Is Geothermal Energy High Maintenance?

Overview of geothermal energy

Geothermal energy is a renewable energy source that derives heat from the earth’s interior for electricity generation and direct heating applications. There are three main types of geothermal energy systems:

– Geothermal power plants use hot water or steam from deep underground reservoirs to drive generators and produce electricity.

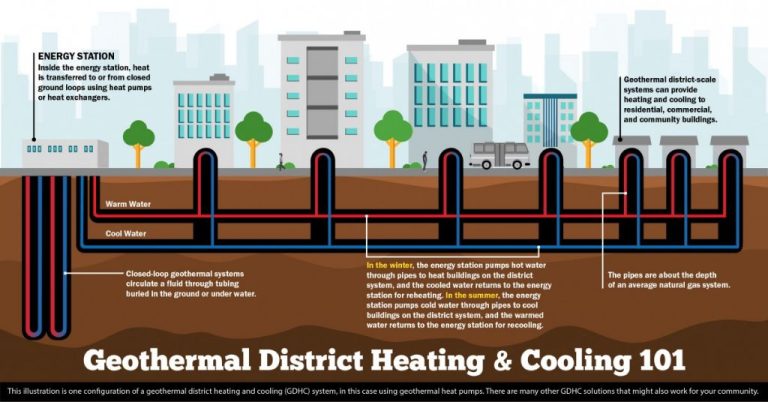

– Geothermal heat pumps use stable ground temperatures near the earth’s surface to provide heating and cooling for buildings.

– Direct use of geothermal reservoirs involves drilling wells into hot water reservoirs to provide heat directly for various processes.

Geothermal power generation works by drilling wells into underground reservoirs of steam and hot water, known as hydrothermal resources. This heated water can reach temperatures over 300°F (150°C). The steam or hot water rises to the surface and powers a turbine connected to a generator, which produces electricity. After being used, the water is returned to the reservoir.

Upfront Costs

The main upfront costs for geothermal energy systems are drilling wells, installing pipes and the heat exchanger, and connecting to the electrical grid.

Drilling geothermal wells is generally the largest upfront cost. Geothermal wells can be over 1 mile deep, which requires expensive specialty drilling rigs. The drilling process also uses a lot of energy and materials. For a typical 5 megawatt geothermal power plant, production wells can cost $2-4 million each.

Piping makes up another major upfront cost. High density polyethylene and steel piping must be installed to carry hot water up from the wells. For a 5 megawatt plant, piping costs may range from $1-2 million.

The heat exchanger unit is also a significant expense, potentially costing over $1 million. These heat exchangers transfer the heat from the hot water coming from underground into a separate loop that drives the electrical turbine.

Finally, connecting the power plant to the electric grid requires extending transmission lines and building interconnection infrastructure. These grid connection costs depend on the plant size and location but may cost hundreds of thousands of dollars.

Operational costs

After the system is installed, there are ongoing costs to operate a geothermal heat pump system. The main operational costs are for electricity to run the pumps and maintenance on the pumps and heat exchanger.

Electricity is needed to run the circulation pumps that move the heat transfer fluid through the loops. This electricity cost is fairly minimal, averaging around $0.15 per square foot annually for residential systems. This is far less than the cost of natural gas or electricity that would be needed to heat and cool the building otherwise.

Routine maintenance is required on the pumps and heat exchanger to keep them operating efficiently. The heat transfer fluid may need periodic testing and replacement as well. Proper maintenance helps ensure optimum performance and maximum lifetime of the system.

Overall, the ongoing operational costs of electricity and standard maintenance are relatively low compared to conventional HVAC systems. This makes geothermal heat pumps an affordable option over the lifetime of the system.

Reliability and Lifetime

Geothermal systems are designed for long lifetimes, typically ranging from 20-50 years. This is significantly longer than other renewable energy technologies like solar panels or wind turbines, which have lifetimes of around 20-25 years. The underground piping used in geothermal systems is built to last for decades without needing replacement.

In addition, geothermal systems have excellent uptime of around 90-95%. This high reliability comes from the constant availability of geothermal energy underground. Since geothermal relies on the Earth’s internal heat rather than variable resources like sunlight or wind, it can provide uninterrupted heating and cooling year-round.

The long lifetimes and consistent uptime mean geothermal systems require less frequent replacement of major parts compared to other renewable energy technologies. Once installed, geothermal systems can operate with minimal downtime for 20 years or more. This reliability is a major advantage of geothermal energy.

Monitoring and Maintenance

Proper monitoring and regular maintenance are important for keeping a geothermal system running efficiently over its lifetime. Annual inspections by a certified technician are recommended to check that all components are functioning properly. During inspections, the technician will monitor electricity usage, check antifreeze levels, and make any adjustments needed to optimize performance.

Annual checkups are also crucial for detecting small problems before they turn into big repairs. Technicians will clean and inspect key components like heat pumps, air filters, and ground loops. They can also monitor the underground loop field for reduced heat transfer or potential leaks. Preventative maintenance helps minimize expensive downtime and keeps the system operating at peak efficiency for decades.

While geothermal systems generally require less maintenance than conventional HVAC systems due to fewer moving parts, owners should still budget for annual inspections. Proactive monitoring and maintenance is key to maximizing the lifetime of a geothermal investment.

Environmental Impact

Geothermal energy has a very low environmental impact compared to conventional power generation methods. Since geothermal plants do not burn fuel to generate electricity, they produce near-zero emissions. The geothermal water and steam used to power the turbines contain negligible levels of harmful gases such as carbon dioxide, nitrogen oxides, and sulfur compounds. This makes geothermal an eco-friendly, sustainable alternative to burning coal, natural gas, or other fossil fuels.

Geothermal reservoirs provide a renewable source of energy that can be tapped indefinitely, if managed properly. The hot water extracted from geothermal wells is continuously replenished in the subsurface by naturally occurring heat from the Earth’s interior. As long as water is returned back into the reservoir after passing through the plant, the geothermal resource can theoretically supply energy forever. This provides a reliable long-term source of clean power with minimal environmental disruption.

That said, steps still need to be taken during geothermal development to minimize impacts on the local environment. Careful reservoir management is crucial to ensure sustainable extraction of heat over time. Air and water pollution controls may be needed to mitigate the release of hydrogen sulfide gas or brine. And surface disturbances should be minimized when drilling wells and installing pipelines. But overall, geothermal stands out as a clean, renewable energy source with tremendous environmental benefits compared to fossil fuel combustion.

Safety

Properly installing a geothermal system is crucial for safety. If not done correctly, there could potentially be leaks of the heat transfer fluid or releases of hydrogen sulfide gas. Hydrogen sulfide is a naturally occurring gas found in some geothermal reservoirs. While it has a distinct “rotten egg” smell at low concentrations, at higher concentrations it can deaden a person’s sense of smell. Inhalation of hydrogen sulfide can be extremely dangerous.

For these reasons, it’s critical that only experienced professionals handle the installation and maintenance of a geothermal system. The loop field piping, heat pump unit, and other components should be installed according to all applicable building codes and manufacturer specifications. Proper ventilation is also key. With good installation and maintenance practices, geothermal systems can operate safely for decades.

Availability of geothermal resources

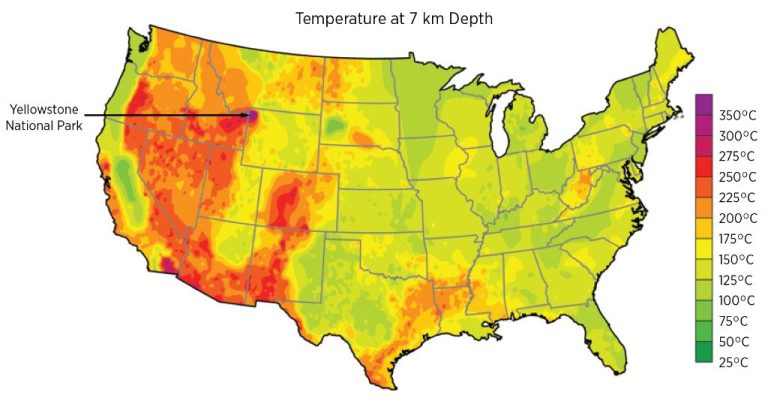

The availability of geothermal resources depends on geographical location. The highest temperature resources that can produce electricity occur within about 6 miles of young volcanic centers or major tectonic plate boundaries where magma comes closest to the surface, such as in the Pacific Rim. There are also high-temperature resources (over 300°F) available at shallower depths in the western US in areas with high heat flow, such as in California, Nevada, Utah, Idaho, and Oregon.

Areas with underground temperatures greater than 212°F can be used for direct heating applications, but lower temperature resources can also be used for geothermal heat pumps. The eastern two-thirds of the US has normal to low underground temperatures (less than 212°F at depths accessible with current drilling technology), which are adequate for space heating and cooling using geothermal heat pumps.

Overall, geothermal resources are available across much of the US, but the highest temperature resources capable of producing electricity are primarily concentrated in the western states near plate boundaries and volcanic activity.

Example system lifetime costs

Breaking down the upfront and maintenance costs of a geothermal system over 20-30 years provides a fuller picture of the long-term financial commitment. A typical 5 ton geothermal heat pump for a medium-sized home might have the following costs:

- Installation cost: $20,000 – $30,000

- Annual maintenance: $250

- Major component replacement every 10-15 years: $5,000 – $8,000

Over 30 years, the total would be approximately:

- Installation: $25,000

- Maintenance: $250 x 30 years = $7,500

- 1 major component replacement at year 15: $6,500

The total 30 year cost would be around $39,000, or approximately $1,300 per year. This provides a realistic estimate of the long-term costs of owning and maintaining a geothermal system. The higher upfront installation cost is offset by very low ongoing maintenance and energy costs over decades of use.

Conclusion

While geothermal power plants require a high upfront investment and extensive siting and resource analysis, once up and running they can have very low maintenance needs and high reliability. The lack of moving parts compared to other renewable energy sources like wind and solar means less wear and tear over decades of operation. And unlike fossil fuels, there is no need to continually acquire fuel. The geothermal resource itself provides the fuel. So while not completely maintenance-free, geothermal plants have lower operational costs than most other energy sources over their project lifetimes. The high upfront investment pays off over time through low maintenance and minimal interruption of generation. So geothermal energy cannot be considered high maintenance compared to alternatives when all factors of capital and operating costs are considered.