What Are The Methods To Produce Bioenergy?

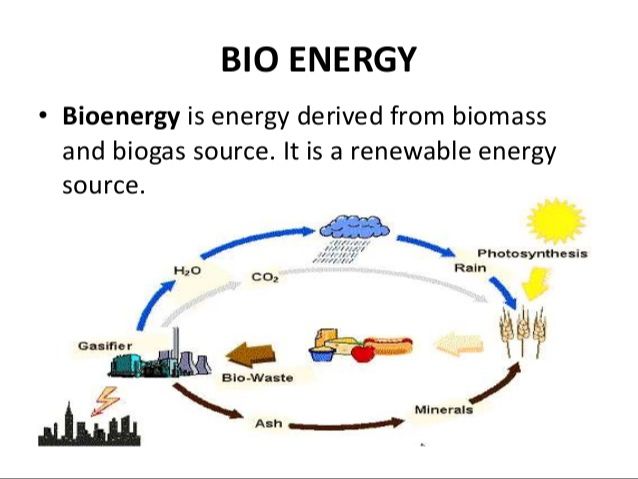

Bioenergy refers to renewable energy derived from organic matter, known as biomass. Biomass includes plant and animal material, as well as organic waste products. The main bioenergy production methods convert biomass into useful energy forms like heat, electricity, transportation fuels, and more (energy.gov).

The primary methods for producing bioenergy include photosynthesis, combustion, anaerobic digestion, fermentation, thermo-chemical conversion, and transesterification. Each method involves converting biomass into biofuels like ethanol, biodiesel, biogas, and solid biofuels (intechopen.com).

Bioenergy is an important renewable energy source because it provides energy while reducing dependence on fossil fuels. Bioenergy production and use emits less greenhouse gases compared to fossil fuels. Expanding bioenergy can support energy security, economic growth, and environmental goals globally.

Photosynthesis

Photosynthesis is the process plants use to convert sunlight into chemical energy in the form of carbohydrates (sugars). This process starts when sunlight is absorbed by chlorophyll, a pigment found in plant cells. Chlorophyll resides in organelles called chloroplasts, which contain the enzymes and proteins needed to carry out photosynthesis. When sunlight strikes chlorophyll, some of the energy is stored in the chemical bonds of glucose or other sugars, which serve as fuel for plants. The entire photosynthetic process relies on the ability of chlorophyll to absorb sunlight, which provides energy to power the synthesis of sugars from carbon dioxide and water (https://www.nature.com/scitable/). Photosynthesis is the primary method plants use to capture solar energy and convert it into chemical energy they can use for growth and other functions.

Combustion

Burning biomass directly for heat and electricity, also known as combustion, is one of the main ways to produce bioenergy. The most common types of biomass used are wood, agricultural waste, and garbage. These materials are directly burned to produce heat, which can then be used to generate electricity via steam turbines or provide process heat for industries.

The main advantage of biomass combustion is that it provides a simple and direct way to extract energy from biomass fuels. The technologies involved, such as boilers and turbines, are also well-established and widely available. In many cases, biomass combustion can utilize waste materials as fuel instead of fossil fuels, reducing environmental impact.

However, biomass combustion also has some disadvantages. Burning biomass can release air pollutants like particulate matter, carbon monoxide, nitrogen oxides, and sulfur dioxide. Controlling these emissions requires additional equipment. There are also limitations in the scale of electricity generation from small biomass combustion plants. Transportation and storage of fuel can be challenging as well (IEA Bioenergy, 2022).

Anaerobic Digestion

Anaerobic digestion is a process that breaks down organic matter such as manure, wastewater biosolids, and food waste in the absence of oxygen [1]. In an anaerobic digester, bacteria decompose organic material to produce biogas, which contains methane, carbon dioxide and small amounts of other gases. The remaining digested material, known as digestate, can be used as a soil conditioner.

Some of the common feedstocks used in anaerobic digestion include animal manure, food scraps, fats/oils/grease, and sewage sludge. The anaerobic digestion process involves four main steps [2]:

- Pre-treatment – feedstocks are prepared to increase surface area for better digestion.

- Hydrolysis – organic polymers are broken down into simpler soluble compounds.

- Acidogenesis – soluble organic compounds are converted into volatile fatty acids, alcohols, hydrogen and carbon dioxide.

- Methanogenesis – the final products (acetic acid, hydrogen) are converted into methane gas.

The biogas produced can be used to generate electricity and heat. The nutrient-rich digestate may be used as fertilizer. Overall, anaerobic digestion helps divert waste from landfills and provides renewable energy.

Fermentation

Fermentation uses microbes like yeast and bacteria to convert the carbohydrates in biomass into alcohols like ethanol or butanol. The key steps involve breaking down sugars like glucose into pyruvate through glycolysis, and then converting pyruvate into ethanol or other alcohols.

Common fermentation technologies include:

- Batch fermentation – This involves fermenting biomass in a closed vessel. It is simple and low-cost but productivity is lower.

- Continuous fermentation – This involves constant addition of new biomass and removal of products from the fermenter to increase productivity. More complex system.

- Cell recycle fermentation – Yeast cells are recycled back into the fermenter after separation to increase cell concentration and productivity.

Key products from fermentation include ethanol, butanol, and lactic acid. Ethanol can be used directly as a transportation biofuel or gasoline additive. Butanol has properties closer to gasoline making it a good biofuel. Lactic acid can be converted to biodegradable polylactic acid polymer.

Some good overviews on fermentation for bioenergy can be found at https://www.eubia.org/cms/wiki-biomass/fermentation/ and this OSU resource.

Thermo-chemical Conversion

Thermo-chemical conversion is the process of converting biomass into biofuels using heat and potentially catalysts in the absence of oxygen. The main methods for thermo-chemical conversion include pyrolysis, gasification, and torrefaction.

In pyrolysis, biomass is heated to between 300-600°C in the absence of oxygen, causing the material to thermally decompose into bio-oil vapor, biochar, and syngas. Fast pyrolysis optimized for producing liquids occurs on timescales of seconds to minutes, while slow pyrolysis can take hours or days and optimizes biochar production. Feedstocks like wood, agricultural residues, and solid waste can be used in pyrolysis. The bio-oil can be refined into transportation fuels or chemicals.[1]

Gasification converts biomass into syngas (carbon monoxide and hydrogen) by applying heat (700-1500°C) in environments with limited oxygen. The resulting syngas can be processed into fuels like ethanol, methanol, and synthetic diesel. Materials like forest residues, agricultural wastes, and energy crops can be gasified.[2]

Torrefaction is a mild pyrolysis process conducted at 200-300°C that removes moisture and makes the biomass more brittle. This improves the fuel characteristics of biomass for combustion and gasification applications.

Compared to direct combustion, thermo-chemical conversion generates a more energy-dense liquid product that can be used for transportation fuels and yields higher conversion efficiencies. The liquid intermediates can also be more readily processed into valuable chemicals.

Transesterification

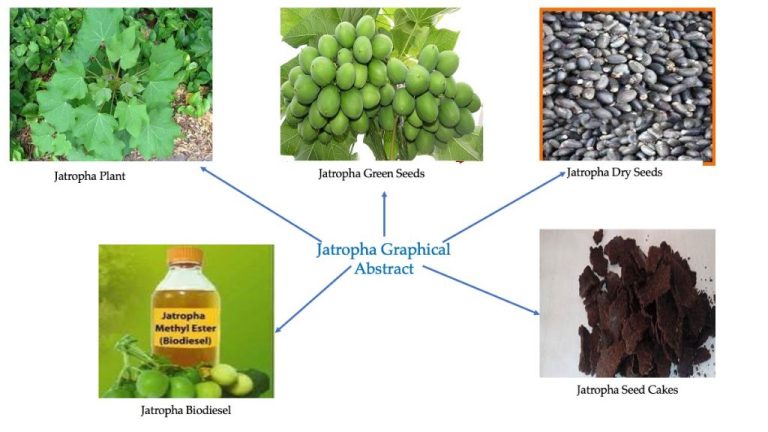

Transesterification is a common method for producing biodiesel through the reaction of vegetable oils or animal fats with an alcohol, usually methanol or ethanol, in the presence of a catalyst like sodium hydroxide. This process converts the triglycerides in the oils/fats into fatty acid alkyl esters, which have properties similar to petroleum-based diesel and can be used as a replacement fuel in diesel engines.

Common feedstocks for transesterification include soybean, canola, palm, corn, and waste cooking oils as well as animal fats like tallow. Methanol is the most widely used alcohol due to its low cost and physical properties. Catalysts like sodium hydroxide (NaOH), potassium hydroxide (KOH), and sodium methoxide (NaOCH3) are commonly used. The reaction occurs at moderate temperatures between 45-70°C and atmospheric pressure.

The transesterification reaction consists of three reversible steps, with glycerol as a byproduct. Optimization of parameters like alcohol to oil molar ratio, catalyst amount, mixing intensity, temperature, and reaction time is necessary to achieve high yields of biodiesel. Excess alcohol is required to drive the equilibrium towards the products.

This method of producing biodiesel has a number of advantages including mild process conditions, high conversion yields, low energy requirements, and simplicity of the process and equipment. However, removal of catalyst, glycerol byproduct, and excess alcohol increases costs. Feedstock quality and free fatty acid content can also limit conversion efficiency.

Source: https://www.sciencedirect.com/topics/engineering/transesterification

Other Methods

Some other methods for producing bioenergy include hydrothermal liquefaction, microbial fuel cells, and algae biofuel production.

Hydrothermal liquefaction involves converting wet biomass like algae into biocrude oil through the use of hot, compressed water. This thermochemical process breaks down the algae into smaller organic compounds that can be refined into fuel (Chen, 20211). Key advantages are its high conversion efficiency and ability to process wet biomass.

Microbial fuel cells utilize bacteria to convert organic matter into electricity through redox reactions. The bacteria break down the organic material and transfer electrons to the anode, creating a current. Water is the main byproduct. MFCs can generate energy from waste sources and do not require an external energy input (Ravichandran, 20222).

Algae is emerging as a promising feedstock for biofuel production through methods like hydrothermal liquefaction, transesterification, fermentation, and pyrolysis. Algae has a high yield potential, can utilize waste resources, and avoids competition with food crops. Challenges include finding cost-effective production and harvesting techniques (Ravichandran, 2022).

Challenges

While bioenergy has many benefits, there are some key challenges that need to be addressed for it to reach its full potential. Some of the main challenges are costs, scaling up technology, and feedstock limitations.

Costs are a major barrier, as bioenergy production can often be more expensive compared to fossil fuels (IRENA, 2022). The high capital and operating costs make it difficult for bioenergy to be cost-competitive. There are also costs associated with feedstock supply, logistics, and pre-treatment.

Scaling up bioenergy technology can be challenging and requires major investments. Most technology is currently at pilot or demonstration scale. Scaling up to industrial scale is complex and costly, involving optimization of conversion processes and integration into existing infrastructure.

Sustainable feedstock supply at scale is another limitation (Balan, 2014). Bioenergy production is constrained by seasonal and geographic availability of feedstocks like agricultural residues. Competing uses for feedstocks, like animal feed or biomaterials, also create supply challenges.

Overcoming these challenges will require continued technological innovations to improve efficiency and lower costs. It also needs supportive government policies like financial incentives. Ultimately, developing sustainable and affordable large-scale feedstock supplies will be key to realizing the full potential of bioenergy.

Future Outlook

The future of bioenergy looks promising, with projections of significant growth and developments in the coming years. According to a 2020 study published in PMC, bioenergy is projected to account for 30% of the growth in renewable energy production from 2018-2023 (Reid, 2020). The International Energy Agency (IEA) also predicts continued expansion of biofuel demand in the coming years, with global biofuel use expected to increase by 9,100 million litres per year in 2022 compared to 2021 (IEA, 2022).

Bioenergy is expected to play a major role in the renewable energy mix going forward. According to market research, the global bioenergy market is projected to reach $295 billion by 2029, growing at a CAGR of 3.8% from 2022-2029 (LinkedIn, 2022). Key developments driving growth include advancements in biofuel technologies, more widespread adoption of biogas, and policies supporting sustainable bioenergy. While challenges remain, projections indicate bioenergy will account for an increasing share of renewable energy production.