grid.

Semiconductor Material

The key component of a solar panel is the photovoltaic (PV) cell which converts sunlight into electricity. PV cells are made of semiconductor materials such as silicon that exhibit a unique electrical property called the photoelectric effect. When sunlight hits the PV cell, photons from the sunlight knock electrons loose from the semiconductor material, allowing the electrons to flow through the material and produce an electric current.

![]()

Silicon is the most commonly used semiconductor material for solar panels because it is readily available and efficient at converting sunlight into electricity. Solar cells can be made from monocrystalline, polycrystalline or amorphous silicon. Monocrystalline silicon cells are created from a single silicon crystal, giving it a uniform structure with maximum efficiency, but also higher production costs. Polycrystalline silicon cells consist of multiple silicon crystal fragments melted together, making them slightly less efficient but easier to produce than monocrystalline cells. Amorphous silicon (a-Si) has a non-crystalline structure which lowers efficiency but allows the material to be deposited in thin flexible layers onto various surfaces.

Other semiconductor materials like gallium arsenide (GaAs) and cadmium telluride (CdTe) are also used in some solar panels. These alternative semiconductors have higher sunlight absorption and conversion efficiency than silicon. However, silicon remains the predominant choice due to its widespread availability, low cost, and proven reliability.

Electrical Contacts

The electrical contacts are a vital component of solar panel cells. As their name suggests, they provide the electrical connections to the semiconductor material that make up the solar cell. The contacts are located on the top and bottom of the cell.

On the bottom of the cell, there is usually a thin layer of metal that covers the entire surface. This forms the negative terminal of the cell. The metal used is typically aluminum, though other conductive metals like copper or silver can also be used.

On the top of the cell, there is a grid-like structure made up of thin metal wires or bars. This grid does not fully cover the top, it consists of thin lines spaced evenly across the surface. The metal grid forms the positive terminal for the solar cell.

The role of both contacts is to collect and transfer the electrical current that is generated when sunlight hits the semiconductor material. The electrical contacts allow the current to flow out of the cell and into the external circuit. Without the contacts, the electrical energy would not be able to be utilized.

The positive and negative terminals need to be electrically isolated from each other for the solar cell to work properly. This is why the top contact is a grid instead of a solid sheet of metal. The grid structure allows sunlight to still reach the semiconductor while also providing an electrical connection.

Antireflective Coating

Solar panels have an antireflective coating that helps increase their energy efficiency. This coating is applied as a thin film to the surface of the solar cells and works by reducing the amount of light that is reflected away.

Without an antireflective coating, over 30% of incoming sunlight would be reflected away rather than absorbed by the solar cell. The coating acts as an optical match between the glass surface and the air, reducing the difference in refractive indexes that causes reflection.

The most common type of coating used is magnesium fluoride, which can reduce reflection down to just 1-2%. By enabling more light energy to enter the cell, the coating enables the panel to generate more electricity from the same amount of sunlight.

Some advanced coatings are even designed with multiple layers to optimize anti-reflection capabilities. Overall, the antireflective coating is a simple but very effective way to meaningfully improve the efficiency and performance of solar panels.

Encapsulant Material

The encapsulant material is an important protective layer in solar panel cells. It encapsulates and seals the solar cells, protecting them from environmental damage. This transparent material commonly consists of ethylene vinyl acetate (EVA) or polyvinyl butyral (PVB).

The main purpose of the encapsulant material is to provide structural support and weather resistance. It cushions the cells and prevents moisture ingress or oxidation. It fills the gaps between cells and binds all the layers together. The encapsulant helps protect the cells from impacts, vibration, and thermal stress.

In addition, the encapsulant material optical properties help maximize light capture. It has a high light transmittance to allow sunlight to pass through with minimal reflection or absorption. The material’s refractive index matches that of the cells to reduce optical losses. This improves overall efficiency and energy generation.

Proper encapsulation is critical for solar panel durability and performance. The encapsulant protects cells from humidity, UV rays, and dirt accumulation over decades in outdoor environments. Quality encapsulant materials enable solar panels to withstand extreme temperatures, wind, and rain for 20-30 year lifespans.

Glass Cover

The glass cover serves as a protective layer on the front of the solar panel. It protects the solar cells and other internal components from damage due to environmental factors like rain, hail, snow, and wind-blown debris. The glass also prevents dust buildup on the cells, which would reduce their efficiency.

The glass cover is typically made from low iron tempered glass. Low iron glass maximizes light transmittance, allowing as much sunlight as possible to reach the solar cells beneath. Tempered glass is stronger and more impact-resistant than standard glass.

In addition to protection and transparency, the glass cover provides structural rigidity to the panel. Solar panels are designed to withstand high wind loads. The glass on the front, along with the strong aluminum frame on the back, lends strength and prevents the panel from flexing too much under windy conditions.

The glass cover is usually around 3-4 mm thick. It is not a single pane but rather two panes of glass fused together into one sheet with ethylene vinyl acetate (EVA). The EVA lamination provides an extra layer of structural support and weather resistance.

Overall, the durable glass cover protects the solar cells from damage while allowing sunlight to pass through efficiently. This results in panels that can withstand decades of exposure to the elements.

Aluminum Frame

Solar panels are normally encased in an aluminum frame that surrounds the edges and provides structural support. The aluminum frame serves several important functions:

- Protection – The metal frame protects the inner components like the glass, semiconductor cells, and wiring from physical damage.

- Rigidity – Aluminum has high tensile strength which prevents the panel from bending or flexing. This rigidity allows panels to be safely transported and mounted.

- Sealing – The frame fully encloses and seals the edges to prevent moisture and dirt from entering inside. This protects the panel from corrosion, short circuits, etc.

- Grounding – The aluminum frame is electrically conductive and can be grounded to dispel any built-up static electricity.

- Mounting – The frame has pre-drilled holes, brackets, or clamps that enable secure and standardized mounting onto rooftops, pole mounts, solar trackers, etc.

The aluminum frame must be correctly engineered with extruded or cast aluminum alloys that can withstand outdoor elements for decades. Proper anodized coatings and seals prevent corrosion and ensure durability.

Junction Box

The junction box is an important component of solar panels that houses the terminals to carry the electricity produced by the solar cells. It regulates and monitors the power output of the panel. Inside the junction box are electrical connections and diodes that control the flow of current and prevent reverse current from entering the panel.

The main functions of the junction box are:

- Regulate power output – It contains bypass diodes that allow current to bypass any solar cells that are underperforming or shaded, so the rest of the panel can keep functioning.

- Monitor performance – It contains sensors to monitor voltage and detect faults or drops in power generation.

- Provide termination point – The positive and negative terminals inside the junction box allow connection of electrical wiring from the panels to controllers, batteries, or the utility grid.

- Protect against weather – The junction box housing protects the sensitive terminals and diodes from weather exposure and damage.

- Allow access for repairs – Junction boxes contain removable access covers to allow technicians to access the interior components for maintenance and repairs.

Proper wiring through the junction box is critical for directing the DC electricity produced by solar panels and integrating the system with other components. The junction box regulates and optimizes solar panel performance.

Conclusion

In summary, a solar panel is made up of several key components that work together to convert sunlight into electricity. The photovoltaic cells, made of semiconductor materials like silicon, are the most important part. When sunlight hits these cells, the energy knocks electrons free from their atoms, allowing electricity to flow. The electrical contacts shuttle these electrons off the cells, while the antireflective coating maximizes light absorption. The encapsulant protects the cells from weather and physical damage, with the glass cover providing further protection. The aluminum frame provides structural support and rigidity. The junction box allows the solar panel’s generated electricity to be connected to external wires. While a basic solar panel may seem simple, its components are carefully engineered to capture and convert solar energy into usable electricity.