Is The Hoover Dam Concrete Still Curing?

Introduction

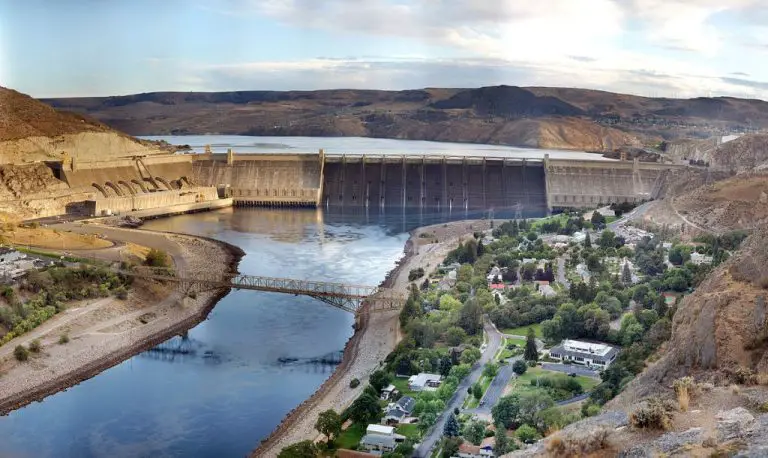

The Hoover Dam, officially known as the Boulder Dam, is one of the most iconic dams in the world. Located on the Colorado River along the border between Nevada and Arizona, it was built between 1931 and 1936 and stands over 700 feet tall. The dam created Lake Mead, the largest reservoir in the United States when full.

To construct a massive concrete structure like the Hoover Dam, proper concrete curing was critical. Curing refers to the process of allowing the concrete time to hydrate and harden once it has been poured and set. This involves maintaining proper moisture and temperature conditions. The curing process can take from 28 days up to several years for full strength gain.

Due to its enormous size and the hot, arid climate of the region, questions have arisen over whether the Hoover Dam concrete is still curing even decades after construction. This article will examine the concrete composition, curing conditions, and maintenance of the dam to determine if the concrete is still gaining strength today.

Construction of the Hoover Dam

Construction of the Hoover Dam began in 1931 and was completed in 1936 (“The Story of Hoover Dam – Concrete”, https://www.usbr.gov/lc/hooverdam/history/essays/concrete.html). The dam contains enough concrete to pave a two-lane highway from San Francisco to New York City. In total, over 4.4 million cubic yards of concrete were used to construct the dam (“Hoover Dam | Bureau of Reclamation”, https://www.usbr.gov/lc/hooverdam/faqs/damfaqs.html).

The concrete was poured in individual, interlocking blocks rather than as one continuous pour. Each block was approximately 25 feet high, 25 feet wide, and 40 feet long. Forms on the upstream and downstream sides contained the concrete while it cured. Once cured, the forms were removed and new forms built on top to pour the next block. This careful sequencing and curing process was critical for ensuring the structural integrity of the final dam.

Concrete Curing Process

Concrete curing is the process of maintaining adequate moisture and temperature conditions in concrete to allow the hydration of cement to occur so that concrete can achieve its maximum strength and durability (Source). After concrete is placed, the hydration of cement begins as water reacts with the cement particles to form a cement paste that binds the mixture together. However, hydration is a time-dependent process that occurs slowly over a period of days and weeks after the concrete is placed.

Proper curing allows optimal cement hydration by keeping the concrete moist and within an appropriate temperature range. As hydration continues over time, the concrete becomes stronger and more durable. Curing is especially important during the first 7 days when concrete gains most of its strength but continues for a month or longer after placement (Source). The rate of hydration and concrete strength gain is influenced by factors like the concrete mixture design, temperature, and moisture availability.

Concrete Composition

Concrete is made up of three basic ingredients: water, aggregate (rock, sand, or gravel) and Portland cement. The proportions of these ingredients can affect the concrete’s properties and how it cures.

Portland cement acts as the binding agent in concrete. During curing, the cement reacts chemically with water in a process called hydration. This produces calcium silicate hydrate, which hardens over time and gives concrete its strength.

The water-cement ratio is an important factor in concrete curing. More water makes concrete easier to pour and shape, but also increases curing time and decreases strength. The optimal water-cement ratio provides enough water for hydration while maintaining strength.

Aggregates like gravel and sand fill the concrete mixture and reduce shrinkage during curing. Larger aggregates typically result in stronger concrete after curing. However, larger aggregates also increase water demand and can make the concrete more porous.

Other concrete ingredients like plasticizers, accelerators, retarders, and air entrainers can affect concrete workability, setting time, and strength development during curing. Understanding how each ingredient impacts curing allows concrete to be tailored to specific applications.

Curing Conditions at Hoover Dam

The climate and weather conditions at the Hoover Dam construction site presented unique challenges for concrete curing. Located in the hot, arid desert of the Black Canyon on the Colorado River, summer temperatures often exceeded 100°F. Concrete curing is greatly affected by temperature. Higher heat causes concrete to cure faster initially but can also lead to increased shrinkage cracks. Extreme heat also increases the water evaporation rate, which is problematic since concrete needs to stay moist while curing [1].

The enormity of the Hoover Dam structure itself also influenced curing. Over 3 million cubic yards of concrete were used to build the 726-foot tall curved gravity arch dam, creating massive amounts of heat during the chemical exothermic curing reactions. The tremendous mass and thickness of the concrete made temperature control and cooling difficult. Removing heat helps concrete cure properly and evenly [2].

Tests on Hoover Dam Concrete

When the Hoover Dam was built in the 1930s, the mass concrete used was scientifically designed and carefully monitored during construction to ensure proper curing and strength development. However, decades later, some concerns emerged about the long-term durability and ongoing curing of the concrete.

To investigate these concerns, an extensive concrete core analysis and testing program was undertaken in 1995 by the United States Bureau of Reclamation. This involved extracting large concrete core samples from within the dam structure and subjecting them to a battery of tests.

The core samples were tested for compressive strength, modulus of elasticity, drying shrinkage, alkali-silica reactivity, sulfate resistance, and chloride ion penetration. The strength and durability testing aimed to evaluate whether the concrete had gained full strength after 60+ years and how it was holding up to environmental factors.

The test results showed the Hoover Dam concrete had continued to cure and gain strength over time. The average compressive strength of the samples was found to be 4,050 psi, exceeding the original design strength of 3,000 psi. The concrete also displayed excellent resistance to sulfate attack and chloride ion intrusion.

Overall, the testing demonstrated the exceptional durability and ongoing curing capacity of the concrete used at Hoover Dam. The scientific mixture design and controlled curing process employed during construction has allowed the concrete to remain robust after over 60 years exposed to hot, arid conditions.

Ongoing Curing at Hoover Dam

Even decades after construction, the concrete at Hoover Dam is still undergoing hydration and curing. Concrete cures through a chemical reaction called hydration, where water reacts with the cement to form calcium silicate hydrate gel that provides strength and durability. Hydration is a long, slow process and can continue for many years.

Tests performed in the 1990s showed that Hoover Dam concrete was still curing and gaining strength after 60 years. Core samples indicated the concrete had increased in strength by 15% since the original testing done during construction in the 1930s [1]. This demonstrates the incredibly slow rate of curing for massive concrete structures like Hoover Dam.

Experts estimate it could take over 500 years for the concrete in Hoover Dam to be fully cured. The curing conditions deep inside the dam are favorable for continued hydration – steady temperature, high moisture, and isolation from weather. This allows the concrete to keep gaining strength indefinitely through slow but ongoing curing.

Maintenance and Repairs

The concrete at Hoover Dam requires ongoing maintenance and repairs as it ages. According to Why A Dam Needs Concrete Repairs and How Those Repairs Save Money, dams like Hoover Dam can develop cracks, spalls, and other deterioration over time. This requires maintenance like crack sealing, patching, joint repairs, and coating applications.

Major repair projects have been undertaken at Hoover Dam over the decades. In the 1980s, engineers discovered cracks in the dam’s wing walls. This led to an extensive four-year renovation project in the late 1990s that involved patching and waterproofing the concrete. More recently in 2015, the Bureau of Reclamation embarked on a $15 million project to upgrade the dam’s downstream mooring and operations buildings, which included concrete repairs.

Proper maintenance and repairs are crucial for an aging structure like Hoover Dam. The extensive concrete repairs and upgrades aim to address deterioration issues and ensure the dam remains functional for many more decades.

Importance of Curing

Proper curing is crucial for ensuring the strength and durability of concrete. According to the National Ready Mixed Concrete Association, “Curing is the maintaining of an adequate moisture content and temperature in concrete for a period of time immediately following placement so that the desired properties may develop.”1 When concrete cures properly, the hydration process can continue, allowing calcium silicate hydrate (C-S-H) bonds to form within the cement, which provides strength and durability.

Without proper curing, concrete can crack, shrink, and become weak. This leads to structural issues and damage over time. According to the American Concrete Institute, cracking may occur due to the tensile stress induced by shrinkage in the concrete exceeding the tensile strength of the concrete.2 Proper curing reduces shrinkage by providing adequate moisture, which helps relieve tensile stresses. This prevents potential cracking and damage.

Overall, proper concrete curing is essential for reinforced concrete structures like dams to achieve their designed strength and to ensure long-term durability and performance.

Conclusion

To summarize, the concrete used to construct the Hoover Dam has continued to cure and strengthen over the decades since its initial pour in the 1930s. This is due to the enormous mass of concrete used, the chemical composition promoting slow and continuous curing, and the ideal curing conditions found inside the dam structure. While the concrete is not still wet, existing testing and measurements show that the concrete has gained strength and will continue to cure indefinitely under the right conditions. In conclusion, the massive amounts of concrete used to build the iconic Hoover Dam can be considered to still be curing even eight decades after the dam’s construction.