Is There Arsenic In Solar Panels?

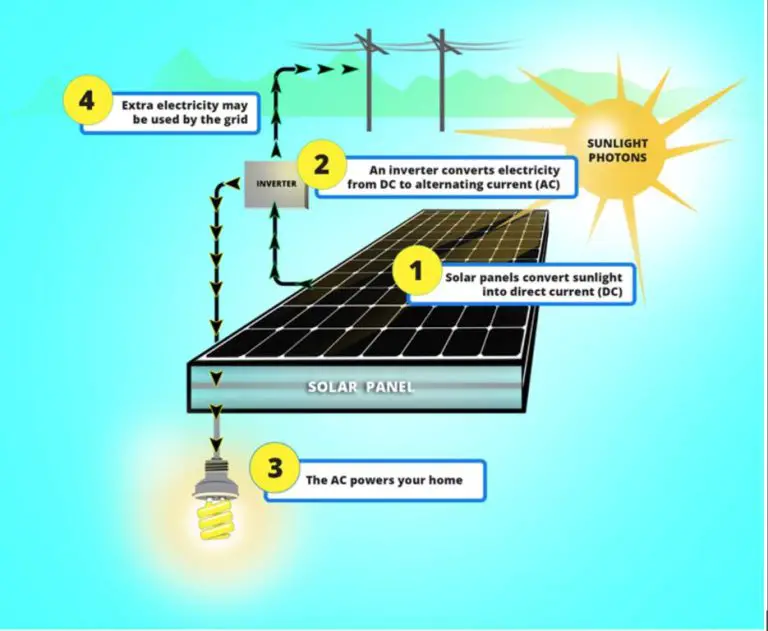

Solar panels are an increasingly popular source of renewable energy for homes and businesses. They work by converting sunlight into electricity through the photovoltaic effect. The key components of a solar panel include silicon cells, metal framing, wiring, protective glass, and encapsulation materials.

Silicon is one of the main ingredients used to manufacture solar cells, which are the building blocks of panels. The cells contain positively charged silicon and negatively charged boron to create an electric field that generates electricity when exposed to sunlight. Thousands of individual cells are connected together and assembled into a weatherproof panel.

Solar panels also contain various metals like aluminum for structural framing, copper for wiring, and silver or tin for electrical connections between cells. Wires and electrical components are encased in protective plastics. The tops of panels have tempered glass covers to protect the cells from weather and impact damage while allowing sunlight to pass through.

Encapsulation seals solar components between layers of plastic polymers, glass, and aluminum. This protects the panel from corrosion and电池材料 snow loads. Taken together, these components work to efficiently convert solar energy into usable electricity.

Arsenic in Silicon

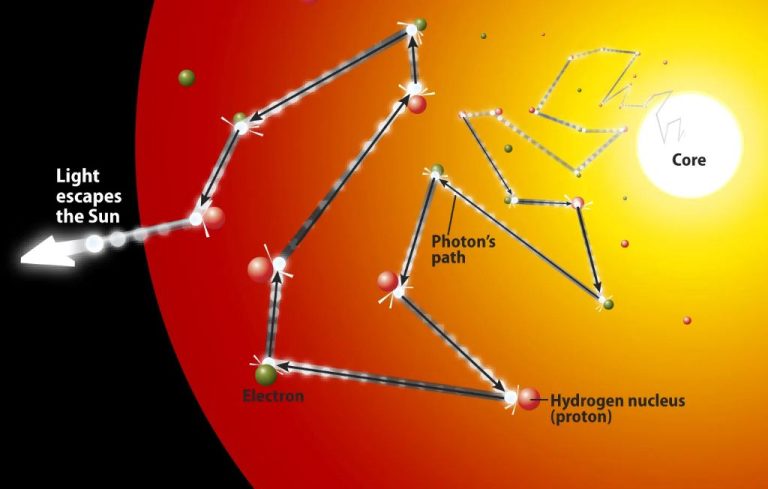

Silicon is the primary material used to make solar panels. It is normally an intrinsic semiconductor, meaning it conducts electricity poorly. To improve its electrical conductivity, silicon is intentionally contaminated or “doped” with other elements in a process called doping. Arsenic is commonly used as an n-type dopant for silicon [1]. When arsenic atoms are introduced into the silicon lattice, they provide extra electrons which greatly increase the material’s ability to conduct electricity.

![]()

Arsenic has a similar atomic radius and bonding properties to silicon, making it an ideal dopant. Its slower rate of diffusion allows it to be used to create junctions and buried layers in silicon devices [1]. Arsenic doping introduces allowable energy states near the conduction band, facilitating the flow of electrons. This makes silicon “n-type”, giving it an excess of electrons [2]. The arsenic doping level typically ranges from 1 to 3 atoms of arsenic per million atoms of silicon.

Arsenic Compounds in Panels

Solar panels may contain the arsenic compounds gallium arsenide (GaAs) and cadmium telluride (CdTe). GaAs is commonly used in high-efficiency photovoltaic solar panels as it absorbs sunlight efficiently, allowing the panels to generate more electricity. CdTe is a semiconductor material that helps improve the efficiency of thin-film solar panels. However, arsenic and some of its compounds are known to be toxic and pose potential health and environmental risks.[1]

Most solar panels today are made from crystalline silicon and do not contain arsenic. But GaAs and CdTe panels may contain small amounts of arsenic as an impurity or dopant to modify the electrical properties of the semiconductor to make it more efficient. While arsenic improves performance, it must be safely encapsulated to prevent contact with the environment or people. Newer manufacturing methods can also reduce arsenic content compared to older panels.[2]

In summary, some types of high-efficiency solar panels may contain the arsenic compounds GaAs and CdTe to improve electrical efficiency. But arsenic content is encapsulated and newer panels have lower amounts of arsenic due to improved manufacturing techniques.

[1] https://scdhec.gov/sites/default/files/Library/OR-1695.pdf

[2] https://grist.org/article/2010-01-06-solars-dirty-little-secret/

Encapsulation

Solar panels are designed to fully encapsulate the silicon cells and any compounds used to dope them, like arsenic. The purpose of encapsulation is to seal the solar cells between layers of protective material to prevent leaching or release of any potentially hazardous substances.

The silicon solar cells are sealed between a tempered glass front, and a polymer encapsulation layer on the back. Polymers such as EVA (ethylene vinyl acetate) or POE (polyolefin elastomer) are commonly used. These encapsulation layers surround the solar cell components and prevent contact with outside air and moisture.[1]

Encapsulants are engineered for long-term reliability. Degradation testing indicates they can maintain their integrity for decades under real-world conditions of heat, moisture, and UV exposure. Proper encapsulation aims to eliminate any leaching risks throughout the operating lifetime of a solar panel.[2]

With robust encapsulation methods, arsenic and other compounds used in solar cell manufacturing can be safely sealed into solar panels with minimal risks of environmental release.

[1] https://www.corebuffalo.org/impact-of-solar-panel-manufacturing

[2] https://interestingengineering.com/science/renewable-energy-paradox-solar-panels-and-their-toxic-waste

Leaching Risk

There has been some concern that toxic heavy metals like cadmium and lead used in solar panels could leach out and contaminate soil or water. However, research shows that the risk of significant leaching from solar panels is low.

The silicon solar cells themselves do not contain high levels of toxic materials. While arsenic and phosphorus are used to dope silicon, the concentrations are very low. According to one study, even broken silicon cells leached only 0.03–0.06 mg/L of arsenic, well below hazardous waste toxicity limits of 5 mg/L.1

Other solar panel components like framing, junction boxes, and wiring can contain some lead and cadmium. However, the encapsulant polymers used to laminate solar panels act as an effective barrier to prevent leaching of heavy metals into the environment.2 One analysis showed that barely detectable levels of metals leached from intact solar panels, orders of magnitude below hazardous waste toxicity limits.3

Overall, research indicates that potential leaching and contamination issues from solar panels are negligible, especially when compared to the benefits of solar power generation.

Recycling and Disposal

Proper recycling and disposal of solar panels is crucial to prevent toxic materials like lead, cadmium, and arsenic from contaminating the environment. Most residential solar panels contain small amounts of these heavy metals encapsulated within the panels. While intact solar panels pose little risk, at end-of-life the metals could leach into soil and water if the panels end up in landfills.

Fortunately, most solar panels are largely recyclable. Up to 90% of the materials, including aluminum, glass, and silicon, can be recovered and reused. Specialized companies shred and separate the panel components, capturing valuable metals for resale. However, proper recycling requires manual disassembly and processing which adds cost. Some manufacturers and installers provide free take-back and recycling services.

In the U.S., most states classify solar panels as universal waste rather than hazardous waste. This aims to promote recycling by easing regulatory burdens on generators. However, critics argue more stringent handling is needed due to the toxicity profile. The solar industry and regulators continue to discuss policy reforms like extended producer responsibility and recycling mandates to further improve end-of-life management.

Worker Safety

Solar panel manufacturing involves the use of hazardous chemicals like arsenic that require precautions to protect workers. According to a study by Spinazzè et al. (2015) published in Annals of Work Exposures and Health, workers involved in producing Cd/As solar modules may be exposed to arsenic through routine handling or accidental contamination.

To mitigate risks, manufacturers follow safety guidelines and regulations to protect employees. This includes the use of protective equipment like respirators and gloves when handling hazardous materials. Workspaces are designed to limit exposure through fume hoods and ventilation. Regular safety training educates workers on proper handling procedures and emergency protocols in case of exposure. By following precautions and monitoring worker health, risks from arsenic exposure can be minimized.

Regulations

There are a few key regulations regarding the management of hazardous materials in solar panels in the United States. The primary regulation is the Resource Conservation and Recovery Act (RCRA), which gives the EPA authority to control hazardous waste from start to finish. Under RCRA, solar panels that test as hazardous waste must be disposed of properly as hazardous waste. Testing involves evaluating waste streams for characteristics of hazardous waste such as toxicity, reactivity, corrosivity, and ignitability using the Toxicity Characteristic Leaching Procedure (TCLP) test (1).

In California specifically, solar panels entering the waste stream that contain heavy metals above thresholds established by the state are classified as Universal Waste and must be handled by special Universal Waste handlers instead of normal solid waste handlers. California’s Universal Waste Rule (Title 22, Division 4.5, Chapter 23) aims to reduce hazardous waste in the municipal solid waste stream by facilitating the proper collection and recycling of certain common hazardous wastes like batteries, fluorescent lamps, and mercury thermostats (2).

At the end of a solar panel’s useful life, the EPA recommends having panels tested at an accredited lab to determine if they are hazardous before disposal. Some state regulations require testing panels before disposal as well. Solar panel producers are also required by OSHA to provide Safety Data Sheets detailing the materials in their panels to inform safe handling practices.

Comparison to Alternatives

Though some arsenic is used in the production of solar panels, the amount is small compared to arsenic emissions from coal power plants. Burning coal releases arsenic into the air, estimated at 3,300 tons per year in the US alone. Comparatively, a typical solar panel might contain around 0.0000002% arsenic by weight.

Other energy sources also carry environmental risks that should be weighed against any potential arsenic exposure from solar panels. Nuclear power produces radioactive waste that must be safely contained for thousands of years. Hydraulic fracturing for natural gas releases methane, a potent greenhouse gas, into the atmosphere. Overall, solar power has a much lower life-cycle environmental impact than fossil fuels.

While more study is needed, the current evidence suggests arsenic in solar panels poses very little risk to human health or the environment compared to the well-documented harms from continued fossil fuel reliance. With proper handling at end-of-life, solar power can provide clean renewable energy with minimal toxic emissions.

Conclusions

In summary, while arsenic is used in the manufacturing process of some solar panels, it does not pose a significant risk of leaching or exposure when the panels are properly encapsulated and handled.

Key findings include:

- Arsenic is added to silicon as a doping agent to improve solar cell efficiency in some types of panels like monocrystalline silicon PV cells.

- The amount of arsenic used is very small, in the range of 1 part per billion.

- Arsenic compounds are encapsulated within solar panels between the front glass, EVA sealing layers, and aluminum frame. This prevents leaching under normal conditions.

- Proper recycling and disposal of solar panels at end of life is important to prevent any potential leaching from broken panels over long periods in landfills.

- Workers involved in manufacturing should follow safety precautions when handling arsenic compounds.

Overall, the tiny amounts of encapsulated arsenic in solar panels should not deter consumers, as the benefits of solar power far outweigh any miniscule risks.